RepRapPro Huxley Sanguinololu wiring

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Wiring | Commissioning | Printing | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

These instructions are open to editing by everyone and anyone. |

Contents

- 1 Alternative

- 2 Goal

- 3 Tools

- 4 Parts

- 5 Important: general rules for wiring up

- 6 Overview

- 7 Step 1: Mounting the Sanguinololu PCB

- 8 Step 2: Power

- 9 Step 3: Endstops

- 10 Step 4: Clipping wires to the frame

- 11 Step 5: Connecting all the wires to the Sanguinololu controller

- 12 Step 6: Double check

- 13 Step 7: Final tidy

- 14 Next step

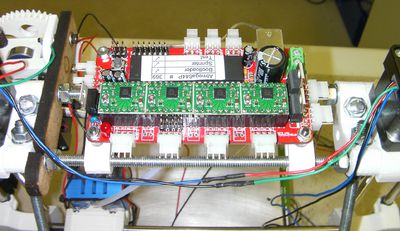

Alternative

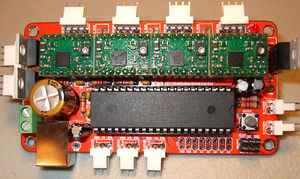

This page describes how to wire up a RepRapPro Huxley that is to be fitted with Sanguinololu Electronics that look like this:

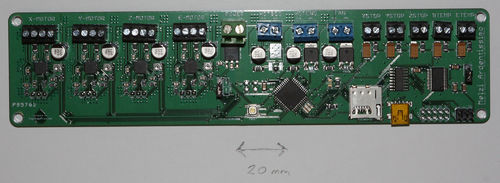

There is a parallel page that describes how to wire up a RepRapPro Huxley that is to be fitted with Melzi Electronics that look like this:

Follow this link for the alternative Melzi wiring page.

Goal

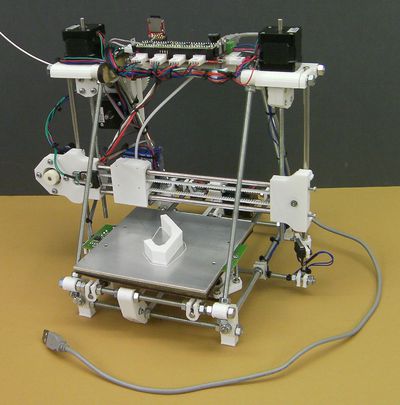

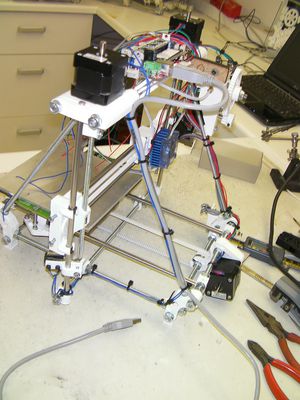

By the end of this stage your machine will look like this (except for the printed part on the bed...) and it will be ready to commission.

Tools

- Wire strippers

- Soldering iron

- Ratchet crimp tool (Rapid Online)

- Small screwdriver

- Multimeter

- Vice

Parts

You will also need the Sanguinololu PCB, wire (the leads for the motors are long and will be cut - use the spare lengths) and a reel of sticky tape.

Important: general rules for wiring up

You will do serious damage to your RepRap electronics if the power is connected backwards. Other damaging mistakes are to short out high-current devices like motors and heaters, and to connect high-voltage devices like stepper drivers to signal inputs like temperature sensors.

So - in the sections below where it tells you to check things - please check them thoroughly. It is worth taking the time...

The connections to the RepRapPro Huxley Sanguinololu controller are made using crimp connectors. These require no soldering. If you don't have a crimp tool, there's a video from Nophead here that shows how to manage without:

<videoflash type="youtube">KEm2PuHBt4Y</videoflash>

When wires leave a device (like a motor) or arrive at a connection (like the screw connectors on the controller) leave a small slack length (about 20mm long) for strain relief - don't have the wires taut.

There are two strategies for attaching wires to the frame:

- Run the wires along their routes and attach them with sticky tape. Then when everything is finished go round the machine removing the sticky tape and replacing it with cable ties.

- Use cable ties from the start, and forget the sticky tape.

The first option takes longer, but allows you easily to correct mistakes without wasting cable ties. The second is quicker, but you will find you have to cut the odd tie and throw it away to edit what you have done.

Neatness is everything. Organising and attaching the wires tidily to the machine will produce a reliable result. A kitten's ball of wool will not.

Finally, when making any changes to the wiring or any other electrical aspect of the machine, first disconnect both the power and the USB.

Overview

What you are going to do is:

- Fit the Sangiuinololu PCB to the top of the RepRapPro Huxley

- Run the wires from all the electrical devices in the machine up to that PCB

- Trim the end of the wires to the right lengths, fit connectors on them, and connect them to the PCB

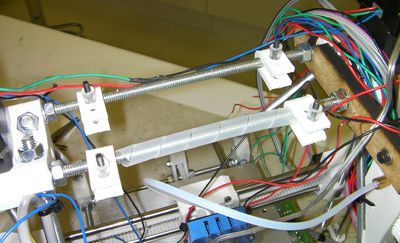

Step 1: Mounting the Sanguinololu PCB

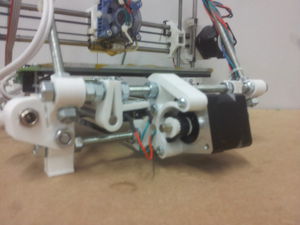

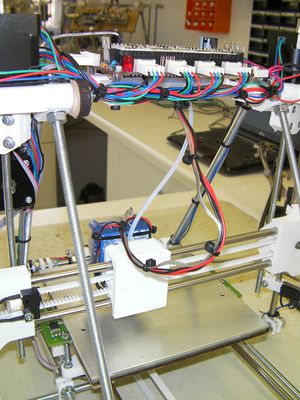

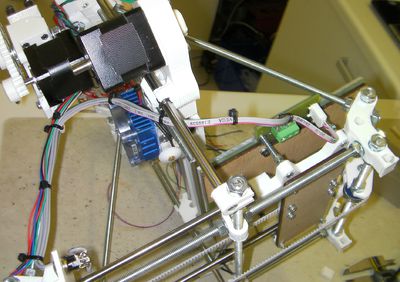

This view is looking from the back of the machine where the Y motor is.

Clip the four printed PCB mounts to the top of the frame. Offer up the PCB and look through its mounting holes to get the gap between them right.

Put the M3 screws through from underneath with washers between the heads and the printed parts. At the front of the machine the screws go through the holes nearest the M6 bar. At the back they go through the holes that are away from the M6 Bar.

Slip the 3mm PVC tubes over the screw threads - friction should hold the screws up, but if it doesn't use a little sticky tape.

Cut a length of coiled cable retainer and fit it between the back mounts as shown. This stops the PTFE filament tube to the extruder hot end rubbing on the threads.

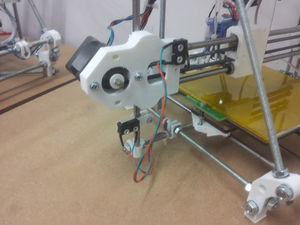

This view is looking from the front of the machine - the other way from the view above.

Put the PCB over the ends of the screws as shown with the four big connectors facing the front, put four washers on, and then four nuts.

When doing up the nuts, take great care that the M3 spanner that you use does not hit and damage any of the electronic components on the PCB. Don't do the nuts up too tight. They want to compress the PVC a little to give a firm fit, that is all.

Step 2: Power

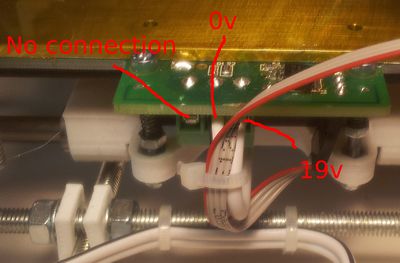

The power from the 19v power supply comes through the connector with positive in the centre and negative around the outside

You will need two power cables in the machine: one about 500 mm long for the controller board, and one about 400 mm long for the heated bed. Both connect to the socket above.

Strip the insulation from the ends of two power wire pairs. For the +19v ends strip about 5mm. For the 0v ends strip about 15mm.

Twist the +19v ends together and tin them. Put a length of heatshrink over both, then solder them to Pin 3 in the picture:

Run the heatshrink down over the pin and shrink it.

Twist the 0v ends together and push the result through Pin 1 , then across and through Pin 2. Keep it clear of Pin 3.

Solder these wires to both Pins 1 and 2. Trim off any excess.

Attach the power socket to the power connector clip then use the 25mm M3 screw to attach this to the back left bottom frame vertex as shown. You can see the Y motor in the picture to give the location. Use washers under both the head and nut of the screw.

The picture shows the wires clipped to the frame - that is done in the next section but one.

Step 3: Endstops

Connect your endstops using two wires each. It is a good idea to use a different colour for each axis as this will make it easier to get the endstops connected to the correct input. The wires you cut from the stepper motors are different colours...

For the limit switch end, crimp or solder a terminal onto the end of the wires, then cover with some heatshrink to insulate the terminal. Connect to the outer pins of the limit switches (the NC = Normally Closed connections; RepRap expects the switch to open when the endstop is hit.)

The endstop switch holes should be drilled out to 3mm diameter so they can be mounted using #4x1/2" self tapping screws (alternatively, #2-56 and M2.5 screws will fit the switch, but are not included).

Y

The Y endstop is mounted beside the Y motor:

X

For the X endstop you will need the sticky pad from the extruder fan that you peeled off and saved. Cut a rectangle from it the size of the face of the switch and stick it on so that...

...it will be between the switch and the X-motor end of the X axis. Make sure that the sticky pad does not stick out and so foul the movement of the switch's lever.

Make a small hole in the sticky pad so that you can put a screw through the lower switch hole, then screw the switch to the X-motor end of the X axis.

Z

The Z endstop switch is mounted using the "h" shaped printed clip on the right-hand smooth Z bar:

Leave a generous loop of wire between the switch and where you first attach it to the frame. You need to be able to move the "h" clip up and down to set the Z zero position.

Step 4: Clipping wires to the frame

Important: don't trim any wires shorter until you come to connect them all to the Sanguinololy PCB in the next section.

Y axis and power

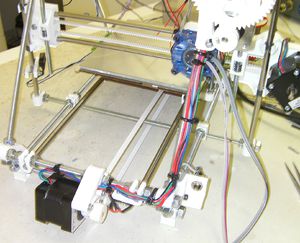

Run the Y stepper motor wires, the Y end-stop wires and both power wires as shown in the picture. Use cable ties to clip them to the rods up as far as just under the extruder drive.

Run all those wires except the bed power wire up beside the extruder drive motor and up just behind the left-hand Z motor. Take care that the wires run clear of the extruder shaft attached to the big gear. Don't put any ties on them yet.

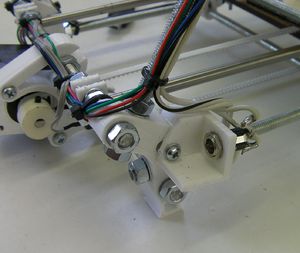

X axis

Next do the X motor and endstop wires as shown. Allow a generous loop so that the full range of Z movement can be accommodated.

Extruder

This picture is looking from the front of the machine.

Next do the extruder motor wires. Again allow a generous loop to permit full X movement at the bottom of the Z travel. Also make sure that the wires are clear of the PTFE tube down which the filament moves. Under no circumstances attach the wires to the tube anywhere along its length.

USB cable and Z end-stop switch

Run the USB cable and Z end-stop wires as shown.

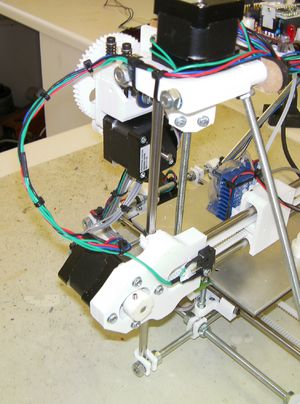

Z motors

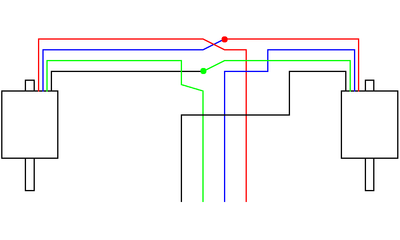

Next in this section do the Z wires.

The two Z motors are connected in series as shown above. Cut two 20mm lengths of heat-shrink sleeving and put it on one of each pair of wires that will be connected together. Then twist the ends and solder them keep the heat shrink well away), then shrink the sleeving over the join.

Run the Z wires along the front under the 4-way connectors (see the picture for the extruder connection above). Have the four wires emerge by the Z connector.

Heated bed signal and power wires

Take the 4-way ribbon cable. Separate the wires at one end for about 15mm.

Push the separated wires into the 4-way insulation displacement connector (IDC). There is no need to strip the wires. Use the jaws of the vice to push the connector together. Be gentle - don't damage the connector by pushing too far.

Plug the connector onto the 4-way pin header on the heated bed at the right in this picture:

Only three of the four wires are used (the forth is for a future enhancement for bed levelling for which your machine is already pre-configured). The unused wire is the nearest to you in the picture.

Connect the power wires as shown to the three-way connector. Only two of the connections are used.

Run the ribbon cable and the bed power wire as shown. Pass the ribbon cable up through past the extruder motor. You can now clip this to the frame beside the extruder motor along with the other wires already running there.

Step 5: Connecting all the wires to the Sanguinololu controller

Don't have any wires pulled taut - allow a loop for strain relief.

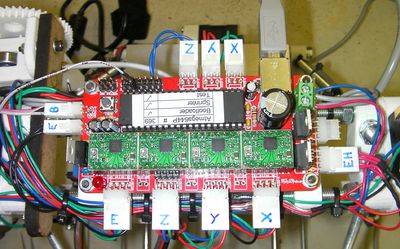

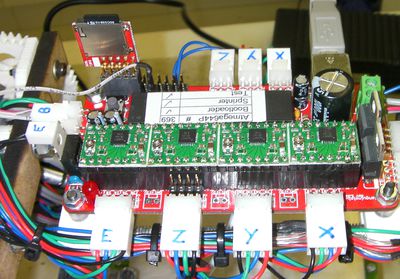

This is a plan view of the Sanguinololu controller. The front of the RepRapPro Huxley is at the bottom of the picture. Click on the image for a blown-up version.

Start with the power wires. These go to the screw connector next to the USB socket. The fan wires also screw into this connector. Make sure you get the polarity right. The red wire in the picture is going to +, the blue to -. You marked the fan polarity when you built the hot end. Double check with a meter that the + connection goes to the middle pin of the power connector. Then plug the power supply in but don't turn it on. Now check that the - connection on the Sanguinololu controller goes the the cylindrical outer shell of the plug on the power supply, a few mm of which will be projecting to allow you to prod it with a meter probe.

The four wire ribbon cable from the hotbed needs to be split. The four wires are (from the outermost edge of the bed): Probe Sensor, Heater, Thermistor, Ground. The sensor isn't supported for now and isn't connected anywhere. See below for the other three.

Next trim wires to length, fit connectors onto them and plug them in as follows (labels from the photograph) anticlockwise round the PCB:

- X, Y, Z at the top of the picture: the end-stops. The connectors are 3-way; just use the outer two connections. There is no polarity - you can wire the end-stops either way round.

- Grey wire from the heated bed ribbon cable that controls the MOSFET. This goes to the third pin on the bottom row (inner row, next to Atmega) of the long connector at the top (to the left of the end-stop connectors): the bed heater control. (This pin is labelled D10: it has a 5V signal when the hot bed needs to heat up, otherwise 0V).

- Connectors B and E: the bed thermistor and the hot-end thermistor respectively. There is no polarity on the hot end thermistor (you can wire this either way round), HOWEVER the bed thermistor wires need to go in the correct orientation. The wire from the ribbon cable connected to the innermost pin on the heatbed is GND. Make sure this is connected to the GND pin of the bed thermistor input on the Sanguinololu PCB (the pin nearest the other thermistor connection).

- Connector E at the bottom of the picture: the extruder motor. Wire sequence left to right: red, blue, green, black.

- Connector Z at the bottom of the picture: the Z motor. Wire sequence left to right: red, blue, green, black.

- Connector Y at the bottom of the picture: the Y motor. Wire sequence left to right: black, green, blue, red.

- Connector X at the bottom of the picture: the X motor. Wire sequence left to right: black, green, blue, red.

- Connector EH on the right: the hot-end heater resistor. For a pro job, solder a Y on the end of each wire and insulate it with heat-shrink as shown, then put all four connections in, one Y in the bottom two, one in the top two. There is no polarity - you can wire each pair either way round. (The double connections reduce current concentrations in the PCB.)

Finally, plug in the SD-card reader:

Step 6: Double check

Use your meter to double-check the power connections.

Make sure that 0v (GND) - the outside of the power connector - runs to the places in the circuitry that you would expect (for example the case of the SD card socket).

Check that the +19v wires run from the central pin on the connector to the right places on the circuit boards.

Check the continuity of the three active bed control wires with a meter from the connections on the controller board to the little blobs of solder on top of the 4-way connector on the heated bed. If you have open-circuit problems, it may be the insulation-displacement connector (IDC). A neat trick with this to rectify an open circuit (thanks to Alan Ryder) is gently to pull the IDC apart, take the wires out, strip them, and tin them. Then reassemble - the tinning ensures good contact with the IDC blades. This is only worth doing if you have problems with the simple method, though.

Step 7: Final tidy

Go round adding extra cable ties (and clipping the tails off the ones you've missed) to get the wiring as neat and tidy as you possibly can.