Prism

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: Experimental

| Description | Mendel Frame

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

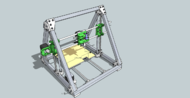

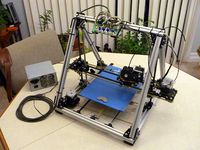

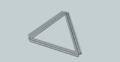

Prism Mendel

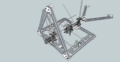

This extruded aluminum frame is a quick upgrade to your standard Sells Mendel. It makes it cleaner, more open and, more importantly, more rigid.

You can start printing parts today, but wait to order parts 'till next week while I finalize a screw/nut count. If you just can't wait. know that I've used less than 100 screws/t-nuts for my build, but over 100 M4 washers.

The only part i don't have designed yet is a mount for the endstops. You can use the endstop holder designed for Prusa, or run without endstops while i design one for 20x20 mounting, or design one yourself and put it up here or on thingiverse.

design goals

I've always disliked how parts of the Mendel jut out. it's a minor complaint, but one I wanted to address as I moved to extruded aluminum. The Z rods are now inside the 'triangle', as is the z motor and y motor. The x axis can still jut out, but how much really depends on which x axis you choose, which isn't really part of this mod. It is much easier to travel with the Prism or make a case for the Prism because of this change. It also just makes the printer build area seem more open and accessible.

Another thing I want to try in the future is making a tent out of Mylar. The tent would hold in the heat from a heated bed and hot end and block errant air currents, but wouldn't get as hot as a heated chamber so overheating motors hopefully won't be a problem. This is going to be much easier to try with the Prism.

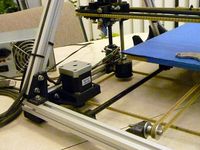

In addition, the y and z motors are in direct contact with the aluminum frame, which should dissipate motor heat nicely.

Unfortunately, for people who like Prusas, the frame won't allow top mounted motors as is. I think moving the motors to the base and using gears to drive the z lead screw is a good workaround if you still want two motors, but belt routing and tensioning is much easier with the Prism, so it might make a Sells-style single motor/belt more attractive again. Either way, a gear driven system also allows other gear ratios and takes care of the shaft coupling issue. However, if you prefer a pure Prusa, the MendelMax is a great alternative.

Another benefit of the Prism is a much larger Z build area(20-60 mm, hard to be precise because it depends mostly on your extruder and x axis) since the Y rods now sit below the bottom end of the Z rods. My Prism is 210mm from the bed to the X rods at ~Max Z, and all of this area is printable because the carriage will not hit the frame rods anymore. The x and y can also be increased, potentially.

Finally, most extruded aluminum profile suppliers cut to size for no extra cost, and the cuts are much more precise than you would get with a hacksaw at home. It's a nice extra that should make assembly and calibration easier.

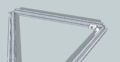

New non-printed parts

(Misumi parts numbers are listed, where applicable, for easy ordering)

- Extruded Aluminum Profile

- 20x20x400 - 9 (HFS5-2020-400)

- M3

- M3x10mm SHCS - ~10-20

- M3 Nut - ~10

- M4

- M4x12mm SHCS - ~70

- M4 T-Nuts (which are compatible with your extrusion) - ~70 (HNKK5-4)

- M4 washer - ~140

- NOT REQUIRED M4 Post-Assembly T-Nut - 20 will run about $10 - makes it easy to attach parts without having to disassemble the whole frame. (HNTA5-4)

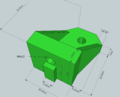

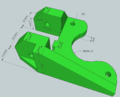

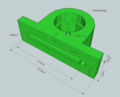

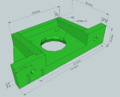

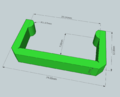

Printed Parts

Files

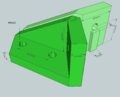

The .Stls for the 60 inside part and Ztop bracket print two pieces at once.

The most up-to-date files will be on github: https://github.com/Buback/Prism-Reprap

Images

Optional pieces:

Build Instructions Notes

The Thick 90 degree part is just to raise the printer up high enough so the z rods and motor shaft don't hit the table/workbench your printer is upon. You can use the thin part for all the vertexes but you're going to need to add many, many extra washers, because either way, you'll need m4x20 screws. I'm sure somebody will come up with a better solution eventually. --Buback 18:24, 27 December 2011 (UTC)

Visual Assembly Guide

I removed my old instructions, as I think the pictures bellow are clearer, but i'll add detailed instructions over the next couple weeks --Buback 17:58, 28 December 2011 (UTC)

Further Development

-There isn't room at the top of the z rods to get a tool in and tighten the screws, which is why you need to put in the z rod first. I'm not pleased with this, and so the first order of business is to figure out a way to fix this. Adding longer 'arms' to the Ztop piece is the obvious solution, but then it's a longer unsupported angled print, which i feel leads to week parts. the other option is to split the part down the middle and make it two parts. the problem here is alignment becomes a bit of an issue, potentially. Anyway, if you'd like to design a part that holds a 8mm (or larger) rod in between two 20x20mm extrusions at a 60deg angle, feel free to post it here.

-Perhaps a dedicated Y and x carriage would be nice. I prefer a vertical X and ball bushings. The X build area could also be made bigger, but is now limited by the x length of the x carriage, and not by the space between the angled bars.

-Fully Parametric parts, a la OpenSCAD.