Rack and Pinion for X-Axis

Posted by theodleif

|

Rack and Pinion for X-Axis April 25, 2012 02:11PM |

Registered: 13 years ago Posts: 1,918 |

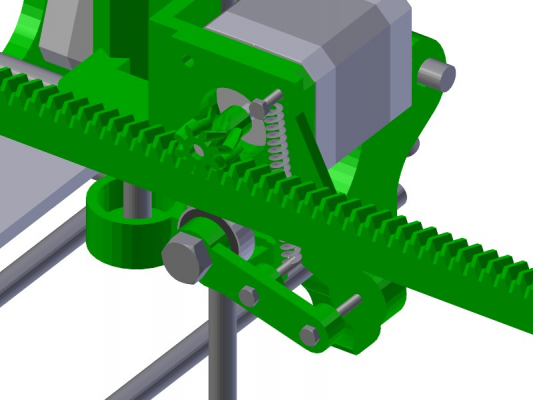

Based on [www.thingiverse.com] I built a replacement for the belt on the x-axis of my Prusa. As Triffid Hunter suggested in his comment, I used a small pinion instead of the big one.

The result looks like this:

Today I tested it:

I observed no backlash. Next I will replace the y-belt.

The result looks like this:

Today I tested it:

I observed no backlash. Next I will replace the y-belt.

|

Re: Rack and Pinion for X-Axis April 25, 2012 02:47PM |

Admin Registered: 15 years ago Posts: 1,470 |

Very nice! I imagine that it probably lowers your maximum speed and acceleration, does it not

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Rack and Pinion for X-Axis April 25, 2012 03:10PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis April 26, 2012 07:31PM |

Registered: 14 years ago Posts: 800 |

could a person try switching it to, m4 threaded rod to save on mass or is there another reason that you would want to use that heavy threaded rod still.?

[mike-mack.blogspot.com]

[mike-mack.blogspot.com]

|

Re: Rack and Pinion for X-Axis April 27, 2012 12:38AM |

Registered: 12 years ago Posts: 13 |

Very nice! I had been thinking about a rack and pinion for a little while. If the gear's teeth mesh with the rack well then there should be no backlash - but that will also depend I guess on the geometry of the teeth, moreso when you're going at very high speeds.

Unfortunately for me I'm getting in on RepRap a little later, and I'm still waiting on the rest of my parts to arrive before I can make one.

One thing that I was thinking about though is durability. I plan to maximize speed, accuracy, and repeatability with my machine, and so if at high speeds I'm wearing down a printed rack or gear really fast, then that would be a problem. Keep us updated! What's the maximum speed you can achieve reliably with your X axis now?

Unfortunately for me I'm getting in on RepRap a little later, and I'm still waiting on the rest of my parts to arrive before I can make one.

One thing that I was thinking about though is durability. I plan to maximize speed, accuracy, and repeatability with my machine, and so if at high speeds I'm wearing down a printed rack or gear really fast, then that would be a problem. Keep us updated! What's the maximum speed you can achieve reliably with your X axis now?

|

Re: Rack and Pinion for X-Axis April 27, 2012 01:39PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis April 27, 2012 03:42PM |

Registered: 13 years ago Posts: 1,918 |

dissidence Wrote:

-------------------------------------------------------

> could a person try switching it to, m4 threaded

> rod to save on mass or is there another reason

> that you would want to use that heavy threaded rod

> still.?

In rack_herringbone.scad, line 16 you find: innerRadius=3.1;//shaft radius, in mm.

Just change the radius to the value you need.

-------------------------------------------------------

> could a person try switching it to, m4 threaded

> rod to save on mass or is there another reason

> that you would want to use that heavy threaded rod

> still.?

In rack_herringbone.scad, line 16 you find: innerRadius=3.1;//shaft radius, in mm.

Just change the radius to the value you need.

|

Re: Rack and Pinion for X-Axis May 03, 2012 02:56PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis May 04, 2012 04:59AM |

Registered: 13 years ago Posts: 35 |

|

Re: Rack and Pinion for X-Axis May 04, 2012 09:51AM |

Registered: 13 years ago Posts: 601 |

I guess the next step in evolution would be to replace the rack with a rigid chain actuator, so that the footprint of the printer is the same as with belts.

|

Re: Rack and Pinion for X-Axis May 04, 2012 11:11AM |

Registered: 12 years ago Posts: 411 |

|

Re: Rack and Pinion for X-Axis May 04, 2012 12:07PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis May 04, 2012 12:17PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis May 04, 2012 02:15PM |

Registered: 11 years ago Posts: 8 |

amazing. as I said on thingiverse I'm very curious to see how this shapes up over extended use but not needing to buy belts is awesome. even if it wears down I'd rather print a new tooth bed than buy belts. for $16 you can print quite a few tooth beds and melt down the old abs into a rubber mold for re-use.

I can easily see a different printer design where the motor moves rather than the rack being a much closer basis for a fully printed printer minus electronis.

great work.

I can easily see a different printer design where the motor moves rather than the rack being a much closer basis for a fully printed printer minus electronis.

great work.

|

Re: Rack and Pinion for X-Axis May 06, 2012 09:37PM |

Registered: 12 years ago Posts: 58 |

|

Re: Rack and Pinion for X-Axis May 06, 2012 11:33PM |

Registered: 13 years ago Posts: 301 |

I had a design with the rack on the platform. [www.youtube.com]

It was setup where you could pull the platform all the way out which was pretty nice for access when removing prints.

It was setup where you could pull the platform all the way out which was pretty nice for access when removing prints.

|

Re: Rack and Pinion for X-Axis May 07, 2012 10:54PM |

Registered: 11 years ago Posts: 79 |

I can only offer a suggestion based on CNC lathe experience. I once tried to convert a lathe that used a rack and pinion drive. At first it was great, as the teeth wore the back lash became horrible. Hopefully the lack of load on the printer will make wear much less of an issue. Those appear to be square teeth, you should consider using an involute tooth. It will wear more even.

The solution I came up with was to use a spring loaded rubber coupling. Basically a tight fitting X coupling with rubber in the middle. The problem was the software had to account for it. It took to many steps to get it moving. And every direction switch required a pause to let the rubber decompress. The final solution ended up being a ball screw that was pretensioned. So a true 0 backlash system. The X coupling could work well for this and take some of the shock out of start and stops. Something like this. [www.lovejoy-inc.com]

The solution I came up with was to use a spring loaded rubber coupling. Basically a tight fitting X coupling with rubber in the middle. The problem was the software had to account for it. It took to many steps to get it moving. And every direction switch required a pause to let the rubber decompress. The final solution ended up being a ball screw that was pretensioned. So a true 0 backlash system. The X coupling could work well for this and take some of the shock out of start and stops. Something like this. [www.lovejoy-inc.com]

|

Re: Rack and Pinion for X-Axis August 25, 2012 03:53AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis October 21, 2012 01:40AM |

Registered: 12 years ago Posts: 539 |

|

Re: Rack and Pinion for X-Axis November 13, 2012 02:02AM |

Registered: 12 years ago Posts: 539 |

|

Re: Rack and Pinion for X-Axis November 14, 2012 11:13AM |

Registered: 14 years ago Posts: 65 |

Interesting thread as I found this Kickstarter offering their injection moulded printer using Rack & Pinion for X.

[www.kickstarter.com]

[www.kickstarter.com]

|

Re: Rack and Pinion for X-Axis November 14, 2012 11:34AM |

Registered: 13 years ago Posts: 1,918 |

|

Re: Rack and Pinion for X-Axis November 14, 2012 04:01PM |

Registered: 14 years ago Posts: 65 |

|

Re: Rack and Pinion for X-Axis November 14, 2012 08:17PM |

Registered: 12 years ago Posts: 156 |

Sorry, only registered users may post in this forum.