Please help me finish my Longboat Prusa

Posted by gsport

|

Re: Please help me finish my Longboat Prusa March 04, 2012 09:11AM |

Hi guys,

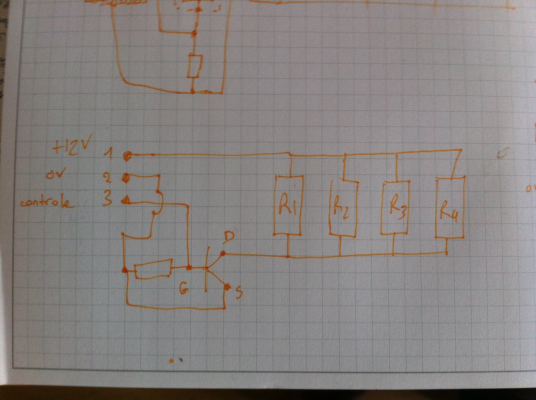

Unfortunately, I followed the instructions on the wiki and killed the transistor Q2 on the board. So it looks like I have to get away with the mosfet of the bed. I plugged the gate with the -V connector on the board (with spare stepper motor calbe). The drain is connected to the heating resistance which I connected on the other end to the +12V external power supply (with spare cable from the external power supply cause I guess lots of current will go through). Finally the Source is connected throught the 1M resistance to a black COM cable of my power supply (is that right or should I use the -12V?).

Does this seem right to you?

I plugged the reprap, moved the axis a bit but after a 20sec it wouldn't move anymore. I unplugged everything and noticed that the board was quite hot after only 20sec of plugging.

Something is going wrong and I am worried I'm going to damage something if I try again. I'll try to get a multimeter this afternoon but I don't know what to check. All this electronic is quite new and complex for me, I'm just a guy who wants to print stuff in 3D

<--Diagram

Thanks!

Unfortunately, I followed the instructions on the wiki and killed the transistor Q2 on the board. So it looks like I have to get away with the mosfet of the bed. I plugged the gate with the -V connector on the board (with spare stepper motor calbe). The drain is connected to the heating resistance which I connected on the other end to the +12V external power supply (with spare cable from the external power supply cause I guess lots of current will go through). Finally the Source is connected throught the 1M resistance to a black COM cable of my power supply (is that right or should I use the -12V?).

Does this seem right to you?

I plugged the reprap, moved the axis a bit but after a 20sec it wouldn't move anymore. I unplugged everything and noticed that the board was quite hot after only 20sec of plugging.

Something is going wrong and I am worried I'm going to damage something if I try again. I'll try to get a multimeter this afternoon but I don't know what to check. All this electronic is quite new and complex for me, I'm just a guy who wants to print stuff in 3D

<--Diagram

Thanks!

|

Re: Please help me finish my Longboat Prusa March 04, 2012 09:16AM |

Registered: 12 years ago Posts: 124 |

Thanks for the replies.

Might try the glass sometime, seems like I could leave the tape underneath so would be very quick and easy to try.

I was impatient last night and just turned it on and it seemed to dry out fine. Once the Kapton tape was on the bed the IR temp readings seemed good, seemed to match the readings pronterface was giving me within 2 or 3 degrees.

Unfortunately my prints totally failed. The extruder works fine if I just tell pronterface to extrude 5mm. 5mm gets fed in and a nice squirge comes out the bottom... however once the print starts it seems to just dither about with the extrusion motor and barely push any out. This bit it squirts out isnt sticking to the bed but just being dragged about and sticking to the hot tip of the hot end....

I assume that I really need to know the orifice size (just using 0.5mm for now but also tried 0.35 and 0.4) but I dont think I am that far off and dont understand why it is not extruding more vigorously...

Any help greatly appreciated.

George

Might try the glass sometime, seems like I could leave the tape underneath so would be very quick and easy to try.

I was impatient last night and just turned it on and it seemed to dry out fine. Once the Kapton tape was on the bed the IR temp readings seemed good, seemed to match the readings pronterface was giving me within 2 or 3 degrees.

Unfortunately my prints totally failed. The extruder works fine if I just tell pronterface to extrude 5mm. 5mm gets fed in and a nice squirge comes out the bottom... however once the print starts it seems to just dither about with the extrusion motor and barely push any out. This bit it squirts out isnt sticking to the bed but just being dragged about and sticking to the hot tip of the hot end....

I assume that I really need to know the orifice size (just using 0.5mm for now but also tried 0.35 and 0.4) but I dont think I am that far off and dont understand why it is not extruding more vigorously...

Any help greatly appreciated.

George

|

Re: Please help me finish my Longboat Prusa March 04, 2012 09:16AM |

Registered: 12 years ago Posts: 21 |

|

Re: Please help me finish my Longboat Prusa March 04, 2012 11:47AM |

Registered: 12 years ago Posts: 124 |

Made a crucial discovery. Turned out that my electronics were getting too hot. They really didnt seem that hot to the touch but I started getting weird shapes (rather than the circle I was printing) and on further investigation I found that the calibration seemed to have totally gone off (100mm of X feed was giving 70mm of movement and when set to home the carriage kept stopping as it obviously thought it should be about there when it was only half way back).

Anyway, long story short, I put a big fan on the electronics (on a separate power supply, putting it on the same PSU as the machine prevented the tip getting to temperature as the fan was obviously sucking a lot of the power).

Having thought I had made good progress I just tried to start a new print only for the tip to catch on the print bed tape and rip through it. I suspect that the aluminium bed is distorting quite a lot under heat... might try the glass sooner rather than later... Any tips on getting the tip height (zero z) just right? (the Longboat has a rigidly mounted bed rather than being on springs) Putting a straight edge across the bed diagonally is pretty depressing... it is a long way off flat even when cold. From "home" to the diagonally opposite corner the centre of the bed is down as much as 0.5mm. Putting the straight edge the other way (at 90 degrees to this) the centre is UP about the same amount!?!?!?

I will try measuring it "hot" once the new tape has dried and see what the change is.

George

Edited 1 time(s). Last edit at 03/04/2012 11:52AM by gsport.

Anyway, long story short, I put a big fan on the electronics (on a separate power supply, putting it on the same PSU as the machine prevented the tip getting to temperature as the fan was obviously sucking a lot of the power).

Having thought I had made good progress I just tried to start a new print only for the tip to catch on the print bed tape and rip through it. I suspect that the aluminium bed is distorting quite a lot under heat... might try the glass sooner rather than later... Any tips on getting the tip height (zero z) just right? (the Longboat has a rigidly mounted bed rather than being on springs) Putting a straight edge across the bed diagonally is pretty depressing... it is a long way off flat even when cold. From "home" to the diagonally opposite corner the centre of the bed is down as much as 0.5mm. Putting the straight edge the other way (at 90 degrees to this) the centre is UP about the same amount!?!?!?

I will try measuring it "hot" once the new tape has dried and see what the change is.

George

Edited 1 time(s). Last edit at 03/04/2012 11:52AM by gsport.

|

Re: Please help me finish my Longboat Prusa March 04, 2012 12:59PM |

Registered: 12 years ago Posts: 313 |

gsport Wrote:

-------------------------------------------------------

> Unfortunately my prints totally failed. The

> extruder works fine if I just tell pronterface to

> extrude 5mm. 5mm gets fed in and a nice squirge

> comes out the bottom... however once the print

> starts it seems to just dither about with the

> extrusion motor and barely push any out. This bit

> it squirts out isnt sticking to the bed but just

> being dragged about and sticking to the hot tip of

> the hot end....

That really sounds like your gcode generator is outputting relative extrusion distances but the firmware is expecting absolute ones.

-------------------------------------------------------

> Unfortunately my prints totally failed. The

> extruder works fine if I just tell pronterface to

> extrude 5mm. 5mm gets fed in and a nice squirge

> comes out the bottom... however once the print

> starts it seems to just dither about with the

> extrusion motor and barely push any out. This bit

> it squirts out isnt sticking to the bed but just

> being dragged about and sticking to the hot tip of

> the hot end....

That really sounds like your gcode generator is outputting relative extrusion distances but the firmware is expecting absolute ones.

|

Re: Please help me finish my Longboat Prusa March 04, 2012 01:49PM |

Registered: 12 years ago Posts: 82 |

The link below details the method I use to level, I also found it helpful to drill out the holes on the bottom aluminium sheet by 1 size so the bolts would move more freely.

Adrians Notes

Adrians Notes

|

Re: Please help me finish my Longboat Prusa March 04, 2012 02:03PM |

Registered: 12 years ago Posts: 22 |

Pierre, It sounds like your Pololu drivers are shutting down due to overheating (as are gsport's)

The 'official' way to calibrate them is here, but you can get close enough by just turning the pot anti-clockwise until the stepper motor stops turning, and then slowly turning it clockwise until the motor runs freely without skipping.

Your MOSFET diagram looks ok to me, but hopefully someone with more experience of interfacing to the Arduino will come along with some useful hints.

-Mark

The 'official' way to calibrate them is here, but you can get close enough by just turning the pot anti-clockwise until the stepper motor stops turning, and then slowly turning it clockwise until the motor runs freely without skipping.

Your MOSFET diagram looks ok to me, but hopefully someone with more experience of interfacing to the Arduino will come along with some useful hints.

-Mark

|

Re: Please help me finish my Longboat Prusa March 04, 2012 02:12PM |

Registered: 12 years ago Posts: 21 |

Thanks Mark.

I got the multimeter and was checking some voltage on the board when I accidentally touched something I shouldn't have with one of the tip (I think I touched simultaneously the +12v and the ground of the GPIO pins). My computer was instantly turned off. I disconnected everything right away. My computer's fine, it survived the chock but I was a bit scared.

Anyway, I decided to unmount the board and solder the initial transistor, unmount the bed and change the config to the one you indicated on the other thread. I'm leveling the thing again and hopefully will be able to run a first test in a moment.

I'll probably buy a heatsink for the board.

Anyway thank you.

Edited 1 time(s). Last edit at 03/04/2012 05:30PM by Pierre le vrai.

I got the multimeter and was checking some voltage on the board when I accidentally touched something I shouldn't have with one of the tip (I think I touched simultaneously the +12v and the ground of the GPIO pins). My computer was instantly turned off. I disconnected everything right away. My computer's fine, it survived the chock but I was a bit scared.

Anyway, I decided to unmount the board and solder the initial transistor, unmount the bed and change the config to the one you indicated on the other thread. I'm leveling the thing again and hopefully will be able to run a first test in a moment.

I'll probably buy a heatsink for the board.

Anyway thank you.

Edited 1 time(s). Last edit at 03/04/2012 05:30PM by Pierre le vrai.

|

Re: Please help me finish my Longboat Prusa March 04, 2012 03:15PM |

Registered: 12 years ago Posts: 21 |

So... It turns out that after that chock, no motor will run. The board could have been damaged. Using printerface, I can't move any axis. The thing is I still can connect, set temperature, heat the hot end and check it, this still works.

Do you think the board is useless? Is there a fuse or something like that?

I also noticed that before, the led would turn on when plugging the usb. Now it only turns on when power is on. And my computer can connect to the printer only when power is on.

Aarrrg. Any idea guys?

Do you think the board is useless? Is there a fuse or something like that?

I also noticed that before, the led would turn on when plugging the usb. Now it only turns on when power is on. And my computer can connect to the printer only when power is on.

Aarrrg. Any idea guys?

|

Re: Please help me finish my Longboat Prusa March 04, 2012 05:31PM |

Registered: 12 years ago Posts: 22 |

Hmm...

Reading the schematics, it looks like the LED is just connected directly to the +5V line which is also connected to the USB 5V, which is why it normally lights up.

If it's only lights up when you switch the main power on, that means that the 5V is only coming from the 12V->5V voltage regulator.

So I'd first check whether you've damaged the USB on your computer first, and whether the 5V line is still working.

Beyond that, I think you'll need to ask the experts on the Sanguino Electronics forum how to diagnose which other parts may have been damaged.

-Mark

Reading the schematics, it looks like the LED is just connected directly to the +5V line which is also connected to the USB 5V, which is why it normally lights up.

If it's only lights up when you switch the main power on, that means that the 5V is only coming from the 12V->5V voltage regulator.

So I'd first check whether you've damaged the USB on your computer first, and whether the 5V line is still working.

Beyond that, I think you'll need to ask the experts on the Sanguino Electronics forum how to diagnose which other parts may have been damaged.

-Mark

|

Re: Please help me finish my Longboat Prusa March 04, 2012 05:45PM |

Registered: 12 years ago Posts: 21 |

Hi Mark,

I think you got it right. I plugged the usb to my macbook and the led turned on. It means I damaged the PC I was using to command the reprap. I'm a bit skeptical about printing with my macbook after what happened to my pc.

I'll try to check on the internet if there is a way to repair the usb. Maybe a fuse in the computer. And I'll continue to check if there is something wrong with the rest of the board.

Pierre

I think you got it right. I plugged the usb to my macbook and the led turned on. It means I damaged the PC I was using to command the reprap. I'm a bit skeptical about printing with my macbook after what happened to my pc.

I'll try to check on the internet if there is a way to repair the usb. Maybe a fuse in the computer. And I'll continue to check if there is something wrong with the rest of the board.

Pierre

|

Re: Please help me finish my Longboat Prusa March 04, 2012 07:05PM |

Registered: 12 years ago Posts: 124 |

Well I switched to a glass bed after ripping two more layers of Kapton tape (for reasons that just dont make any sense; the tip was on it's second layer and was well clear yet still somehow managed to tear the tape in the shape of the perimeter of the part).

So far (three attempts at one layer each) the glass seems great, so thanks for the tip (the only glass I had was a piece of 1.7mm picture frame glass ?!?!?!)

My problem now seems to be keeping the heat in the hot end. The machine works great for about half the first layer (probably 2minutes or so) and then when it speeds up for the infill you can see the extruded string get thinner and thinner and the motor start struggling.

Should I have some sort of thermal paste between the block with the heater resistor and thermocouple in it? Should I try to insulate the outside? or should I just slow it down (though it is packing up while running at just 0.3 of the 45mm/sec it wants to do on the higher layers (reduced from 60!).

It seems to me like the hot end is underperforming by a massive margin rather than just a small margin ?!?!?

I used the "monitor printer" box on pronterface on this last print and put the temp up to 190. But it still seemed to be unable to keep up with the power requirements and the extruded string became very thin and the extruder started to skip on the first layer.... Pronterface was still claiming temps of 188 plus but there was no way this was the case inside the tip...

Any ideas?

George

Oh yes, and I turned all the pots down by about 20 degrees so thanks for that pointer too.

Edited 2 time(s). Last edit at 03/04/2012 07:42PM by gsport.

So far (three attempts at one layer each) the glass seems great, so thanks for the tip (the only glass I had was a piece of 1.7mm picture frame glass ?!?!?!)

My problem now seems to be keeping the heat in the hot end. The machine works great for about half the first layer (probably 2minutes or so) and then when it speeds up for the infill you can see the extruded string get thinner and thinner and the motor start struggling.

Should I have some sort of thermal paste between the block with the heater resistor and thermocouple in it? Should I try to insulate the outside? or should I just slow it down (though it is packing up while running at just 0.3 of the 45mm/sec it wants to do on the higher layers (reduced from 60!).

It seems to me like the hot end is underperforming by a massive margin rather than just a small margin ?!?!?

I used the "monitor printer" box on pronterface on this last print and put the temp up to 190. But it still seemed to be unable to keep up with the power requirements and the extruded string became very thin and the extruder started to skip on the first layer.... Pronterface was still claiming temps of 188 plus but there was no way this was the case inside the tip...

Any ideas?

George

Oh yes, and I turned all the pots down by about 20 degrees so thanks for that pointer too.

Edited 2 time(s). Last edit at 03/04/2012 07:42PM by gsport.

|

Re: Please help me finish my Longboat Prusa March 05, 2012 02:54AM |

Registered: 12 years ago Posts: 82 |

|

Re: Please help me finish my Longboat Prusa March 05, 2012 06:34AM |

Registered: 12 years ago Posts: 51 |

@Pierre If it helps I have on several occasions in the past short circuited something connected to USB on my macbook pro and there was an in-built cut-out in the OS which popped up a warning message and disabled the USB port until my next reboot. Can't comment on your diagram but I'm sure someone else will. Maybe check the Longboat wiki page?

@George

If your Kapton tape is ripping then either your print bed isn't level or, if you have checked this, then maybe your Z axis isn't calibrated (I use a piece of paper to check the gap is about 1-2 sheets from the bed in various locations). I suggest you get this resolved rather than switching to glass (which might mean your nozzle is touching the glass when it shouldn't be).

If your extruder is struggling, then things to check are:

1. That your current to your motors is about right.

2. That your hobbed bolt is not clogged with plastic. Take out the idler and spin it around to see if you can see visible plastic on the hobbed part. Then carefully remove it and don't damage the hobbed bit.

Regarding heat - your thermistor should be regulating heat. In the end I abandoned my thermistor table and used the default #1 thermistor in Sprinter instead. Using this, the best temperature so far for me is 220 degrees C. While my thermistor is the one from RS, all 100k thermistors should be very similar. Ps Faberdashery seem to recommend 210 degrees so I don't think I'm far out.

Regarding the rate of extrusion - Glyn is right that this needs calibrating. have you set your E steps per mm as outlined in Richaps slic3r guide? I think you'll end up in the 500-550 range for E-steps per mm once you calibrate it.

Edited 2 time(s). Last edit at 03/05/2012 01:12PM by another_reprapper.

@George

If your Kapton tape is ripping then either your print bed isn't level or, if you have checked this, then maybe your Z axis isn't calibrated (I use a piece of paper to check the gap is about 1-2 sheets from the bed in various locations). I suggest you get this resolved rather than switching to glass (which might mean your nozzle is touching the glass when it shouldn't be).

If your extruder is struggling, then things to check are:

1. That your current to your motors is about right.

2. That your hobbed bolt is not clogged with plastic. Take out the idler and spin it around to see if you can see visible plastic on the hobbed part. Then carefully remove it and don't damage the hobbed bit.

Regarding heat - your thermistor should be regulating heat. In the end I abandoned my thermistor table and used the default #1 thermistor in Sprinter instead. Using this, the best temperature so far for me is 220 degrees C. While my thermistor is the one from RS, all 100k thermistors should be very similar. Ps Faberdashery seem to recommend 210 degrees so I don't think I'm far out.

Regarding the rate of extrusion - Glyn is right that this needs calibrating. have you set your E steps per mm as outlined in Richaps slic3r guide? I think you'll end up in the 500-550 range for E-steps per mm once you calibrate it.

Edited 2 time(s). Last edit at 03/05/2012 01:12PM by another_reprapper.

|

Re: Please help me finish my Longboat Prusa March 05, 2012 08:25AM |

Registered: 12 years ago Posts: 124 |

Thanks Glyn and another reprapper.

Done the calibration and luckily for me it didnt need any adjustment from the stock value. Extruded 29.8mm with 30mm of feed which is within about the margin I can measure accurately so I left it.

It is also notable that everything works fine at first, what looks like the correct amount of material comes out and it feeds fine. It is only when the machine starts to speed up above about 10mm/sec that the issue arises.

My feeling is that the issue is with the conduction of heat between the block where the heater and (crucially) measurement are and the tip where we actually need the heat and would like to know the temperature. I think that some conductive medium at the thread might help this a lot, I have some actic silver and some normal silicone heat sink goo from PC processor mounting applications, but I wonder if they will be suitable at 200C when they are presumably designed for use below 100C.... ?? The Artic silver I have is the older ceramique which the website specifies is good between -150 and >180 for short term use and -150 -125 for "long term" use. Obviously >180 might mean 190-200 is OK, but what constitutes "long term" use etc....?

Also those temperatures you are using another reprapper seem very high, is that for ABS? I have been using (what Pronterface says is) 185 and 190 which seems sufficient to get a good flow, but maybe this is my problem.

Can people let me know what temp they use for PLA?

Thanks

George

PS the Kapton tape definitely ripped without the tip coming into direct contact with it, or even within 0.5mm... The Glass has really improved the flatness of the bed, might get some 6mm or so to further help this.

Edited 2 time(s). Last edit at 03/05/2012 08:32AM by gsport.

Done the calibration and luckily for me it didnt need any adjustment from the stock value. Extruded 29.8mm with 30mm of feed which is within about the margin I can measure accurately so I left it.

It is also notable that everything works fine at first, what looks like the correct amount of material comes out and it feeds fine. It is only when the machine starts to speed up above about 10mm/sec that the issue arises.

My feeling is that the issue is with the conduction of heat between the block where the heater and (crucially) measurement are and the tip where we actually need the heat and would like to know the temperature. I think that some conductive medium at the thread might help this a lot, I have some actic silver and some normal silicone heat sink goo from PC processor mounting applications, but I wonder if they will be suitable at 200C when they are presumably designed for use below 100C.... ?? The Artic silver I have is the older ceramique which the website specifies is good between -150 and >180 for short term use and -150 -125 for "long term" use. Obviously >180 might mean 190-200 is OK, but what constitutes "long term" use etc....?

Also those temperatures you are using another reprapper seem very high, is that for ABS? I have been using (what Pronterface says is) 185 and 190 which seems sufficient to get a good flow, but maybe this is my problem.

Can people let me know what temp they use for PLA?

Thanks

George

PS the Kapton tape definitely ripped without the tip coming into direct contact with it, or even within 0.5mm... The Glass has really improved the flatness of the bed, might get some 6mm or so to further help this.

Edited 2 time(s). Last edit at 03/05/2012 08:32AM by gsport.

|

Re: Please help me finish my Longboat Prusa March 05, 2012 10:05AM |

Registered: 12 years ago Posts: 124 |

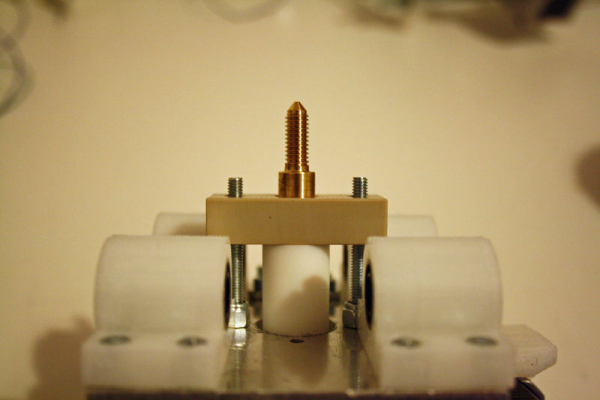

So I started taking my hot end apart to put thermal grease on the threads for the heater block and everything is in a very bad state:-

1. The thermistor has come free of the block (no biggie)

2. The heater resistor seems to be loose in the heater block, I think that there may not be much silicone holding it in but wont know for sure till it cools and I get it all apart, hopefully not a big deal.

3. Now the problem part. There was a small blob of PLA sticking out above the PEEK support block?!? Hey, how did that get there? Turns out that the threaded end of the teflon part has broken off?!?!?

George

1. The thermistor has come free of the block (no biggie)

2. The heater resistor seems to be loose in the heater block, I think that there may not be much silicone holding it in but wont know for sure till it cools and I get it all apart, hopefully not a big deal.

3. Now the problem part. There was a small blob of PLA sticking out above the PEEK support block?!? Hey, how did that get there? Turns out that the threaded end of the teflon part has broken off?!?!?

George

|

Re: Please help me finish my Longboat Prusa March 05, 2012 01:50PM |

Registered: 12 years ago Posts: 51 |

George

I think it is highly unlikely that there is a thermal transfer issue between your heater resistor and your hot end in the thread. The screw & thread design facilitates heat conduction and doesn't need any paste.

It does sound like a temperature problem but I think you need to increase your temperature to be near to 210-220 degrees C if you are using the supplied faberdashery PLA. Don't take my word for it, read what they say here: [forums.reprap.org]

I think it is likely that your PTFE insulator broke due to high pressure in the nozzle when you were extruding through the right amount of PLA but at too low a temperature.

My heater resistor came loose when I replaced the thermistor. I reset it back into place using Acc Silicoset 158 [uk.rs-online.com] which is supposed to go up to 300 degrees C.

My threaded end of the PTFE insulator also broke and I too had PLA coming out the top of the Peek block. I bought a new PTFE insulator to replace it. You'll need to replace yours too. This seems to be a common fault: [forums.reprap.org]

Maybe you could ask the rep rap kit store for a new PTFE nozzle insulator. Or give up on that design and buy your own hot end (there are other designs), maybe a J-head from hotends.com, or the groovemount design from makergear.com

But I am not in a position to advise which is best!

I think it is highly unlikely that there is a thermal transfer issue between your heater resistor and your hot end in the thread. The screw & thread design facilitates heat conduction and doesn't need any paste.

It does sound like a temperature problem but I think you need to increase your temperature to be near to 210-220 degrees C if you are using the supplied faberdashery PLA. Don't take my word for it, read what they say here: [forums.reprap.org]

I think it is likely that your PTFE insulator broke due to high pressure in the nozzle when you were extruding through the right amount of PLA but at too low a temperature.

My heater resistor came loose when I replaced the thermistor. I reset it back into place using Acc Silicoset 158 [uk.rs-online.com] which is supposed to go up to 300 degrees C.

My threaded end of the PTFE insulator also broke and I too had PLA coming out the top of the Peek block. I bought a new PTFE insulator to replace it. You'll need to replace yours too. This seems to be a common fault: [forums.reprap.org]

Maybe you could ask the rep rap kit store for a new PTFE nozzle insulator. Or give up on that design and buy your own hot end (there are other designs), maybe a J-head from hotends.com, or the groovemount design from makergear.com

But I am not in a position to advise which is best!

|

Re: Please help me finish my Longboat Prusa March 05, 2012 02:20PM |

Registered: 12 years ago Posts: 22 |

Hi George,

You are not alone, I also had the same happen to me after running the machine for an extended period of time.

I think the standard hotend really needs a heatsink or a fan.

I was able to salvage the nozzle by heating it up on the RepRap so it was just hot enough to soften the plastic, and then it could be removed easily with a pair of pliers and scraped out of the threads.

I replaced it with one of these, which is a direct drop in replacement, and have had no further problems. Unfortunately it looks like they are sold out at the moment.

-Mark

You are not alone, I also had the same happen to me after running the machine for an extended period of time.

I think the standard hotend really needs a heatsink or a fan.

I was able to salvage the nozzle by heating it up on the RepRap so it was just hot enough to soften the plastic, and then it could be removed easily with a pair of pliers and scraped out of the threads.

I replaced it with one of these, which is a direct drop in replacement, and have had no further problems. Unfortunately it looks like they are sold out at the moment.

-Mark

|

Re: Please help me finish my Longboat Prusa March 05, 2012 02:46PM |

Registered: 12 years ago Posts: 82 |

I had the same problem too. In my case I think the nuts came loose on the bolts which retain the PEEK block and the whole end moved towards the bed so the nozzle was blocked then causing pressure to build and break the PTFE at the screw/brass interface.

I managed to fix it by the following methods though.

1. Clean the brass of molten PLA by repeatedly heating it in a blowtorch then dunking in meths (obviously do this outside), this is really very effective at cleaning it up.

2. Managed to lathe the end of the PTFE (with my drill) and then screw it into the brass thread, did not cut a thread just self tapped it.

3. Replaced assembly and made sure PEEK block tight to the extruder and put on lock nuts to the bolts this time.

Working ok at the moment, touch wood.

I managed to fix it by the following methods though.

1. Clean the brass of molten PLA by repeatedly heating it in a blowtorch then dunking in meths (obviously do this outside), this is really very effective at cleaning it up.

2. Managed to lathe the end of the PTFE (with my drill) and then screw it into the brass thread, did not cut a thread just self tapped it.

3. Replaced assembly and made sure PEEK block tight to the extruder and put on lock nuts to the bolts this time.

Working ok at the moment, touch wood.

|

Re: Please help me finish my Longboat Prusa March 05, 2012 03:37PM |

Registered: 12 years ago Posts: 124 |

Thanks for all the help.

I wish I had known about the temperatures. I assumed that as it seemed to extrude well enough the default was working fine, when I did finally put it up to 190 I wasn't confident it wasn't too hot and it seemed "runnier" already. I am used to trying to keep the temps as low as possible and using more pressure to get better material properties....

I really dont understand what happened to mine, the thread seems to have broken in tension and the PTFE part was a fiendishly tight fit in the extruder body at the top so I can only assume that the nuts came loose and the whole thing got pushed down and the M8 (I assume, can anyone confirm this) PTFE thread was weaker than that super tight fit at the top (otherwise it could have simply dislodged itself at the top).

I have also found that my heater resistor has worked loose because it seems to have only had silicone at each end.

So I am going to try to get this working again and want to fix a few design flaws:-

1. (Once I get it apart) I am going to remove all the threads below the heater block so that they dont gum up with PLA and make disassembly a pain.

2. Why is the PTFE even threaded into the tip? Surely this has the potential to leave a small gap between the very end of the PTFE and the brass, if/when PLA works its way into this crack it will create a physical key to the body which seems bad. If I simply remove the threads and have a smooth connection it can fit completely flush on this surface (axially). This would also mean that the PTFE couldnt break under tension and would just pop out... Has anyone ever tried putting a viton O-ring in at this spot to try to prevent hot plastic working its way back up past the incoming stock?

3. I could possibly cut the brass tip off this extruder to give myself a nozzle with a male thread and make a new aluminium barrel (with a female nozzle thread) above with the heater resistor and thermocouple built directly in to give more accurate readings and allow easy cleaning (unscrew the tip, heat it up and extrude all the build up)? Though I worry slightly about the differential expansion between the brass and aluminium opening up a gap for the PLA to fill...

Do you think that I can get away with just shortening the existing PTFE part by the 6mm or so that I would need to modify it?

Any other ideas?

George

Edited 1 time(s). Last edit at 03/05/2012 03:38PM by gsport.

I wish I had known about the temperatures. I assumed that as it seemed to extrude well enough the default was working fine, when I did finally put it up to 190 I wasn't confident it wasn't too hot and it seemed "runnier" already. I am used to trying to keep the temps as low as possible and using more pressure to get better material properties....

I really dont understand what happened to mine, the thread seems to have broken in tension and the PTFE part was a fiendishly tight fit in the extruder body at the top so I can only assume that the nuts came loose and the whole thing got pushed down and the M8 (I assume, can anyone confirm this) PTFE thread was weaker than that super tight fit at the top (otherwise it could have simply dislodged itself at the top).

I have also found that my heater resistor has worked loose because it seems to have only had silicone at each end.

So I am going to try to get this working again and want to fix a few design flaws:-

1. (Once I get it apart) I am going to remove all the threads below the heater block so that they dont gum up with PLA and make disassembly a pain.

2. Why is the PTFE even threaded into the tip? Surely this has the potential to leave a small gap between the very end of the PTFE and the brass, if/when PLA works its way into this crack it will create a physical key to the body which seems bad. If I simply remove the threads and have a smooth connection it can fit completely flush on this surface (axially). This would also mean that the PTFE couldnt break under tension and would just pop out... Has anyone ever tried putting a viton O-ring in at this spot to try to prevent hot plastic working its way back up past the incoming stock?

3. I could possibly cut the brass tip off this extruder to give myself a nozzle with a male thread and make a new aluminium barrel (with a female nozzle thread) above with the heater resistor and thermocouple built directly in to give more accurate readings and allow easy cleaning (unscrew the tip, heat it up and extrude all the build up)? Though I worry slightly about the differential expansion between the brass and aluminium opening up a gap for the PLA to fill...

Do you think that I can get away with just shortening the existing PTFE part by the 6mm or so that I would need to modify it?

Any other ideas?

George

Edited 1 time(s). Last edit at 03/05/2012 03:38PM by gsport.

|

Re: Please help me finish my Longboat Prusa March 05, 2012 04:22PM |

Registered: 12 years ago Posts: 82 |

|

Re: Please help me finish my Longboat Prusa March 05, 2012 07:32PM |

Registered: 12 years ago Posts: 124 |

Thanks Glyn. So did you loose nearly 11mm of PTFE length? Presumably you had to trim the bolts?

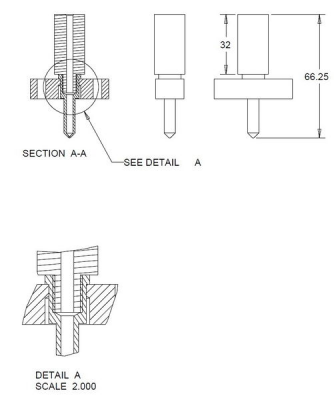

I took everything apart and made my best attempts to measure it all.

If anyone else is looking for this information:-

The hole in the tip appears to be nominally 0.5 though at heat I found it to be nearer 0.55 (hard to measure this accurately though).

Hole through PTFE section seems to be 3.4-3.5, but I found that the lower end of mine was alarmingly flared out to 4mm at the base. I have no way of knowing if it was like this from new, I suspect that it has deformed but the OD is fairly consistent.

The PTFE extends about 11mm (10.7mm) into the brass tip (M8 thread) Not really surprising that this breaks so easily when you consider that this is tantamount to a 3.4mm hole in a 6.5mm piece of stock, so 1.5mm wall thickness and a severe stress concentration factor.

Hole is brass tip is 3.4mm and extends to within 1.2mm of the end. (ie the 0.5mm hole is 1.2mm long).

I think I want to design a new hot end but if I do I will start a new thread...

Once again thanks for all the help.

George

I took everything apart and made my best attempts to measure it all.

If anyone else is looking for this information:-

The hole in the tip appears to be nominally 0.5 though at heat I found it to be nearer 0.55 (hard to measure this accurately though).

Hole through PTFE section seems to be 3.4-3.5, but I found that the lower end of mine was alarmingly flared out to 4mm at the base. I have no way of knowing if it was like this from new, I suspect that it has deformed but the OD is fairly consistent.

The PTFE extends about 11mm (10.7mm) into the brass tip (M8 thread) Not really surprising that this breaks so easily when you consider that this is tantamount to a 3.4mm hole in a 6.5mm piece of stock, so 1.5mm wall thickness and a severe stress concentration factor.

Hole is brass tip is 3.4mm and extends to within 1.2mm of the end. (ie the 0.5mm hole is 1.2mm long).

I think I want to design a new hot end but if I do I will start a new thread...

Once again thanks for all the help.

George

|

Re: Please help me finish my Longboat Prusa March 06, 2012 11:39AM |

Registered: 12 years ago Posts: 124 |

For anyone else who has (or is planning to buy this printer).

I now realise that my hot end failed (at least in part) because of a design flaw.

The counterbored part of the hole in the PEEK for the brass nozzle was much deeper than the lip on the nozzle itself and also a very tight fit. While the PTFE part was too large a diameter to fit inside the PEEK counterbore.

The result of this was that when assembled there was a 3mm gap between the brass nozzle and the step that should have supported it, so when hot the pressure of extrusion could push the brass part deeper into the PEEK component with the only support being the M8 thread on the end of the PTFE part. Additionally any gap between the tip of the PTFE and the brass would let melted PLA into this gap and put additional force on this junction.

I would suggest that anyone with this hot end who hasn't broken it yet take this apart and put a shoulder on the end of the PTFE just above the thread so that it can fit inside the PEEK. This will take the stress off that M8 thread and should prevent the issue that I (and others) have had.I will be doing this on my re-build.

George

I now realise that my hot end failed (at least in part) because of a design flaw.

The counterbored part of the hole in the PEEK for the brass nozzle was much deeper than the lip on the nozzle itself and also a very tight fit. While the PTFE part was too large a diameter to fit inside the PEEK counterbore.

The result of this was that when assembled there was a 3mm gap between the brass nozzle and the step that should have supported it, so when hot the pressure of extrusion could push the brass part deeper into the PEEK component with the only support being the M8 thread on the end of the PTFE part. Additionally any gap between the tip of the PTFE and the brass would let melted PLA into this gap and put additional force on this junction.

I would suggest that anyone with this hot end who hasn't broken it yet take this apart and put a shoulder on the end of the PTFE just above the thread so that it can fit inside the PEEK. This will take the stress off that M8 thread and should prevent the issue that I (and others) have had.I will be doing this on my re-build.

George

|

Re: Please help me finish my Longboat Prusa March 06, 2012 12:06PM |

Registered: 12 years ago Posts: 82 |

I did lose about 10mm from the PTFE part as I chopped it where the thread ended and I cut the bolts accordingly so I can unscrew the heater block without taking the whole extruder to bits.

You are dead right about the design flaw and when I re-made the end I reduced the size of the cylinder to fit into the PEEK block so it pressed right down to the shoulder I'm afraid I forgot about that part of the reconstruction.

I have just had to dissassemble my hot end as I had the same symptoms as you however I think my problem was due to a gunky build up of greenish PLA. It seems it must be reacting with the copper in the brass somehow.

Anyway cleaned the brass with the blowtorch/meths method, cut the thread on the PTFE so it fitted further into the brass re-assembled and seems ok again.

I think I read somewhere that you need to clean the nozzles occasionally looks like I will need to do it every 40mtrs of filament.

Edited 1 time(s). Last edit at 03/06/2012 01:53PM by glyn.

You are dead right about the design flaw and when I re-made the end I reduced the size of the cylinder to fit into the PEEK block so it pressed right down to the shoulder I'm afraid I forgot about that part of the reconstruction.

I have just had to dissassemble my hot end as I had the same symptoms as you however I think my problem was due to a gunky build up of greenish PLA. It seems it must be reacting with the copper in the brass somehow.

Anyway cleaned the brass with the blowtorch/meths method, cut the thread on the PTFE so it fitted further into the brass re-assembled and seems ok again.

I think I read somewhere that you need to clean the nozzles occasionally looks like I will need to do it every 40mtrs of filament.

Edited 1 time(s). Last edit at 03/06/2012 01:53PM by glyn.

|

Re: Please help me finish my Longboat Prusa March 06, 2012 02:31PM |

Registered: 12 years ago Posts: 22 |

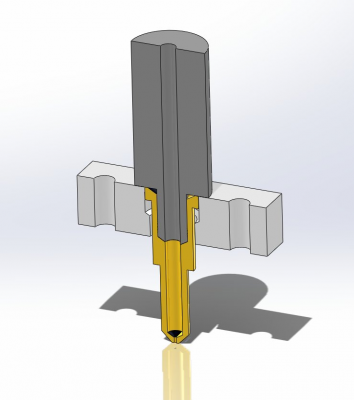

Interestingly this design shows it the 'correct' way around.

The photographs here, also show it correctly.

But it's obviously a major design flaw that the counterbore is the same diameter as the nozzle clamping flange.

It's far too easy to put it on the wrong way around.

-Mark

Edited 1 time(s). Last edit at 03/06/2012 02:36PM by Bloomoo.

The photographs here, also show it correctly.

But it's obviously a major design flaw that the counterbore is the same diameter as the nozzle clamping flange.

It's far too easy to put it on the wrong way around.

-Mark

Edited 1 time(s). Last edit at 03/06/2012 02:36PM by Bloomoo.

|

Re: Please help me finish my Longboat Prusa March 06, 2012 02:48PM |

Registered: 12 years ago Posts: 124 |

That is interesting. So the reprapkitstore obviously misunderstood this and changed a few dimensions.

In the instructions/wiki it is clearly shown the way I have it above

Also my image above is absolutely to scale and you can see that there is a big gap between the 9mm shaft of the nozzle below the lip and the 10mm clearance hole in the PEEK so assembling it the correct way round would lead to an incredibly loose fit with effectively no location.

George

Edited 1 time(s). Last edit at 03/06/2012 03:08PM by gsport.

In the instructions/wiki it is clearly shown the way I have it above

Also my image above is absolutely to scale and you can see that there is a big gap between the 9mm shaft of the nozzle below the lip and the 10mm clearance hole in the PEEK so assembling it the correct way round would lead to an incredibly loose fit with effectively no location.

George

Edited 1 time(s). Last edit at 03/06/2012 03:08PM by gsport.

|

Re: Please help me finish my Longboat Prusa March 08, 2012 03:05PM |

Registered: 13 years ago Posts: 98 |

|

Re: Please help me finish my Longboat Prusa March 09, 2012 07:19AM |

Registered: 12 years ago Posts: 124 |

So I fixed up my hot end which seems to work well now and re-calibrated the feed rate.

I realised that my Kapton tape ripped the first time because of course as the PTFE 8mm thread broke it let the tip move down to hit, but I am printing on glass now which does seem really good.

The problem I have now is that the outside perimeter of whatever I am printing "curls up", so as the layers lay down the tip starts rising up to ride over these bumps there is no such issue on the inside perimeter.

Any ideas? I was wondering if my temperature (205C with faberdashery 3mm PLA) is too high or low and the material is contracting soon after deposition and so creating a circumfrential tension that is pulling it up? Any ideas?

George

I realised that my Kapton tape ripped the first time because of course as the PTFE 8mm thread broke it let the tip move down to hit, but I am printing on glass now which does seem really good.

The problem I have now is that the outside perimeter of whatever I am printing "curls up", so as the layers lay down the tip starts rising up to ride over these bumps there is no such issue on the inside perimeter.

Any ideas? I was wondering if my temperature (205C with faberdashery 3mm PLA) is too high or low and the material is contracting soon after deposition and so creating a circumfrential tension that is pulling it up? Any ideas?

George

|

Re: Please help me finish my Longboat Prusa March 09, 2012 08:49AM |

Registered: 12 years ago Posts: 82 |

|

Re: Please help me finish my Longboat Prusa March 09, 2012 09:02AM |

Registered: 12 years ago Posts: 124 |

Sorry, only registered users may post in this forum.