Eventorbot 1.2

Eventorbot! Open source 3D printer.

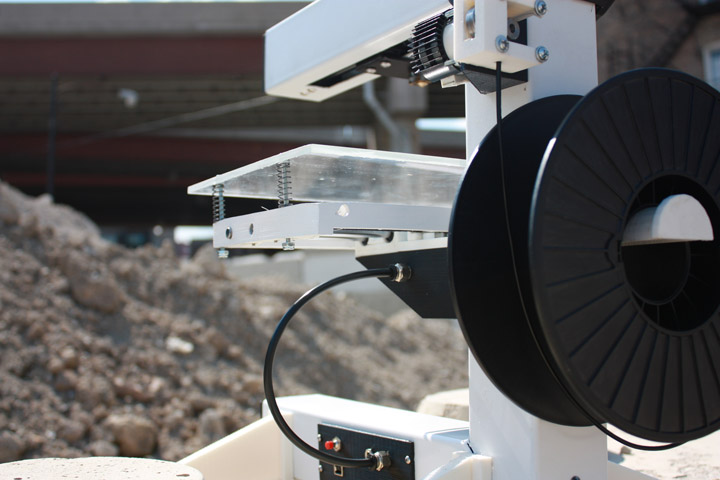

The Mission and challenge behind Eventorbot, was to build a rigid, low cost 3d printer. Using less parts, easy to assemble, and is capable to self replicate most of its parts. It is 100% open source project, and all plans are available for anyone interested. Since 80% of the Eventorbots parts are printable. Once you build your first machine, you can make it even more affordable for friends, family, or the community. With the single solid steel frame, it eliminates 40% of parts and cost that other 3d printers uses for a housing and structure. Making it easier and more affordable for anyone to own a 3d Printer ("Lets just start printing our own stuff").

The unit is supposed to resemble a robotic arm with hydraulic tubes. It was designed for prints to be less affected by vibrations. With the 1 solid frame, any vibrations of any axis will cause the other axis to move with it. For example: If the X axis causes a slight vibration/1mm movement to the right, the Z and Y axis will also move that 1mm to the right. This will result in a better print as everything will remain squared.

For more images and updates like:

http://www.facebook.com/pages/Eventorbot/111169638934671

For those who do not have access to a 3D printer. You can order the plastic parts and frame at: http://www.kickstarter.com/projects/1874396831/eventorbot-open-source-3d-printer

UPDATE:

Eventorbot has met its funding goal!

Well, I'm speechless and overwhelmed with all the support. I will like to say a BIG thank you for all the support, kind words, and to all the backers. To be able to share and have your interest in something I created is a great feeling. Everyone of you guys have made something that was a big dream become reality. Eventorbot, as a 3D printer is now going to happen! You will have no regrets in owning a Eventorbot, our machine will be a strong contender.

Thank you... thank you... thank you...

Video clips and build tutorials:

http://www.youtube.com/user/eventorbot

Parts list:

(1) 4' long, 2 1/2" metal square tube (this will be used for the main frame and the hot head mount). Diagram: http://www.thingiverse.com/download:85781

(3) Nema 17 stepper motor (at least 3 kg-cm 4 Wire). Specs for current motors used PDF: http://eventorbot.com/pics/3%20kg-cm%204%20Wire%20NEMA%2017%20Stepper%20Motor.pdf

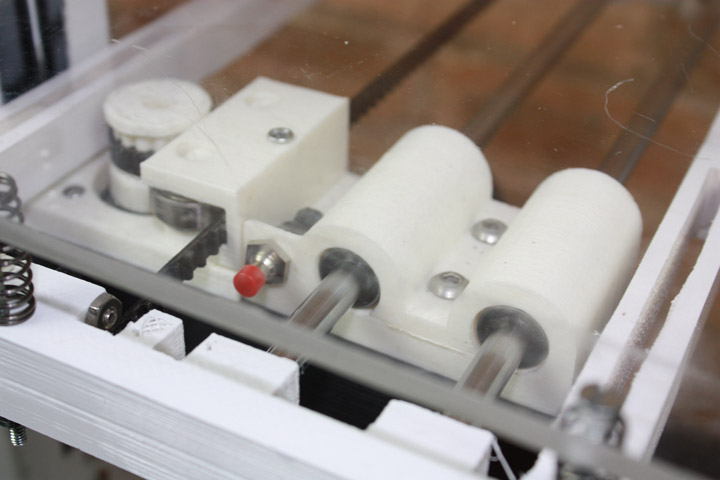

(1) Geared stepper motor for extruder. (model: PG35L-048).

(12) 8mm linear bearings, model: LM8UU. Pic: http://eventorbot.com/pics/LM8UU.jpg

(4) 8mm ball bearing, model: 608Z. Pic: http://eventorbot.com/pics/608Z.jpg

(1) 9 1/2" long 5/16 threaded rod (for Z axis). Note: Most likely you will have some leftover after your 9 1/2" cut, use that piece to cut a 13mm long piece for: http://eventorbot.com/pics/rod%20for%20extruder%20bearing.jpg

(6) 10.5" long 8mm rod. Pic: http://eventorbot.com/pics/8mm%20linear%20rod.jpg

(1) Coupler 5mm to 8mm. Pic: http://eventorbot.com/pics/5mm-8mm%20coupler.jpg

(1) Set of printed plastic parts (stl files listed on thingiverse.com soon).

(optional) 1 set of printed decorative end caps (stl files listed on thingiverse.com soon).

(1) Set of screws. List: http://eventorbot.com/hardware.htm

(1) Sanguinololu 1.3a mother board with ramps. Ramps to be compatible to steppers (it should come with pin connectors and pins). Pic: http://eventorbot.com/pics/Sanguinololu%20board.jpg

(1) MK7 drive gear (gear to drive the filament). Pic: http://eventorbot.com/pics/mk7_drive_gear.jpg

(1) 4 foot of XL timing belt. PDF: http://eventorbot.com/pics/XL%20schematic.pdf

(4) Push button momentary end stop switches. Pic: http://eventorbot.com/pics/Push%20button%20momentary%20switch.JPG

(1) Bed. Aluminum or pexi-glass 8.5" x 11", 1/8" thick. (thickness does not have to be exact). Diagram: http://eventorbot.com/pics/bed%20diagram.skp

(4) Springs for bed (this box should have all the springs you need for any circumstances: http://www.homedepot.com/h_d1/N-5yc1v/R-100142075/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=springs&storeId=10051#.UDZP5tXDCSo

(8) Rubber feet (bore holes need to be able to allow 10-32 screws) Pic: http://eventorbot.com/pics/rubber%20feet.jpg

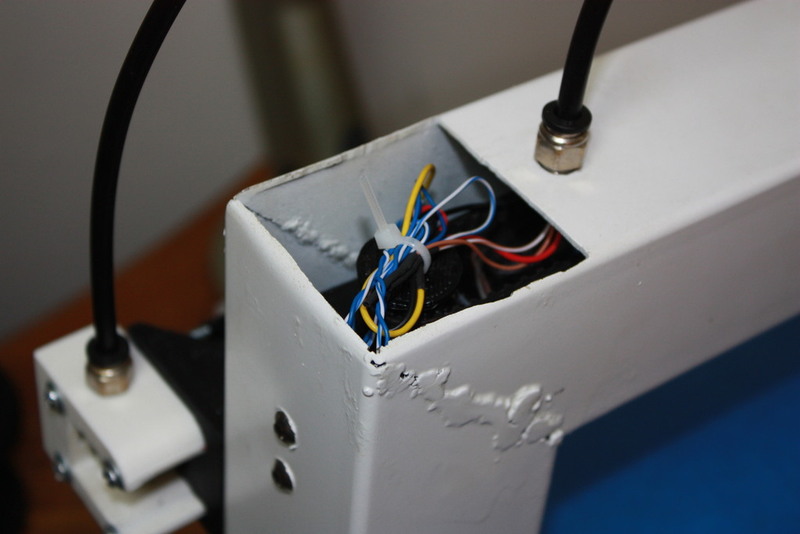

(1) Roll of 1/4" black poly tubing. Cut to: (1)14" for hothead wires, (1)20" for filament feeder, (1)12" for bed to mother board tray connection. Pic: http://eventorbot.com/pics/hose.jpg

(6) Air pneumatic tube 6mm push in connector fittings. (Total Size 21mm x 12mm/ 0.82" x 0.47"(L*W) Thread Diameter 9mm/ 0.354) Pic: http://eventorbot.com/pics/hose%20connector.jpg

(1) 5.5 mm x 2.1mm DC power jack socket female panel mount connector. Pic: http://eventorbot.com/pics/DC%20Power%20Jack.jpg NOTE: If you choose to use a hotbed, upgrade this jack to something that can handle at least 13amps. As for your power source, you can use a Xbox 360 power brick. Xbox 360 power brick is 16amp and is more then enough to handle the power (under $20.00).

(1) Laptop charger 12 volt DC at least 5 amp. Pic: http://eventorbot.com/pics/power%20supply.jpg

(1) Hot end assembly: http://www.youtube.com/watch?v=ahse-027CR4&feature=plcp

== Locations for screws ==

File: "Hardware.skp" shows the locations of all the screws. Please use the free google sketchup software, to zoom and view in 3D. http://www.thingiverse.com/download:86011

== Printable plastic parts ==

STL files and quantity's of prints:

(2) bed A p1 P-022: http://www.thingiverse.com/download:85931

(2) bed A p2 P-023: http://www.thingiverse.com/download:85932

(1) bed carriage p1 P-012: http://www.thingiverse.com/download:85921

(1) bed carriage p2 P-013: http://www.thingiverse.com/download:85922

(1) bed carriage p2 P-015: http://www.thingiverse.com/download:85924

(1) bed carriage p3 P-014: http://www.thingiverse.com/download:85936

(1) bed p1 P-020: http://www.thingiverse.com/download:85929

(1) bed p2 P-021: http://www.thingiverse.com/download:85930

(1) extruder housing P-002: http://www.thingiverse.com/download:85911

(2) footing 1 P-009: http://www.thingiverse.com/download:85917

(4) footing 2 P-010: http://www.thingiverse.com/download:85918

(1) mother board tray P-003: http://www.thingiverse.com/download:85912

(3) motor mount P-005: http://www.thingiverse.com/download:85913

(2) pulley gear P-006: http://www.thingiverse.com/download:85914

(2) rod support p1 P-016: http://www.thingiverse.com/download:85925

(2) rod support p2 P-017: http://www.thingiverse.com/download:85926

(1) spool holder P-011: http://www.thingiverse.com/download:85919

(1) spool holder 2 P-011: http://www.thingiverse.com/download:85920

(1) x carriage P-007: http://www.thingiverse.com/download:85915

(1) x carriage part 2 P-008: http://www.thingiverse.com/download:85916

(1) z carriage p1 P-018: http://www.thingiverse.com/download:85927

(1) z carriage p2 P-019: http://www.thingiverse.com/download:85928

Optional Decorative caps:

(2) corner cap P-001: http://www.thingiverse.com/download:85933

(2) end cap P-004: http://www.thingiverse.com/download:85934

After you have finished the frame and have welded the corners together, you will also have to cut a 2.5" x 2.5" square on top of the frame (the corner caps will cover this corner).