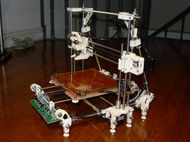

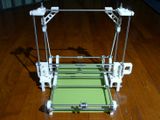

RepRap Samuel

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Silpstream's Augmented Mendel a.k.a Samuel

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

RepRap Samuel is designed to reuse the vitamins and some parts from the Prusa Mendel i2 or the Mendel. As such, an owner of either of the RepRaps should be able to print the new parts on their existing 3D printer to rebuild it into Samuel. It's design objectives are:

- Reuse vitamins and parts from RepRap Mendel

- Increase build volume in the Z-axis

- Improve X-motion stability

- Upgrade X-axis to newer vertical designs

CREDITS

The following components were used in this project:

- Unbreakable Bar Clamp by mikepcw - [1]

- Prusa Leveling Vertex by Ahasuerus - [2]

- Bed levelling thumb wheel by Wired1 - [3]

- 40mm Supportless, Directed Cooling Fan Duct for MendelMax & Prusa by AeroMonkeyDork - [4]

- The frame stabiliser was also from Thingiverse, but the thing seems to have been removed.

Specification

- Size: 420x420x440mm

- Build Volume: 196m x 196 mm x 200mm

- 5 x NEMA 17 motors

- Electronics: Should work with most RepRap electronics

- Structural materials: M8 rods, ABS/PLA

Parts

M8 Rods

The quantity and lengths of the rods are the same as that of the Prusa Mendel i2.

| Quantity | Part | Comment | 6 | 370mm M8 threaded rod | 2 used at rear of frame. 2 used to connect front and rear of frame. 2 used to create vertical frame. Longer is okay. | 4 | 294mm M8 threaded rod | 2 used at front of frame, and 2 more diagonally to support the vertical frame. Longer is okay. | 3 | 440mm M8 threaded rod | 2 are used to secure the z-motor mount, while one goes across as top support. Longer is okay. | 2 | 210mm M8 threaded rod | Used for the z-axis. Longer is better to give more build height. Can also be replaced with 8mm lead screws or M5/M6 but you'll need to make a nut adaptor. | 2 | 350mm 8mm smooth rod | Used for the z-axis, cannot be shorter than 330mm. Longer is okay. | 2 | 405mm 8mm smooth rod | Used for the y-axis, must not be shorter than 405mm. Longer is okay. | 2 | 420mm 8mm smooth rod | Used for the x-axis, cannot be shorter than 410mm. Longer is okay. |

|---|

Bearings

| Quantity | Part | Comment | 4 | 608zz | 2 are optional as you only need one in front and 1 in rear. Look at pictures for better understanding. | 5 | 623z | Only need 4 if you choose not to use the direct drive extruder in this project. 2 used of x-idler. 2 used for y-motor mount. | 1 | 625zz | You need this only if you want to support the shaft on the y-motor. | 10 | LM8UU | 3 for print bed, 3 for x-carriage, and 4 for x-ends. | 2 | F8-19M | These are optional trust bearings that are used on the z-axis. The bearing dimensions are 8mmx19mmx7mm. |

|---|

Printed

You can find all files on reprap_samuel@GitHub.

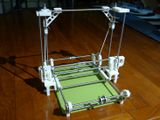

Build

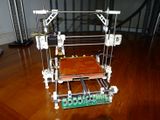

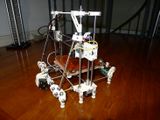

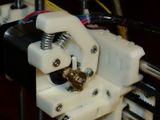

Detailed pictures to show how the parts go together.