Peltier heated bed

Posted by north90ty

|

Peltier heated bed February 25, 2012 12:38AM |

Registered: 13 years ago Posts: 50 |

I have been thinking about heating the printbed with Peltier elements ( http://en.wikipedia.org/wiki/Thermoelectric_effect) .

A peltier element gets hot on one side and cold on the other side when you apply some voltage over it. Normally they are used as cooling elements. They can produce more heat than you put power in it because they transport heat from the cold to the warm side. They are very compact and have large power in a small housing.

Did anybody try this before? what are the results?

i have a heated bed with peltiers almost ready to fire up.

A peltier element gets hot on one side and cold on the other side when you apply some voltage over it. Normally they are used as cooling elements. They can produce more heat than you put power in it because they transport heat from the cold to the warm side. They are very compact and have large power in a small housing.

Did anybody try this before? what are the results?

i have a heated bed with peltiers almost ready to fire up.

|

Re: Peltier heated bed February 25, 2012 01:28AM |

Registered: 12 years ago Posts: 229 |

It would be interesting if you could direct the hot and cold sides of a peltier to the hot and cold sides of a hotend.

I haven't tried these yet b/c they are either too expensive for the area they cover (heatbed) or the wrong shape / size (extruder).

I'd like to see your progress though!

I haven't tried these yet b/c they are either too expensive for the area they cover (heatbed) or the wrong shape / size (extruder).

I'd like to see your progress though!

|

Re: Peltier heated bed February 25, 2012 11:54AM |

Registered: 13 years ago Posts: 50 |

Peltiers are generally available in 20x20 up to 50x50mm and are about 3mm thick. For a hot-end it is a very ugly package, and they generally break down at those temperatures.

Another limiting factor is the maximum temperature difference between hot and cold side, which is about 70C.

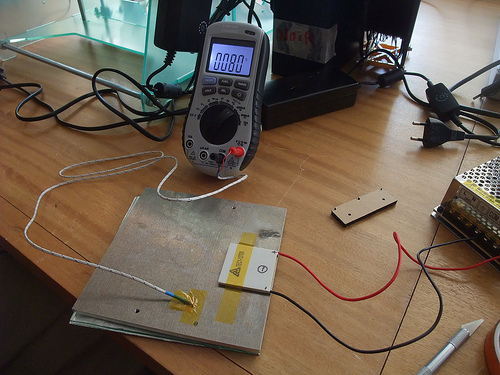

For the heated bed i placed the peltier (40x40mm) in the center of a 200x200mm aluminium bed of 5mm thick. I placed two peltiers on top of each other, running the "cold" one at 5v and the "hot" one at 12v. Hopefully the maximum temperature difference is now large enough to get the bed at 110C.

In theory the system could be used to "water"cool the steppers and use the heat generated by the steppers to heat the bed. Making a very efficient heated bed.

Another limiting factor is the maximum temperature difference between hot and cold side, which is about 70C.

For the heated bed i placed the peltier (40x40mm) in the center of a 200x200mm aluminium bed of 5mm thick. I placed two peltiers on top of each other, running the "cold" one at 5v and the "hot" one at 12v. Hopefully the maximum temperature difference is now large enough to get the bed at 110C.

In theory the system could be used to "water"cool the steppers and use the heat generated by the steppers to heat the bed. Making a very efficient heated bed.

|

Re: Peltier heated bed February 25, 2012 05:08PM |

Registered: 14 years ago Posts: 195 |

This came up a little while ago here. [forums.reprap.org]

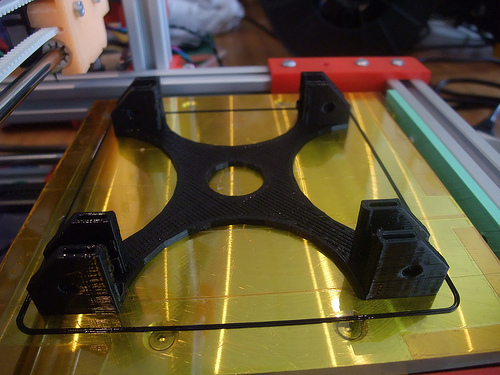

but since then I changed to a 5mm aluminum thick build surface, 50mm x 50mm module and I can hit 105o~110oC at 12V.

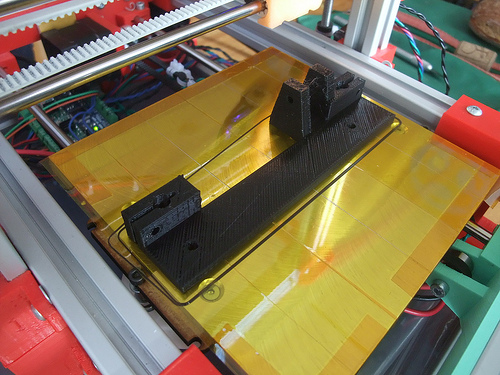

Attached are pics of how I crudely mounted the module.

but since then I changed to a 5mm aluminum thick build surface, 50mm x 50mm module and I can hit 105o~110oC at 12V.

Attached are pics of how I crudely mounted the module.

|

Re: Peltier heated bed February 25, 2012 11:14PM |

Registered: 14 years ago Posts: 800 |

i think the piece on the small end is going to need to be a little bigger, the heat is coming from the air, so i think your gonna want more surface area than that

[mike-mack.blogspot.com]

[mike-mack.blogspot.com]

|

Re: Peltier heated bed February 26, 2012 06:59AM |

Registered: 13 years ago Posts: 1,797 |

CdnReprap:

those pics are interesting. it would be nice to see a flir image on how heat is spread out in the aluminum over the entire bed, can you print parts that stick on the edges of the bed?

another thing, what does thermal shock do to the parts when the peltiers is reverse voltage? do you ever need to cool the bottom of the peltier, or in this case is it ok that the other side has no way to dissipate the heat and stay cool?

With the aluminum plate the peltier does seem more cost effective, but I would worry about heat spreading evenly. a flir camera would show the results as is.

possibly you would want to insulate the sides and bottom of aluminum to assure that the delta change in temperature equalizes throughout the entire plate.

how long does it take for the peltier bed to heat up. i have a resistor bed with 8ohm 20watt resistors in series that heats up in 8 minutes to 110c for example. does the peltier offer a benefit to heating times?

those pics are interesting. it would be nice to see a flir image on how heat is spread out in the aluminum over the entire bed, can you print parts that stick on the edges of the bed?

another thing, what does thermal shock do to the parts when the peltiers is reverse voltage? do you ever need to cool the bottom of the peltier, or in this case is it ok that the other side has no way to dissipate the heat and stay cool?

With the aluminum plate the peltier does seem more cost effective, but I would worry about heat spreading evenly. a flir camera would show the results as is.

possibly you would want to insulate the sides and bottom of aluminum to assure that the delta change in temperature equalizes throughout the entire plate.

how long does it take for the peltier bed to heat up. i have a resistor bed with 8ohm 20watt resistors in series that heats up in 8 minutes to 110c for example. does the peltier offer a benefit to heating times?

|

Re: Peltier heated bed February 26, 2012 02:58PM |

Registered: 14 years ago Posts: 195 |

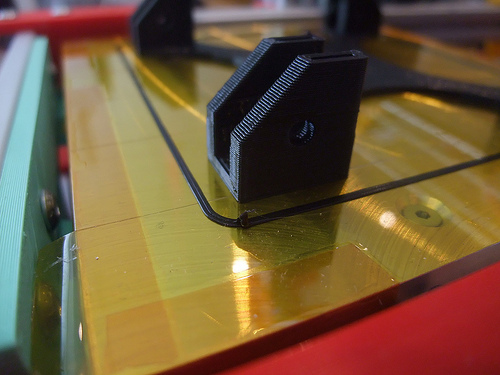

dissidence: I'm using it as a heater so I'm not concerned with the cold side, the small metal part is only holding the module onto the bed.

jamesdanielv: I don't have a flir cam but I'll take a few measurements around the bed with some thermocouples and pop back and share. I do print full trays with no issue using 3M projector transparencies.

I don't reverse the voltage because it would damage the module the way I have it setup. I would need to replace the small metal clamp with a heatsink in order to cool the bed. When I rigged that up I only wanted to heat it so I haven't tried cooling but if I ever make a chocolate printer that will be a feature.

The opposite side of the module stays cool.

I agree Insulation will definetly make an improvement but to be honest... when I slapped it together I was just rigging it up as a quick test and it worked just fine so I never took it off. never saw a reason to mess with it, but now that I have the bed off I might as well insulate it.

Warm up time is is probably 20 minutes or so..but I don't need to have and temp sensor or control circuit because it acts as a PTC heater.(self regulates)

power wise it needs 12v ~5A

jamesdanielv: I don't have a flir cam but I'll take a few measurements around the bed with some thermocouples and pop back and share. I do print full trays with no issue using 3M projector transparencies.

I don't reverse the voltage because it would damage the module the way I have it setup. I would need to replace the small metal clamp with a heatsink in order to cool the bed. When I rigged that up I only wanted to heat it so I haven't tried cooling but if I ever make a chocolate printer that will be a feature.

The opposite side of the module stays cool.

I agree Insulation will definetly make an improvement but to be honest... when I slapped it together I was just rigging it up as a quick test and it worked just fine so I never took it off. never saw a reason to mess with it, but now that I have the bed off I might as well insulate it.

Warm up time is is probably 20 minutes or so..but I don't need to have and temp sensor or control circuit because it acts as a PTC heater.(self regulates)

power wise it needs 12v ~5A

|

Re: Peltier heated bed February 27, 2012 11:54PM |

Registered: 13 years ago Posts: 50 |

@CdnReprap

That is great what you've been working on, you are really just using the peltier as an resistor (that is self regulating though)?

I tried to make a double stage and hopefully use the peltier effect.

Well my try was not a great success, the "hot" peltier runs cold at 12v 7amp, the cold one at 5v 2.5amp. Up to 65 degrees it all works good, the cold side is colder than room temperature and the heated bed warms up pretty quick (up to 65C in 10 minutes). But trying to run it any warmer doesn't really work, the "cold" side gets warm as well, which means that there is no "peltier" effect, meaning that i just run them as resistors. The maximum temperature i reached was 95C.

Also because i used 40x40mm peltiers, there is a severe temperature gradient over the bed (225X230mm). Pretty useless. I hoped that the 5mm aluminum would eventually warm up pretty evenly, but this doesn't seem to be the case.

That is great what you've been working on, you are really just using the peltier as an resistor (that is self regulating though)?

I tried to make a double stage and hopefully use the peltier effect.

Well my try was not a great success, the "hot" peltier runs cold at 12v 7amp, the cold one at 5v 2.5amp. Up to 65 degrees it all works good, the cold side is colder than room temperature and the heated bed warms up pretty quick (up to 65C in 10 minutes). But trying to run it any warmer doesn't really work, the "cold" side gets warm as well, which means that there is no "peltier" effect, meaning that i just run them as resistors. The maximum temperature i reached was 95C.

Also because i used 40x40mm peltiers, there is a severe temperature gradient over the bed (225X230mm). Pretty useless. I hoped that the 5mm aluminum would eventually warm up pretty evenly, but this doesn't seem to be the case.

|

Re: Peltier heated bed March 03, 2012 03:43PM |

Registered: 13 years ago Posts: 615 |

I love the apparent simplicity of your peltier-heated-bed !

Now I'm thinking to eventually use a similar heatbed for my experimental huxley, since the bed is 140x140mm one element is probably sufficient (and cheaper than the reprappro-pcb)

But I've two questions :

*you said it hit ~100°C at 12v, if we supply less voltage I suppose it heat less ? (for pla)

*I noted that you made your TEC yourself, do you think any similar peltier (12708) will work (e.g. this one is only rated to 3.9amps), or it is better to ask one from you ?

Now I'm thinking to eventually use a similar heatbed for my experimental huxley, since the bed is 140x140mm one element is probably sufficient (and cheaper than the reprappro-pcb)

But I've two questions :

*you said it hit ~100°C at 12v, if we supply less voltage I suppose it heat less ? (for pla)

*I noted that you made your TEC yourself, do you think any similar peltier (12708) will work (e.g. this one is only rated to 3.9amps), or it is better to ask one from you ?

|

Re: Peltier heated bed April 16, 2012 07:05PM |

Registered: 13 years ago Posts: 615 |

Yaaay ! My little 40x40mm element works great !

Not had printed on the bed yet, but the experience of this afternoon is positive : from 20°C to 50°C in few seconds for the element (I was a little scared at first), progressively warming the bed up to 80°C and probably more if I had left it more time (but I'll only need 60°c for pla ^^)

about // liberapay // flickr // wiki // thingiverse - github

Not had printed on the bed yet, but the experience of this afternoon is positive : from 20°C to 50°C in few seconds for the element (I was a little scared at first), progressively warming the bed up to 80°C and probably more if I had left it more time (but I'll only need 60°c for pla ^^)

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Peltier heated bed April 16, 2012 09:47PM |

Registered: 12 years ago Posts: 411 |

|

Re: Peltier heated bed April 17, 2012 09:01AM |

Registered: 13 years ago Posts: 615 |

I remember someone asking the same

In fact it's an Orca v030 made with 4mm acrylic, and modified for linear bearings ( [www.thingiverse.com] )

In fact it's an Orca v030 made with 4mm acrylic, and modified for linear bearings ( [www.thingiverse.com] )

|

Re: Peltier heated bed April 17, 2012 03:24PM |

Admin Registered: 17 years ago Posts: 177 |

Of course, it may also be possible to reverse the current and cool the bed when a print has finished to detach the printed parts by differential contraction. They could then simply be swept off the bed by lowering the X axis and then moving Y.

best wishes

Adrian

[reprap.org]

[reprapltd.com]

best wishes

Adrian

[reprap.org]

[reprapltd.com]

|

Re: Peltier heated bed April 21, 2012 05:24PM |

Registered: 13 years ago Posts: 615 |

|

Re: Peltier heated bed April 21, 2012 06:36PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Peltier heated bed April 21, 2012 09:14PM |

Registered: 14 years ago Posts: 195 |

|

Re: Peltier heated bed April 22, 2012 06:55AM |

Registered: 12 years ago Posts: 313 |

I'd love a Peltier-heated platform, I could print plastic and chocolate without swapping the build platform.

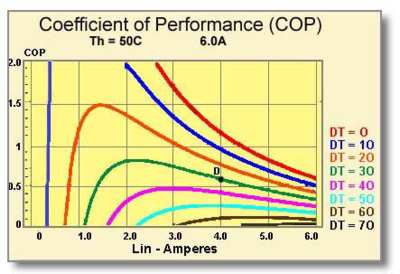

The heat sinks are a problem, though. Peltier element's CoP (coefficient of performance, which is the amount of transferred heat divided by the input power) drops dramatically as the temperature difference between the sides increases. In practice this means that the heat sink must be significantly better than 1 K/W, or the Peltier won't be doing almost any actual work except converting input power to heat. And heat sink like that, if air-cooled, is pretty big. I have built a couple of Peltier fridge projects and even for a 50-80 W Peltier, water cooling on the hot side is almost mandatory for getting good performance.

But here's an idea I just had: print a thin plastic piece containing water channels and sandwich that under the top build plate. Then pipe cold or hot water through it. I think I'll try that for the chocolate printing.

The heat sinks are a problem, though. Peltier element's CoP (coefficient of performance, which is the amount of transferred heat divided by the input power) drops dramatically as the temperature difference between the sides increases. In practice this means that the heat sink must be significantly better than 1 K/W, or the Peltier won't be doing almost any actual work except converting input power to heat. And heat sink like that, if air-cooled, is pretty big. I have built a couple of Peltier fridge projects and even for a 50-80 W Peltier, water cooling on the hot side is almost mandatory for getting good performance.

But here's an idea I just had: print a thin plastic piece containing water channels and sandwich that under the top build plate. Then pipe cold or hot water through it. I think I'll try that for the chocolate printing.

|

Re: Peltier heated bed April 27, 2012 11:46AM |

Registered: 12 years ago Posts: 45 |

|

Re: Peltier heated bed April 27, 2012 05:52PM |

Registered: 12 years ago Posts: 313 |

At 60C temperature differential the peltier element does pretty much no more useful work than a power resistor would. And this applies both to heating and cooling applications!

Stacking peltiers is a pretty esoteric configuration. Because the basic efficiency is pretty low, the second (and further) peltiers have to transfer the heat dumped by the first one and have their heat dumped forwards so efficiently that their performance doesn't go down the toilet.

Even in a single 50W element fridge setup, you have to dump the total heat (80W or so) with no more than 10C difference between the hot side and the ambient to avoid the efficiency plummeting. That's really hard to do with air cooling. (Which explains why the cheap and cheerful peltier travel fridges have afwul performance).

Stacking peltiers is a pretty esoteric configuration. Because the basic efficiency is pretty low, the second (and further) peltiers have to transfer the heat dumped by the first one and have their heat dumped forwards so efficiently that their performance doesn't go down the toilet.

Even in a single 50W element fridge setup, you have to dump the total heat (80W or so) with no more than 10C difference between the hot side and the ambient to avoid the efficiency plummeting. That's really hard to do with air cooling. (Which explains why the cheap and cheerful peltier travel fridges have afwul performance).

|

Re: Peltier heated bed April 27, 2012 07:19PM |

Registered: 12 years ago Posts: 72 |

ttsalo Wrote:

-------------------------------------------------------

> At 60C temperature differential the peltier

> element does pretty much no more useful work than

> a power resistor would. And this applies both to

> heating and cooling applications!

I disagree, for heating they are ideal.

Using either a reasonable size heatsink with fan on the cold side, (Or water-heating it to allow for a larger heatsink and less moving mass.) you not only have the pumped heat going into the heat-bed but you also have all of the electrical energy put into the peltier going towards the heating of the heat-bed.

-------------------------------------------------------

> At 60C temperature differential the peltier

> element does pretty much no more useful work than

> a power resistor would. And this applies both to

> heating and cooling applications!

I disagree, for heating they are ideal.

Using either a reasonable size heatsink with fan on the cold side, (Or water-heating it to allow for a larger heatsink and less moving mass.) you not only have the pumped heat going into the heat-bed but you also have all of the electrical energy put into the peltier going towards the heating of the heat-bed.

|

Re: Peltier heated bed April 30, 2012 12:16PM |

Registered: 12 years ago Posts: 313 |

Well, here's a performance graph from one manufacturer. (The ratio of pumped heat to input power)

We were talking about 60+ degree temperature differentials, in those conditions you only get at most 10% bonus from the Peltier effect compared to a power resistor. At a differential of 30 degrees or less, you can get a lot of useful work out of a Peltier, but not at 60.

We were talking about 60+ degree temperature differentials, in those conditions you only get at most 10% bonus from the Peltier effect compared to a power resistor. At a differential of 30 degrees or less, you can get a lot of useful work out of a Peltier, but not at 60.

|

Re: Peltier heated bed April 30, 2012 04:08PM |

Registered: 12 years ago Posts: 72 |

|

Re: Peltier heated bed May 14, 2012 04:50PM |

Registered: 13 years ago Posts: 615 |

Today I could test my peltier heated bed in normal use condition (i.e properly mounted, direct on a 6mm alu plate with heatsink compound, with insulation : [reprap.org], [reprap.org] and driven by the mainboard, that was my main concern because I failed to make it work previously due to an inadequate firmware)

And it seems to went from 20°C to 50-60°C in maybe 5 seconds... !

(I didn't measured the temp rise, but it quickly became too hot to keep touching the print surface)

yngndrw Wrote:

-------------------------------------------------------

> That's a fair point while it's at its final

> temperature, but when it starts heating from cold

> the temperature difference is going to be less.

> Therefore you should get a faster warm-up time and

> use less energy getting it up to temperature.

about // liberapay // flickr // wiki // thingiverse - github

And it seems to went from 20°C to 50-60°C in maybe 5 seconds... !

(I didn't measured the temp rise, but it quickly became too hot to keep touching the print surface)

yngndrw Wrote:

-------------------------------------------------------

> That's a fair point while it's at its final

> temperature, but when it starts heating from cold

> the temperature difference is going to be less.

> Therefore you should get a faster warm-up time and

> use less energy getting it up to temperature.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Peltier heated bed May 14, 2012 06:05PM |

Registered: 12 years ago Posts: 72 |

|

Re: Peltier heated bed May 16, 2012 08:37AM |

Registered: 13 years ago Posts: 615 |

|

Re: Peltier heated bed October 07, 2012 01:06PM |

Registered: 13 years ago Posts: 615 |

A little report on the peltier bed, it's still working fine !

I rarely use the full print surface, but recently I made some prints that can show that with a 4-5mm alu plate (140x140mm) the heat distribution is good even if the peltier is only 40x40mm : no curling.

A spool roller which is ~100x100mm

Or this 135mm wide part (foldarap-y-idler)

about // liberapay // flickr // wiki // thingiverse - github

I rarely use the full print surface, but recently I made some prints that can show that with a 4-5mm alu plate (140x140mm) the heat distribution is good even if the peltier is only 40x40mm : no curling.

A spool roller which is ~100x100mm

Or this 135mm wide part (foldarap-y-idler)

about // liberapay // flickr // wiki // thingiverse - github

|

Re: Peltier heated bed October 07, 2012 04:38PM |

Registered: 11 years ago Posts: 477 |

|

Re: Peltier heated bed October 07, 2012 05:16PM |

Registered: 13 years ago Posts: 615 |

|

Re: Peltier heated bed October 07, 2012 06:10PM |

Admin Registered: 15 years ago Posts: 1,470 |

xiando Wrote:

-------------------------------------------------------

> Peltiers are an impractical solution for the

> purpose described here (aside from cooling for the

> motors). Seeing that one of the goals of rerap is

> to reduce expense and system complexity, this

> seems a specious discussion.

Cheaper than using power resistors, easier than using nichrome wire, and far simpler than a PCB heater. How is it impractical? They are basically being used as thin power resistors, and do a better job of transferring heat to the build plate than power resistors because of the increased contact area.

-------------------------------------------------------

> Peltiers are an impractical solution for the

> purpose described here (aside from cooling for the

> motors). Seeing that one of the goals of rerap is

> to reduce expense and system complexity, this

> seems a specious discussion.

Cheaper than using power resistors, easier than using nichrome wire, and far simpler than a PCB heater. How is it impractical? They are basically being used as thin power resistors, and do a better job of transferring heat to the build plate than power resistors because of the increased contact area.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Peltier heated bed October 07, 2012 06:18PM |

Registered: 11 years ago Posts: 334 |

Even if there are other ways of achieving the same results, that doesn't mean having options is a bad idea. Considering the ease of using a peltier, it looks to be a viable option. It is also quite easy to use 2 of them to spread the heat more evenly over the print table without much extra work.

Sorry, only registered users may post in this forum.