Filament Jamming Detection/ru

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

The intent of this document is to show one way of detect filament jamming/stopping using various

methods or some variations. One priority of the method is keep the costs as low as possible and

with less change in procediments and firmware as possible.

The detection method uses information of the filament itself and do not uses any of extruder

moving parts to take its actions and can detect either end of filament, filament jamming inside

nozzle, extruder slipping, knot in the spool and more.

The basic detection system reads filament motion using a little friction with the filament and

using this to drive a encoder wheel. If for any reason the filament stop moving the encoder will

stop turn and the firmware can detect the problem and take some action.

As the intent is to keep all changes at minimum to the actual hardware and software, the detector

is designed to be modular and independent - although it is still possible to integrate with the

extruder mechanism for space optimization.

I am separating the mechanism in three parts: mechanical detection of movement, sensor readings

of the data and firmware interpretation of the readings.

Contents

Mechanical detection of moving

Mechanical detection uses friction with the filament to detect its movement. This friction must

be as low as possible so as to require minimal torque from the extrusion mechanism and prevent

changing any other characteristics of the actual build of the printer.

The core function is based on a friction wheel using teeth or some plastic/rubber material which

will be forced to move with the filament. This movement is transferred to an encoder wheel with

or without a gear system and then read using either an optical or mechanical endstop. Also, any

system which can read movement from an encoder wheel can be used.

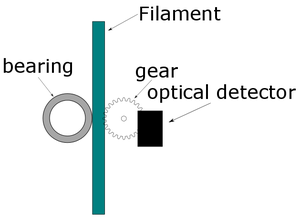

In above example I used a gear touching the filament in same way many extruders work and using a

bearing to keep the correct pressure and then read the gear movement using an optical endstop

which triggers with each gear teeth passing through it.

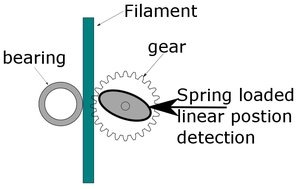

There are many other possible approaches such as but not limited to the use of a rubber piece or

another similar material to move the wheel along with the filament and/or use gears to translate

the wheel move to an encoder or yet use other methods as mechanical endstop to trigger the

encoder movement. (see Image 3)

Sensing the Movement

The second part is to use the mechanical data to get some electrical signal to the firmware. This

can be achieved either using an optical detector, mechanical detector or electric effect sensor,

such as hall effect or electrical resistance (potentiometer/trimpot) attached to the wheel, which

trigger an electrical signal to the control board.

See below various ways of detect:

- Use an optical endstop to read the gears or the encoder wheel;

- Use an mechanical endstop to read the gears or de encoder wheel;

- Use hall effect sensor to detect the movement of the gear or wheel by sensing electrical

current change in detriment of the wheel movement or position;

- Use electrical voltage variation to detect the actual position or movement of the wheel (as

much like some servo motors work)

- Use position variant readers to detect physical linear position (see image 2)

After the movement have been detect this signal must be send to the control board or its movement

control section/chip/controller. This board or section will be called as “board” in the rest of

this document to keep it simple to read.

Firmware interpretation of Data

After the signal arrives the control board the firmware must manipulate this data despite of the

format of the signal, which can be either digital or analogic.

In firmware there are two possible ways to track the position. The easy way is simple compare the

movement of the extruder axis with the feedback and check if they are reasonably compatible but

not necessary identical. Other way is count each step of the input format and keep precise

feedback control. At this point all above problems can be detected and actions be taken. Despite of different

nature of all above mention problems not necessary all them are distinguishable and the firmware

must consider this fact.

The first and immediate problem that can be detected is the filament stop, which can be either

the end of filament, the extruder jamming, the extruder slipping or knot in the spool. This cases

the print can be paused and the user can fix the problem avoiding the loss of what has been

printed so far. A second problem is the extruder motor skipping steps. In that case, the precise read of the

position can be used to compensate this and temporarily fix the problem and avoid the lose of

what was already print. Note that a parcial jamming will grind the filament and cause the same effect of the extruder

motor skipping steps, then it causes the same effect and is detectable.

Each firmware “has” to be studied to avail the possibility of this implementation as long as its

requirements and necessary considerations.

Repetier Firmware already has most of this implemented as: FTS - Filament Tracking System and

more info can be found at:

Gallery of Images

Files and Resources

My version is using rubber wheels from an old desktop ink jet printer, some small bearings,

printed parts, M3 screws and nuts.

Work to be done

Implement a test version on some firmware

This document

This document is double licensed and is also licensed under Creative Commons Attribution for

RafaelEstevam and was first written in September of 2016 by RafaelEstevam. The original

version can be found here: