Print quality on reprap vs commercial machine

Posted by Jeremy

|

Print quality on reprap vs commercial machine November 14, 2008 03:59PM |

While looking at pictures of objects printed with repstraps and commercial machines, I noticed a difference in the smoothness of the finish.

Objects printed with repstraps have visible layering on the sides, and noticeable holes on the top and/or bottom layers. When I looked at pictures of objects made from commercial machines, I noticed slight color differences between layers; however, it looked like a filled in, smooth, solid finish.

So my question is, why the difference? Is it the extrusion diameter and/or speed, a preference settings in the software, or resurfacing of the commercially printed objects?

Objects printed with repstraps have visible layering on the sides, and noticeable holes on the top and/or bottom layers. When I looked at pictures of objects made from commercial machines, I noticed slight color differences between layers; however, it looked like a filled in, smooth, solid finish.

So my question is, why the difference? Is it the extrusion diameter and/or speed, a preference settings in the software, or resurfacing of the commercially printed objects?

|

Re: Print quality on reprap vs commercial machine November 14, 2008 05:05PM |

Admin Registered: 17 years ago Posts: 7,879 |

It's mainly the filament diameter. Most people are working with 0.5mm to 0.8mm whereas commercial machines are about 0.25mm.

If you look at this object made on a commercial machine it doesn't look any better than objects I have made [www.cgl.uwaterloo.ca]

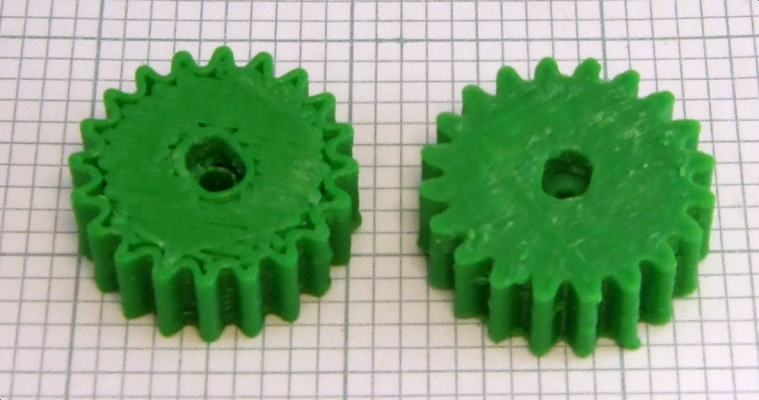

Here are two objects I made, one with 0.5mm and the other with 0.3mm filament.

I have a demo salt pot made on a commercial machine that looks very good but if you run your fingernail over it you can feel the ridges. There are also some gaps in the infill where it meets the holes.

[www.hydraraptor.blogspot.com]

If you look at this object made on a commercial machine it doesn't look any better than objects I have made [www.cgl.uwaterloo.ca]

Here are two objects I made, one with 0.5mm and the other with 0.3mm filament.

I have a demo salt pot made on a commercial machine that looks very good but if you run your fingernail over it you can feel the ridges. There are also some gaps in the infill where it meets the holes.

[www.hydraraptor.blogspot.com]

|

Re: Print quality on reprap vs commercial machine November 17, 2008 04:52PM |

|

Re: Print quality on reprap vs commercial machine November 17, 2008 05:03PM |

Admin Registered: 17 years ago Posts: 7,879 |

They are both printed with the same software. The problem with the first one is that the zigzag fill pattern cant reach into the teeth due to the width of the filament. This is not the usual case, most shapes get filled much better than that. The plastic flow rate was also a little lower than optimum.

Despite its looks, the object is still very strong and functional. Here is a gallery of all the things I have made using 0.5mm filament: [sites.google.com]. You will see that most objects have a better top surface.

Edited 1 time(s). Last edit at 11/17/2008 05:14PM by nophead.

[www.hydraraptor.blogspot.com]

Despite its looks, the object is still very strong and functional. Here is a gallery of all the things I have made using 0.5mm filament: [sites.google.com]. You will see that most objects have a better top surface.

Edited 1 time(s). Last edit at 11/17/2008 05:14PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Print quality on reprap vs commercial machine November 17, 2008 05:23PM |

Admin Registered: 16 years ago Posts: 13,886 |

... atached are two images of the salt-pot and a paperclip with support-layers made on a comercial machine.

AFAIK the best comercial FDM-heads output filament with diameter of 0,18 mm and i know there were some prototyping with 0,12mm.

With fluids and dispensers you can fab with smaller dots and trays - Objet can print 0,05mm blobs of UV-curable resins and some wax-inkjets are capable of 0,03mm droplets but only with extreme viscouse fluids (lower viscosity than water!).

For a special problem with an extreme high-viscous glue (>40000MPas, behaves like thick honey or tooth-paste) i developed a dipping dispenser but it's not fast enough for serious fabbing - see atached image "Folie3.jpg" - the droplets are 0,03mm in diameter, but with the special technique i can print much smaller than 0,01mm regardles of the viscosity!

Viktor

AFAIK the best comercial FDM-heads output filament with diameter of 0,18 mm and i know there were some prototyping with 0,12mm.

With fluids and dispensers you can fab with smaller dots and trays - Objet can print 0,05mm blobs of UV-curable resins and some wax-inkjets are capable of 0,03mm droplets but only with extreme viscouse fluids (lower viscosity than water!).

For a special problem with an extreme high-viscous glue (>40000MPas, behaves like thick honey or tooth-paste) i developed a dipping dispenser but it's not fast enough for serious fabbing - see atached image "Folie3.jpg" - the droplets are 0,03mm in diameter, but with the special technique i can print much smaller than 0,01mm regardles of the viscosity!

Viktor

|

Re: Print quality on reprap vs commercial machine November 17, 2008 05:37PM |

Admin Registered: 16 years ago Posts: 13,886 |

|

Re: Print quality on reprap vs commercial machine November 17, 2008 06:44PM |

Admin Registered: 17 years ago Posts: 7,879 |

The smallest drills I have are 0.3mm so I haven't tried anything less than that. The guys at Metalab use 0.3mm I think and have very good results.

I don't know what the maximum pressure is. I think the limit would be the plastic slipping by shearing the thread that the drive screw cuts. Certainly 0.3mm is no problem with ABS so I expect I could go smaller as long as I don't try to extrude too quickly.

As my machine has 0.006mm resolution it would be good fun to try making tiny objects with 0.1mm filament.

I am interested in paste dispensing for making surface mount circuits. Some pads are only about 0.25mm so it would need to be quite fine. I presume you can get syringe needles that fine?

[www.hydraraptor.blogspot.com]

I don't know what the maximum pressure is. I think the limit would be the plastic slipping by shearing the thread that the drive screw cuts. Certainly 0.3mm is no problem with ABS so I expect I could go smaller as long as I don't try to extrude too quickly.

As my machine has 0.006mm resolution it would be good fun to try making tiny objects with 0.1mm filament.

I am interested in paste dispensing for making surface mount circuits. Some pads are only about 0.25mm so it would need to be quite fine. I presume you can get syringe needles that fine?

[www.hydraraptor.blogspot.com]

|

Re: Print quality on reprap vs commercial machine November 17, 2008 09:37PM |

Admin Registered: 17 years ago Posts: 1,791 |

nophead,

Look for "Dispensing Needles", e.g.

$12 - 25ga x 1 1/2" dispensing needles (tips) - 100 Pack

(25 Gauge = ID inch:0.01 ~= .25 mm)

[shop.ebay.com]

This site is promising as well, they appear to have a variety of needle types,

{SS flexible, conical for solder dispensing, etc.}:

[www.dispensinglink.com]

(There seems to be a lot of literature and websites on paste dispensing and microdispensing; haven't read any of it. )

Keep us posted on how small you're able to go; I'm curious when we'll hit a wall with the RepRap extruder and have to switch over to inkjet heads, repurposed or purpose-made:

[www.microfab.com]

Wear eye protection or have a 'squirt screen' in place when squeezing fluids and pastes, by the way.

Look for "Dispensing Needles", e.g.

$12 - 25ga x 1 1/2" dispensing needles (tips) - 100 Pack

(25 Gauge = ID inch:0.01 ~= .25 mm)

[shop.ebay.com]

This site is promising as well, they appear to have a variety of needle types,

{SS flexible, conical for solder dispensing, etc.}:

[www.dispensinglink.com]

(There seems to be a lot of literature and websites on paste dispensing and microdispensing; haven't read any of it. )

Keep us posted on how small you're able to go; I'm curious when we'll hit a wall with the RepRap extruder and have to switch over to inkjet heads, repurposed or purpose-made:

[www.microfab.com]

Wear eye protection or have a 'squirt screen' in place when squeezing fluids and pastes, by the way.

|

Re: Print quality on reprap vs commercial machine November 18, 2008 03:23AM |

Admin Registered: 16 years ago Posts: 13,886 |

... the smallest needles i used were 0,1mm OD or 0,06mm ID for micro-vacuum-gripping.

AFAIK they're only usable for fluids like water or acetone ...

For paste i used needles with 0,15mm ID - but i had to shorten the length for constant flow or it would stall over (drying) time.

For the rudimentary specs of my Pico-dispenser you can look here: [depatisnet.dpma.de] - i used a kind of dipping needle with some tricky surface-tension effects - so i can place droplets as small as the needle-diameter (e.g. 5 microns or even smaller!)

Beside: - some gyus draw 20 nanometer thick traces with a 'wet AFM-needle' on a silizium-surface

Viktor

AFAIK they're only usable for fluids like water or acetone ...

For paste i used needles with 0,15mm ID - but i had to shorten the length for constant flow or it would stall over (drying) time.

For the rudimentary specs of my Pico-dispenser you can look here: [depatisnet.dpma.de] - i used a kind of dipping needle with some tricky surface-tension effects - so i can place droplets as small as the needle-diameter (e.g. 5 microns or even smaller!)

Beside: - some gyus draw 20 nanometer thick traces with a 'wet AFM-needle' on a silizium-surface

Viktor

|

Re: Print quality on reprap vs commercial machine November 18, 2008 02:51PM |

Nophead, looking at your gallery, I'm really impressed by the results. However, I did notice the same issue on your heart shaped box. The top layer does not fill all the way to the edge. I noticed is videos that the edges are "drawn" first then the insides are filled in. Does the software support putting a solid layer over the entire top, over lapping the edges? It would take cleaning up around the edge, but then you would end up with a total fill on the top layer.

Just by thoughts,

Jeremy

Just by thoughts,

Jeremy

|

Re: Print quality on reprap vs commercial machine November 18, 2008 03:31PM |

Admin Registered: 17 years ago Posts: 7,879 |

The top of the lid of the heart shaped box was actually the bottom when it was printed.

The infill plastic on the first layer doesn't meet the edge as well as it does on the top layer. I am not sure why actually. Commercial made objects show the same effect, although the newer machines seem to be a lot better. I think perhaps it is because the underside of the filament meets a cold surface and solidifies quickly in its cylindrical shape but the top of the filament is being pushed around by the hot nozzle so it loses it cylindrical shape and is smeared around into the corners.

A little more plastic on the first layer may make it look more like the last layer, but it may also make it harder to remove from the foundation raft. It needs a weak weld to the raft and this is achieved with a lower temperature and less squashing of the filament so that it stays cylindrical and so it only meets tangentially.

I don't think missing off the outline would be beneficial. It would just leave a ragged edge that would need cleaning up. You might as well just remove the bottom layer with a sander if you don't like the look of it. Quite often it is the bottom of the object so it doesn't really matter. It is only objects that are made upside down that you notice it.

[www.hydraraptor.blogspot.com]

The infill plastic on the first layer doesn't meet the edge as well as it does on the top layer. I am not sure why actually. Commercial made objects show the same effect, although the newer machines seem to be a lot better. I think perhaps it is because the underside of the filament meets a cold surface and solidifies quickly in its cylindrical shape but the top of the filament is being pushed around by the hot nozzle so it loses it cylindrical shape and is smeared around into the corners.

A little more plastic on the first layer may make it look more like the last layer, but it may also make it harder to remove from the foundation raft. It needs a weak weld to the raft and this is achieved with a lower temperature and less squashing of the filament so that it stays cylindrical and so it only meets tangentially.

I don't think missing off the outline would be beneficial. It would just leave a ragged edge that would need cleaning up. You might as well just remove the bottom layer with a sander if you don't like the look of it. Quite often it is the bottom of the object so it doesn't really matter. It is only objects that are made upside down that you notice it.

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.