MetalicaRap:old info

Given Electricity is 2kwh per hour .5Euro/hr Part A Material; Stainless steal, Size; 300x300x200mm Weight; 15Kg 10µ Stainless powder (40 to 100Euro/kg) melt print 100µ Z layer thickness

1 minute per 100µ each layer See below; 1 minute per Z 100µ layer, each layer preheated 20 degrees Centigrade under melting-point followed by printed by beam5.33 minute per Every 10th layer Z axis correction see below ;

SEM ( part assumed to occupy 1/9 of whole print area; 1/9* 300*300=10 000<math>mm^2</math> measurement at every 10µ, SEM picture 500x500 pixel so 5mmx5mm, So for 10,000<math>mm^2</math> need 400 SEM pictures 10,000/25= 400 4x pictures from 4 picups gives effect of different angles? for 3D picture reconstruction so real distances, 400 5mmx5mm pictures, 250ms a picture = 100sec. plus time of mechanical movement of electron gun between .024m square patches at .03m per second is 12y strips each 0.3m strip takes 10 seconds to travel, so in all takes 120 seconds to cover build area( Risk of underestimate factor x100 ) 100+120=220 or 3.66 min Remove metal by Vaporization 1ms per 70µ diameter spot area 4000x10-6<math>mm^2</math> ( 850µs duration & 150µs beam movement) 1/10 of part high(Risk of underestimate factor x2) ( 1/10*10 000mm2/ 4000x10-6 <math>mm^2</math>= 1x105 spots 1x105 spots*1ms= 100Sec 1.66min

Time so far 200* Z correction layers 5.33 Min each 1066 + 1800 printed layer 1min each = 2866 min ( 2.0 days) Cost 690 Euro materials 600Euro Electricity 90

Part B

Material; Aluminum Size; 300x300x20mm Weight; 1.5Kg Aluminum 15Euro 10µ powder, melt print 100µ Z layer thickness

Time 20* Z correction layers 5.33 Min each + 180 printed layer 1min each = 287 Min 4.8 hours

Cost 27 Euro materials 22 Euro Electricity 5 Euro

Further manufacturing walk through

Powder

injection molding powder

Aluminum powder 15 Euro/Kg 10µ

Carbon chromium 40Euro a kg. 74µ

Stainless powder 40Euro/kg 10µ

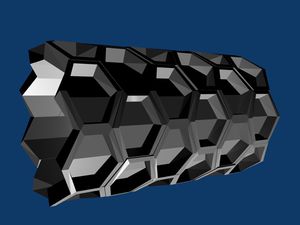

Some say the "lots of small rigid parts joined together" approach -- illustrated on the right -- has "too many joins" for a vacuum chamber. Would a relatively soft material in the gaps between parts -- like the Pb lead between parts of a stained-glass window -- compress enough to make it air-tight? Normally use copper wire to make up "CF flange".[1]

As the main consideration is avoiding non MetalicaRap conventional machining, can you make the copper wire pinch/seal of a CF flange out of the edge of a purchased plain rectangular plate? Is there a better approach? Print the coper flange then uncoil?

NB. It can also weld finished parts together placed in the chamber, the chamber is twice as wide XY as build area approximately, as it needs space for removable metal powder hoppers!, can you use this extra space?,

Chamber 1.3m high, 1m wide, 0.6m depth powder build chamber is 0.3m High 0.3m Bredth 0.3m wide

Door size is up to you, could be a full side eg 1.3m by 1m.

Outstanding questions,

Which insulator for cylinder holding 100KV terminal in electrical feed-through in to chamber ? PTFE? See page 5 [7] Which insulator to secure tungsten wire? Which ceramic?

Which wire for coil windings ? (4A) telflon coated copper? Maybe? Which thermal conducting material for anode support structure? copper 20100 alternatives? See page 5 [9] What insulator for surrounding the central stalk that makes the internal electrical connection to the hot IrCe metal ring which goes up through the cathode stem?

- Self study the material science to help us with its development free at this site[2]'' STUDY

Rejected design approaches

- Cartesian Electron Gun A 600W (60KV 10mA) close to build platform on Cartesian X,Y support. Providing subtractive micro vaporizing and vision system

So we are no longer restricting the design to known 2 gun technological solution, (i.e. 2 guns. One close to the target and one far from the target, 1m away (having functions SEM / Micro vaporizing and melting across build area respectively)) Carbon nanotube coated needles have been used and may be worth investigating

.General material issues;

The materials usually have limited lifespan due to sublimation at higher temperatures.

Design Tools

Electron Gun Collector(/cathode) Simulation Software (not for the faint hearted!)

Some people suggest the most acurate way for Electron gun design is it to be done manually with formula through consideration of 3 effects on electrons; Electromagnetic fields, laws of motion, Space charge (electrons pushing on each other). Here are two formula explanations and manuel calculations of pierce guns,; first a large non filament gun example See here [3], Second an example of Pierce weld gun See fig.3 [4] ), See final equations to give velocity of electron in equation(1.9) and beam current as (equation 2.10)See equations here [5] .

Others argue simulation software is accurate enough and necessary it was used 1980's onwards to refine design of the electron gun, See example design process of a gun cathode See page 19 here [6].

Cathode voltage choice controls minimum penetration depth of electrons energy in to the metal powder/target, beam current choice influences power transfer rate from electron beam to metal, once cathode voltage and max beam current are decided, Electron Gun Collector/cathode Simulation programs are used to design the appropriately cathode anode surface shapes to achieve the said max beam current at the applied cathode voltage, while maintaining at the gun crossover point the required beam power (Watts) at the optimum gun crossover diameter (cm) (gun crossover is situated in the middle of the anode see main electron gun diagram above), the gun crossover diameter is the primary factor controlling the final beam spot size on build platform/target ( other negative effects come from coil imperfections and aperture electron wave interference patterns) .

- For comparison try to get hold of open source charge particle/electron trajectory analysis programs, some times called electron gun computer simulation programs, like SAM or ULTRASAM (USAM) (By m Tiunov BINP russia )or maybe TREDI with modification?Get here[7], ( # -indicates confirmed as currently for commercial sale with no useful free trial version, #EGUN [8] / #EGN2w, windows version/ #EGN2w is currently seen as obsolete but will work fine for us, byBill Herrmannsfeldt, Reinard Becker University of Frankfurt/M, [9]) or #TRAK or #MAGIC). GENERAL RESEARCH

But for now we will try with a general magnetostatic program like Poisson for tracking through coils and calculating resultant forces on coils ( later we track beam live with UAL see above ) and unfortunately we have no solution for cathode anode design as we require space charge calculations and temperature and field regime "Schottky emission" which this CPO student limited version blocks, but you can get to know the principles behind it by play with CPO, ( CPO Boundary element method simulation program student version for standard pierce gun cathode shape/ solutions, Download CPO here [10] install and run in XP compatibility mode! (right click properties / compatibility tab) , Pictures [11] Installation help[12]).

Poisson/Superfish are a suite programs for Unix or Windows, containing the key subprograms called; automesh and poisson and pandira the suite is available from Los Alamos Accelerator Code Group (LAACG) First Register your name on the download page and then the download site offers instant Download, Download page here [13], Due to the complexity of the input file format of automesh (AUTOMESH.IN) two "helper" programs Geometric modeler download Poisson/superfish here[14] and ViewGraph download here [15] are essential for input and output respectively. So using Geometric modeler to create the input file to Automesh which combines the settings list and mesh shape to produce the problem file which is then analyzed by running subprogram POISSON. Which output file is plotted by ViewGraph or Geometric modeler.

So in general terms Run Geometric modeller to aid the production of the required input files for automesh, upon running automesh the problem set up is achieved. Once automesh has finished running and creating the problem file ( XXXXXXXXX.T35 ) then the solver program Poisson acts on this file to do the simulation of the design, The Gun simulation is an magnetostatic problem so is solved through Poisson equations ie uses subprogram called "Poisson"( We do not use RF cavities in the electron gun so ignore programs for tuning them, with FISH in the program name) . See summary of POISSON suite input and output files here input & output files using POISSON suite. You can confirm you output with approximate hand calculations at centers of coils See formula here , Deflection of beam by coil here [16] , coil Magnetic field B calculations [17], Background Coil design[18].

Old self replication method

Hexagonal x40 halfhexagonal x16 endpieces x16, 384 bolts (what does this mean?), copper wire, main door can use a Viton O ring perhaps, or a metal to metal seal with vacuum oil or vacuum wax as a sealant. old solar cell material deposition rate of a few micrometers per minute / electron beam heating evaporation deposition EBPVD [19] / possibly a micro pulsed electron deposition process,

Calculations for 1m cubed box design - too expensive Step 1 - Required thickness approximation

I've calculated plate thickness, constrained by maximum deflections of 0.01 & 0.03 inches = 0.254 & 0.762 mm and pressure differential of 1 atm sea level for the largest dimension plates, ie electron gun tube length 0.80 diameter .032 on top ; H 0.8 x W0.8 x Depth 0.4 (assuming smaller plates will have less deflection)

Online calculator for fixed rectangular plate (Bypass calculation limit by clearing your cookies)[20]

old links before TWI blocked pages 1. http://www.twi.co.uk/content/spasaug2006.html

1A.http://www.twi.co.uk/content/eb_variants.html#ref3

Simple just plate chamber with electron gun tube length .080 diameter 0.32 on top ; H 0.8 x W0.8 x Depth 0.4 area 2.56

Material

Stainless Steel 304 (check this)

Youngs modulus E GPa Stainless Steel 207

Poissions ratio v 1 0.3

Uniform loading p Pa 101325

Individual plate sides of chamber given 0.253097 mm max plate deflection

Width Lx mm 800

Length Ly mm 800

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Individual plate sides of chamber given 0.761671615 mm max plate deflection

Width Lx mm 800

Length Ly mm 800

thickness needed 15.8 ( 15.8mm ( 5/8inch)( deflection 0.683mm) 2098 euro per m sq.)2.56 x 2098 do again BAD PRICE? = 5370 euro(( do we need to go up to 316 stainless?)

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Material

Aluminium

Youngs modulus E GPa 62.053

Poissions ratio v 1 0.3

Uniform loading p Pa 101325

Individual plate sides of chamber given 0.253097 mm max plate deflection

Width Lx mm 800

Length Ly mm 800

thickness needed

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Individual plate sides of chamber given 0.761671615 mm max plate deflection

Width Lx mm 800

Length Ly mm 800

thickness needed 25 Aluminum plate (deflection .583mm) 2.56 m sq. 2000 euro[21]

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

another possible chamber with no electron gun tube.

Simple just plate chamber no electron gun tube ; H 1.6 x W0.8 x Depth 0.4

Material

Stainless Steel 304 (check this)

Youngs modulus E GPa Stainless Steel 207

Poissions ratio v 1 0.3

Uniform loading p Pa 101325

Individual plate sides of chamber given 0.253097 mm max plate deflection

Width Lx mm 800

Length Ly mm 1600

thickness needed 40.6 do again

Width Lx mm 400

Length Ly mm 1600

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Individual plate sides of chamber given 0.761671615 mm max plate deflection

Width Lx mm 800

Length Ly mm 1600

thickness needed 28.2 do again ( 1inch 25.4mm 1200 euro per m sq.) so 6.4m x 1200 = 7680 euro(( do we need to go up to 316 stainless?)

Width Lx mm 400

Length Ly mm 1600

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA

Material

Aluminium

Youngs modulus E GPa 62.053

Poissions ratio v 1 0.3

Uniform loading p Pa 101325

Individual plate sides of chamber given 0.253097 mm max plate deflection

Width Lx mm 800

Length Ly mm 1600

thickness needed 59.3

Width Lx mm 400

Length Ly mm 1600

thickness needed TBA

Width Lx mm 400

Length Ly mm 1080

thickness needed TBA

Individual plate sides of chamber given 0.761671615 mm max plate deflection

Width Lx mm 800

Length Ly mm 1600

thickness needed 41.1 40mm Aluminium plate 6.4 m sq 4708 euro[22]

Width Lx mm 400

Length Ly mm 1600

thickness needed TBA

Width Lx mm 400

Length Ly mm 800

thickness needed TBA next steps - Material prices ?? - using next larger standard dimensions ?? - factoring in compressive stresses from edge loading (buckling)