Mendel wobble in z-axis of prints

Posted by Lenbok

|

Mendel wobble in z-axis of prints November 19, 2011 02:23AM |

Registered: 15 years ago Posts: 81 |

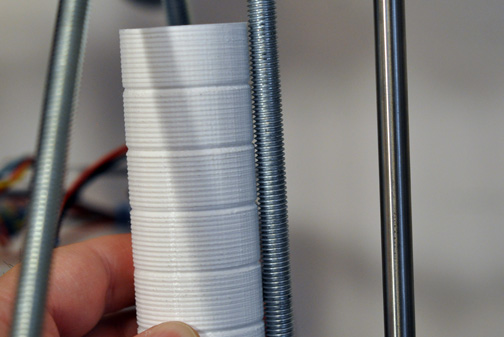

Hey all. I built an original mendel about a year ago, and up until recently I've only being printing at about 0.35mm layer thickness. When I moved to printing with thinner layers I noticed a wobble in the z-axis of my prints. The wobble has a wavelength of 1.25mm (which is the thread pitch of the Z threaded rods). I figure that it was not apparent at the thicker layers mostly due to the relatively low number of layers per 1.25mm. Here is a picture that demonstrates the problem, with two prints, one at 0.15mm layer thickness and one at 0.25mm layer thickness:

z-wobble every 1.25mm

I have done a couple of upgrades to the mendel to see whether they help the issue, but to no avail:

- Upgraded from BZP threaded rod to 304 stainless threaded rod, with no apparent bends.

- Upgraded from printed T5 pulleys / XL belt combo (whoops!) to commercial T5 pulleys / T5 belt (from sdp-si.com)

The wobble seems not to be from the X or Y axis shifting left or right, as it is symmetric in all axes - it seems more like the Z axis is not rising linearly w.r.t each revolution of the threaded rod.

Any ideas? Something to do with the Z-axis nut side of things? Or electronics/firmware? (I'm using gen3 electronics with makerbot firmware).

z-wobble every 1.25mm

I have done a couple of upgrades to the mendel to see whether they help the issue, but to no avail:

- Upgraded from BZP threaded rod to 304 stainless threaded rod, with no apparent bends.

- Upgraded from printed T5 pulleys / XL belt combo (whoops!) to commercial T5 pulleys / T5 belt (from sdp-si.com)

The wobble seems not to be from the X or Y axis shifting left or right, as it is symmetric in all axes - it seems more like the Z axis is not rising linearly w.r.t each revolution of the threaded rod.

Any ideas? Something to do with the Z-axis nut side of things? Or electronics/firmware? (I'm using gen3 electronics with makerbot firmware).

|

Re: Mendel wobble in z-axis of prints November 19, 2011 05:55AM |

Registered: 13 years ago Posts: 1,797 |

are you using makerbot firmware?

slow down z axis acceleration in machines.xml file located in my documents dir,slow down max speed on z axis

when z axis rises, it is single axis usually and at firmware full speed not software settings. so it goes by whatever the max speed is set for firmware.

a hack i had to do for tonokip was place a 1400microsecond delay between pulse for z axis step. newer firmware has settings that allow easy adjustment to max speed.

slow down z axis acceleration in machines.xml file located in my documents dir,slow down max speed on z axis

when z axis rises, it is single axis usually and at firmware full speed not software settings. so it goes by whatever the max speed is set for firmware.

a hack i had to do for tonokip was place a 1400microsecond delay between pulse for z axis step. newer firmware has settings that allow easy adjustment to max speed.

|

Re: Mendel wobble in z-axis of prints November 19, 2011 06:16AM |

Registered: 13 years ago Posts: 2,947 |

That may actually be an issue with the layer height you are using. Try dividing 1mm by your Z steps per mm and then find a layer thickness that is equal to a multiple of that number.

Example:

1mm / 2560 steps per mm = 0.000390625

0.2mm / 0.000390625 = 512 steps exactly.

but 0.22mm / 0.000390625 = 563.2 will cause the effect you see in your prints because it drops the .2 for four layers until it can make it up on the fifth. So you end up with four layers of 0.219921875 and every fifth would be 0.2203125

Example:

1mm / 2560 steps per mm = 0.000390625

0.2mm / 0.000390625 = 512 steps exactly.

but 0.22mm / 0.000390625 = 563.2 will cause the effect you see in your prints because it drops the .2 for four layers until it can make it up on the fifth. So you end up with four layers of 0.219921875 and every fifth would be 0.2203125

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Mendel wobble in z-axis of prints November 19, 2011 09:40AM |

Registered: 13 years ago Posts: 1,780 |

I was also thinking of the same thing. I agree that it looks the layer thickness is changing at each layer resulting in bulging. But even if he's using Gen 3 electronics at 840 steps/mm in his Mendel, the step size in z is still too small (0.0012 mm) to account for the bulging. That's well below 1% of the layer thickness even at a layer height of 0.15 mm.

Can this happen if one of the gears on the lead screws are not round or mounted off-center?

Edited 1 time(s). Last edit at 11/19/2011 09:41AM by brnrd.

Can this happen if one of the gears on the lead screws are not round or mounted off-center?

Edited 1 time(s). Last edit at 11/19/2011 09:41AM by brnrd.

|

Re: Mendel wobble in z-axis of prints November 19, 2011 04:30PM |

Registered: 15 years ago Posts: 81 |

I originally thought it could be caused by eccentric Z pulleys too, which is why I went from printed to commercial ones. There is no visible eccentricity.

Here are another couple of side by side prints, this time layer thickness 0.2mm, but trying W/T of 1.4 (on the left) and 2.2 (on the right).

Varying W/T. 0.2mm layers. W/T 1.4 and 2.2

Here are another couple of side by side prints, this time layer thickness 0.2mm, but trying W/T of 1.4 (on the left) and 2.2 (on the right).

Varying W/T. 0.2mm layers. W/T 1.4 and 2.2

|

Re: Mendel wobble in z-axis of prints November 20, 2011 07:15AM |

Registered: 13 years ago Posts: 1,352 |

|

Re: Mendel wobble in z-axis of prints November 20, 2011 08:56AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel wobble in z-axis of prints November 20, 2011 10:06AM |

Registered: 13 years ago Posts: 1,352 |

A picture would help at least to see if you do have a mendel and not a prusa, and which type exactly.

In classical mendel the z threaded rods are hold at bottom in 608 bearings. If the pulley would be eccentric, i think it wouldnt make a difference other than i think the belt tension, and its a long belt which can absorb that. A eccentric pulley wont be able to move aside the 608 bearing or its mount. Could leverage the other end but its not a leverage-able position its actually the lower side and its unfavorable, and again the X assembly and Z nuts should be rock solid so it shouldnt be able to move it against the Z rods unless Z rods bearing have huge play.

On the other hand, in classic mendel the Z nuts distance between center is independent from the z smooth rods, and therefore are adjustable along the x axis (unlike prusa). At least one of the nuts (see ~180 constraint one). I think what is more likely to happen, is the distance between center of Z nuts does not coincide with the distance between the centers of 608 bearings, therefore the shape made by rods is trapezoidal instead of perfectly rectangular. Therefore to cope with difference in distance, the rods can very well become bent, hence the wobble.

First the Z smooth rods need to be perfectly parallel and rectangular. Usually checking the distance between opposite diagonal corners ensures that the shape is not rhombic, then top and bottom checks its not a trapeze either. Then loosening the assembly with the nuts, i would use new fresh nuts and new fresh straight rods, and make the rods parallel with the z rods while tightening nuts in the x axis. Then i would tighten the nuts making sure that inside their traps, the nuts have zero play (e.g. they dont move either in x or y direction). And finally i would check that Z threaded rods are now perfectly parallel and in same plane with Z smooth rods which were checked before.

Also maybe the Z nuts are not properly fitted inside their traps, maybe are in wrong position or tightening them there makes them shift. Traps are made of 2 parts, say if one is bigger than the other it also might shift the thread rods position in more or less same manner - instead of being in center and same plane with Z smooth rods - which could make same thing, X movement not consistent along Z movement.

After sorting the rest, i would also tighten the Z smooth rods bearings. Any sort of X stage movement could not happen unless these have a play too.

Edited 4 time(s). Last edit at 11/20/2011 10:53AM by NoobMan.

In classical mendel the z threaded rods are hold at bottom in 608 bearings. If the pulley would be eccentric, i think it wouldnt make a difference other than i think the belt tension, and its a long belt which can absorb that. A eccentric pulley wont be able to move aside the 608 bearing or its mount. Could leverage the other end but its not a leverage-able position its actually the lower side and its unfavorable, and again the X assembly and Z nuts should be rock solid so it shouldnt be able to move it against the Z rods unless Z rods bearing have huge play.

On the other hand, in classic mendel the Z nuts distance between center is independent from the z smooth rods, and therefore are adjustable along the x axis (unlike prusa). At least one of the nuts (see ~180 constraint one). I think what is more likely to happen, is the distance between center of Z nuts does not coincide with the distance between the centers of 608 bearings, therefore the shape made by rods is trapezoidal instead of perfectly rectangular. Therefore to cope with difference in distance, the rods can very well become bent, hence the wobble.

First the Z smooth rods need to be perfectly parallel and rectangular. Usually checking the distance between opposite diagonal corners ensures that the shape is not rhombic, then top and bottom checks its not a trapeze either. Then loosening the assembly with the nuts, i would use new fresh nuts and new fresh straight rods, and make the rods parallel with the z rods while tightening nuts in the x axis. Then i would tighten the nuts making sure that inside their traps, the nuts have zero play (e.g. they dont move either in x or y direction). And finally i would check that Z threaded rods are now perfectly parallel and in same plane with Z smooth rods which were checked before.

Also maybe the Z nuts are not properly fitted inside their traps, maybe are in wrong position or tightening them there makes them shift. Traps are made of 2 parts, say if one is bigger than the other it also might shift the thread rods position in more or less same manner - instead of being in center and same plane with Z smooth rods - which could make same thing, X movement not consistent along Z movement.

After sorting the rest, i would also tighten the Z smooth rods bearings. Any sort of X stage movement could not happen unless these have a play too.

Edited 4 time(s). Last edit at 11/20/2011 10:53AM by NoobMan.

|

Re: Mendel wobble in z-axis of prints November 20, 2011 06:56PM |

Registered: 13 years ago Posts: 1,780 |

The printer has z pulleys and there are no z pulleys in the Prusa since the motor is connected to the lead screw, so I think it's an original (Sell's) Mendel as he stated.

The gear in the motor translates rotation in the motor to linear motion in the belt and then the gears under each threaded rod translate it back to rotation again. This translation depends on the radial distance between the center of the shaft/lead screw and the belt. If the gears are not centered in the motor shaft or one of the the threaded rods, then the rotational motion of the threaded rod(s) would be uneven but it would catch up at every revolution.

The gear in the motor translates rotation in the motor to linear motion in the belt and then the gears under each threaded rod translate it back to rotation again. This translation depends on the radial distance between the center of the shaft/lead screw and the belt. If the gears are not centered in the motor shaft or one of the the threaded rods, then the rotational motion of the threaded rod(s) would be uneven but it would catch up at every revolution.

|

Re: Mendel wobble in z-axis of prints November 20, 2011 07:09PM |

Registered: 15 years ago Posts: 81 |

It is an original ("sells") mendel, not a prusa.

The Z pulleys are this one from sdp-si: T5 Z-pulley, which do have a snugly fitting 8mm bore.

The Z-nuts are held tight in the x-vert-drive-nut-trap parts. I have not replaced these nuts during my replacements of rods / belts / pulleys.

It seems like the only remaining candidates are to replace the Z-nuts and double-check the distances from 608 bearing to Z smooth rod and similarly between the Z nuts and smooth rod, but I don't really see how they could cause the effect I'm seeing.

I may try printing a wall that is 200mm in the X axis to see how the effect varies with proximity to each of the Z-rods.

The Z pulleys are this one from sdp-si: T5 Z-pulley, which do have a snugly fitting 8mm bore.

The Z-nuts are held tight in the x-vert-drive-nut-trap parts. I have not replaced these nuts during my replacements of rods / belts / pulleys.

It seems like the only remaining candidates are to replace the Z-nuts and double-check the distances from 608 bearing to Z smooth rod and similarly between the Z nuts and smooth rod, but I don't really see how they could cause the effect I'm seeing.

I may try printing a wall that is 200mm in the X axis to see how the effect varies with proximity to each of the Z-rods.

|

Re: Mendel wobble in z-axis of prints November 20, 2011 07:28PM |

Registered: 13 years ago Posts: 2,947 |

You may want to run a die over the threaded rod to make sure its a consistent diameter and pitch.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Mendel wobble in z-axis of prints November 20, 2011 07:59PM |

Registered: 13 years ago Posts: 1,352 |

Lenbok Wrote:

-------------------------------------------------------

> replace the Z-nuts and double-check the distances

> from 608 bearing to Z smooth rod and similarly

> between the Z nuts and smooth rod, but I don't

> really see how they could cause the effect I'm

> seeing.

If it would be a rectangular shape, it wouldnt. But if nuts are in wrong place then it forces a trapeze shape which gets worse at lower z heights, and the threaded rods have nothing else to do but to bent in the new shape, which gets them bent, and hence they shall wobble further on. I would ensure all shapes are rectangular and not else, and i would check with a caliper distances between each threaded rod and its smooth rod nearby.

Also if you are out of ideas, here is another thought. If the 608 trap/cage/ constraint or w/e that is, if its too big for the bearing, it might get a very similar effect. Like that thing 2 children stay at each end and go up-down, the bearing could be moving like that hardly perceivable but amplified along the rod. I would make sure that bearing is fit and the 3 screws near it holds it tight perfectly in only one place.

Edited 1 time(s). Last edit at 11/20/2011 08:00PM by NoobMan.

-------------------------------------------------------

> replace the Z-nuts and double-check the distances

> from 608 bearing to Z smooth rod and similarly

> between the Z nuts and smooth rod, but I don't

> really see how they could cause the effect I'm

> seeing.

If it would be a rectangular shape, it wouldnt. But if nuts are in wrong place then it forces a trapeze shape which gets worse at lower z heights, and the threaded rods have nothing else to do but to bent in the new shape, which gets them bent, and hence they shall wobble further on. I would ensure all shapes are rectangular and not else, and i would check with a caliper distances between each threaded rod and its smooth rod nearby.

Also if you are out of ideas, here is another thought. If the 608 trap/cage/ constraint or w/e that is, if its too big for the bearing, it might get a very similar effect. Like that thing 2 children stay at each end and go up-down, the bearing could be moving like that hardly perceivable but amplified along the rod. I would make sure that bearing is fit and the 3 screws near it holds it tight perfectly in only one place.

Edited 1 time(s). Last edit at 11/20/2011 08:00PM by NoobMan.

|

Re: Mendel wobble in z-axis of prints November 20, 2011 10:28PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel wobble in z-axis of prints November 20, 2011 11:28PM |

Registered: 15 years ago Posts: 81 |

The drive pulley on the motor is this one: T5 Z-drive pulley, it also fits snugly on the stepper (and having a different number of teeth than the threaded rod pulleys, wouldn't cause problems that coincide with the threaded rod thread pitch).

|

Re: Mendel wobble in z-axis of prints November 21, 2011 12:23AM |

Registered: 13 years ago Posts: 1,780 |

OK. Thanks. This is quite puzzling.

I asked because I'm considering changing my belts and pulleys to GT2 per mendelmax.com so I was curious what pulleys you got for the z axis.

I asked because I'm considering changing my belts and pulleys to GT2 per mendelmax.com so I was curious what pulleys you got for the z axis.

|

Re: Mendel wobble in z-axis of prints November 21, 2011 03:42AM |

Admin Registered: 17 years ago Posts: 7,879 |

It seems too dramatic a difference to be an eccentric pulley.

One issue I have found with M8 nuts is that the face is not always perfectly perpendicular to the thread when they pull tight. That would make the bottom bearings roll around on their rim against the three M4 washers underneath. If the washers were not at exactly the same height you might get that sort of effect.

I recently checked the Z-axis of my Prusa with a digital scale and found the stainless steel studding I use to be remarkably accurate. No matter where I stopped it the scale was within 0.02mm. I did have to fit the anti-backlash springs though as without them I had significant backlash.

[www.hydraraptor.blogspot.com]

One issue I have found with M8 nuts is that the face is not always perfectly perpendicular to the thread when they pull tight. That would make the bottom bearings roll around on their rim against the three M4 washers underneath. If the washers were not at exactly the same height you might get that sort of effect.

I recently checked the Z-axis of my Prusa with a digital scale and found the stainless steel studding I use to be remarkably accurate. No matter where I stopped it the scale was within 0.02mm. I did have to fit the anti-backlash springs though as without them I had significant backlash.

[www.hydraraptor.blogspot.com]

|

Re: Mendel wobble in z-axis of prints November 21, 2011 07:44AM |

Registered: 13 years ago Posts: 1,352 |

nophead Wrote:

-------------------------------------------------------

> One issue I have found with M8 nuts is that the

> face is not always perfectly perpendicular to the

> thread when they pull tight.

Thats very correct, and its common for all threads and common nuts. To move freely, a play is needed between thread and its nut. When tightening that play has to go away so the nuts always end up at an angle that is *not* perpendicular anymore in regards to rod. Angle being the result of the play that dissapeared. Checking by hand, a full metal nut when its free on the thread "giggles" a little, half of that is the offset which causes the angle. And the *giggling* ends will be the position it ends up when tightened in either direction. Bigger the thread more visible the offset is. A anti-vibration "grover" type of washer (like those washers that are like 1 spiral spring) might modify this offset a little. Also i think techincally there are like 20 nuts types for different purposes, and there is a letter coding system, just nobody uses it.

A fast way to get rid of this specific effect is to use "connector" nuts type (again not sure of word), are those nuts that are extra long like 15-20mm. Imho these should be best for those bottom bearing cages, and also instead of the usual Z nuts.

-------------------------------------------------------

> One issue I have found with M8 nuts is that the

> face is not always perfectly perpendicular to the

> thread when they pull tight.

Thats very correct, and its common for all threads and common nuts. To move freely, a play is needed between thread and its nut. When tightening that play has to go away so the nuts always end up at an angle that is *not* perpendicular anymore in regards to rod. Angle being the result of the play that dissapeared. Checking by hand, a full metal nut when its free on the thread "giggles" a little, half of that is the offset which causes the angle. And the *giggling* ends will be the position it ends up when tightened in either direction. Bigger the thread more visible the offset is. A anti-vibration "grover" type of washer (like those washers that are like 1 spiral spring) might modify this offset a little. Also i think techincally there are like 20 nuts types for different purposes, and there is a letter coding system, just nobody uses it.

A fast way to get rid of this specific effect is to use "connector" nuts type (again not sure of word), are those nuts that are extra long like 15-20mm. Imho these should be best for those bottom bearing cages, and also instead of the usual Z nuts.

|

Re: Mendel wobble in z-axis of prints November 21, 2011 08:19AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel wobble in z-axis of prints November 21, 2011 09:22AM |

Registered: 13 years ago Posts: 1,352 |

Its hardly perceivable and quite neglectable, but all nuts go this way. Unless they have zero play, which is impossible on metal/metal, so thats why for trapezoidal screws ppls go for acetal nuts or teflon nuts and stuff like that.

Edited 1 time(s). Last edit at 11/21/2011 09:27AM by NoobMan.

Edited 1 time(s). Last edit at 11/21/2011 09:27AM by NoobMan.

|

Re: Mendel wobble in z-axis of prints November 21, 2011 10:50AM |

Registered: 13 years ago Posts: 818 |

Has anyone tried making a PLA nut to replace the M8's? - I made some Delrin (Acetal) ones for my first repstrap by drilling a Delrin block and partly tapping then using a heated M8 rod melt into the Delrin to give a nice zero backlash nut for the Z Axis, it worked perfectly.

I do wonder if you could do the same trick with melting a rod into a Nut shaped PLA printed part.

[richrap.blogspot.com]

I do wonder if you could do the same trick with melting a rod into a Nut shaped PLA printed part.

[richrap.blogspot.com]

|

Re: Mendel wobble in z-axis of prints November 21, 2011 03:35PM |

Registered: 15 years ago Posts: 81 |

So, I did an experiment where I printed a bar that was 180mm in X axis. The rightmost end of the bar is 80mm from the right Z leadscrew and 260mm from the left leadscrew, so any wave at that end would be dominated by the right leadscrew. Similarly, the other end of the bar would be dominated by any wave induced by the left leadscrew. Potentially each leadscrew could induce its own wave and they may or may not be in phase with each other - if out of phase then the wave effect might cancel out at some point down the length of the bar.

When I printed this out the wave was uniform down the length of the bar. This is shown in the top bar here: 180mm long bar showing uniform wave

(with such a long thin object there was a little warping at the ends, even with PLA)

I then loosened the Z belt, and rotated the right leadscrew 1/2 turn under the belt (without rotating the left leadscrew), tightened the Z belt, and levelled the platform w.r.t the new height on the right. I printed the bar again (the bottom bar of the picture). In theory that should have caused the wave at the right hand side of the bar to be 180deg out of phase - however the print came out exactly the same!

I cut each bar so I could look closer at the phase of left vs right end, this is shown here: Matching ends of each bar to check phase

(at top is the first bar, matching right end of bar against the left end. Under that is the second bar, matching the right end against the left end).

I am still quite puzzled how this could be occurring...

When I printed this out the wave was uniform down the length of the bar. This is shown in the top bar here: 180mm long bar showing uniform wave

(with such a long thin object there was a little warping at the ends, even with PLA)

I then loosened the Z belt, and rotated the right leadscrew 1/2 turn under the belt (without rotating the left leadscrew), tightened the Z belt, and levelled the platform w.r.t the new height on the right. I printed the bar again (the bottom bar of the picture). In theory that should have caused the wave at the right hand side of the bar to be 180deg out of phase - however the print came out exactly the same!

I cut each bar so I could look closer at the phase of left vs right end, this is shown here: Matching ends of each bar to check phase

(at top is the first bar, matching right end of bar against the left end. Under that is the second bar, matching the right end against the left end).

I am still quite puzzled how this could be occurring...

|

Re: Mendel wobble in z-axis of prints November 21, 2011 04:02PM |

Registered: 13 years ago Posts: 2,947 |

Great test. I know this would be a lot of work but could you turn one of the captive nuts 180deg and retest.

Another test you could do is see how far the belt moves with each layer change. Just use the jog panel to move it your layer height while measuring the distance the belt travels horizontally.

With gen3 firmware do you get microstepping? If you do not it could still be the issue I mentioned [forums.reprap.org]

Another test you could do is see how far the belt moves with each layer change. Just use the jog panel to move it your layer height while measuring the distance the belt travels horizontally.

With gen3 firmware do you get microstepping? If you do not it could still be the issue I mentioned [forums.reprap.org]

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Mendel wobble in z-axis of prints November 21, 2011 04:39PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel wobble in z-axis of prints November 21, 2011 06:25PM |

Registered: 15 years ago Posts: 81 |

gen3 does half-stepping I believe. I'm slicing with skeinforge. I just inspected the Z values and they look good - all incrementing by the expected amount:

$ grep ^"G1 X" zwobbletest.rrv5.gcode | awk '{print $4}' | uniq -c

721 Z0.18

715 Z0.38

717 Z0.58

369 Z0.78

369 Z0.98

369 Z1.18

369 Z1.38

369 Z1.58

369 Z1.78

369 Z1.98

369 Z2.18

369 Z2.38

369 Z2.58

369 Z2.78

369 Z2.98

369 Z3.18

...

It strikes me that another potential location for rounding type errors could be in the gcode -> binary s3g that makerbot firmware goes though. If that is the case, it should show up with the belt movement test, which I'll have a go at tonight.

I will then try the captive nut rotation idea (I was planning on swapping them for new ones as a straw-grabbing-hope-this-fixes-things change).

Thanks for the help and suggestions, guys! This is a nut I'd really like to crack :-)

$ grep ^"G1 X" zwobbletest.rrv5.gcode | awk '{print $4}' | uniq -c

721 Z0.18

715 Z0.38

717 Z0.58

369 Z0.78

369 Z0.98

369 Z1.18

369 Z1.38

369 Z1.58

369 Z1.78

369 Z1.98

369 Z2.18

369 Z2.38

369 Z2.58

369 Z2.78

369 Z2.98

369 Z3.18

...

It strikes me that another potential location for rounding type errors could be in the gcode -> binary s3g that makerbot firmware goes though. If that is the case, it should show up with the belt movement test, which I'll have a go at tonight.

I will then try the captive nut rotation idea (I was planning on swapping them for new ones as a straw-grabbing-hope-this-fixes-things change).

Thanks for the help and suggestions, guys! This is a nut I'd really like to crack :-)

|

Re: Mendel wobble in z-axis of prints November 21, 2011 08:57PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Mendel wobble in z-axis of prints November 23, 2011 05:44PM |

Registered: 12 years ago Posts: 3 |

bit of a noob so sorry if I'm barking up the wrong tree, trying to get a handle on some of the issues I willl face when I do my first print (hopefully soon) from your first pic the error is much smaller at the top were the print its only a couple mm across, could it be caused by backlash (rodflex) on the xy axis due to the deceleration being too high and there for moving the nuts/barsm admittedly i dont see why it would be periodic. I was also wondering which bit has the correct width on the wobble?

|

Re: Mendel wobble in z-axis of prints November 24, 2011 06:01AM |

Registered: 15 years ago Posts: 81 |

Well, I'd say that nophead called it.

I noticed that it was possible to wiggle the right z-rod slightly within the captive nut (suggesting the nut was nice and square) but the left one didn't have such play, so I figured maybe it was a bit skew somehow causing the problem. So I dismantled the left x-vert-drive-nut-trap. With that out it was possible to freely spin the z-rod in the bearing, at which point I could see that the bearing was faintly rising/falling with each rotation. I undid the M8 nuts holding the rod into the bearings, replaced them with new nuts, carefully checking they were seating nicely (didn't actually bother removing the bearing itself from it's cage). Freely spinning the z-rod showed the rise/fall no longer occurring. I reassembled the left x-vert-drive-nut-trap (also trying to get it so the z-rod had the same freedom within the nut that the right side had). Had time to do a quick print this morning and the z-wave is gone (will post a picture soon). I still don't understand why the wave was showing uniformly along the whole length of my long test bar - I would have thought it would be much more pronounced on the side closest to the problem z-rod.

In answer to wilot309, I think the effect was virtually nonexistent at the top of the first print because the small area at the top meant the layers weren't fully cool when placed on each other, and things got smoothed out.

Thanks for the help guys!

I noticed that it was possible to wiggle the right z-rod slightly within the captive nut (suggesting the nut was nice and square) but the left one didn't have such play, so I figured maybe it was a bit skew somehow causing the problem. So I dismantled the left x-vert-drive-nut-trap. With that out it was possible to freely spin the z-rod in the bearing, at which point I could see that the bearing was faintly rising/falling with each rotation. I undid the M8 nuts holding the rod into the bearings, replaced them with new nuts, carefully checking they were seating nicely (didn't actually bother removing the bearing itself from it's cage). Freely spinning the z-rod showed the rise/fall no longer occurring. I reassembled the left x-vert-drive-nut-trap (also trying to get it so the z-rod had the same freedom within the nut that the right side had). Had time to do a quick print this morning and the z-wave is gone (will post a picture soon). I still don't understand why the wave was showing uniformly along the whole length of my long test bar - I would have thought it would be much more pronounced on the side closest to the problem z-rod.

In answer to wilot309, I think the effect was virtually nonexistent at the top of the first print because the small area at the top meant the layers weren't fully cool when placed on each other, and things got smoothed out.

Thanks for the help guys!

|

Re: Mendel wobble in z-axis of prints November 24, 2011 01:59PM |

Registered: 15 years ago Posts: 81 |

Here is a picture showing before and after the left rod adjustment (both 0.2mm layers, W/T is 2.2 and 1.8):

Before/after left z-rod adjustment

The right hand print does have a new issue with the piece getting shorter in the x axis throughout the print, but that just looks like something causing increasing x axis backlash (probably something not properly tightened after reassembling things), the backlash is more visible on the top:

Top view of backlash

Before/after left z-rod adjustment

The right hand print does have a new issue with the piece getting shorter in the x axis throughout the print, but that just looks like something causing increasing x axis backlash (probably something not properly tightened after reassembling things), the backlash is more visible on the top:

Top view of backlash

|

Re: Mendel wobble in z-axis of prints November 24, 2011 02:02PM |

Registered: 13 years ago Posts: 2,947 |

Great to know. This is one of those things that need to be added to the solutions to printing problems page I heard about a few months back.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Mendel wobble in z-axis of prints July 10, 2012 12:36PM |

Registered: 12 years ago Posts: 53 |

After a few months of getting very nice prints, my mendel has developed the same problem. Will replacing the captive nuts solve this problem? It seems that the nuts are over constrained in the mendel design. Is there a way to let the z-axis nuts move slightly in the holder since it is the smooth rod that holds the axis in place?

Sorry, only registered users may post in this forum.