Cubex to RepRap Conversion

Contents

Introduction

The Cubex Duo and Cubex Trio are printers by 3D systems released sometime around 2012, 2013, with a hefty price tag and a proprietary system they created a lot of disappointment to customers. The end result being an Amazon review page where 83% of the reviewers gave the product 1 star. Check that out here: http://www.amazon.com/The-CubeX%C2%99-Duo-3D-Printer/dp/B00D45ZNKA The point of this page is to show how the printer can be converted into an open source RepRap machine by stripping everything out of it except for the stepper motors, endstops, smoothrods and frame itself. The electronics, LCD, power supply etc are replaced to produce a printer with a 300x300mm heated bed, 1, 2 or 3 hot-ends, a 24V power supply for the heated bed and electronics and stepper motors and a full graphic LCD controller with SD card support.

This page will have links to all the files, parts and firmware configuration and software necessary to run these printers as RepRap machines rather than 3Dsystems machines.

Strip down

The first part of working with these machines essentially involves removing everything proprietary about them, that includes the electronics, the electronics mounted on the X-carriage, the filament spool cartridge readers in the bottom and for me I also removed the hot-ends, I've seen people that use the existing hot-ends but I wanted to be able to print high-temp materials and didn't want to deal with the fuss of a machine that is basically a RepRap with some unknown hot-end produced by 3Dsystems.

The parts that I kept in place are the stepper motors, the endstops(at least the X and Y) and mechanical setup of the smooth rods, the frame and the outer casing.

There are some things you should know about the existing machines in order to complete this build. A lot of people had trouble finding information on the stepper motors, I was able to find a data sheet on all of the steppers except for the Z-axis stepper which is a Nema 23.

The stepper motors on all axes except for Z and extruders are M42STH38-1684S from Motion Control Products. The datasheet for the stepper can be found here: http://www.motioncontrolproducts.com/pdfs/nema17-stepper-motor-42mm.pdf

In case they take down the datasheet I've also uploaded the datasheet to the RepRap wiki, get it here: http://reprap.org/mediawiki/images/6/68/MotionControlPlus-Nema17-stepper-motor-42mm-datasheet.pdf

Once you've removed all of the components then you can proceed to start the actual build. For this you'll need some parts some of which are printed and some of which are bought.

Parts

Printed parts(http://www.thingiverse.com/thing:1239945):

- Brackets to hold the e3d V6 hot-ends

- Case for the 24V PSU

- Case for the Rumba electronics

- LCD case/holder

- Filament spool holders

- Z-axis endstop adjuster

- Spacers/plates for heated bed

Electronics:

- 1xRumba board

- 6xA4988 Pololu stepper driver board

- 5x1m stepper extension wires

- 1xRepRapDiscount Full Graphic Smart Controller

- 1xMicroswitch

Hot Ends

The hot-ends the Cubex Duo mods have are e3d V6s, these hot-ends are installed with ATC Semitec 104GT-2 thermistors, which can be purchased here: http://e3d-online.com/100k-Ohm-NTC-Thermistor-Semitec?search=semitec and the Reprap wiki page for them is here: reprap.org/wiki/Thermistor#ATC_Semitec_104GT-2. Sometimes somebody rips out a thermistor and its a sad day, good to have backups, just in case. They are mounted in the extruderw from the original Cubex build. The bracket for them is here and its recommended to print replacements in ABS or Colorfabb CF20.

These thermistors can take up to 295C, the firmware currently has a shut off if the hot-ends go above 290 degrees. This high temperature of the hot-end means its possible to print more exotic matierals such as Tritan from Taulman. The hot-ends have a teflon tube insert going down into the cold-zone but a 24V axial fan maintains a the cool termpature on the heatsink to prevent heat-creep which causes jams. The firmware is currently set to turn on both hot-end fans when either hot-end gets above 70C.

These hot-ends are also capable of high-speeds because they can put out a lot more volume than most hot-ends. Speeds up to 100mm/s are possible extrusion wise, might not be so good for the frame though :).

Firmware

The firmware for the Rumba board is located here: http://reprap.org/wiki/File:Firmware-Cubex-Duo-RepRap-Remake.zip

Slicers

I found that Cura wasn't capable of doing some of the more useful dual extruder functions such as choosing which extruder to print an object or two different objects with two different extruders, there was just functions like print support or in-fill with second extruder. Two programs that can handle dual extrusion are MatterControl/MatterSlice and Simplify 3D. MatterControl/Matterslice is open-source, free and pretty powerful but its not very intuitive at first. Simplify3D is great in almost all respects but costs $150. Slicer profiles located here: http://reprap.org/mediawiki/images/4/4d/CubexSlicingProfiles.zip

Cura

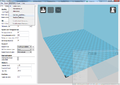

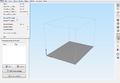

The setup for Cura is fairly easy, unfortunately you can't just import a machine profile so here is a gallery of the setup for the Cubex Duo with Cura. The bed size numbers are coded in the firmware so the machine won't travel beyond those values. The page are the recommended settings for 100 micron layer height. Those settings can be imported by going to File>Open Profile and then choosing the provided Cura PLA profile.

Matter Control

MatterControl can be downloaded for free at http://www.mattercontrol.com/#jumpMatterControlDownloads, there is also a RepRap Wiki page aobut it here: http://reprap.org/wiki/MatterControl

Simplify3D

Importing the machine profile in Simplify3D is pretty straightforward, simply go to File>Import FFF profile and use the provided FFF file.

Profiles for Simplify3D and MatterControl will be up shortly.