Printing Metals

Posted by Mike L

|

Printing Metals January 01, 2012 01:22AM |

Registered: 12 years ago Posts: 3 |

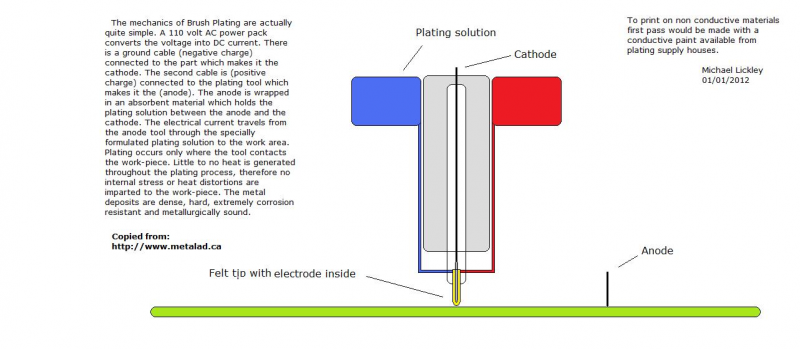

Hi I found reprap just a couple of weeks ago and I had an idea, it has probably already been tried but it should be almost easy to print metal by brush electroplating. I will attach a jpeg of my idea.

|

Re: Printing Metals January 01, 2012 02:04AM |

Registered: 13 years ago Posts: 226 |

That's quite an intriguing idea. I certainly haven't heard of anyone trying that in context of reprap.

What would the plating solution typically consist of? The wikipedia article on Electroplating says "Both components are immersed in a solution called an electrolyte containing one or more dissolved metal salts as well as other ions that permit the flow of electricity." - are these easy to come by do you know?

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

What would the plating solution typically consist of? The wikipedia article on Electroplating says "Both components are immersed in a solution called an electrolyte containing one or more dissolved metal salts as well as other ions that permit the flow of electricity." - are these easy to come by do you know?

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Printing Metals January 01, 2012 04:26AM |

Registered: 13 years ago Posts: 226 |

So, after a crash-course in electroplating thanks to Google and Youtube, I now know a little more

A couple of points I haven't yet been able to find out - to what extent can the plating process be layered? That is, does the newly plated part continue to act as a cathode, allowing incrementally more metal to build up? To what extent would the plate continue to be effective? Several millimeters or even centimeters?

Also, how quickly can the metal be deposited? From one youtube video I saw that the brush had an immediate effect but then he was applying it on the same spot for quite a while afterwards.

Certainly interesting - and it could be useful in the reprapability of circuits.

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

A couple of points I haven't yet been able to find out - to what extent can the plating process be layered? That is, does the newly plated part continue to act as a cathode, allowing incrementally more metal to build up? To what extent would the plate continue to be effective? Several millimeters or even centimeters?

Also, how quickly can the metal be deposited? From one youtube video I saw that the brush had an immediate effect but then he was applying it on the same spot for quite a while afterwards.

Certainly interesting - and it could be useful in the reprapability of circuits.

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Printing Metals January 01, 2012 05:18PM |

Registered: 12 years ago Posts: 3 |

|

Re: Printing Metals January 01, 2012 05:43PM |

Registered: 12 years ago Posts: 3 |

I myself do not have the means to do any hardware development (funds or facilities) nor have I ever used a plating system, however I infer the following based on a video / voice over from [www.caswellplating.com] .....Once a metal film has been deposited its thickness can be added to by more passes, the speed of the pass effects rate of deposition, other factors would be; contact patch size of the tip, thickness of felt between anode and cathode , voltage/current used, composition of cathode (purity of metal, size), rate of flow , temp and composition the solution.

|

Re: Printing Metals January 01, 2012 06:24PM |

Admin Registered: 16 years ago Posts: 13,886 |

... the plating process is extreme slow when measured in adding metal-thickness per time - you'll need hours to days and some kilo- to megawatts of energy to 'build' a usefull 3D-part

Much more common for 'metal-fabbing' is electro-eroding, where you remove metal with electrical discharging ... but too really time- and energy-consumpting ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Much more common for 'metal-fabbing' is electro-eroding, where you remove metal with electrical discharging ... but too really time- and energy-consumpting ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Printing Metals January 03, 2012 06:27AM |

Registered: 13 years ago Posts: 818 |

I spotted a UK company at a recent trade show that had an different Inkjet method of 3D printing that involved a subsequent post-process to make the parts 95% solid Titanium. ultra fine detail, stunning parts.

The parts on display were all less than 40mm but they all looked highly impressive.

[richrap.blogspot.com]

The parts on display were all less than 40mm but they all looked highly impressive.

[richrap.blogspot.com]

|

Re: Printing Metals January 03, 2012 11:43AM |

Registered: 13 years ago Posts: 601 |

|

Re: Printing Metals January 03, 2012 05:48PM |

Registered: 13 years ago Posts: 643 |

Maybe it could do overhangs. As drawn, its essentially a felt tip pen drawing plating solution onto the surface. You could run the edge of the tip around the work to print horizontally.

But, yes, very very slow, and the plating solutions are expensive. First hit I get quotes £12.75 for 250ml of copper - which, according to their calculator, gets you ~620mm^3 of plated copper. There are probably cheaper suppliers, particularly since we would be ordering in bulk, but I can't see this being economical.

But, yes, very very slow, and the plating solutions are expensive. First hit I get quotes £12.75 for 250ml of copper - which, according to their calculator, gets you ~620mm^3 of plated copper. There are probably cheaper suppliers, particularly since we would be ordering in bulk, but I can't see this being economical.

|

Re: Printing Metals January 07, 2012 06:17PM |

I have done a ton of research on this, which you can find on the wiki, just use the wiki index page and browse by materials,. then go to metals. Teh problem is internal stress/unequilibriated stress. Which means that the metal is being stretched in placves and compressed in other places, basically. Read about stress in welding, it's the same thing. Just read the stuff on the wiki and you will understand.

Probably the most promising method for low budget metal printing right now is to do the process at a very high temperature or to give it a stress relief bake afterwards. This is the only known way to deposit normal metal alloys with stresses in the range of normal manufactured metal goods.

To get both low stress and high accuracy like it5 you would have to invent something new. I bet it could be done but it would require substantial development.

Probably the most promising method for low budget metal printing right now is to do the process at a very high temperature or to give it a stress relief bake afterwards. This is the only known way to deposit normal metal alloys with stresses in the range of normal manufactured metal goods.

To get both low stress and high accuracy like it5 you would have to invent something new. I bet it could be done but it would require substantial development.

Sorry, only registered users may post in this forum.