RUG/Pennsylvania/State College/Solidworks OHM

Back to State College RepRap Main

This page has been flagged as containing duplicate material. An editor has suggested merging this page or section into Open Hybrid Mendel . (Discuss)

Contents

Overview

The Open Hybrid Mendel (or OHM) is a project of the State College Reprap Users Group. It is a Mendel design, which uses both standard Sells Mendel parts, a Prusa Z drive, various redesigns from the community at large, and a number of small design improvements developed in our PSU Reprap class. It is so named due to this hybridization of designs, and obtains the 'Open' designation from the OpenX and OpenY axes it uses. The prototype for the OHM design was Etherdais_Unit_One. On this page there are the sub-assemblies and full assembly of the most up to date OHM design done on SolidWorks. Under each sub-assembly and the final assembly there are screen pictures and zip-files for all the parts. So be prepared because you now have the power to create your very own OHM!

Files

This is a table of all of the packed Solidworks assemblies and 3D PDFs for each subassemblies. A 3D PDF is a [universal 3D file] that will allow any user to view a 3D model without a specialized 3D modeling software. To view these files, you may need to save the PDF to your computer to open it rather than view it in your browser. The full assembly is too large to effectively view in a 3D PDF, so this file is not available at this time.

| Assembly | Solidworks Zip File | 3D PDF |

| Full OHM | Media:Ohm solidworks assembly.zip | n/a |

| Frame | Media:Frame assembly.zip | Media:Frame_Assem_pdf.PDF |

| Z Axis | Media:Z-axis.zip | Media:Z-axis_pdf.PDF |

| X Axis | Media:X-axis.zip | Media:Xaxis_pdf.PDF |

| Bed/Carriage | Media:Bed_assembly.zip | Media:Bed_carriage_assem_pdf.PDF |

| Extruder | Media:Extruder.zip | Media:Extruder_Assembly_pdf.PDF |

Full Assembly

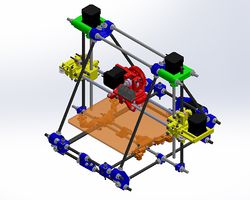

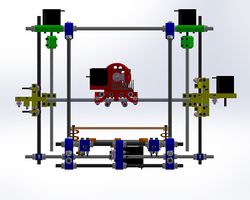

This is the full assembly in SolidWorks. Each subassembly is represented by a different color of printed pieces.

- Open Hybrid Mendel Full Assembly

Above are SolidWorks pictures of the full assembly. Below is the zip file containing all parts and hardware:

Media:OHM_Assembly.zip

Subassemblies

Though all parts work together to make a 3D model somewhat like a human body; we broke the assembly down to five sub-assemblies.

Frame

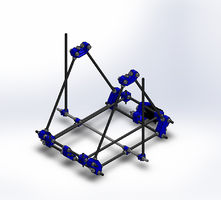

The OHM uses Camiel's thin shelled Vertex design, maintaining vertices similar to the Sells design, but using less filament. The frame has one motor that powers a belt to move the bed in the y-axis. It uses threaded rods to connect the vertices and is the same as the original Mendel design.

- Open Hybrid Mendel Frame

Above are SolidWorks pictures of the frame assembly. Below is the zip file for this assembly:

Media:Frame assembly.zip

Z Axis Assembly

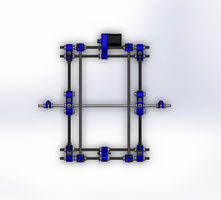

The OHM uses a Prusa double motor design for driving the Z axis, avoiding the large prints and continuous belt of the Sells Z-drive design. We still use Sells bar clamps to clamp the smooth rod to the Z-motor mounts, as they are compatible, and look sharp together.

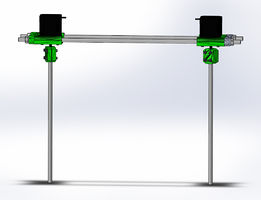

- Open Hybrid Mendel Z Axis

Above are SolidWorks pictures of the z-axis assembly. Below is the zip file for this assembly:

Media:Z-axis.zip

X-Z Axis Assembly

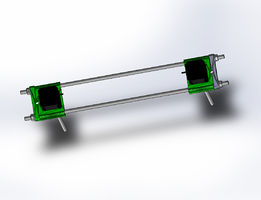

Currently, the OHM build uses something like a standard Sells X-Z assembly, as described here in Mendel_X-axis. An important change in the design of the assembly is to be noted. The x vert drive side plate 360 end is no longer being used for future RepRap parts. A modified version of the 360 end is being used. This piece is longer and doesn’t require a spacer piece. This allows for adjustment as well as a better belt configuration that reduces stress.

- Open Hybrid Mendel X-Z Axis

Above are SolidWorks two pictures of the x-z axis assembly. Below is the zip file for this assembly:

Media:X-axis.zip

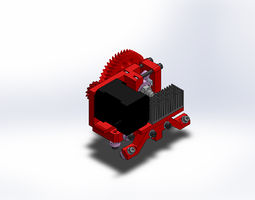

Y Bed Carriage

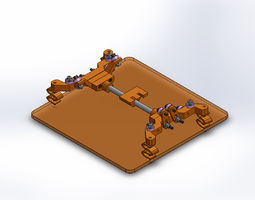

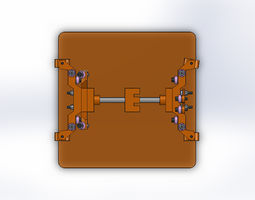

The OHM uses a modified OpenY, with an optoless belt harness, and a second 90/180 arm in place of the 90/270 arm. This demands two additional bearings, but we find the result is more stable, while retaining the benefits of the OpenY. A modified Sells y-motor bracket is used, which avoids printing an unused endstop holder from the original Sells design. The original Sells y-bar clamps seem well suited for mounting y-axis opto-endstops.

- Open Hybrid Mendel Y Bed Carriage

Above are SolidWorks pictures of the y bed carriage assembly. Below is the zip file for this assembly:

Media:Bed_assembly.zip

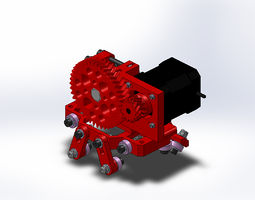

Extruder and Carriage

We are in the process of finding a design which is more compatable with the TechZone steel hot tips we've been using recently, though the current design is a hack of herringbone extruder gears, and GregFrost's hinged wades extruder.

- Open Hybrid Mendel Extruder and Carriage

Above are SolidWorks pictures of the extruder and carriage assembly. Below is the zip file for this assembly:

Media:Extruder.zip