User:Las5661/Blog

Contents

- 1 Blog 1: Some awesome things found on Thingiverse

- 2 Blog 2: OSE Project Discussion

- 3 Blog 3: 3D Printed Robohand

- 4 Blog 4: Review of Classmate's Blog 2s

- 5 Blog 5: Review of the 3D Printing Media Timeline

- 6 Blog 6: Where Should the Class Go From Here

- 7 Blog 7: Article Responses

- 8 Blog 8: Article on How 3D Printing Could Effect Intellectual Property Rights

- 9 Blog 9: What Filament To Use and Where To Get It From

- 10 Blog 10: Research and Information on Hot Tips

- 11 Blog 11: What I Have Learned From the Show and Tells This Semester and Which Was My Favorite

Blog 1: Some awesome things found on Thingiverse

Thingiverse is a website used to share files of 3D objects people have designed and printed.

Something Amazing/Beautiful

I'm amazed! For anyone who knows me, they know I am a huge Halo fan. The fact that someone was able to make this out of 3D printed parts leaves me speechless.

Design Here: Halo 4 Helmet Full Size

Something Funny and Strange

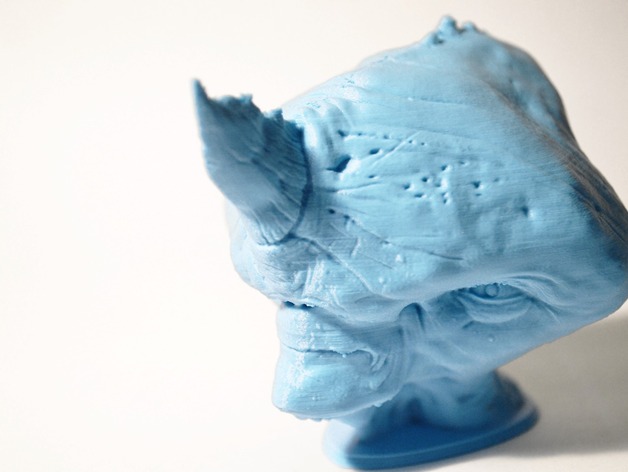

I'm not exactly sure what/who Rhino Man is, but this printed bust sure does look strange to me.

Design Here: RhinoMan

Something Useless

It's cool to look at but I can't think of any practical use for it.

Design Here: Six Handles Fancy

Something Useful

This is probably the most interesting tablet stand I've ever seen.

Design Here: Octopus Tablet Stand

Something that surprised me

As a Doctor Who fan, this is awesome to begin with. What surprised me the most about it is that it was printed using a glow in the dark plastic and then wired with blue LEDs inside of it to give it the glowing effect.

Design Here: Tardis

Blog 2: OSE Project Discussion

A) General Impression of the OSE Project

In general, the OSE project strikes me as a unique idea that could impact 3rd world and developing countries in a very good way. The amount of contributions made to the project by people other than Marcin was also incredible. Upon considering how this project will hold up in the future, I find it incredibly likely that the large companies making the more expensive commercial products will not be too happy about this venture and may go so far as to try to shut down the project. Companies such as John Deere would not like it if their products began to be beaten out by the cheaper alternative of making your own tractor. Thinking business wise, it would make sense to prevent this project from continuing in the long run, or risk losing customers/business.

After reading about the project in more depth on their website at http://blog.opensourceecology.org/, it seems that the community behind the project has been increasing at a steady rate since its inception. I commend the fact that there is a full-time group of people willing to help the project. These people have taken up positions that include project managers and operations managers. With this amount of support and leaders, I believe the OSE community can continue to increase for at least the next few years.

I decided to research the tractor a bit more and see just how easy it would be to create my own. After reading through a bit of the manual, it doesn't seem like it would be as easy to fabricate my own tractor as I initially thought. Although it would definitely be a challenge to create, with enough time and resources, it could be done. If a part were to break during the creation of the tractor however, someone without experience in fabricating and with no concept of how a tractor works, the tractor might never be able to finished. Considering I do not have an extensive amount of manufacturing experience, I feel that it would be extremely hard for someone without past experience to accomplish this project.

B) New Yorker Article and Marcin's Response

In Emily Eakin's article in the New Yorker at http://www.newyorker.com/reporting/2013/12/23/131223fa_fact_eakin, a more doubtful critique of Marcin’s ideology and tendencies is written rather than a report on his and the project's accomplishments. In the article, she does raise a valid point however; she says that, "among the obstacles he has faced is a dearth of skilled acolytes: the people who show up at his farm typically display more enthusiasm for his ideas than expertise with a lathe or a band saw." I for one would fall into this category; while being able to work on this project would be awesome, I wouldn't bring a lot of know how to the table. I believe that it was unnecessary for her to discuss his journaling tendencies or mock his food consumption however.

Marcin responded to this article at http://opensourceecology.org/wiki/New_Yorker_-_Article_Response. In general, it seemed to be a good response to the article critique. At the end of the article, Marcin says, “I am proposing a much more optimistic representation of our work than the social melodrama that the article appears to emphasize.” While I can see why a person in Marcin's position would never focus on the problems ahead of the project team, but at some point, he may not be able to remain blind to the many problems that could prevent the success of his project. Again, I find fault with what Marcin says regarding average people rising to the occasion and creating their own machines. I, being an average person, do not see myself as currently capable of making a machine such as a tractor. Marcin has a Ph.D, as well as years of experience with machines and blueprints; so he is obviously an intelligent guy. If his definition of average means people with excellent design skills, as well as years of background experience with machines, then his statement would be fine. Unfortunately, that is not the standard definition of "average".

C) PSU Club Possibilities

While there is quite a large number of organizations and clubs at Penn State, including THON and the 3D Printing Club to name just 2, I believe an OSE club might garner some interest, but I believe that they would run into problems regarding what I expressed above. Yes, many people would want to help out and build something, but with current experience, limited funds and places to manufacture, and limited time beside school work, I'm skeptical that a project of any size could be finished. If I were to contact a particular Penn State faculty member in order to garner support for such a club however, I would approach Dr. Brennan first. He was my professor for Industrial Robotics and for Vehicle Dynamics, as well as the leader of the autonomous vehicle research team. I would approach him first because he seems like someone who is always willing to push the envelope regarding design, programming, and invention.

Blog 3: 3D Printed Robohand

Who, When, and Where

The Robohand design was created by Ivan Owen and Richard Van As. The first prototype of their design was made out of metal and was made in November 2012 while the first 3D printed version was made in January 2013. Ivan Owen did his work on the Robohand from Seattle, Washington, while Richard Van As worked from Johannesburg, South Africa.

Where Could I Go To Get One

The designs for the Robohand can be found on the thingiverse website and were posted by MakerBot.

The design can be found here: Robohand

News Articles

By doing a simple google search for robohand news articles, many links can be found related to this technology. The links returned by google range from articles covering hand prostheses for little kids to articles covering 3D printed beaks and legs for animals such as eagles and ducks.

This link for example goes to an article about a little girl who was given a 3D printed robotic: Robotic Hand

This link goes to an article about a group of people who 3D printed legs and webbed feet for disabled ducks: Legs for Ducks

This link goes to an article about an eagle who received a 3D printed beak to replace the top half of its beak that had been lost after it was shot in the face by a poacher: 3D Printed Beak

Blog 4: Review of Classmate's Blog 2s

Tony Armlin

After reading through Tony's Blog 2 responses, I can easily assume that Tony is on board with the OSE project. Based on his responses, he seems to think it's a great idea and is all for it. His responses were concise and answered each question that was posed to us but he also didn't embellish or expand on anything to what I would consider a noteworthy extent.

Yuan Chai

I found Chai's responses to the questions posed to us in Blog 2 to be rather insightful. Something noteworthy that Chai discussed in his blog was that he finds the OSE project to be a waste of resources. He thinks that Marcin hasn't taken enough into account regarding the project. Chai lists a few important things that he thinks Marcin has overlooked or just not professed on a public scale such as the economic cost of the project, the energy consumption, and the factor of safety. Chai also finds the same fault with the project as me; the average person wouldn't have the experience or know-how to complete these projects. Chai goes a step further than me however and references another example which is a powercube. He provides a link to this powercube example on his Blog 2 page.

Todd Troutman

Something that Todd stated in his Blog 2 that I found to be noteworthy was a more poignant discussion regarding the New Yorker's article about Marcin. Todd discussed in his blog that the article not only points out many of the faults with the project, but also how Marcin seems to be set in his ways to the point of alienating other people and not addressing the faults that have been expressed regarding the OSE project.

Graham Deever

In Graham's Blog 2, he notes how, if the project were to be implemented correctly, it could allow developing countries and the developing parts of the world to develop at a much quicker pace. He also made a note that this same kind of project could possibly be used in the future for developing other planets for a human colony/society which I found to be a really interesting way of looking at it.

Kevin Moyer

After reading through Kevin's blog, I found that he discussed the same pitfall that I found with the project for the majority of his Blog 2. I did note however that he went into a greater amount of detail than I did regarding this pitfall. Kevin explained the specific experiences one would most likely need in order to complete one of these OSE projects and also explained what parts of the tractor's construction he as a mechanical engineering student at Penn State didn't even understand.

Jessica Mewkalo

What I found to be noteworthy in Jessica's Blog 2 responses was the fact that she considered how the OSE project could effect the economy in the long run. She states that if everyone started building their own machines, companies (John Deere being a good example when considering the tractor) would go out of business. I thought this was a really realistic way to look at how this project would effect society.

Eva Abeniacar

While the opinion that Eva expresses in her Blog 2 is the opposite of mine, I did find it noteworthy and agreeable that, if more people were to become involved with this project and work towards its advancement, the better it would become.

Nam Pham

Nam went over many good points in his Blog 2 responses but we shared most of the same view points and discussion topics.

Dongao Yang

From the beginning of his Blog 2 responses, Dongao makes it clear that he is not a fan of the OSE project. He professes in his blog that there are too many pitfalls with the project for him to have a positive view of it. Two of the most noteworthy pitfalls that he talks about concern durability and safety. He explains that open source is okay for things like 3D printing; if one operates a 3D printer incorrectly, there isn't that large of a safety hazard risk. When you get into the things that the OSE project concerns such as tractors, open source isn't such a good idea and should be left to the professionals.

Blog 5: Review of the 3D Printing Media Timeline

Upon first skimming through the timeline, I was surprised to see that 3D printing dates all the way back to 1984. I found this surprising because I hadn’t heard of 3D printing before my sophomore year of college in 2011. The media timeline can be found on the Scrugmembers wiki page.

1) In my opinion, would say Chuck Hull’s invention of the first 3D printer on March 11, 1986 was most likely the largest contribution to 3D printing and is therefore the most important event in its development as a whole. While it could be argued that Chuck's development of the method to print 3D objects using digital data is the most important contribution, I believe that the theoretical process would not have been so widely known without the invention of the physical machine. I also found it interesting that the same method of adding one layer at a time was developed 30 years ago and is still used by the various forms of 3D printers today. I’m amazed that a method developed many years before I was born is still so widely used.

2) When considering an event that may have not been that important to the development of 3D printing, it would be my opinion that the CNN article from 2005 may have been a bit of an exaggeration when considering 3D printing. The title of the article, “The Machine That Can Copy Anything,” seems a bit bold and presumptuous. While I can understand that the article's title is meant to draw in readers, I still believe that the title over exaggerates the capabilities of 3D printers. Even if this were to have been written more presently, I would still be of the opinion that the title is still an exaggeration of the current capabilities. Upon reading the article, I realized that it didn’t really relate to the title and that it was fortunate that the advancements of 3D printing were being publicized. From reviewing the timeline since the release of the article, there has been quite a growth in 3D printing technology.

3) The thing I found to be the most interesting was the possibility to print materials other than plastic such as food or artificial organs made from arranging sugar in a lattice orientation. The benefit to humanity if we were able to print food on a large scale would be huge and could help to end starvation. Personally, I would be in support of a project that would supply 3D printers to third world countries for the purpose of creating food for those in danger of starvation. When thinking about what we could also do with the ability to 3D print artificial organs, the benefits would be enormous. Donors would no longer be needed and the artificial organs could be printed to fit a specific person. This would make it so that the risk of one's body not responding or accepting the transplanted organ from a donor would no longer be an issue. These kinds of topics are definitely some things that I would be really interested to learn more about.

Blog 6: Where Should the Class Go From Here

As I gain more and more experience with 3D printers, I come to appreciate the merit and vision of those that work with them even more. Projects like the OSE project have the capability to kick-start a community. It's possible to create artificial prosthetics that can improve the quality of living for people and animals. The topic of 3D printing food is one that I find incredibly intriguing. The number of ways that being able to 3D print food could help people in third world countries is astronomical. 3D printing food is something that I feel is within reach of where the class currently is. In my opinion, most of the class is comfortable with trouble shooting and assembling the printers used presently. The transition into printing food would be a logical path to pursue as a more advanced step. If there was to be enough interest in the pursuit, I think that developing a project to pursue the creation of a 3D printer that has the ability to print food would be an awesome venture to pursue.

Another direction that I feel the class could take is in a direction that would earn some extra money to be used for the classes advancement. While the current method of printing parts for the EDSGN 100 students is fine and dandy, it does use up filament that ultimately has to be paid for and also time. A 3D printing service could be created that would offer the printing of parts for any Penn State student that could actually generate a small amount of income that could be used by the class to buy more filament or replacement parts in the event that a printer were to break down. Using the same method that is used currently by the EDSGN 100 students, someone could submit a part to a website and the service would print it for them for a small charge.

Blog 7: Article Responses

Article 1

An article was posted on theguardian.com that covers the possibility of 3D printing inexpensive scientific equipment rather than purchasing the equipment at insane prices. As I have discussed in my previous blogs, I think that the possibility of using 3D printing to make the lives of those living in the "developing world" is quite enticing and should be pursued with an extensive amount of vigor. Upon reading the article, I think the possibility of saving money for research and opening up a larger crowd to the idea of experimentation and testing would be great for the scientific community as a whole.

An example that was detailed in the article was about a colourimeter used for water testing that was created via 3D printing. An actual colourimeter would have originally cost the lab $2000, but through the use of 3D printing, was printed for $50. When considering how this difference in price could help researchers in developing countries obtain the appropriate equipment, I believe that this is an awesome idea. I think this same idea could also be applied in a college setting; instead of a department using up a chunk of their funding to purchase a piece of equipment, the same product could be created by individuals at the college for a much cheaper price. This would allow many more colleges, not just well-funded, big-name universities to perform the same kinds of experiments and tests.

It is stated in the article that, “companies relying on extracting monopoly prices on products for which there is already an equivalent open-source alternative must either reduce their margins or continue to innovate to remain economically viable.” While I don't believe that the big businesses referenced in this quote may view this possibility as simply as this, I do think that a bit of competition might be a good thing to introduce. It is through competition and trying to "out-do the other guy" that great strides are made in respective fields. If the possibility of 3D printing one's own lab equipment did come to fruition on a large enough scale, the quote is absolutely right in saying that the companies would need to innovate and improve their products in order to turn a profit each year.

While I personally haven't printed anything that could be considered research equipment, I’m sure that there are some students somewhere on the Penn State campus that have 3D printed parts that could be considered research equipment. An example that comes to my mind is that, from Alexandre's presentation in class, he had been printing various things that were being used in tensile tests.

Article 2

An article posted to kurzweilai.net covered the development and creation of an AFM or atomic force microscope that had a resolution up to a nanometer. The AFM was constructed by PhD students using Arduinos, LEGO pieces, specialized 3D-printed parts, and electronics that anyone could go to RadioShack and buy. I was initially thrown for a loop by the misleading title, I expected to see details behind the AFM and instructions on how to build my own. Nevertheless though, it sounded like an awesome project with a great deal of positive potential.

After searching online for a bit, I couldn't find much more than some pictures of the AFM itself and the students involved. I was still hoping to find a set of instructions or at least a good description of the microscope. Due to the lack of available information though, it is my guess that at least some of the parts appear to be printable. Some of the main structure and platform of the microscope could be printed, but that's about it I think. The measuring devices and finer detailed areas of the microscope would either need to come from the LEGO pieces or electronics area. As of this moment, with the minimal amount of information I was able to come across, I don't believe that this project is open source. If it were though, there would be a great deal more potential for other students to further advance the project beyond the current realm. If the small number of PhD students could achieve such a level of functionality as this in just 5 days, imagine how much more this project could be advanced over the years if thousands or millions of minds were allowed to brainstorm and add their knowledge to the collective pot.

Blog 8: Article on How 3D Printing Could Effect Intellectual Property Rights

The definitions below were copied from Google.

Copyright - The exclusive legal right, given to an originator or an assignee to print, publish, perform, film, or record literary, artistic, or musical material, and to authorize others to do the same.

Trademark - A symbol, word, or words legally registered or established by use as representing a company or product.

Patent - A government authority or license conferring a right or title for a set period, esp. the sole right to exclude others from making, using, or selling an invention.

Trade Secret - A secret device or technique used by a company in manufacturing its products.

The difference between patents and copyrights, as noted from the definitions presented above, is that patents focus on inventions and the like whereas copyrights focus on works of expression such as music and art. The difference between patents, copyrights, and trade secrets are that the first two are granted by the government while the latter is not. Trade secrets are not granted by the government because the government does not know the secrets; the secrets are trade advantages that are only known to the particular company that created/owns them. Lastly, unlike the others that protect material objects, a trademark is a right to a symbol or name that is granted by the government.

Article Responses

The five I's are identified in this article as identification, impossible, infringement, impractical, and Irrelevant. These five I's represent the implications that 3D-Printing presents by allowing anybody to be able to print just about anything on their own. As information is more readily available and more easily shared, it becomes very hard to identify who owns the rights to designs, codes, and other things. Also, as the ability to identify what belongs to whom becomes harder, a point may be reached where this ability becomes impossible to implement. When this point is reached, IP enforcement may become obsolete entirely.

I would honestly have to agree with the article's statement that 3D printing may lead to IP enforcement becoming harder. I do not think that IP protection will disappear completely however. It is my opinion that, in order to remain relevant, IP offices may have to become less restrictive in their agreements in general. An example could be that IP offices could stop trying to limit the creation of patented inventions that are to be used in an academic sense, but that they could continue to limit business's ability to create patented items in order to protect the industry leaders.

In my opinion, creative commons presents a better method of ensuring the protection of intellectual property rights. The intentions behind its creation seem to consist of making an easier way for people to protect their work while allowing it to be shared as well. I think that as open source communities continue to grow that creative commons would make for a good model for the open source community to follow. I was curious about how Creative Commons would protect and enforce the rights of the owner if a business were to steal something and turn a profit from it. Overall, I think that creative commons is a great compromise that allows for the protection of IP rights while still allowing inventions to be shared in an open source way.

Blog 9: What Filament To Use and Where To Get It From

1.) We want to know the good, bad, and ugly with regard to suppliers. Who makes quality filament at a good cost? Who should we avoid?

As with many things, I find that the fewer middle-men are involved, the less expensive the product is for me. To me, this means that the most cost efficient way to get good filament is to buy it from a company that just supplies 3D printing filament. The best supplier I have found for filament is Ultimachine. I recently bought a pound of natural colored PLA filament from ultimachine for around $20.00. I am currently still using the filament and have gone through approximately 15 hours of printing with the filament to great success without making a sizeable dent in the filament length.

Another site I always search when looking to buy just about anything is Amazon. They always seem to have a variety of choices for any product I am looking for so I searched for "3D printing filament". Since Amazon can be thought of as an online mega-store, they have a large variety of filaments ranging in type, color, and size.

2.) We want to start doing dual extrusion on a more regular basis. There are a variety of ways we might start using support materials. Which materials do you think we should use? Why do you think we should use them? Once you've chosen a material you think we might use, find suppliers and estimate costs in $/kg or $/lb.

After talking with some of the TAs at The Learning Factory here on Penn State's University Park Campus, I learned that they use PVA which is some sort of gel-like, thermoplastic substance to support all of their prints. This PVA support material fills up all of the open space between the part and the bottom of the tray. Once the print is finished, the part then is soaked in some kind of solution that dissolves the support material. Unfortunately, this soaking process adds about a day of "wait" time to the total printing time. This process is also why using the printers in The Learning Factory is rather costly.

After doing a google search and looking through some of the links, the cheapest price I could find for water soluble PVA was here. To summarize the price results:

100-299 rolls 12.30$/roll 300-499 rolls 10.66$/roll ≥500 rolls 9.84$/roll, each roll contain 0.5kg material.

3.) Pretend you are shopping for material for your own needs. Who do you choose?

This is really an easy response for me since I have already purchased my own material from Ultimachine. I would have to recommend them since I was able to buy a decent amount of filament for a cheap price and it arrived really quickly.

Blog 10: Research and Information on Hot Tips

1.) What designs are currently available and how do they compare to one another? What designs should be avoided and which are the most reliable?

This design seems to be more stable with regards to its temperature control. It also separates the heating unit from the extruder. The motor for the extruder has less room to sit in this design however. This causes the motor to throw off the center of gravity of the entire extruding unit, causing the hot tip to point down at an angle instead of straight down.

This hot tip design implements a method of using thermocouple wires with hot tips, which seems to be a more reliable way of controlling the temperature. The current design that we implement on the repraps in class allow relatively easy access to the wires, which can be good at times, but also leads to short circuits in some situations.

On Thingiverse, there is a hot end which is easy to build. From what is described and stated about the design, while this hot tip is cleaner, longer, and thinner than what we currently use in class, it seems to have a harder time with regards to temperature control.

The design I personally like the most is this one. I like this one the most because the temperature control seems to be quite good and it theoretically has a great sense of functionality through the combination of the hot tip and the heat sink.

2) Pretend you are shopping for a hot tip for your own needs. Which design would you choose?

After doing some research, I found that there is a great deal of variety when it comes to the price of hot tips. An example of this variety can be seen when comparing this one and this one. From what I can tell, both hot tips seem to be the same thing but the second one is twice the price of the first one.

When it comes down to which vendor I would be comfortable purchasing a hot tip from however, I would always choose the vendor I am familiar with and have purchased 3D printing materials from before. While there might be better hot tip deals or designs out there, my preference would stem from the fact that I am familiar with their reliability and customer support as a vendor.

Here is a guide that has been posted to the wiki page and does a great job of comparing hot tip types/designs.

Blog 11: What I Have Learned From the Show and Tells This Semester and Which Was My Favorite

My favorite show and tell presentations this semester have been the presentations about the smart phone apps that are on the market that allow users to take pictures of objects for 3D scanning purposes. My favorite presentation was the one given by Drew where he showed the class how Flickr images can be used to create a model of Notre Dame through PhotoSynth. He went above and beyond for this show and tell by showing us all how he created a 3D model of one of his boots using approximately 40 pictures taken from all sides of the boot and Autodesk 123D. I find these kinds of presentations to be the most interesting because I feel like the pushing the envelope regarding 3D scanning will in turn further progress 3D printing. Its my opinion that through easier 3D scanning methods, 3D printing will become easier to do and more user friendly; it would enable someone with no 3D modeling experience or skills to simply scan the real life object and get a 3D model of the object out of it. While Drew did mention that he had a few complications with the program, it seemed to work quite well when analyzing the end result. I'm sure that as time goes on, more programs like these will become available and further improvements will be made to the process.

Regarding the 3D scanning of objects in order to get 3D printable models, I have been observing what Chai has been doing regarding scanning and printing the lion shrine to be fascinating. Having seen his most recent print of the lion shrine, I can honestly say that I am thoroughly impressed by the quality of the print, and by extension, the quality of the 3D scanned model. I have also been working with Todd on 3D scanning people and faced via the xbox 360 kinect system. The scans from the kinect have not come out quite as well as those done my Drew using the smart phone app, but I feel like it would be beneficial to see if the scans improved if the more recent, xbox one kinect were to be used.

I feel that is worth noting that one other presentation that I found really interesting was the one about 3D printing living tissue and organic/biological things. This has started to become a reality around the world as people have organs, bone, and prosthetics 3D printed for them. If this becomes the norm, I feel like there would be less worry about one's body rejecting the transplanted organ or bone because it would have been 3D printed using the person's own cells. A recent, real world example related to this topic can be found in my bonus blog entry below.