Reprap-able generator: STL files included!

Posted by Gene Hacker

|

Reprap-able generator: STL files included! May 08, 2008 06:50PM |

Registered: 16 years ago Posts: 174 |

Check out this reprapable 3 phase alternator I made, I don't have a reprap so it hasn't been tested yet. It is fairly crude, but it should be able to generate electricity.

You need:

8 mm threaded rod nuts and washers

enamel coated copper wire, about 36 gauge should do

1 608 skate bearing, 8mm ID, 22 mm OD, cost $1.00

[www.skates.com]

8 9 mm diameter neodymium disc or ring magnets, cost $5.20

[www.supermagnetman.net]

Epoxy or glue

Power drill, optional, for winding coils

There are 3 files, the stator(where the coils go), the armature(alternator magnet 2), and the coil winding tool, which is optional if you want to wind them by hand.

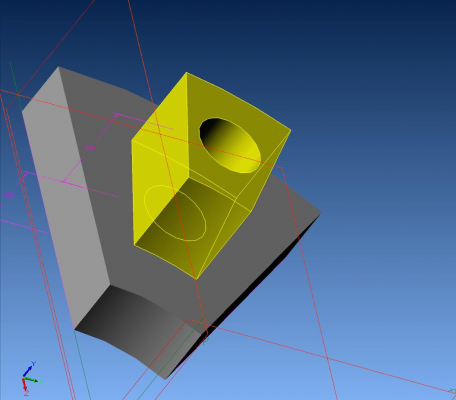

The coil winding tool: The coil winding tool connects to a power drill via a length of 8mm threaded rod held on to it by nuts. Wind a couple times by hand then use the power drill to wind the rest until the coil covers about as much area as the tool. Carefully feed the wire back and forth as not to have it cross over itself. Remember leave some wire with the insulation off so you can connect them! Wind 9 coils.

coilwinderforalternator.stl

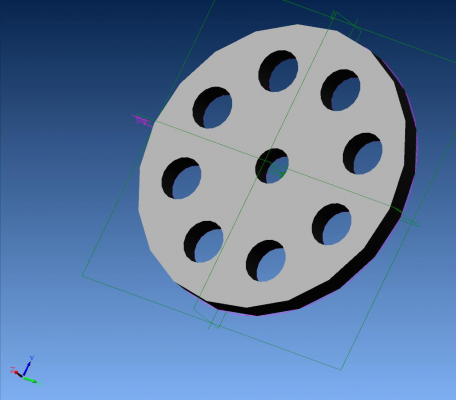

The stator: The hole in the center is where the skate bearing goes, screw some threaded rod in from one of the side holes to keep it in place. Next wind the coils, then put the threaded rod through the bearing. Then secure the threaded rod to the bearing with two nuts and two washers.

alternatorstator3.stl

You should wire the coils together as seen in steps 12 and 14: [www.instructables.com]

Or if you are familiar with alternators in wye configuration.

[www.tpub.com]

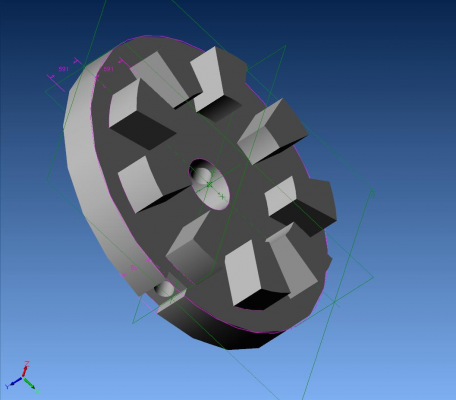

The armature: put magnets in holes with the poles n-s-n-s-n-s... configuration and glue them in with epoxy. Them attach the armature to the threaded rod of the stator using nuts. Adjust the armature so that it is as close to the coils as possible and can freely rotate.

Wind turbines anyone?

You need:

8 mm threaded rod nuts and washers

enamel coated copper wire, about 36 gauge should do

1 608 skate bearing, 8mm ID, 22 mm OD, cost $1.00

[www.skates.com]

8 9 mm diameter neodymium disc or ring magnets, cost $5.20

[www.supermagnetman.net]

Epoxy or glue

Power drill, optional, for winding coils

There are 3 files, the stator(where the coils go), the armature(alternator magnet 2), and the coil winding tool, which is optional if you want to wind them by hand.

The coil winding tool: The coil winding tool connects to a power drill via a length of 8mm threaded rod held on to it by nuts. Wind a couple times by hand then use the power drill to wind the rest until the coil covers about as much area as the tool. Carefully feed the wire back and forth as not to have it cross over itself. Remember leave some wire with the insulation off so you can connect them! Wind 9 coils.

coilwinderforalternator.stl

The stator: The hole in the center is where the skate bearing goes, screw some threaded rod in from one of the side holes to keep it in place. Next wind the coils, then put the threaded rod through the bearing. Then secure the threaded rod to the bearing with two nuts and two washers.

alternatorstator3.stl

You should wire the coils together as seen in steps 12 and 14: [www.instructables.com]

Or if you are familiar with alternators in wye configuration.

[www.tpub.com]

The armature: put magnets in holes with the poles n-s-n-s-n-s... configuration and glue them in with epoxy. Them attach the armature to the threaded rod of the stator using nuts. Adjust the armature so that it is as close to the coils as possible and can freely rotate.

Wind turbines anyone?

|

Re: Reprap-able generator: STL files included! May 08, 2008 06:57PM |

Registered: 16 years ago Posts: 174 |

|

Re: Reprap-able generator: STL files included! May 08, 2008 07:21PM |

Registered: 16 years ago Posts: 370 |

|

Re: Reprap-able generator: STL files included! May 10, 2008 11:55AM |

Registered: 16 years ago Posts: 622 |

That's pretty sweet. I'm giving serious thought to getting my RepStrap going this weekend on something other than parts for a darwin. Having a homemade alternator for a wind turbine would be about as Geek as I could get aside from making a computer and an operating system to run on it!

I've got a 1mm tip on my RS so the print would go really quickly and since the dimensions on this don't seem to be hugely important it could be a perfect fit for my machine.

Nice work

Demented

I've got a 1mm tip on my RS so the print would go really quickly and since the dimensions on this don't seem to be hugely important it could be a perfect fit for my machine.

Nice work

Demented

|

Re: Reprap-able generator: STL files included! May 11, 2008 01:18AM |

Registered: 16 years ago Posts: 174 |

I too am thinking of printing this, if I can get my repstrap to extrude something other than frosting...

Well, I have been contemplating steppers. I've been thinking something akin to a brushless motor, with coils on the inside and a bunch of magnets on the outside. 360 magnets, at one magnet per degree, which could be expensive. Well, it just so happens that they sell big sheets of the stuff they make fridge magnets out of, and the sheets are covered in an alternating N-S... pole arrangement that might be ideal for steppers.

Only problem with this sort of stepper is that it tends to be big and may require some changes in repraps parts.

Well, I have been contemplating steppers. I've been thinking something akin to a brushless motor, with coils on the inside and a bunch of magnets on the outside. 360 magnets, at one magnet per degree, which could be expensive. Well, it just so happens that they sell big sheets of the stuff they make fridge magnets out of, and the sheets are covered in an alternating N-S... pole arrangement that might be ideal for steppers.

Only problem with this sort of stepper is that it tends to be big and may require some changes in repraps parts.

|

Re: Reprap-able generator: STL files included! May 11, 2008 05:59AM |

|

Re: Reprap-able generator: STL files included! May 11, 2008 12:06PM |

Registered: 16 years ago Posts: 174 |

|

Re: Reprap-able generator: STL files included! May 11, 2008 03:36PM |

Admin Registered: 17 years ago Posts: 1,915 |

That's not all that hard. Most of the power in a Darwin is being used in the stepper motors. With the Keling that you can buy from rrrf.org, if I get it right, you rig that unipolar drive up in series to keep the amperage below 2 amps, which is the limit for the driver board, you get 1.5 amps per stepper. Now the z-axis should be cold most times, so it effectively uses no energy. The x and y, otoh, will draw 1.5amps x 2 steppers x 12 volts or 36 watts and should be running more or less continuously. Figure maybe 2 amps for the extruder heater for another 24 watts and maybe half an amp max for the extruder pump gearmotor so that's about another 6 watts.

Assume that the boards draw a negligible amount of amperage, which isn't a half bad thumb-suck.

You've got 6 + 24 + 36 = 66 watts total.

Your PC is going to be drawing maybe 5-10 times that amount. That bears some thinking about. I'm thinking about it very seriously right now as you can see in... [www.3dreplicators.com]

Edited 3 time(s). Last edit at 05/11/2008 03:39PM by Forrest Higgs.

Assume that the boards draw a negligible amount of amperage, which isn't a half bad thumb-suck.

You've got 6 + 24 + 36 = 66 watts total.

Your PC is going to be drawing maybe 5-10 times that amount. That bears some thinking about. I'm thinking about it very seriously right now as you can see in... [www.3dreplicators.com]

Edited 3 time(s). Last edit at 05/11/2008 03:39PM by Forrest Higgs.

|

Re: Reprap-able generator: STL files included! May 11, 2008 08:13PM |

Registered: 16 years ago Posts: 293 |

About the power consumption of RepRap:

I just used a watt meter to measure the actual consumption of the RepRap while powering 3 steppers (hold torque). It was about 50 watts then, but that was with other steppers scavenged from broken/outdated printers. Now I use the BitsFromBytes steppers that I've documented on the Wiki now. I'm running mine off 5 volts instead of 12 volts because of the low coil resistance of my steppers and the fact that I use PIC based electronics. This reduced the torque A LOT, but it was still enough to run everything. I get the impression that my steppers (from BitsFromBytes) are much over-powered but my PIC electronics are under-cooled to run them at 12 V. I'll re-measure its power consumption soon!

And now ON TOPIC:

Great work this generator. Would really like to see an actual build of it. I wonder Watt kind of power it can generate... We could RepRap things to attach to it as well but some shapes may be hard. A water wheel perhaps?

The inverse function of a generator is a motor. If we can build a generator, shouln't we also be able to make motors (to increase the replication fraction)?

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

I just used a watt meter to measure the actual consumption of the RepRap while powering 3 steppers (hold torque). It was about 50 watts then, but that was with other steppers scavenged from broken/outdated printers. Now I use the BitsFromBytes steppers that I've documented on the Wiki now. I'm running mine off 5 volts instead of 12 volts because of the low coil resistance of my steppers and the fact that I use PIC based electronics. This reduced the torque A LOT, but it was still enough to run everything. I get the impression that my steppers (from BitsFromBytes) are much over-powered but my PIC electronics are under-cooled to run them at 12 V. I'll re-measure its power consumption soon!

And now ON TOPIC:

Great work this generator. Would really like to see an actual build of it. I wonder Watt kind of power it can generate... We could RepRap things to attach to it as well but some shapes may be hard. A water wheel perhaps?

The inverse function of a generator is a motor. If we can build a generator, shouln't we also be able to make motors (to increase the replication fraction)?

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: Reprap-able generator: STL files included! May 11, 2008 11:13PM |

Registered: 16 years ago Posts: 235 |

I think that motors are more difficult than generators because they require a degree of precision. Technically, a bicycle computer is a generator. It has a single magnet passing by a tiny coil developing a charge. But if one were to charge the coil instead, they would find that this 'generator' of sorts would not work as a motor. Now this is an extremely warped example, and I am with you Erik, if we can build a generator, than why not a motor?

Jay

Jay

|

Re: Reprap-able generator: STL files included! May 12, 2008 11:23AM |

Registered: 16 years ago Posts: 174 |

|

Re: Reprap-able generator: STL files included! May 12, 2008 04:43PM |

Registered: 16 years ago Posts: 235 |

|

Anonymous User

Re: Reprap-able generator: STL files included! May 12, 2008 05:23PM |

Gene Hacker Wrote:

-------------------------------------------------------

> Well, I have been contemplating steppers. I've

> been thinking something akin to a brushless motor,

> with coils on the inside and a bunch of magnets on

> the outside. 360 magnets, at one magnet per

> degree, which could be expensive. Well, it just so

> happens that they sell big sheets of the stuff

> they make fridge magnets out of, and the sheets

> are covered in an alternating N-S... pole

> arrangement that might be ideal for steppers.

I just happen to have a roll of this material; it was left in my store stock room by a previous tenant. If you want a sample, I can send it to you if you're willing to pay the shipping. But the magnetic field is weak, so it might not work that well.

If might be better to not use permanent magnets; maybe go back to 19th century designs. Can an "air core" motor be build using reprapped plastic parts?

-------------------------------------------------------

> Well, I have been contemplating steppers. I've

> been thinking something akin to a brushless motor,

> with coils on the inside and a bunch of magnets on

> the outside. 360 magnets, at one magnet per

> degree, which could be expensive. Well, it just so

> happens that they sell big sheets of the stuff

> they make fridge magnets out of, and the sheets

> are covered in an alternating N-S... pole

> arrangement that might be ideal for steppers.

I just happen to have a roll of this material; it was left in my store stock room by a previous tenant. If you want a sample, I can send it to you if you're willing to pay the shipping. But the magnetic field is weak, so it might not work that well.

If might be better to not use permanent magnets; maybe go back to 19th century designs. Can an "air core" motor be build using reprapped plastic parts?

|

Anonymous User

Re: Reprap-able generator: STL files included! May 12, 2008 06:47PM |

I found a web mention of an air-core electric motor; it has a permanent magnet armature and stationary coils, with the benefit of being brushless. They seem to be being used primarily as meters on vehicle dashboards (not set up for full rotation). This might be due to a lack of power, or maybe just the momentum of engineering tradition.

Maybe the all-solenoid design would be best. As a child, I had an AFX slot-car set that had an interesting motor design; the motors laid flat in the car, connected to the wheels by a differential. The permanent magnets also pulled pulled the car to the tracks for fast turns. But the best part is that the motor was very flat, a design element that would make it quicker to crank out on a RepRap-type device. The AFX motor design could be modified to use all solenoids, since coils are easier to make in a small shop than magnets. Then again, small hobby magnets are pretty cheap so maybe a design could be worked out using stock magnets.

I found a page with pictures of the AFX motor and chassis:

[members.aol.com]

I've seen pictures of flat gear systems made in the RepRap, and I don't think that this is a big leap. With the current resolution, it might be better to make a slightly bigger motor.

Edited 1 time(s). Last edit at 05/12/2008 07:01PM by drvanthorp.

Maybe the all-solenoid design would be best. As a child, I had an AFX slot-car set that had an interesting motor design; the motors laid flat in the car, connected to the wheels by a differential. The permanent magnets also pulled pulled the car to the tracks for fast turns. But the best part is that the motor was very flat, a design element that would make it quicker to crank out on a RepRap-type device. The AFX motor design could be modified to use all solenoids, since coils are easier to make in a small shop than magnets. Then again, small hobby magnets are pretty cheap so maybe a design could be worked out using stock magnets.

I found a page with pictures of the AFX motor and chassis:

[members.aol.com]

I've seen pictures of flat gear systems made in the RepRap, and I don't think that this is a big leap. With the current resolution, it might be better to make a slightly bigger motor.

Edited 1 time(s). Last edit at 05/12/2008 07:01PM by drvanthorp.

|

Re: Reprap-able generator: STL files included! May 12, 2008 09:55PM |

Registered: 16 years ago Posts: 174 |

From what it seems, air core motor still require permanent magnets.

[www.mikesflightdeck.com]

Definately reprapable. Probably fairly accurate.

On eliminating magnets, variable reluctance stepper motors, have no permanent magnets. The only problem is they are weak, and require reprap to cut ferromagnetic metal sheets. So does reprap have a working milling head?

[www.allaboutcircuits.com]

[www.mikesflightdeck.com]

Definately reprapable. Probably fairly accurate.

On eliminating magnets, variable reluctance stepper motors, have no permanent magnets. The only problem is they are weak, and require reprap to cut ferromagnetic metal sheets. So does reprap have a working milling head?

[www.allaboutcircuits.com]

|

Re: Reprap-able generator: STL files included! May 14, 2008 12:14PM |

Registered: 16 years ago Posts: 622 |

|

Re: Reprap-able generator: STL files included! May 14, 2008 01:31PM |

Registered: 16 years ago Posts: 174 |

|

Re: Reprap-able generator: STL files included! May 14, 2008 05:46PM |

Registered: 16 years ago Posts: 235 |

|

Re: Reprap-able generator: STL files included! May 14, 2008 07:18PM |

Registered: 16 years ago Posts: 56 |

Well not exactly sure if it will help but ran across this website the other day. and it looks like they have a fairly wide range of magnets. [www.supermagnetman.net]

|

Re: Reprap-able generator: STL files included! May 14, 2008 07:27PM |

Registered: 16 years ago Posts: 370 |

redskinsjbs Wrote:

-------------------------------------------------------

> I don't know if the Darwin is rigid enough to hold

> a dremel. Is it is, you will have to go

> reeeeaaaaallll slow.

...or be making very very shallow cuts (like traces on a copper-clad board ).

).

I agree though, I suspect that the Darwin frame is simply not suitable for most milling operations. My guess is that you will be able to mill circuit boards, very soft wood, foam, and wax, but not much else. Remember also that Darwin isn't designed to handle the vibrations that come with having a tens-of-thousands RPM motor attached, and I suspect that those grub bolts will come loose pretty quickly. Precision is also an issue.

This is definitely something worth testing, however. *Adds to impossibly long list of things to do once I have a working RepRap*.

-------------------------------------------------------

> I don't know if the Darwin is rigid enough to hold

> a dremel. Is it is, you will have to go

> reeeeaaaaallll slow.

...or be making very very shallow cuts (like traces on a copper-clad board

).

).I agree though, I suspect that the Darwin frame is simply not suitable for most milling operations. My guess is that you will be able to mill circuit boards, very soft wood, foam, and wax, but not much else. Remember also that Darwin isn't designed to handle the vibrations that come with having a tens-of-thousands RPM motor attached, and I suspect that those grub bolts will come loose pretty quickly. Precision is also an issue.

This is definitely something worth testing, however. *Adds to impossibly long list of things to do once I have a working RepRap*.

|

Re: Reprap-able generator: STL files included! May 14, 2008 08:57PM |

Registered: 16 years ago Posts: 174 |

Since the milling head is pretty much nixed, why not use electrochemical machining? Where you cover the work piece in salt water hook it up to a positive electrode and move a small metal syringe shooting salt water hooked up to the negative electrode where you want to machine the work piece. It might be possible to replace the syringe with pencil lead in aquarium tubing, for cheapness.

[www.eod.gvsu.edu]

[www.indoor.flyer.co.uk]

[en.wikipedia.org]

[www.eod.gvsu.edu]

[www.indoor.flyer.co.uk]

[en.wikipedia.org]

|

Re: Reprap-able generator: STL files included! May 15, 2008 03:16AM |

Admin Registered: 16 years ago Posts: 13,884 |

... another problem with a dremel is the instability of the dremel itself ...

Here ( [forums.reprap.org] ) i atached a dremel to my CNC-mill and milled 3mm thick sheets of foamed plastic to stack them together to a 3D-object.

The body and mechanical setup of the CNC-mill is very rigid, but the dremel isn't, so the cutted surfaces weren't so excellent.

Another point is the massive out-wearing of the dremel-bearings when forced to move sideways - it went very loud after only one hour milling and i think it should break down after some hours continuous work.

With a real mill-head i have perfect surfaces and expect thousands hours of lifetime, but the millhead is much heavier then the dremel, so wouldn't fit to the normal reprap or repstrap ...

Viktor

Here ( [forums.reprap.org] ) i atached a dremel to my CNC-mill and milled 3mm thick sheets of foamed plastic to stack them together to a 3D-object.

The body and mechanical setup of the CNC-mill is very rigid, but the dremel isn't, so the cutted surfaces weren't so excellent.

Another point is the massive out-wearing of the dremel-bearings when forced to move sideways - it went very loud after only one hour milling and i think it should break down after some hours continuous work.

With a real mill-head i have perfect surfaces and expect thousands hours of lifetime, but the millhead is much heavier then the dremel, so wouldn't fit to the normal reprap or repstrap ...

Viktor

|

Re: Reprap-able generator: STL files included! May 15, 2008 05:14PM |

Registered: 16 years ago Posts: 113 |

|

Anonymous User

Re: Reprap-able generator: STL files included! May 16, 2008 12:52PM |

|

Re: Reprap-able generator: STL files included! May 16, 2008 03:35PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi drvanthorp,

... some years ago i tried with magnetic Neodymium-powder embedded in plastic - you need a very strong electro-magnet to orient the particles until the resin is hardened, but with a perfect setup you can achieve until 70% the strength of a normal Neodymium-magnet - eg. 0,8 Tesla max ...

In a `home-brewed' setup you can use other materials too - e.g. crush some magnetized ferrites to powder and mix it with 2K-epoxy.

I think with a good electromagnet and focussing poles you should be able to get until 3 Tesla of magentizing force (VAC in Hanau/Germany were magnetizing with 25 Tesla!), so it should be able to get some magnetic poles with magnetic saturation between 0,3 and 0,4 Tesla - a bit weak, but suitable for alternators and 'plastic-motors'.

For reluctance-systems you can use iron-powder in epoxy for reprapping or moulding the cores ...

Viktor

... some years ago i tried with magnetic Neodymium-powder embedded in plastic - you need a very strong electro-magnet to orient the particles until the resin is hardened, but with a perfect setup you can achieve until 70% the strength of a normal Neodymium-magnet - eg. 0,8 Tesla max ...

In a `home-brewed' setup you can use other materials too - e.g. crush some magnetized ferrites to powder and mix it with 2K-epoxy.

I think with a good electromagnet and focussing poles you should be able to get until 3 Tesla of magentizing force (VAC in Hanau/Germany were magnetizing with 25 Tesla!), so it should be able to get some magnetic poles with magnetic saturation between 0,3 and 0,4 Tesla - a bit weak, but suitable for alternators and 'plastic-motors'.

For reluctance-systems you can use iron-powder in epoxy for reprapping or moulding the cores ...

Viktor

|

Re: Reprap-able generator: STL files included! May 18, 2008 02:47PM |

Registered: 16 years ago Posts: 174 |

|

Re: Reprap-able generator: STL files included! May 18, 2008 04:11PM |

Admin Registered: 16 years ago Posts: 13,884 |

|

Re: Reprap-able generator: STL files included! May 18, 2008 04:48PM |

Registered: 16 years ago Posts: 370 |

VDX Wrote:

-------------------------------------------------------

> ... to much heat 'kills' all the magnetization, so

> you have to recrystallize the ferrites in a strong

> magnetic field to made it back ...

>

> Viktor

How does the strength of this field compare to the strength necessary to align the Neodymium-doped plastic you described above?

-------------------------------------------------------

> ... to much heat 'kills' all the magnetization, so

> you have to recrystallize the ferrites in a strong

> magnetic field to made it back ...

>

> Viktor

How does the strength of this field compare to the strength necessary to align the Neodymium-doped plastic you described above?

|

Re: Reprap-able generator: STL files included! May 18, 2008 05:14PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Kyle,

i didn't know it exactly, but think you must have nearly 6- to 10-fold the magnetization you want to receive in your part.

The only information i heard about high-definition-magnetisition at VAC: they used 25-Tesla-superconducting coils for magnetizing high-volume-NdFeB-Magnets with more then 1,4 Tesla. But this was the 'technology-border' some years ago, i think below 1 Tesla and for small volumes you can go with 3 to 5 Tesla, what's possible with normal electromagnets and focussing iron-poles ...

Viktor

i didn't know it exactly, but think you must have nearly 6- to 10-fold the magnetization you want to receive in your part.

The only information i heard about high-definition-magnetisition at VAC: they used 25-Tesla-superconducting coils for magnetizing high-volume-NdFeB-Magnets with more then 1,4 Tesla. But this was the 'technology-border' some years ago, i think below 1 Tesla and for small volumes you can go with 3 to 5 Tesla, what's possible with normal electromagnets and focussing iron-poles ...

Viktor

|

Re: Reprap-able generator: STL files included! September 11, 2008 12:09AM |

Sorry, only registered users may post in this forum.