THOR Simpson

Release status: Obsolete

| Description | Grounded Delta Printer

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

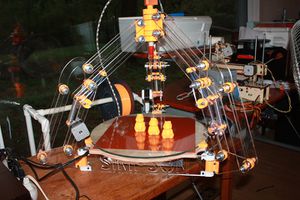

THOR (THe ORiginal) Simpson is a experimental grounded delta robot 3D printer prototype, built in 2013 by Nicholas Seward in Hot Springs, Arkansas, USA. Simpson is named after George Gaylord Simpson who came up with the idea of Quantum Evolution, the theory that evolution can happen in abrupt burst. The name signifies that this is a quick divergence (idea to first print in 1 month) from other existing designs.

NOTE: It is not suggested to build this model. You can find more advanced versions here.

Contents

Design Goals

- No linear rails

- Build volume at least as big as a Mendel

- Print speed at least as fast as a Mendel

- Low center of gravity

- Low cost (<$400)

- Fully printable except for bearings, bolts, bed, and electronics

- Fast assembly times

- Easy to calibrate

Specifications

- Build Volume: about 10L

- Build Area: about 350mm diameter

- Build Height: 190mm

- Speed: >200mm/s

- Realistic Print Speed: 60mm/s

- Cost: $390

- Estimated Build Time: 4 hours

Videos

<videoflash>xrn3XtTlJhU</videoflash>

<videoflash>ZXEcocEHfRQ</videoflash>

<videoflash>uug9d01Yyy8</videoflash>

Bill of Materials

Bill of Materials with vendors The total cost is $390. That is cheating a little bit. I didn't include any shipping and I broke everything down to its unit cost even if I have to buy extras that I am not going to use. You can certainly build this machine for less than $500.

- Lots of printed plastic

- 57 skate bearings

- 8 6805 bearings for hub

- All fasteners are M3 and M8. All nuts have nylon inserts.

- Spectra fishing line drive

- Azteeg X1

- Ubis hotend

- 4x NEMA17 Steppers

- Birch covered in glass for the build platform.

Firmware

Your choice. Currently gcode is transformed and then sent to Simpson. I use Repetier.

Software

I have included 3 python scripts to help with calibration, bed leveling, and coordinate transformation.

- parameters.py is used to put in the basic geometry of the machine and is where you will eventually put your leveling information

- zero.py will generate gcode for a calibration routine. Run it and use gauge.stl to measure and recode all the offsets into an array in parameters.py

- segmentize.py will convert standard gcode into gcode that Simpson can run. Long lines are broken into segments and positions and feed rates are interpolated.

Assembly

Note: I assembled the much more complex version in the picture above in 12 hours. Much of that time was wasted reprinting various parts, unbolting, and rebolting. I have combined many parts and have drastically reduced the part count and produced an assembly manual. I estimate that the assembly time will be on the order of 4 hours but that is yet to be verified. Considering I could have assembled the more complex version in 8 hours without an assembly manual, 4 hours seems reasonable. There are about 60 bolts. If you can install one bolt every 4 minutes then you can assemble Simpson in 4 hours. Everything has alignment seats so you don't have worry about alignment.

After main assembly, add rubber bands to each arm one at a time until you can push the effector to any location in the print volume and when release the effector will return home. (top dead center) After you have installed the rubber bands run your fishing line. Loop the line back and forth until you have a mechanical advantage that will work for all positions in the build volume. (I will post more details as I build baby Simpson.)

Homing

Simpson has no endstops and they really aren't needed due to the spring return. Later he may get tension sensors for each string. This will allow Simpson to never let any slack in the fishing line and be posed by hand.

- Turn the motors off.

- Press up on the effector until you are as high as Simpson will go.

- Press the home key in your host software.

- Disconnect and reconnect your printer just to make sure.

- Print.

RepRapNess

- >40% plastic

- <13% hardware

- about 37% wooden bed and glass

- 341 parts

- 59 plastic parts

- 54 unique parts

- 24 unique printable parts

- 53 hour replication time at 33mL/hour

- Can make a larger version of itself

Future Developments

- Go back to single arm design if possible. (Increase the torsional stiffness.)

- Enable auto leveling by using the extruder as a probe..

- Add coordinate transformations in firmware.

Links

- Solidus Labs Dogleg grounded delta robot (GDR) 3D Printer: http://forums.reprap.org/file.php?178,file=20399,filename=ScreenHunter_211_Oct._26_08.10.jpg ; http://www.youtube.com/watch?v=f9sChfAbNeM (this really needs its own RepRap wiki page)