PhilosophyPage

This is a reprint of Adrian Bowyer's Keynote Address on the RepRap project given to the Seventh National Conference on Rapid Design, Prototyping & Manufacturing, at the Centre for Rapid Design and Manufacture in High Wycombe in June 2006.

Contents

- 1 The Self-replicating Rapid Prototyper ─ Manufacturing for the Masses

The Self-replicating Rapid Prototyper ─ Manufacturing for the Masses

Adrian Bowyer

Centre for Biomimetic and Natural Technology, Department of Mechanical Engineering, University of Bath, UK.

Abstract

This paper introduces the RepRap project ─ a project to build a replicating rapid prototyper. This machine, if successful, will be an instance of a von Neumann Universal Constructor, which is a general-purpose manufacturing device that is also capable of reproducing itself, like a biological cell. The way the RepRap machine will work is outlined, and the parts of the machine that exist at the time of writing are shown and described. Some predictions are also given on the possible impact of the RepRap machine on the human economy in the event of the project's success.

1. Introduction

The two most important phenomena in biology are self-replication and self-assembly, and many organisms ─ like bacteria, daffodils, and you and me ─ do both. Of the two, self-replication is the more important because it is by self-replication that Darwin's law of evolution works [3]. Indeed, the simplest organisms ─ viruses ─ just organize their own replication; they need to hijack one of the many self-replicating self-assemblers (you and me again) to do the putting-together bit.

Symbiosis is a lesser, but still important, biological phenomenon. Perhaps the most famous instance of symbiosis is the one between the insects and the flowering plants, which evolved in the Tithonian age of the late Jurassic about 140 mya. The [ sessile] plants bribe insects with nectar to convey their pollen to distant mates; the insects get a meal, and the plants get to self-replicate. Another example is human agriculture which, though sometimes viewed as transformed hunting and gathering, is perhaps better viewed as a collection of symbioses between us and our food species. The most evolutionarily successful of all birds has been the [ domestic chicken], a position it holds solely because of its symbiotic relationship with the most powerful organism that has ever lived.

What has all this to do with engineering?

In the 1950s John von Neumann invented a theoretical engine that he called a universal constructor [7]. A universal constructor is a computer linked to a manufacturing robot, both having sufficient sophistication in hardware and software to be able to make a copy of themselves. von Neumann was interested in the mathematical and computational aspects of such a machine, but he gave it the name he did because he realised that, ultimately, it could manufacture anything that is physically possible. Further, the link between such a machine and a biological cell is obvious; cells are universal constructors.

There have been a number of successful attempts to make universal constructors, both in simulation (see, for example, Pesavento [9]) and in hardware (see, for example, Zykov et al. [12]). These experiments are of considerable interest, but the physical universal constructors that have been built are limited by requiring a supply of intricate building blocks to be available in their world before they can self-replicate. This is not cheating; after all, you need a supply of amino acids and polysaccharides to be available in your world before you can self-replicate.

Much of the difficulty in making a universal constructor comes from the need for it to be able to self-assemble as well as to self-replicate. But suppose, biomimetically, that we were to follow the example of viruses and to make a universal constructor that could just self-replicate, and that left the assembly problem to another replicator? Suppose, to be specific, that we were to make a universal constructor that could manufacture its component parts, but that left their assembly to people?

If the universal constructor gave those people something useful in return, then the result would be a symbiosis between the two, such as that between the flowers and the insects. In particular, if this universal constructor could make other industrial goods, those would constitute a reward for helping it to reproduce. The universal constructor would be the flowers, the goods would be the nectar, and the people would take the role of the insects.

This paper is about the making of such a universal constructor.

2. Rapid prototyping

There is a sense in which a well-equipped manufacturing workshop is (just about) a universal constructor ─ it could make many of the machine tools that are in it. The trouble is that the better-equipped the workshop is the easier it becomes to make any one item, but the greater the number and diversity of the items that need to be made. It is certainly the case that human engineering considered as a whole is a universal constructor; it self-propagates with no external input.

But, while logically the idea of a closed self-reproducing system is as indivisible as the ideas of uniqueness or of pregnancy (one cannot be a little bit of either), considered instead from the point of view of elegance, a biological cell is more closed than human engineering, which ─ in turn ─ is more closed than the workshop. What is needed for an elegant and practical universal constructor is a single machine.

In 1974 the prescient David Jones, writing under the pen-name Daedalus in the New Scientist, described how one might selectively photopolymerize a vat of liquid monomer using a laser to manufacture a three-dimensional object under the direct control of a computer [5]. His article was intended as a joke.

Wyn Kelly Swainson's patent for the same idea was subsequently published in 1977, though he had filed it in 1971 [11]. This was the beginning of practical additive manufacture of three-dimensional parts under computer control ─ rapid prototyping.

Rapid prototyping has many advantages, but from the requirements of a universal constructor one stands out: the fact that simple computer programs are all that are needed to drive it. The single biggest, and still not completely solved, problem of traditional subtractive manufacture is the automation of collision-free tool-path planning. No such planning is required for rapid prototyping.

Since Jones and Swainson many other techniques for rapid prototyping have been developed. Three of the most significant are selective laser sintering (SLS), filament deposition modelling (FDM), and the MIT powder/ink-jet-glue process [1].

A rapid prototyping machine that can make most of its own component parts will clearly be easier to design if one avoids things like high-powered lasers; having the machine make a laser from scratch would be difficult. More subtly, ink-jet print heads (though cheap) are intrinsically hard to make as they involve microfabrication, and so a machine based on them would be unlikely (in the medium term) to be able to liberate itself from that one bought-in part.

Of the predominant technologies, that leaves FDM. For FDM one just needs a nozzle about 0.5mm in diameter, a heater, and a forced supply of polymer. When I started the project that this paper describes I decided to use FDM for those reasons. The project is to build an FDM replicating rapid prototyper, or RepRap for short.

3. Developing the RepRap machine

There are essentially three parts to any rapid prototyping machine:

- One or more material-deposition or write heads,

- A Cartesian robot, and

- The software to drive them.

I decided early on that I was not going to labour extravagantly to have the machine make simple cheap and ubiquitous parts like screws and electric motors. As you will see in the next section, these should become manufacturable by the machine through a natural process in the course of time, but for the first machine it is acceptable for them to be bought in (by analogy with the amino acids and polysaccharides).

I also decided that the machine was going to have to be able to work with both an electrical insulator (a polymer, for preference) and a conductor so that it could build its own circuitry automatically. It would not make the chips ─ these parts (also ubiquitous and cheap) would be plugged in subsequent to manufacture. The electric-circuit manufacturing technique is described in another paper in these proceedings [10], and so that will not be repeated here.

3.1 The write head

This leaves the write-head, the robot, and the software. Figure 1 shows the current development of the RepRap write head.

Figure 1. The RepRap write head. The large graph-paper squares are 10mm.

A 60 RPM geared electric motor (A) drives a screw chamber (B) in which a threaded rod is forced against a rod of polymer. As the thread turns, the polymer is pushed downwards to a heated nozzle (C) and is extruded out of the bottom. The control electronics are shown at (D).

Figure 2. The working principle of the write-head drive.

Figure 2 shows the original sketch by Vik Olliver1 posted on the RepRap blog for the device. Olliver's idea is beautifully simple: apart from the motor and the polymer itself it has only one moving part, and that is an off-the-shelf length of screw thread. And, of course, almost the entire device is made by FDM rapid prototyping.

The selection of a polymer for RepRap to use involved, as always, a compromise: low cost, low melting point, and high strength were all factors. The melting point, in particular, was important as the hotter that parts get the more power they need and the more difficult they become to insulate. It was decided to use polycaprolactone; this is as tough as nylon at room temperature, but starts to melt around 60oC. The nozzle consists of a length of PTFE that insulates the final brass section at the bottom from the rest of the device. This is heated with a length of nichrome wire. The device runs at around 120oC.

The controller consists of a PIC 16F628 switching an H-bridge using pulse-width modulation (PWM) to set the speed and direction of the motor, and switching a power darlington to control the heater element. Temperature feedback to the PIC is from a thermistor attached to the nozzle.

Other decisions were to give each device in the whole RepRap machine (such as the write heads) its own PIC, to power the entire machine from a single 12v bus (implying 5v regulators to go with the PICs), and to have the PICs and an external driving PC networked together. Currently the PICs and PC are arranged on a token ring using their serial interfaces, but we may change this to an I2C interface in the future. The great benefit of these arrangements is that only three wires run round the machine: power, ground, and signal. It also makes the design highly modular, easily allowing the addition of new write heads, for example, each with its own controller.

The polycaprolactone write head is complete, tested, and working; a number of them have already been built by RepRap researchers round the world.

FDM rapid prototyping also needs to use a support material for overhangs, of course. We intend to use icing sugar paste for this. It is easily obtainable, entirely non-toxic, simple to dilute to a wide range of consistencies, holds its form well (think cake decoration), sets very hard, and can be worked at room temperature. It is also water-soluble, which makes the removal of the support from a finished part very easy. The RepRap team are in the process of designing a rapid-prototyped motorised syringe for depositing it. This would form a second write head.

3.2 The Cartesian robot

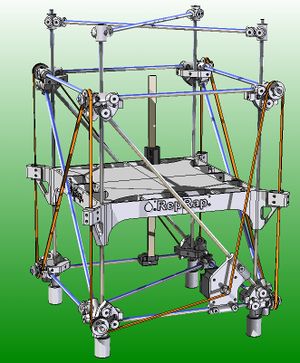

The Cartesian robot is, at the time of writing, being constructed by Ed Sells, another member of the team. Figure 3 shows an image of it from the CAD system.

The robot consists of a framework of ground steel rods held together by rapid-prototyped corner pieces. These also hold the RP drive wheels for the timing belt (brown) that moves the horizontal platform up and down. This platform is made in four identical sections to allow the machine to make them itself within its own working volume. The platform will be the Z axis of the machine; the X and Y axes will be made using the rectangle of rods at the top. The axes will be driven by stepper motors. Again, each stepper will have its own PIC and two H-bridge drivers. Experiments have shown that the speed of communications is easily fast enough to synchronise a three-dimensional DDA algorithm to drive all the axes at once in a straight line. The steppers are 400-steps-per-revolution devices, giving a linear [ resolution of 0.1mm]. They generate a respectable torque at 12v, but, of course, one of the great assets of additive manufacturing is that it is virtually zero-force. It is intended to park a number of write heads for different materials along one top edge, with the machine going and picking up each head when it is needed.

All the hardware of RepRap has been designed either to be rapid prototyped or to be readily available and cheap. Indeed the majority of the parts that it does not make for itself can be got from a good ironmonger.

3.3 The software

The software for the machine falls into two categories. The first is that for slicing and cross-hatch-filling STL files, and for sending commands to the machine itself; this will run on the PC and is being written entirely in Java to give platform independence. The second is the low-level code that is programmed into the PICs; this is being written in C, which is portable, and is also fast and efficient both for development and when compiled into the PICs.

There are also a lot of programs needed for design and development. The RepRap researchers are using open-source software for this: Art of Illusion for mechanical design, Kicad for electronics, SDCC for a PIC C compiler and Eclipse as a Java environment.

4. The biomimetics of RepRap

In this and the following sections, I will give some indication of the sorts of things that may happen if RepRap becomes widely used. But I should start by emphasising that this is unlikely for one very simple statistical reason: most research projects do not lead to world-changing products, and it would be hubris to imagine that RepRap will be any different. However, in the improbable event that RepRap does take off, then the consequences could be profound. Let us start by considering evolution.

RepRap will be a mechatronic device using entirely conventional (indeed simple) engineering. But it is really a piece of biology. This is because it can self-replicate with the symbiotic assistance of a person. Anything that can copy itself immediately and inescapably becomes subject to Darwinian selection, but RepRap has one important difference from natural organisms: in nature, mutations are random, and only a tiny fraction are improvements; but with RepRap, every mutation is a product of the analytical thought of its users. This means that the rate of improvement should be very rapid, at least at the start; it is more analogous to selective breeding ─ the process we used to make cows from aurochs and wheat from wild grass. Evolution can be relied on to make very good designs emerge quickly. It will also gradually eliminate items from the list of parts that need to be externally supplied. Note also that any old not-so-good RepRap machine can still make a new machine to the latest and best design.

Though initially RepRap is using polycaprolactone as its main working polymer, it is intended to switch as soon as practicable to polylactic acid. This thermoplastic has a rather higher melting point than polycaprolactone, but has the great advantage that it can be made by fermentation from starch. This means that it should be possible to use biomass (maize, for example, or potatoes) as a source material, with the RepRap machine making the fermenter, of course. Thus not only would the machine be self-replicating, so would its material supply. It would also lock up atmospheric carbon in durable plastic goods, though polylactic acid is ultimately biodegradable.

5. The economics of RepRap

Karl Marx and Frederick Engels wrote in the Communist Manifesto [6] that, "By proletariat is meant the class of modern wage labourers who, having no means of production of their own, are reduced to selling their labour power in order to live." This diagnosis is essentially correct; it is a commonplace that people with resources can quite easily use them to acquire more, but people without have to try exceptionally hard to get anywhere, and most of them never do. Marxism then goes on to say that the way to fix this problem is for the proletariat to seize the means of production by revolution, which is a good candidate for the all-time worst-idea in human history. Whenever it is applied the main things produced are corpses, and in the last hundred years the body count from this idea's application was even worse than that from Nazism. So the Marxist prescription, unlike its diagnosis, is plain wrong. Its prognosis also turns out to be wrong ─ it predicted that the revolution would happen first in the most industrially-advanced nation (Britain at the time), whereas in practice Marxist revolutions tend to happen in countries making the transformation from an agrarian economy to an industrial one.

So Marx's marks were 33% - not very good. But keep his correct diagnosis in mind...

A RepRap machine will have almost no value, though it has the potential to create wealth like no other technology we have. This seems a surprising and paradoxical conjunction, but it is an inevitable consequence of self-replication. First, let us examine the wealth.

All current engineering production generates goods in an [ arithmetic progression]. Sometimes this is very fast − suppose an injection moulding machine makes plastic combs at the rate of 10,000 an hour. Suppose further that a RepRap machine can make one copy of itself a day, and also just one comb. After merely 18 days, the RepRap machines will be making more combs than the injection moulder, assuming people give them house-room. Self-copying rapid-prototyping machines can multiply exponentially and so can the goods they produce. No technology other than self-copying can do this, and exponential production growth is the fastest that is mathematically possible (which is why all living organisms use it). At one machine per day, after one month there would be a machine for every man, woman, and child on the planet. Of course, any exponential growth must run up against resource limits, and this would happen well before the month was out...

The inherently exponential nature of self-replication allows very fast growth in material wealth. But, as I wrote above, it makes the RepRap machine itself almost worthless. The reason is simple: if I sell you one for €1,000, you can use it to make copies and sell them for €900; people who buy them can sell for €800, and so on right down to the cost of the raw materials. (The target price for raw materials for the first version of RepRap is €300, incidentally.) Thus, though it is in everyone's interest to have a universal constructor, it is in no company's interest to make and to sell one, because one is all they would sell. Ultimately, RepRap will have the same effect on the cost of the goods it produces; it makes a significant dent in the whole idea of added value, and hence in the very principles of money itself.

It is because of this that the RepRap project is being run exclusively on government grants and charitable contributions from enthusiasts on the web. Consequently I have decided to give the entire machine and all its design files away free under the GNU General Public Licence, like Linux. This ensures that no one (especially not me) has control over, and restrictions on, the technology. It is a happy coincidence that this - the morally correct thing to do - is also the only stable strategy.

Widespread adoption of RepRap would also reduce transportation. Most consumer items undergo many separate journeys between the production of their raw materials and their final arrival at a person's home. But if people were to begin making things by downloading designs from the web to their own rapid prototyping machine, then just raw material would have to be transported (and not even that, if the source biomass was grown proximally). We are also investigating the possibility that a RepRap machine could make its own recycler, thus reducing the need to transport waste as well.

Self replication is not new to human economics: our oldest technology − agriculture − is entirely founded on self-copying machines: the animals, plants, and micro-organisms that are its products. Exactly because of the economic arguments above, agriculture gets most effectively done by the poorest people on Earth; when material added-value approaches zero, labour costs become the only significant item. It is only because of trade restrictions by the richest countries that the entire world's food is not grown by the poorest. Those countries (like poor individuals, as Marx pointed out) have great difficulty getting involved in the world's manufacturing economy because of the high capital cost of setting up conventional manufacturing. But if any individual or small collective can have a RepRap machine for the same cost as a dishwasher, this might change, especially if they can grow the source of the working polymer as a crop.

So the self-copying and evolving RepRap machine may allow the revolutionary ownership, by the proletariat, of the means of production. But it will do so without all that messy and dangerous revolution stuff, and even without all that messy and dangerous industrial stuff. I have decided to call this economics Darwinian Marxism...

6. Two possible RepRap-produced goods

At the start, RepRap will almost certainly be used to make simple goods, like combs, coat hooks and cat flaps. With added-in components the first version will also be able to make things like digital cameras and MP3 players. But as evolution expands the capacity of the machine more advanced products will become possible. The RepRap wiki (accessible from the main project site at http://reprap.org) has a page devoted to useful products that a RepRap machine might make, contributed by the public at large. These range from water purifiers to solar panels. Here I would like briefly to give two further examples of my own to illustrate how revolutionary RepRap technology might become.

6.1 The Open Phone

There are already projects to develop open-source cell-phones; Tux Phone is a good example [8].

In a recent paper, Damsgaard et al. [3] bemoaned the fact that free wireless networks are subject to the tragedy of the commons − more and more people use the free resources until traffic gets so clogged that the network becomes useless.

However, there is a stable game-theoretic solution to this problem that they did not describe (I doubt that I am the first to realise this).

Consider a wireless network in which each node has the following characteristics:

- It attenuates its power in proportion to the proximity of its other interlocutor (as cell-phones do at the moment);

- It acts as a hub and a router for its neighbours in its own right; and

- It experimentally interrogates any new node to ensure that it conforms to characteristics 1 and 2. If the new node does not, its signals are not relayed.

A network of nodes with these characteristics can grow virtually without limit, as adding new nodes also adds bandwidth. And selfish attempts to insert nodes that do not act as repeaters are automatically rendered pointless.

The result is a commons the acreage of which grows with every sheep that comes to graze.

Any network could be set up this way, but the obvious thing to do it with is wi-fi internet, with interfaces wherever possible to the existing wired internet. This could be used both for computers, or just for a mobile phone consisting of a microcontroller, a wi-fi card, and some voice-over-internet software.

Clearly such a phone could be made by individuals equipped with RepRap machines from an open-source design distributed on the web, and its widespread adoption would mean a significant reduction in business for ─ if not the end of ─ conventional phone companies.

6.2 Open Pharma

Some new patented drugs cost many thousands of pounds per patient per year, and the cost of automated chemical synthesisers is dropping all the time. When patients (or their insurance companies) find it cheaper to get a desktop robot drug-maker than a year's supply of drugs, their path becomes obvious. Recall that patent law allows individuals to make patented items without royalty for their own personal use.

But automated synthesisers are inherently versatile − they can make many compounds, not just one. Human nature being what it is, people will start to experiment, and will exchange pharmacological ideas with each other via patient groups and the like. (Human nature being what it is, some of the experimentalists will also inadvertently poison themselves, of course.)

Obviously, the personal possession of an evolved RepRap machine would allow an individual to make such a robot, again from open designs distributed on the web.

This potentially has the ability to make drug development and synthesis a collaborative exercise, like open-source software, and to cut large pharmacological companies out of the process altogether. It would disruptively liberalise the chemical treatment of disease.

7. Conclusions

The RepRap machine is almost fully designed, and half-built. As work on it progresses, all the researchers are releasing all the results freely on the web, so anyone can join in. The target capital cost of the resources needed to make a RepRap machine is €300.

A successful RepRap machine in symbiosis with people would evolve and improve by artificial selection, like agricultural and domestic organisms.

If RepRap is widely adopted (as with all research projects, a low probability), then it may have a profound impact on human wealth and economics, completely eliminating some industries and leading to the genesis of new ones. More importantly, it may preferentially allow the world's poorest people to step onto the rungs of the manufacturing ladder.

8. Acknowledgments

The RepRap project has been supported by grants from the Nuffield Foundation, the EPSRC, and the University of Bath Innovative Manufacturing Research Centre. I would like to thank them all for their generosity. In addition, individuals have made charitable donations to the project via the web. I would like to thank them too; those who did not wish to remain anonymous are listed on the project's website.

I would also like to thank my research student, Ed Sells for his excellent work on the project. In addition to Ed and me there are five other RepRap researchers ─ two from New Zealand: Vik Olliver and Simon McAuliffe, and three from the USA: Forrest Higgs, Brett Bellmore, and Zach Smith1. These people are working tirelessly on the project for no reward, simply because they are interested in it and believe in it. I would like to end by thanking them for their selflessness and dedication.

References

- 1.Chua, C.K. et al.: Rapid Prototyping: Principles and Applications, World Scientific Publishing, ISBN: 9812381171, 2003.

- 2.Damsgaard, D., Parikh, M.A., and Rao, B.: Wireless commons perils in the common good, Communications of the Association for Computing Machinery, Volume 49 , Issue 2, February 2006.

- 3.Darwin, C.: On The Origin of Species by Means of Natural Selection, or The Preservation of Favoured Races in the Struggle for Life, pub. John Murray, London, November 24, 1859.

- 4.The Food and Agriculture Organization of the United Nations at http://www.fao.org/documents/show_cdr.asp?url_file=/docrep/004/ad452e/ad452e30.htm

- 5.Jones, D. ("Daedalus"): Ariadne Column - last item, New Scientist, 3 October 1974.

- 6.Marx, K. and Engels, F.: Manifesto of the Communist Party, London, 1848.

- 7.von Neumann, J.: The Theory of Self-Reproducing Automata, ed. A. W. Burks, University of Illinois Press, 1966.

- 8.Patel, S. The Tux Phone project at http://www.surjpatel.com/

- 9.Pesavento, U.: An Implementation of von Neumann's Self-Reproducing Machine, Artificial Life Journal, 2, 337--354, 1995.

- 10.Sells, E., and Bowyer, A.: Directly incorporating electronics into rapid prototypes, this volume.

- 11.Swainson, W.K.: Method, medium and apparatus for producing three-dimensional figure product, US Patent 4041476, 1977.

- 12.Zykov V., Mytilinaios E., Adams B., Lipson H.: Self-reproducing machines, Nature Vol. 435 No. 7038, pp. 163-164, 2005.

-- Main.AdrianBowyer - 21 Jul 2006