Cartesian Bot Hints

Helping The Bracing

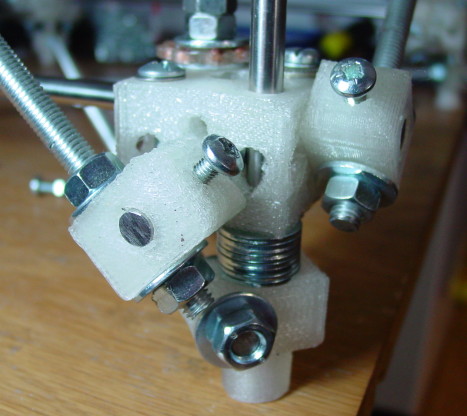

When jostled a lot, the corner blocks can work down the frame and alter the alignment. More annoyingly, this can cause the locknuts on the bottom of the Z driver rods to collide with the diagonal braces on the bottom face of the frame and make the Z axis jam.To prevent this, fill the space between the diagonal brackets with hand-squidged CAPA (Polymorph) or a stack of washers. If you transport your machine a lot, consider putting CAPA filler or reprapped pieces of tube between the bottom of the lower diagonal brackets and the ground. This will stop the frame slowly slipping down the vertical supports.

Note also that two bolts have been placed through the corner bracket to strengthen it for transport, following lessons given by the TSA.

Caution! Brittle Plastic

If using parts fabricated from a commercial RP machine, take special caution to

- Remove ALL support material. scraps of support material cause uneven stresses in the parts and can cause failure.

- Make sure to print some sort of test piece (an extra diagonal tie bracket, for example) to find out how brittle your plastic is. it can save you lots of headaches.