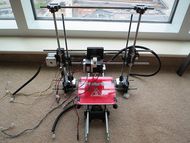

3DPrintMi

Release status: working

| Description | Open Frame Reprap

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

3DPrintMi combines the minimalistic, open frame style of the Printrbot/Wallace with the fixed Y Gantry system of the Mendel. The printed parts are designed to be produced rapidly, efficiently and assembled easily. The primary goal for this printer was to incorporate the maximum number of printed parts, thus enabling self replication. Built from the ground up, this RepRap requires very little tooling and does not need specially made parts (e.g. lasercut pieces) for it to function.

My first RepRap was printed off the Printrbot+ and was dubbed the "Mutant Printrbot". The first iteration of my printer had several design flaws, which I corrected in the second iteration, named the 3DPrintMi.

Specifications

- Printed Parts: 31-35

- Non-Printed Parts: 279 - 281

- Total Cost: $340 - $450

- Material Cost

- Printed Parts: ?

- Vitamins: $105 - $130

- Electronics: $240 - $315

- Printer Dimensions: 38cm x 43cm x 41cm (15" x 17" x 16")

- Build Area: 152mm x 152mm x 200mm (6" x 6" x 8") or 200mm x 200x x 200mm (8" x 8" x 8")

- Precision: ???

- Accuracy: 0.15mm (current layer height tested)

- Speed: 60mm/s perimeter, 120mm/s infill

- Units of Measurement: Metric

Videos

Assembly of the 3DPrintMi

<videoflash>9lfONhUdHPo</videoflash>

My first RepRap printing the 3DPrintMi

<videoflash>7hH3ASi5rJ0</videoflash>

3DPrintMi printing the [Tree Frog by MorenaP]

<videoflash>jkWKzN3Rvwo</videoflash>

Printrbot+ and his son (my first RepRap, father of 3DPrintMi) printing together

<videoflash>C-fGKSsrgCo</videoflash>

Features

- In compliance with Vertical X Axis Standard, compatible with Mendel style X gantry

- Fully printed Y carriage platform

- Extruder mount compatible with Wade Extruder/Bowden or Direct Drive(QU-BD MBE)

- Adjustable frame allows increased build volume (Working)

- Fully parametric

- 56% Plastic, 44% vitamins (Volume)

Additional Info

- Estimated assembly time = 2 - 3 hours (excludes electronic/board assembly)

- Estimated total print time of a printed set = 28+ hours

- Estimated total plastic usage of a printed set = 370 cc @ 60% infill

- Power requirement = 80W to 100W (Hotend @ 240C, Hotbed @ 95C)

Documentation

Future Development

- Design a new Y Carriage to retrofit a LC build platform as an alternative to the printed Y Carriage.

- Optimize parts to cut down plastic usage without compromising frame rigidity.

- Fishing line for linear drive

- Create a LC assembly board template to speed up assembly time. No need to measure with caliper during construction.