Granule Extruder for large custom 3D printer

Posted by mattinv

|

Granule Extruder for large custom 3D printer March 03, 2012 01:24PM |

Registered: 12 years ago Posts: 4 |

Good morning everybody,

I'm currently working on the design of a rather large 3D printer, with a maximum budget of $3000-$3200. You can find a bunch of info on my work on this blog: [3dlargeprinter.blogspot.com]

I have been working trying to find a solution to the filament possibly getting stuck in the bowden tube, and the cost of the print when I will have to use 1.5-2.5 kg of filament. To solve the first issue, I could simply put the extruder on the gantry, like most Reprap. I opted for the Ultimaker design originally because I wanted to keep a light head, insuring accuracy and high speed. Since the gantry, in its current form, is very rigid and can handle quite a bit of weight, I started to explore this possibility.

I also looked at the cost of filament, and extruding your own is the only solution for cheap material... The problem seems to be that, if tolerances are not respected, the injection nozzle end up clogging up, and the extruder often fails to grab the filament.

So to solve both issues , the only solution is to mount the plastic extrusion mechanism and make it into a printing head. I looked at a few designs and articles.

[reprap.org]

[forums.reprap.org]

[reprap.org]

[forums.reprap.org]

[reprap.org]

[forums.reprap.org]

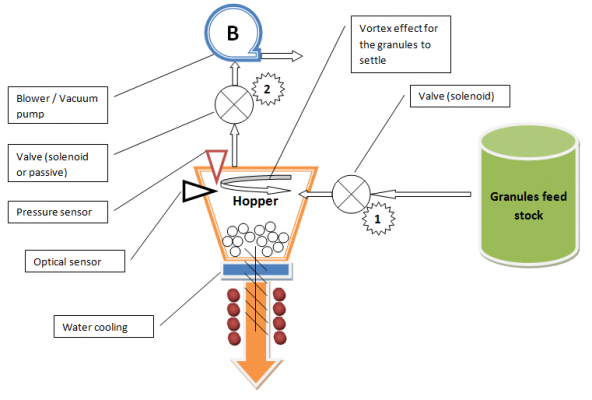

I just posted a version of a possible granule extruder and I was wondering what your thoughts were. I tried to use as many commonly available parts as possible.

I'm currently working on the design of a rather large 3D printer, with a maximum budget of $3000-$3200. You can find a bunch of info on my work on this blog: [3dlargeprinter.blogspot.com]

I have been working trying to find a solution to the filament possibly getting stuck in the bowden tube, and the cost of the print when I will have to use 1.5-2.5 kg of filament. To solve the first issue, I could simply put the extruder on the gantry, like most Reprap. I opted for the Ultimaker design originally because I wanted to keep a light head, insuring accuracy and high speed. Since the gantry, in its current form, is very rigid and can handle quite a bit of weight, I started to explore this possibility.

I also looked at the cost of filament, and extruding your own is the only solution for cheap material... The problem seems to be that, if tolerances are not respected, the injection nozzle end up clogging up, and the extruder often fails to grab the filament.

So to solve both issues , the only solution is to mount the plastic extrusion mechanism and make it into a printing head. I looked at a few designs and articles.

[reprap.org]

[forums.reprap.org]

[reprap.org]

[forums.reprap.org]

[reprap.org]

[forums.reprap.org]

I just posted a version of a possible granule extruder and I was wondering what your thoughts were. I tried to use as many commonly available parts as possible.

|

Re: Granule Extruder for large custom 3D printer March 03, 2012 03:53PM |

Registered: 13 years ago Posts: 226 |

Hi,

I don't know enough to comment on your design, but I will look forward to following your progress! Amongst the myriad things on my todo list is "build auger extruder" so i'm glad you're blogging what you're doing.

Cheers,

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

I don't know enough to comment on your design, but I will look forward to following your progress! Amongst the myriad things on my todo list is "build auger extruder" so i'm glad you're blogging what you're doing.

Cheers,

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Granule Extruder for large custom 3D printer March 03, 2012 05:40PM |

Registered: 15 years ago Posts: 376 |

Looks a neat design, there doesn't appear to be any flaws in your thinking from what I can see.

Have you done any trial feeding granules down a tube to replenish the hopper? I know this is quite difficult to do so this may be your main problem.

Powder and granules are sometimes transported using a fluid bed (Air pumped into the granules so they behave like a fluid) so this might be an option.

An alternative would be to monitor how much you are extruding, and at intervals return the head to a home position to fill the hopper from above using a simple chute and hinged door arrangement. It might be an idea to make sure the top of the granule hopper is free of any mechanism so you can implement this if you get issues.

Have you done any trial feeding granules down a tube to replenish the hopper? I know this is quite difficult to do so this may be your main problem.

Powder and granules are sometimes transported using a fluid bed (Air pumped into the granules so they behave like a fluid) so this might be an option.

An alternative would be to monitor how much you are extruding, and at intervals return the head to a home position to fill the hopper from above using a simple chute and hinged door arrangement. It might be an idea to make sure the top of the granule hopper is free of any mechanism so you can implement this if you get issues.

|

Re: Granule Extruder for large custom 3D printer March 03, 2012 10:34PM |

Registered: 12 years ago Posts: 4 |

|

Re: Granule Extruder for large custom 3D printer March 04, 2012 11:15AM |

Registered: 12 years ago Posts: 4 |

I update the blog with the principles of this new extruder concept.

Details on the working mechanisms on: [3dlargeprinter.blogspot.com]

Any feedback?

Details on the working mechanisms on: [3dlargeprinter.blogspot.com]

Any feedback?

|

Re: Granule Extruder for large custom 3D printer December 22, 2012 07:13PM |

Registered: 11 years ago Posts: 305 |

|

Re: Granule Extruder for large custom 3D printer December 22, 2012 09:58PM |

Registered: 11 years ago Posts: 143 |

You know what is sometimes really valuable?

Go to museum's that demonstrate technology from the 1800's and early 1900's and see how they used to make things back then.

A lot of really good mechanical idea's were thought of in those days because they didn't have software and computers to solve and fudge their mechanical issues.

Much of that stuff is forgotten these days because we've "evolved" beyond those designs, but the the truth is that we haven't really, we're just not looking at those idea's anymore. I get very inspired when I see how the "mechanical" age used to approach problems like this.

Jon

Go to museum's that demonstrate technology from the 1800's and early 1900's and see how they used to make things back then.

A lot of really good mechanical idea's were thought of in those days because they didn't have software and computers to solve and fudge their mechanical issues.

Much of that stuff is forgotten these days because we've "evolved" beyond those designs, but the the truth is that we haven't really, we're just not looking at those idea's anymore. I get very inspired when I see how the "mechanical" age used to approach problems like this.

Jon

|

Re: Granule Extruder for large custom 3D printer December 22, 2012 11:50PM |

Registered: 11 years ago Posts: 1,171 |

I love the idea of this. I think like many that the feeding of the auger would be the biggest hurdle. Might want to look into how injection molding machines do it.

I think a solid immobile head with a 3 axis bed would be a good way.

Just think, you only buy a bunch of natural material and then small amounts of pigment pellets and mix and match colors as you wish.

I think a solid immobile head with a 3 axis bed would be a good way.

Just think, you only buy a bunch of natural material and then small amounts of pigment pellets and mix and match colors as you wish.

|

Re: Granule Extruder for large custom 3D printer December 23, 2012 04:07AM |

Registered: 11 years ago Posts: 11 |

|

Re: Granule Extruder for large custom 3D printer June 15, 2013 10:06PM |

Sorry, only registered users may post in this forum.