WatBot

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

| Description | documenting a generic tool/artpiece

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

| FILE ID# | TYPE | DESCRIPTION | AVAILABLE FORMATS | CREATED/RESERVED BY |

|---|---|---|---|---|

| Your-File-Name | SOLID MODEL ASSEMBLY | These are CAD files for the Solid Model Assembly | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC) |

| Your-File-Name | CAD FILES FOR PARTS | These are CAD files for each part. | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC) |

| Your-File-Name | EVEN MORE FILES | These are are even more files. | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC)|- |

| Your-File-Name | SOLID MODEL ASSEMBLY | This is the final finished machine | N/A | --Example User 12:00, Tomorrow's Date, 20xx (UTC) |

Please edit this and click the links to put in your own files! --Sebastien Bailard 08:34, 10 September 2010 (UTC)

Contents

Goals

1. Provide a way for me (an architecture master's student) to learn, and take with me, the *equipment* that is becoming essential to our practice-my school has a 6 axis Kuka robot, 4 laser cutters and a bunch of CNC mills/water-jets/etc, but for most of us, after graduation we work in offices/design practices without the budgets for these sorts of gear.

2. 3D printer: makes having a higher Z-axis useful

3. CNC router: MDF, plywood, aluminum, maybe zinc sheeting(no idea about how tough this is, just thinking of architectural materials) drilling holes in steel?

4. Modularity: swapping out plastic extruder for spindel for laser - have not tackled this but imaging some sort of steel sleeve with grooves and maybe a bottom shelf with a hole and a top that can be clamped on.

5. Build platform: constrained by equipment already purchased (see below)

Means

Although it can't self-replicate, hoping that this can be made through the cheap commoditization of the materials used (ie: cheapest ballscrews available sourced from Chinese ebayers) with the goal of decentralizing means of production.

Forum Posts

Progress

Software-side, it looks like EMC or any RepRap software will work -- firmware and host software -- see CAM Toolchains. It looks like all of them support the Prusa, and the WatBot uses exactly the same 4-motor arrangement -- software drives XYZ plus spindle/extruder, and a slaved axis is hard-wired in parallel to one of the main axis.

BoM:

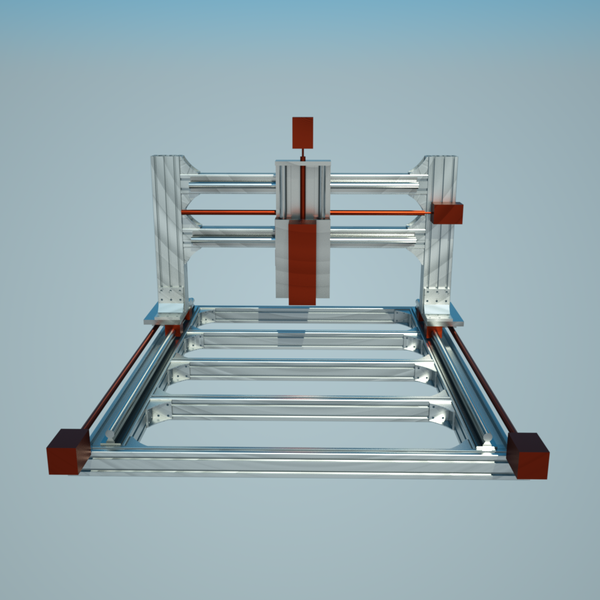

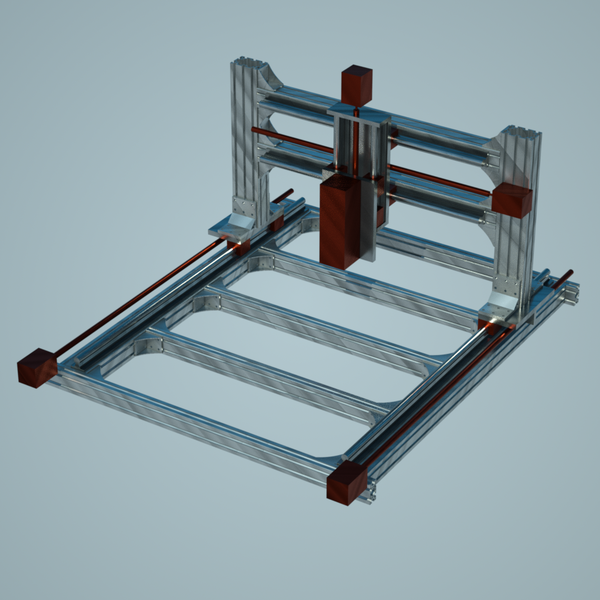

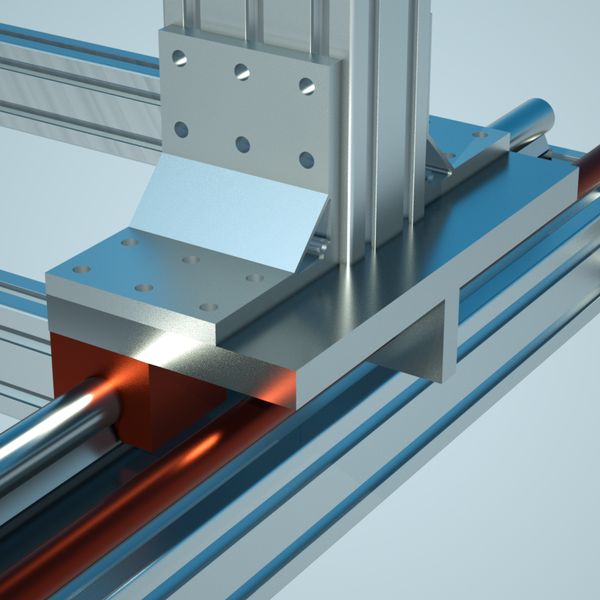

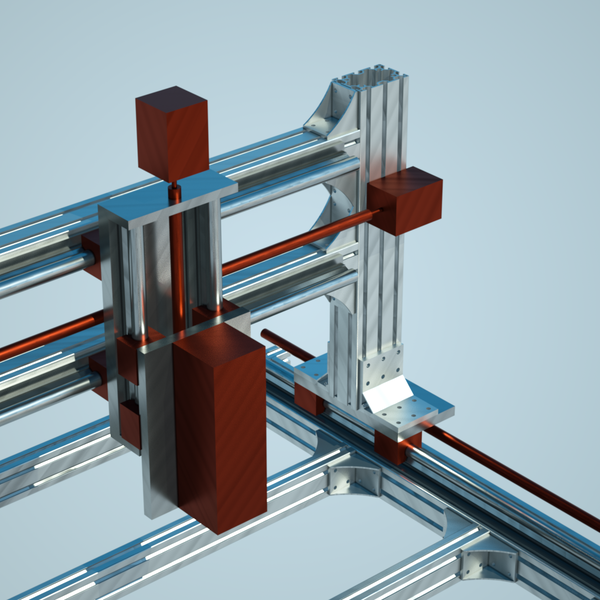

3060, 6060 and 6090 misumi aluminum extrusions+brackets+screws/nuts shown in renders below

Chinese 2.2kw spindle

Hitachi 2.2kw VFD

x4 425oz-in Keling NEMA23

12.5A 48V Keling PSU

Gecko G540

x2 1100mm, x1 750mm, x1 350mm linearmotion2008 ballscrews/nuts + supported rail/bearing block/mount/couplings kit