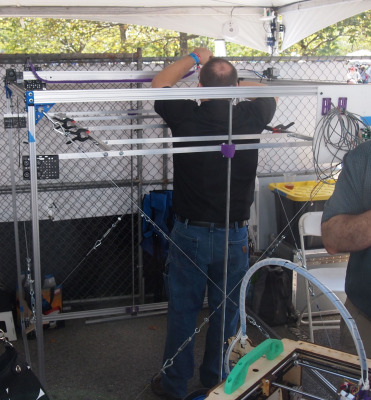

Large-scale 3d printer

Posted by asifjahmed

|

Large-scale 3d printer November 30, 2011 07:04PM |

Registered: 12 years ago Posts: 29 |

How come I don't see any large-scale 3d printers?

I have a couple of parts I'd like to make that are approx. 20"x6"x2" - and it doesn't seem like any existing design can handle such a part. I also want it to be made of ABS, so I know warping might be an issue with such a long part.

Any theories, suggestions, criticisms?

Thanks.

I have a couple of parts I'd like to make that are approx. 20"x6"x2" - and it doesn't seem like any existing design can handle such a part. I also want it to be made of ABS, so I know warping might be an issue with such a long part.

Any theories, suggestions, criticisms?

Thanks.

|

Re: Large-scale 3d printer November 30, 2011 07:17PM |

Registered: 12 years ago Posts: 21 |

I can't speak from personal experience, but I've heard people say that just increasing the scale of a printer doesn't work so well as it introduces a bunch of other issues that didn't exist in the smaller size.

I'd also imagine a heated build surface would take a bunch of amps as my prusa build surface draws around 11A most of the time.

Does your item have to be built as a single object in one print? Or could it be broken up into smaller prints that are joined together? Search for Turtle Shell Racer on thingiverse and see how they did a RC car that is roughly 4 times larger than the Makerbot build surface by breaking the shell parts into for quadrants.

Ostrich99

I'd also imagine a heated build surface would take a bunch of amps as my prusa build surface draws around 11A most of the time.

Does your item have to be built as a single object in one print? Or could it be broken up into smaller prints that are joined together? Search for Turtle Shell Racer on thingiverse and see how they did a RC car that is roughly 4 times larger than the Makerbot build surface by breaking the shell parts into for quadrants.

Ostrich99

|

Re: Large-scale 3d printer November 30, 2011 07:38PM |

Admin Registered: 17 years ago Posts: 7,879 |

To make something that big in ABS would require a heated chamber at about 70C. That makes a reprap made from plastic parts unsuitable.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Large-scale 3d printer November 30, 2011 08:18PM |

Registered: 13 years ago Posts: 1,780 |

asifjahmed Wrote:

-------------------------------------------------------

> How come I don't see any large-scale 3d printers?

>

> I have a couple of parts I'd like to make that are

> approx. 20"x6"x2" - and it doesn't seem like any

> existing design can handle such a part. I also

> want it to be made of ABS, so I know warping might

> be an issue with such a long part.

>

> Any theories, suggestions, criticisms?

>

> Thanks.

Get yourself one of these or ask stratasys.com to print the part for your. It has a build volume of 3'x2'x3'.

-------------------------------------------------------

> How come I don't see any large-scale 3d printers?

>

> I have a couple of parts I'd like to make that are

> approx. 20"x6"x2" - and it doesn't seem like any

> existing design can handle such a part. I also

> want it to be made of ABS, so I know warping might

> be an issue with such a long part.

>

> Any theories, suggestions, criticisms?

>

> Thanks.

Get yourself one of these or ask stratasys.com to print the part for your. It has a build volume of 3'x2'x3'.

|

Re: Large-scale 3d printer November 30, 2011 08:33PM |

Registered: 12 years ago Posts: 29 |

|

Re: Large-scale 3d printer November 30, 2011 09:22PM |

Registered: 12 years ago Posts: 156 |

|

Re: Large-scale 3d printer November 30, 2011 09:43PM |

Registered: 13 years ago Posts: 581 |

As nophead said, absolutely no way unless you do a 70-90C heated chamber. Even 3X3X3" parts can start to crack with just a heated bed.

For a high temp heated chamber, you need to keep the steppers either cooled, under-powered, or outside the heated area.

Also, the hot end needs some form of active cooling (ie: pipe in cold air from outside the chamber) otherwise the filament will soften and jam.

Doing all this and getting a reasonable feed rate is a huge challenge, and inherently violates at least one patent.

www.Fablicator.com

For a high temp heated chamber, you need to keep the steppers either cooled, under-powered, or outside the heated area.

Also, the hot end needs some form of active cooling (ie: pipe in cold air from outside the chamber) otherwise the filament will soften and jam.

Doing all this and getting a reasonable feed rate is a huge challenge, and inherently violates at least one patent.

www.Fablicator.com

|

Re: Large-scale 3d printer November 30, 2011 10:20PM |

Registered: 12 years ago Posts: 29 |

Thanks for the replies.

Didn't realize the steppers would care much about the higher temps. I was planning to figure out some sort of cooling solution for the filament.

Andrew - can you elaborate on your last line? Getting a reasonable feed rate is a challenge - why? Also, what patents would I be violating? So I can't build my own machine that does these things?

Didn't realize the steppers would care much about the higher temps. I was planning to figure out some sort of cooling solution for the filament.

Andrew - can you elaborate on your last line? Getting a reasonable feed rate is a challenge - why? Also, what patents would I be violating? So I can't build my own machine that does these things?

|

Re: Large-scale 3d printer November 30, 2011 11:48PM |

Registered: 13 years ago Posts: 581 |

To print 20in well will require much more strength than the usual printers. The deflection of an axis over that distance can be very significant unless you are using much thicker rods. Also, some serious thought needs to be put into belt thickness, tensioning, etc to prevent a lot of vibration. All of this means a lot more mass, power, and design work, or reduced speed. (assuming you stick with standard Mendel mechanics)

Depending on what you want to print, copying the ultimaker mechanics and extending the Z to 20in might be workable.

Stratasys currently holds the patent for a heated build chamber (how they managed to patent a temperature controlled box is beyond me)

The specific wording is something along the lines of controlling the build chamber's temperature so the plastic part being built is above the stress relaxation temperature, but below the glass transition temperature (ie 70c-90c for most abs)

Also, somebody (I'm pretty sure it's Stratasys) has a patent for a method of keeping the stepper motors out of the heated chamber. Probably easy enough to skirt, but it's there nonetheless.

www.Fablicator.com

Depending on what you want to print, copying the ultimaker mechanics and extending the Z to 20in might be workable.

Stratasys currently holds the patent for a heated build chamber (how they managed to patent a temperature controlled box is beyond me)

The specific wording is something along the lines of controlling the build chamber's temperature so the plastic part being built is above the stress relaxation temperature, but below the glass transition temperature (ie 70c-90c for most abs)

Also, somebody (I'm pretty sure it's Stratasys) has a patent for a method of keeping the stepper motors out of the heated chamber. Probably easy enough to skirt, but it's there nonetheless.

www.Fablicator.com

|

Re: Large-scale 3d printer December 01, 2011 01:23AM |

Registered: 12 years ago Posts: 38 |

|

Re: Large-scale 3d printer December 01, 2011 07:32AM |

Registered: 12 years ago Posts: 29 |

|

Re: Large-scale 3d printer December 01, 2011 08:38AM |

Registered: 15 years ago Posts: 376 |

I do get flustrated sometimes on forums as there always seems about 20 people giving reasons why you can't do something and very few saying why you can. Is it any wonder why development of the reprap is so slow.

Scaling any design up doesn't work, its a basic engineering principle. "If an ant was the size of a man it would be able to lift a house"....in fact it wouldn't even be able to lift itself and its legs would snap due to the fact that its mass cubes as its size doubles.

I couldn't find any patents which say Stratasys have rights on heated build chambers. Here is a list from Stratasys, perhaps the list is incomplete.

Patent Applications

Building a machine with 20" travel would not be an issue, its just a case of careful design. There are hundreds of configurations of machines larger than that with accuracy high enough for FDM. You can also compensate in software for axis sag if you go larger anyway. This is common on vertical boring machines and other large equipment, where the bed may be several meters in size. My Delta Robot was enormous compared to a prusa, and at least it proved that a rigid machine can be made quite large using threaded bar type structures. Also note the part is long and thin, this give the possibilty of making a narrow machine which could be more rigid.

If you have a look at the build area from the initial post, its about twice that of a prusa 120 sq inches instead of about 64 sq inches

A 30A 12V power supply would drive this. These are easily available and used already in the reprap community. Check Adrians Prusa Notes for suppliers. Silicone heated rubber plated could also be used. These can be driven from the mains.

Part warping as stated above is probably your biggest hurdle, but this depends on your part shape, extrusion method and temperatures. Basically you wont know until you give it a go. Even then you might be able to tweak the settings and print order to improve things. How many here produce solid parts, which I imagine would not crack quite as easily as semi filled parts which do warp and can crack. They just take longer to print.

In Short......YES it can be done... until someone proves otherwise.

Scaling any design up doesn't work, its a basic engineering principle. "If an ant was the size of a man it would be able to lift a house"....in fact it wouldn't even be able to lift itself and its legs would snap due to the fact that its mass cubes as its size doubles.

I couldn't find any patents which say Stratasys have rights on heated build chambers. Here is a list from Stratasys, perhaps the list is incomplete.

Patent Applications

Building a machine with 20" travel would not be an issue, its just a case of careful design. There are hundreds of configurations of machines larger than that with accuracy high enough for FDM. You can also compensate in software for axis sag if you go larger anyway. This is common on vertical boring machines and other large equipment, where the bed may be several meters in size. My Delta Robot was enormous compared to a prusa, and at least it proved that a rigid machine can be made quite large using threaded bar type structures. Also note the part is long and thin, this give the possibilty of making a narrow machine which could be more rigid.

If you have a look at the build area from the initial post, its about twice that of a prusa 120 sq inches instead of about 64 sq inches

A 30A 12V power supply would drive this. These are easily available and used already in the reprap community. Check Adrians Prusa Notes for suppliers. Silicone heated rubber plated could also be used. These can be driven from the mains.

Part warping as stated above is probably your biggest hurdle, but this depends on your part shape, extrusion method and temperatures. Basically you wont know until you give it a go. Even then you might be able to tweak the settings and print order to improve things. How many here produce solid parts, which I imagine would not crack quite as easily as semi filled parts which do warp and can crack. They just take longer to print.

In Short......YES it can be done... until someone proves otherwise.

|

Re: Large-scale 3d printer December 01, 2011 08:46AM |

Registered: 12 years ago Posts: 29 |

Thanks, Martin! I appreciate you taking the time to post all of that.

I have gotten some good insight from everyone who responded - I appreciate it.

Now I just have to decide whether or not to tackle such a project.

I am thinking to use the ultimaker style gantry system and aluminum extrusions for the frame. Still pondering whether to go bowden extruder or not.

Also - I really want soluable support material. I know I can easily have 2 bowden extruders and 2 hot ends - is there software to support the second extruder for support material?

Thanks again!

I have gotten some good insight from everyone who responded - I appreciate it.

Now I just have to decide whether or not to tackle such a project.

I am thinking to use the ultimaker style gantry system and aluminum extrusions for the frame. Still pondering whether to go bowden extruder or not.

Also - I really want soluable support material. I know I can easily have 2 bowden extruders and 2 hot ends - is there software to support the second extruder for support material?

Thanks again!

|

Re: Large-scale 3d printer December 01, 2011 08:50AM |

Registered: 13 years ago Posts: 1,780 |

I don't see anyone saying that it can't be done. There are commercial printers that can do it, so it obviously can be done. As far as building a reprap printer to print the size of the parts he wants with ABS, everyone agrees that he needs a heated chamber. Of course, if someone can come up with an extrudable plastic that doesn't shrink or does so by an insignificant amount upon cooling, then we can do away with heated build chambers.

BTW, here's the Reprap Mondo printer that comes close in build volume (12"x18"x11").

BTW, here's the Reprap Mondo printer that comes close in build volume (12"x18"x11").

|

Re: Large-scale 3d printer December 01, 2011 10:20AM |

Registered: 15 years ago Posts: 376 |

I@ brnd. I dont agree you need a heated build chamber and neither does Pazu or grassroots engineering.

Double head extruders are becoming more popular. There are a few popping up on thingiverse. There is also a lot of work at producing removable ABS support material. I find it tends to be a little wasteful of material, so prefer to design my parts without overhangs where possible, but it depends on what you are making.

Take a look at Hydra MMM and check out the blog link from the wiki.

I have used modified versions of his firmware, so it does work well and is easy to understand.

The machine is aluminium extrusion based and has firmware for multiple heads.

Double head extruders are becoming more popular. There are a few popping up on thingiverse. There is also a lot of work at producing removable ABS support material. I find it tends to be a little wasteful of material, so prefer to design my parts without overhangs where possible, but it depends on what you are making.

Take a look at Hydra MMM and check out the blog link from the wiki.

I have used modified versions of his firmware, so it does work well and is easy to understand.

The machine is aluminium extrusion based and has firmware for multiple heads.

|

Re: Large-scale 3d printer December 01, 2011 10:54AM |

Registered: 13 years ago Posts: 581 |

Martin, nobody said it can't be done, just that it it would be very hard to do well.

It is just as (if not more) important to point out all the pitfalls on a path than to just say go for it. If he doesn't have the level of skill and desire to continue given the very accurate warnings of others, then we saved him a lot of time. If he has said skills and desire, we simply gave him a list of challenges to overcome.

This is the patent I was referring to:

[www.google.com]

The other list that was linked is for current applications, not held patents.

I don't think they would do anything if you made yourself a machine with a heated chamber, but I would be cautious about posting too much about it. Patent infringement and enabling patent infringement are the topic of many lawsuits. Disclaimer: I don't know much of anything about law.

As for not needing a heated chamber for abs; I met the grassroots engineering guy, and got to look at the huge abs part he made. There are a number of sections which warped significantly. Also, hollow cylinders are about the the least warp prone parts around.

www.Fablicator.com

It is just as (if not more) important to point out all the pitfalls on a path than to just say go for it. If he doesn't have the level of skill and desire to continue given the very accurate warnings of others, then we saved him a lot of time. If he has said skills and desire, we simply gave him a list of challenges to overcome.

This is the patent I was referring to:

[www.google.com]

The other list that was linked is for current applications, not held patents.

I don't think they would do anything if you made yourself a machine with a heated chamber, but I would be cautious about posting too much about it. Patent infringement and enabling patent infringement are the topic of many lawsuits. Disclaimer: I don't know much of anything about law.

As for not needing a heated chamber for abs; I met the grassroots engineering guy, and got to look at the huge abs part he made. There are a number of sections which warped significantly. Also, hollow cylinders are about the the least warp prone parts around.

www.Fablicator.com

|

Re: Large-scale 3d printer December 01, 2011 01:22PM |

Registered: 12 years ago Posts: 29 |

Thanks, Andrew. That patent is difficult to follow. I have a hard time understanding how I would be violating a patent by enclosing my printer and heating it with some method. Not doubting you by any means, more just wondering if there is a legitimate way around that.

I want to bring support material and larger, faster prints to the community. I know I am new here, but I am quite skilled when it comes to innovating these types of things.

First things first though, I will get a Mendel/Prusa and start playing around there first. I actually have yet to even do any 3d prints at all

Andrew - I very much like your fablicator design. Which brand of aluminum extrusions are you using? Also, are you selling kits for this?

I want to bring support material and larger, faster prints to the community. I know I am new here, but I am quite skilled when it comes to innovating these types of things.

First things first though, I will get a Mendel/Prusa and start playing around there first. I actually have yet to even do any 3d prints at all

Andrew - I very much like your fablicator design. Which brand of aluminum extrusions are you using? Also, are you selling kits for this?

|

Re: Large-scale 3d printer December 01, 2011 01:44PM |

Registered: 13 years ago Posts: 581 |

In my opinion, the patent is extremely broad, and completely indefensible (and should not have been granted in the first place in my opinion)

Unfortunately it takes an army of lawyers to challenge any patent from a company like stratasys.

It does not say anything about how the chamber is heated and enclosed, only that the part is kept between the glass transition and stress relaxation temperatures. So it doesn't matter how you heat it, enclose it, etc. Anything which keeps the part area between ~70c and ~90C

is in violation. I've looked into this a lot, and it would be very beneficial to me to sell machines that use a heated chamber. Thus ends my rant.

Anyway...

I'm using 80/20, not selling kits, just complete printers. There are enough kits out there for the moment, and most of the cost is materials anyway.

www.Fablicator.com

Unfortunately it takes an army of lawyers to challenge any patent from a company like stratasys.

It does not say anything about how the chamber is heated and enclosed, only that the part is kept between the glass transition and stress relaxation temperatures. So it doesn't matter how you heat it, enclose it, etc. Anything which keeps the part area between ~70c and ~90C

is in violation. I've looked into this a lot, and it would be very beneficial to me to sell machines that use a heated chamber. Thus ends my rant.

Anyway...

I'm using 80/20, not selling kits, just complete printers. There are enough kits out there for the moment, and most of the cost is materials anyway.

www.Fablicator.com

|

Re: Large-scale 3d printer December 01, 2011 01:50PM |

Registered: 12 years ago Posts: 29 |

|

Re: Large-scale 3d printer December 01, 2011 08:19PM |

Registered: 15 years ago Posts: 59 |

You know, the STRATASYS link is a list of patent applications, not granted patents. Based on recent experience at my job, the patent office is making it a lot harder to get patents that are not very non-obvious.

Just because STRATASYS says that they want to patent it, does not mean that they will succeed.

You know, some of the ideas, like '20080317894' the extrusion tip cleaning assembly, sounds like something that was is on the mendel. Was it on the Darwin?

fdavies

Just because STRATASYS says that they want to patent it, does not mean that they will succeed.

You know, some of the ideas, like '20080317894' the extrusion tip cleaning assembly, sounds like something that was is on the mendel. Was it on the Darwin?

fdavies

|

Re: Large-scale 3d printer December 02, 2011 05:21AM |

Registered: 15 years ago Posts: 81 |

Here is one pretty large reprap that is at the printing stage:

[lebigrep.org]

The build volume is: 1000x1000x1700mm, whatever that is in quotation mark units ;-)

[lebigrep.org]

The build volume is: 1000x1000x1700mm, whatever that is in quotation mark units ;-)

|

Re: Large-scale 3d printer December 02, 2011 07:08AM |

Registered: 12 years ago Posts: 29 |

|

Re: Large-scale 3d printer December 02, 2011 03:58PM |

Registered: 13 years ago Posts: 601 |

I'm sure it CAN be done, but even if it does work exactly as it does at our small scale, the end result might not be worth it.

First issue is what your primary use would be. if you spend a lot of money building a big printer and only build reprap-sized objects, you've wasted a lot of money. If you have a design that cannot be printed on a reprap as it currently is, like a long tube, or skis, you can modify you printer to extend just one axis with less work, time, and money.

I don't know where/how he got his number (infill density, print speed) but Murd quotes 15 cm3 per hour on a mendel, so for the le BigRep, 66 hours to print 1m. A lot can happen in that time to mess up the print, And if you don't have a machine to recycle the plastic, it is a large investment of money, too. you will want to be absolutely certain it will work properly from start to finish.

Another problem is that you have to start taking into account gravity and object weight when designing objects. he says his mobius net print will be 12 lbs when completed!. Before i printed something that uses up >$100 of plastic, I'd want to do some sort of stress analysis on a design to make sure it won't break when used. dropping is even scarier, as I've had small pieces break when dropped.

Certainly there are some things that can only be built on a 3d printer, but i don't know if it's really within the 'hobbyist' scope (of skills, budget, time) of most users to go bigger, since it would take a large investment in time and money just to print, not to mention the time and money needed to design, build, and troubleshoot the machine.

But I know that big industry wants bigger printers (printing metal, mostly) so let them invest in R&D and we will eventually benefit form their research.

First issue is what your primary use would be. if you spend a lot of money building a big printer and only build reprap-sized objects, you've wasted a lot of money. If you have a design that cannot be printed on a reprap as it currently is, like a long tube, or skis, you can modify you printer to extend just one axis with less work, time, and money.

I don't know where/how he got his number (infill density, print speed) but Murd quotes 15 cm3 per hour on a mendel, so for the le BigRep, 66 hours to print 1m. A lot can happen in that time to mess up the print, And if you don't have a machine to recycle the plastic, it is a large investment of money, too. you will want to be absolutely certain it will work properly from start to finish.

Another problem is that you have to start taking into account gravity and object weight when designing objects. he says his mobius net print will be 12 lbs when completed!. Before i printed something that uses up >$100 of plastic, I'd want to do some sort of stress analysis on a design to make sure it won't break when used. dropping is even scarier, as I've had small pieces break when dropped.

Certainly there are some things that can only be built on a 3d printer, but i don't know if it's really within the 'hobbyist' scope (of skills, budget, time) of most users to go bigger, since it would take a large investment in time and money just to print, not to mention the time and money needed to design, build, and troubleshoot the machine.

But I know that big industry wants bigger printers (printing metal, mostly) so let them invest in R&D and we will eventually benefit form their research.

|

Re: Large-scale 3d printer December 02, 2011 09:37PM |

Registered: 12 years ago Posts: 141 |

|

Re: Large-scale 3d printer December 03, 2011 09:02PM |

Registered: 13 years ago Posts: 485 |

Parabolic Wrote:

-------------------------------------------------------

> ok - well how about "slightly" enlarging the prusa

> design? The build plate is roughly 9.5 inches -

> how about increasing that to 12 and scaling the

> machine accordingly - would it still work the

> same? Realistically, all that is is just longer

> rods - no?

These guys are selling printers with build platforms as large as 16"x16".

-------------------------------------------------------

> ok - well how about "slightly" enlarging the prusa

> design? The build plate is roughly 9.5 inches -

> how about increasing that to 12 and scaling the

> machine accordingly - would it still work the

> same? Realistically, all that is is just longer

> rods - no?

These guys are selling printers with build platforms as large as 16"x16".

|

Re: Large-scale 3d printer December 05, 2011 05:56PM |

Registered: 14 years ago Posts: 172 |

Andrew Diehl Wrote:

-------------------------------------------------------

> Also, somebody (I'm pretty sure it's Stratasys)

> has a patent for a method of keeping the stepper

> motors out of the heated chamber. Probably easy

> enough to skirt, but it's there nonetheless.

Not all Stratasys machines keep the steppers out of the heated chamber - my FDM 1600 has the entire X-Y stage including steppers inside the heated chamber. However, the chamber only goes to 70C - the big Fortus machines that can run higher temp plastics like Ultem 9085 keep the steppers out of the chamber and can go much higher on the chamber temperature.

[haveblue.org]

-------------------------------------------------------

> Also, somebody (I'm pretty sure it's Stratasys)

> has a patent for a method of keeping the stepper

> motors out of the heated chamber. Probably easy

> enough to skirt, but it's there nonetheless.

Not all Stratasys machines keep the steppers out of the heated chamber - my FDM 1600 has the entire X-Y stage including steppers inside the heated chamber. However, the chamber only goes to 70C - the big Fortus machines that can run higher temp plastics like Ultem 9085 keep the steppers out of the chamber and can go much higher on the chamber temperature.

[haveblue.org]

|

Re: Large-scale 3d printer December 14, 2011 07:22AM |

Registered: 12 years ago Posts: 49 |

|

Re: Large-scale 3d printer September 22, 2013 11:02AM |

Registered: 10 years ago Posts: 33 |

Hi asifjahmed

You can find large 3d printer of print size 400x400x300mm here

www.3dprintersonlinestore.com/mendel-max

You can find large 3d printer of print size 400x400x300mm here

www.3dprintersonlinestore.com/mendel-max

|

Re: Large-scale 3d printer September 22, 2013 12:33PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Large-scale 3d printer September 22, 2013 06:13PM |

Registered: 11 years ago Posts: 381 |

I'm currently in the design stage of building a large format printer. Like many have said, its not easy to do. It can be done though and I have seen it done well even without a heated build chamber. My design calls for one though but I just finished a printer that is a scaled up version of printrbots Simple platform. Mines called the Simple XL and it has about 8x11x12 inch platform. We have run into a good deal of resistance on certain larger prints. There are all kinds of techniques that can be used to help eliminate warping or cracking in those larger prints. We are well on our way to outfitting our Simple XL with a dual direct drive setup so we can print dissolvable supports as we have done with our printrbot plus that has dual extruders.

All of the mentioned potential issues brought up are valid but, they can be overcame. It won't be easy but don't let that stop you. I just address one issue at a time and move onto the next. I would post pics of the Simple XL but I can't on here due to size limitations. So if you want to check it out click on the link via my signature. It is updated regularly.

--------------| For Everything |--------------------------

Check it out here:

[reprapsquad.wordpress.com].

---------| For Everything Prototype Related |------

Now featuring comp case mods:

[RepRapLab.wordpress.com]

--------------| Find us at Twitter|------------------------

@REPRAPSQUAD (RS Main)

[mobile.twitter.com]

@REPRAPSQUADHQ (ProtoLab)

[mobile.twitter.com]

All of the mentioned potential issues brought up are valid but, they can be overcame. It won't be easy but don't let that stop you. I just address one issue at a time and move onto the next. I would post pics of the Simple XL but I can't on here due to size limitations. So if you want to check it out click on the link via my signature. It is updated regularly.

--------------| For Everything |--------------------------

Check it out here:

[reprapsquad.wordpress.com].

---------| For Everything Prototype Related |------

Now featuring comp case mods:

[RepRapLab.wordpress.com]

--------------| Find us at Twitter|------------------------

@REPRAPSQUAD (RS Main)

[mobile.twitter.com]

@REPRAPSQUADHQ (ProtoLab)

[mobile.twitter.com]

Sorry, only registered users may post in this forum.

That is ENORMOUS!!!!!!!!

That is ENORMOUS!!!!!!!!