Tantillus portable 3D printer

Posted by Sublime

|

Re: Tantillus portable 3D printer May 17, 2012 09:18PM |

Registered: 12 years ago Posts: 411 |

Well hey Sublime, I think the Tantillus looks awesome! The build platform is a bit small for my uses, but I really like the attractive, compact design. It manages to be cool-looking and nerdy without looking like something that came out of a mad scientist's laboratory! I'm also curious about the cabling arrangement you've used for the motion. Looks pretty neat.

|

Re: Tantillus portable 3D printer May 17, 2012 09:35PM |

Registered: 13 years ago Posts: 2,947 |

Pointedstick Wrote:

-------------------------------------------------------

> Well hey Sublime, I think the Tantillus looks

> awesome! The build platform is a bit small for my

> uses, but I really like the attractive, compact

> design. It manages to be cool-looking and nerdy

> without looking like something that came out of a

> mad scientist's laboratory! I'm also curious about

> the cabling arrangement you've used for the

> motion. Looks pretty neat.

I will get some pictures and video up of the drive in a few days.

-------------------------------------------------------

> Well hey Sublime, I think the Tantillus looks

> awesome! The build platform is a bit small for my

> uses, but I really like the attractive, compact

> design. It manages to be cool-looking and nerdy

> without looking like something that came out of a

> mad scientist's laboratory! I'm also curious about

> the cabling arrangement you've used for the

> motion. Looks pretty neat.

I will get some pictures and video up of the drive in a few days.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 18, 2012 10:06AM |

Registered: 12 years ago Posts: 46 |

|

Re: Tantillus portable 3D printer May 18, 2012 01:24PM |

Registered: 13 years ago Posts: 2,947 |

It does use a standard laptop power supply that is plugged into a Q type connector on the back which can easily have a car adapter or flight adapter plugged into it.

The battery thing is an idea I would like to attempt but did not want to make any claims that I could not back up. There is just enough room inside still for a cordless drill battery which should be able to power it for a few hours on a full charge.

The battery thing is an idea I would like to attempt but did not want to make any claims that I could not back up. There is just enough room inside still for a cordless drill battery which should be able to power it for a few hours on a full charge.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 12:03AM |

Registered: 15 years ago Posts: 332 |

|

Re: Tantillus portable 3D printer May 19, 2012 12:13AM |

Registered: 13 years ago Posts: 301 |

|

Re: Tantillus portable 3D printer May 19, 2012 12:16AM |

Registered: 15 years ago Posts: 332 |

|

Re: Tantillus portable 3D printer May 19, 2012 12:17AM |

Registered: 12 years ago Posts: 58 |

Just wanted to chime in, I have seen the Tantillus printing, _and_ have designed my own printer that performs pretty well (see video at [youtu.be] , which also has my homebuilt CNC router and various other cool homebuilt tools), and I can say with no qualifications that the Tantillus beats my prusa based printer in almost every way you can measure, and if I was to redesign a new printer, it would be a similar Ultimaker/Tantillus style design. The lower flying mass of the tantillus extruder means much faster acceleration, but also way less vibration and overshoot. You know those weird "flying flag" irregularities you get on the side of a high speed print on a prusa? Gone on the tantillus for that reason. The stable cantilevered Z is a better design too IMHO. I cannot think of a way to get less moving mass in a 3d printer, while still maintaining accuracy.

Disclosure, I know Brad, and I cut his wooden Tantillus panels, but am also a raging egomaniac, so it ain't easy to admit that I got thoroughly out-engineered. Anyhow, the Tantillus is a solid printer, and the limited build area is just the result of being realistic about cooling deformation and build area. I have recommended it as a replacement for the Makerbot at our local Hackspace.

New Citadel Mendel

Our Maker Faire projects.

677 mm/s rapids.

Old Sherline/EMC2 first run.

Disclosure, I know Brad, and I cut his wooden Tantillus panels, but am also a raging egomaniac, so it ain't easy to admit that I got thoroughly out-engineered. Anyhow, the Tantillus is a solid printer, and the limited build area is just the result of being realistic about cooling deformation and build area. I have recommended it as a replacement for the Makerbot at our local Hackspace.

New Citadel Mendel

Our Maker Faire projects.

677 mm/s rapids.

Old Sherline/EMC2 first run.

|

Re: Tantillus portable 3D printer May 19, 2012 12:38AM |

Registered: 13 years ago Posts: 2,947 |

james glanville Wrote:

-------------------------------------------------------

> Just for the record, you say tantillus does 90mm/s

> hex infill, my prusa2 does 180 no problems, and i

> think I might get 250 eventually when I upgrade to

> better smooth rods, so that definitely isn't a

> selling point of tantillus.

It has the acceleration set at 9000mm/s^2 which is almost pulling 1g during acceleration.

The jerk is set at 20mm/s

Also the infill was set at 80% which means each hex is only about 1mm in diameter and the acceleration at 9000mm/s^2 means it is going back and forth like when trying to do infill in a narrow walled item. Feel free to try it out and you will see it is impossible to do on a machine with a moving extruder motor unless you have the acceleration lower which means it never reaches those speeds. You will also notice that the infill either will not touch the sides or causes bumps on the outside. But with Tantillus the quality at that speed is as good or better than the best tuned prusa at 30mm/s. I am not trying to put down any other machine but simply stating a fact about the moving mass. I love my prusa and still use it side by side with my Tantillus's. Another thing I will be posting pictures of very soon is the fact that you never get the resonance that leaves ghost lines after a bump like [www.thingiverse.com] demonstrates.

You will also notice in the video that the machine is not shaking and trying to jump off the table.

-------------------------------------------------------

> Just for the record, you say tantillus does 90mm/s

> hex infill, my prusa2 does 180 no problems, and i

> think I might get 250 eventually when I upgrade to

> better smooth rods, so that definitely isn't a

> selling point of tantillus.

It has the acceleration set at 9000mm/s^2 which is almost pulling 1g during acceleration.

The jerk is set at 20mm/s

Also the infill was set at 80% which means each hex is only about 1mm in diameter and the acceleration at 9000mm/s^2 means it is going back and forth like when trying to do infill in a narrow walled item. Feel free to try it out and you will see it is impossible to do on a machine with a moving extruder motor unless you have the acceleration lower which means it never reaches those speeds. You will also notice that the infill either will not touch the sides or causes bumps on the outside. But with Tantillus the quality at that speed is as good or better than the best tuned prusa at 30mm/s. I am not trying to put down any other machine but simply stating a fact about the moving mass. I love my prusa and still use it side by side with my Tantillus's. Another thing I will be posting pictures of very soon is the fact that you never get the resonance that leaves ghost lines after a bump like [www.thingiverse.com] demonstrates.

You will also notice in the video that the machine is not shaking and trying to jump off the table.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 01:11AM |

Registered: 13 years ago Posts: 2,947 |

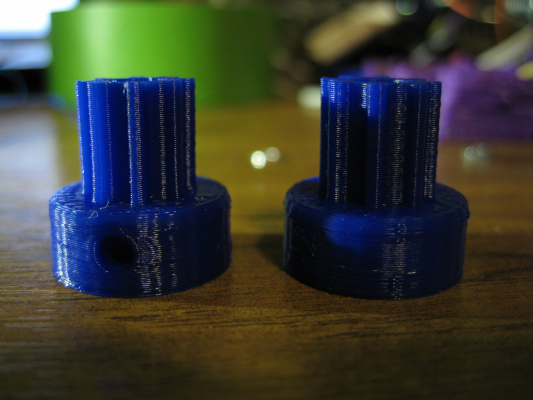

These are some parts I printed today to show the resonance effect.

Both are printed with the same PLA and with 0.5 nozzles. (the high frequency video is using a 0.35mm nozzle)

And like I said in the last post I am not putting down any of the other machines.

The effect you see on the Prusa printed parts are very minor and only visible when printing in dark solid colors. Also the effect is so small you can not feel it, but under some light you can see it.

Edited 1 time(s). Last edit at 05/19/2012 01:11AM by Sublime.

Both are printed with the same PLA and with 0.5 nozzles. (the high frequency video is using a 0.35mm nozzle)

And like I said in the last post I am not putting down any of the other machines.

The effect you see on the Prusa printed parts are very minor and only visible when printing in dark solid colors. Also the effect is so small you can not feel it, but under some light you can see it.

Edited 1 time(s). Last edit at 05/19/2012 01:11AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 01:47AM |

Registered: 12 years ago Posts: 72 |

|

Re: Tantillus portable 3D printer May 19, 2012 02:06AM |

Admin Registered: 12 years ago Posts: 819 |

Hi Sublime,

first of all thanks for your work - Tantillus just looks georgous and fits exactly into what i was looking for as a second printer. I will move to a new house some time next year and will have the prusa downstairs in the work room so i need a second one for my office upstairs I wanted to have something that is cased and small but still fun working with. Tantillus looks exactly what i need.

I wanted to have something that is cased and small but still fun working with. Tantillus looks exactly what i need.

I still have some spare parts from my prusa that i could use here, i have a arduino mega around and Pololu stepper drivers so not much needed.

Some questions left:

- What hotend are you using? have you planned to release different extruder versions for different hotends?

- you don't use a heated bed so far, do you? That was my prefered version also (PLA only)

- What power supply do you use? I read somewhere that its integrated.

- Is the electronic and cables somehow accessible for maintenance? i tbink about tuning stepper power...

you should have an option in your Indiegogo campaign to donate some money to get the files and details earlier

Thanks again for your good work - keep it up!

Frank

Frank

first of all thanks for your work - Tantillus just looks georgous and fits exactly into what i was looking for as a second printer. I will move to a new house some time next year and will have the prusa downstairs in the work room so i need a second one for my office upstairs

I wanted to have something that is cased and small but still fun working with. Tantillus looks exactly what i need.

I wanted to have something that is cased and small but still fun working with. Tantillus looks exactly what i need. I still have some spare parts from my prusa that i could use here, i have a arduino mega around and Pololu stepper drivers so not much needed.

Some questions left:

- What hotend are you using? have you planned to release different extruder versions for different hotends?

- you don't use a heated bed so far, do you? That was my prefered version also (PLA only)

- What power supply do you use? I read somewhere that its integrated.

- Is the electronic and cables somehow accessible for maintenance? i tbink about tuning stepper power...

you should have an option in your Indiegogo campaign to donate some money to get the files and details earlier

Thanks again for your good work - keep it up!

Frank

Frank

|

Re: Tantillus portable 3D printer May 19, 2012 02:51AM |

Registered: 13 years ago Posts: 2,947 |

Helmi Wrote:

-------------------------------------------------------

> I still have some spare parts from my prusa that i

> could use here, i have a arduino mega around and

> Pololu stepper drivers so not much needed.

>

> Some questions left:

>

> - What hotend are you using? have you planned to

> release different extruder versions for different

> hotends?

The kits have a J-head Mk-IV-B in both 0.5mm and 0.35mm. I suggest to run the 0.5 first as 0.35 is very easy to clog and requires you to have it perfectly calibrated.

Edit: I should add that it uses a groove mount so almost any groove mount hotend can be used the only thing that needs consideration is the length. It can be shorter than a J-head by about 20mm which would give it a build height of 120mm's but if it is any longer than a J-head it will reduce the build height.

> - you don't use a heated bed so far, do you? That

> was my prefered version also (PLA only)

I have built 7 different machines in the past 2 years and only one has a heated bed and that is the one I never use. I found that blue tape worked so well and the finish matches the sides far better than when printed on glass. But that is not to say I have not considered having heated beds made for Tantillus or just use a makerbot cupcake or thingomatic heated bed as it is the same size.

> - What power supply do you use? I read somewhere

> that its integrated.

It uses a laptop power supply rated at 90 watts (15v @ 5/6A) and is plugged into a Q-type power connector fitted in the back of the case. This allows you to use a cigarette lighter adapter to power it in a car, work van, RV, etc. And yeah back when the first pictures of the printed case were released a lot of speculation was made on things like batteries. Which are still possible as it has just enough space to fit a cordless drill battery in the bottom between the extruder, RAMPS board, LCD and Z motor.

> - Is the electronic and cables somehow accessible

> for maintenance? i tbink about tuning stepper

> power...

Yes the bottom is completely open on the laser cut case and the printed case should have a bottom which gets screwed to the lip in the bottom of the case. I installed the electronics in the printed case by screwing them to the bottom panel which is removable. The electronics are mounted to the left side panel of the laser cut case.

>

> you should have an option in your Indiegogo

> campaign to donate some money to get the files and

> details earlier

The case files are available already for everyone and the rest will only be 27 more days ( I do promise to release the files the day the campaign ends regardless of reaching the funding goal )

The files live [github.com]

>

> Thanks again for your good work - keep it up!

>

Thanks for the kind words. Be sure to look through my other github repos I have lots of cool stuff to print.

> Frank

Edited 1 time(s). Last edit at 05/19/2012 02:58AM by Sublime.

-------------------------------------------------------

> I still have some spare parts from my prusa that i

> could use here, i have a arduino mega around and

> Pololu stepper drivers so not much needed.

>

> Some questions left:

>

> - What hotend are you using? have you planned to

> release different extruder versions for different

> hotends?

The kits have a J-head Mk-IV-B in both 0.5mm and 0.35mm. I suggest to run the 0.5 first as 0.35 is very easy to clog and requires you to have it perfectly calibrated.

Edit: I should add that it uses a groove mount so almost any groove mount hotend can be used the only thing that needs consideration is the length. It can be shorter than a J-head by about 20mm which would give it a build height of 120mm's but if it is any longer than a J-head it will reduce the build height.

> - you don't use a heated bed so far, do you? That

> was my prefered version also (PLA only)

I have built 7 different machines in the past 2 years and only one has a heated bed and that is the one I never use. I found that blue tape worked so well and the finish matches the sides far better than when printed on glass. But that is not to say I have not considered having heated beds made for Tantillus or just use a makerbot cupcake or thingomatic heated bed as it is the same size.

> - What power supply do you use? I read somewhere

> that its integrated.

It uses a laptop power supply rated at 90 watts (15v @ 5/6A) and is plugged into a Q-type power connector fitted in the back of the case. This allows you to use a cigarette lighter adapter to power it in a car, work van, RV, etc. And yeah back when the first pictures of the printed case were released a lot of speculation was made on things like batteries. Which are still possible as it has just enough space to fit a cordless drill battery in the bottom between the extruder, RAMPS board, LCD and Z motor.

> - Is the electronic and cables somehow accessible

> for maintenance? i tbink about tuning stepper

> power...

Yes the bottom is completely open on the laser cut case and the printed case should have a bottom which gets screwed to the lip in the bottom of the case. I installed the electronics in the printed case by screwing them to the bottom panel which is removable. The electronics are mounted to the left side panel of the laser cut case.

>

> you should have an option in your Indiegogo

> campaign to donate some money to get the files and

> details earlier

The case files are available already for everyone and the rest will only be 27 more days ( I do promise to release the files the day the campaign ends regardless of reaching the funding goal )

The files live [github.com]

>

> Thanks again for your good work - keep it up!

>

Thanks for the kind words. Be sure to look through my other github repos I have lots of cool stuff to print.

> Frank

Edited 1 time(s). Last edit at 05/19/2012 02:58AM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 04:01AM |

Registered: 13 years ago Posts: 2,947 |

I added a video clip of the Tornado my Martijn being printed at speeds from 45mm/s to 180mm/s with a 0.35mm nozzle at 0.15 layers. There is also a short clip of the cable drive at the end.

[www.youtube.com]

[www.youtube.com]

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 04:05AM |

Admin Registered: 12 years ago Posts: 819 |

|

Re: Tantillus portable 3D printer May 19, 2012 04:16AM |

Registered: 13 years ago Posts: 2,947 |

Helmi Wrote:

-------------------------------------------------------

> Your video is set to private

Oops... fixed. I had as private while Youtube performed its edits.

-------------------------------------------------------

> Your video is set to private

Oops... fixed. I had as private while Youtube performed its edits.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 04:39AM |

Admin Registered: 12 years ago Posts: 819 |

Ok, great. Thanks.

Sublime Wrote:

-------------------------------------------------------

> The kits have a J-head Mk-IV-B in both 0.5mm and

> 0.35mm. I suggest to run the 0.5 first as 0.35 is

> very easy to clog and requires you to have it

> perfectly calibrated.

i already rund 0.35mm nozzle and i'm okay with that so no problem there.

> Edit: I should add that it uses a groove mount so

> almost any groove mount hotend can be used the

> only thing that needs consideration is the length.

> It can be shorter than a J-head by about 20mm

> which would give it a build height of 120mm's but

> if it is any longer than a J-head it will reduce

> the build height.

ok - i have to look around for some different hotends - i'm currently only using those from reprap-fab.org which are quite good but i'd probably go with some other on this printer.

> I have built 7 different machines in the past 2

> years and only one has a heated bed and that is

> the one I never use. I found that blue tape worked

> so well and the finish matches the sides far

> better than when printed on glass. But that is not

> to say I have not considered having heated beds

> made for Tantillus or just use a makerbot cupcake

> or thingomatic heated bed as it is the same size.

ok at least to have an option is always good.

> The case files are available already for everyone

> and the rest will only be 27 more days ( I do

> promise to release the files the day the campaign

> ends regardless of reaching the funding goal )

>

> The files live

> [github.com]

do you also have 2d dxf files ready for cnc cutting? I think i'd build that case out of wood or probably dibond instead of printing it.

Will you release source files too or just the stls? How did you design the stuff? Having it paramectric would be good as i'd definitely go with metric screws. Getting imperial stuff isn't that easy here in Germany. I'd still have to look about how to solve the 8mm rods/608 bearing issue. Won't get that 5/16" stuff here i guess.

Apart from that i'm really impressed by the work you've done - i wish i could contribute that much to the community.

Frank

Frank

Sublime Wrote:

-------------------------------------------------------

> The kits have a J-head Mk-IV-B in both 0.5mm and

> 0.35mm. I suggest to run the 0.5 first as 0.35 is

> very easy to clog and requires you to have it

> perfectly calibrated.

i already rund 0.35mm nozzle and i'm okay with that so no problem there.

> Edit: I should add that it uses a groove mount so

> almost any groove mount hotend can be used the

> only thing that needs consideration is the length.

> It can be shorter than a J-head by about 20mm

> which would give it a build height of 120mm's but

> if it is any longer than a J-head it will reduce

> the build height.

ok - i have to look around for some different hotends - i'm currently only using those from reprap-fab.org which are quite good but i'd probably go with some other on this printer.

> I have built 7 different machines in the past 2

> years and only one has a heated bed and that is

> the one I never use. I found that blue tape worked

> so well and the finish matches the sides far

> better than when printed on glass. But that is not

> to say I have not considered having heated beds

> made for Tantillus or just use a makerbot cupcake

> or thingomatic heated bed as it is the same size.

ok at least to have an option is always good.

> The case files are available already for everyone

> and the rest will only be 27 more days ( I do

> promise to release the files the day the campaign

> ends regardless of reaching the funding goal )

>

> The files live

> [github.com]

do you also have 2d dxf files ready for cnc cutting? I think i'd build that case out of wood or probably dibond instead of printing it.

Will you release source files too or just the stls? How did you design the stuff? Having it paramectric would be good as i'd definitely go with metric screws. Getting imperial stuff isn't that easy here in Germany. I'd still have to look about how to solve the 8mm rods/608 bearing issue. Won't get that 5/16" stuff here i guess.

Apart from that i'm really impressed by the work you've done - i wish i could contribute that much to the community.

Frank

Frank

|

Re: Tantillus portable 3D printer May 19, 2012 04:53AM |

Registered: 13 years ago Posts: 2,947 |

Helmi Wrote:

-------------------------------------------------------

> do you also have 2d dxf files ready for cnc

> cutting? I think i'd build that case out of wood

> or probably dibond instead of printing it.

Yes/no I do have dxf and svg but they do not have any built in offset for milling. You will have to do that yourself.

>

> Will you release source files too or just the

> stls?

Yes everything I have as I see no reason to hold it back.

How did you design the stuff? Having it

> paramectric would be good as i'd definitely go

> with metric screws. Getting imperial stuff isn't

> that easy here in Germany. I'd still have to look

> about how to solve the 8mm rods/608 bearing issue.

> Won't get that 5/16" stuff here i guess.

Its designed in Blender as I am a mesh modeller. But I did make it largely parametric as to make my life easier (80-90%) only a few parts are modelled manually via mesh manipulation and they were for cosmetic reasons. But I really don't think it will be necessary to make a metric version as most of the holes are metric sizes ( I model in metric but use imperial parts because Canada stocks Imperial hardware despite being a metric country ). The only thing that could cause an issue for the metric are the nut traps in the X/Y axis ends which are need to hold the nuts because you can not hold them with a wrench even if you wanted to.

If anyone finds that a metric size will not work they can post in the support forum [forums.reprap.org] and I will most likely be able to make the change if they are not able to.

>

> Apart from that i'm really impressed by the work

> you've done - i wish i could contribute that much

> to the community.

Thanks I am really passionate about RepRap and the way it can improve all of our lives (even if just our sanity).

>

> Frank

-------------------------------------------------------

> do you also have 2d dxf files ready for cnc

> cutting? I think i'd build that case out of wood

> or probably dibond instead of printing it.

Yes/no I do have dxf and svg but they do not have any built in offset for milling. You will have to do that yourself.

>

> Will you release source files too or just the

> stls?

Yes everything I have as I see no reason to hold it back.

How did you design the stuff? Having it

> paramectric would be good as i'd definitely go

> with metric screws. Getting imperial stuff isn't

> that easy here in Germany. I'd still have to look

> about how to solve the 8mm rods/608 bearing issue.

> Won't get that 5/16" stuff here i guess.

Its designed in Blender as I am a mesh modeller. But I did make it largely parametric as to make my life easier (80-90%) only a few parts are modelled manually via mesh manipulation and they were for cosmetic reasons. But I really don't think it will be necessary to make a metric version as most of the holes are metric sizes ( I model in metric but use imperial parts because Canada stocks Imperial hardware despite being a metric country ). The only thing that could cause an issue for the metric are the nut traps in the X/Y axis ends which are need to hold the nuts because you can not hold them with a wrench even if you wanted to.

If anyone finds that a metric size will not work they can post in the support forum [forums.reprap.org] and I will most likely be able to make the change if they are not able to.

>

> Apart from that i'm really impressed by the work

> you've done - i wish i could contribute that much

> to the community.

Thanks I am really passionate about RepRap and the way it can improve all of our lives (even if just our sanity).

>

> Frank

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 05:00AM |

Admin Registered: 12 years ago Posts: 819 |

> Yes/no I do have dxf and svg but they do not have

> any built in offset for milling. You will have to

> do that yourself.

dxf files should never have any offset for production. this is done from the CAM software in next step - so not a problem at all.

> Its designed in Blender as I am a mesh modeller.

> But I did make it largely parametric as to make my

> life easier (80-90%) only a few parts are modelled

> manually via mesh manipulation and they were for

> cosmetic reasons.

I guess i have to have a closer look at blender. Working with google sketchup and OpenSCAD only so far. didn't even know blender makes it possible to make things parametric.

> But I really don't think it will

> be necessary to make a metric version as most of

> the holes are metric sizes ( I model in metric but

> use imperial parts because Canada stocks Imperial

> hardware despite being a metric country ). The

> only thing that could cause an issue for the

> metric are the nut traps in the X/Y axis ends

> which are need to hold the nuts because you can

> not hold them with a wrench even if you wanted

> to.

hm ok - well i'll have a closer look as soon as the files are released. Would be good if everything metric fits well so i just have to find out where to get 5/16" rods or bearings that fit on 8mm ones.

btw regarding all other posts on that topic here in the thread: I have several different rods in different quality and they all measure 7,99mm to 8,01mm - maybe you have to by worse quality to get that 7,95 ones

> If anyone finds that a metric size will not work

> they can post in the support forum

> [forums.reprap.org] and I will

> most likely be able to make the change if they are

> not able to.

That's a good deal - thank you.

Frank

Frank

> any built in offset for milling. You will have to

> do that yourself.

dxf files should never have any offset for production. this is done from the CAM software in next step - so not a problem at all.

> Its designed in Blender as I am a mesh modeller.

> But I did make it largely parametric as to make my

> life easier (80-90%) only a few parts are modelled

> manually via mesh manipulation and they were for

> cosmetic reasons.

I guess i have to have a closer look at blender. Working with google sketchup and OpenSCAD only so far. didn't even know blender makes it possible to make things parametric.

> But I really don't think it will

> be necessary to make a metric version as most of

> the holes are metric sizes ( I model in metric but

> use imperial parts because Canada stocks Imperial

> hardware despite being a metric country ). The

> only thing that could cause an issue for the

> metric are the nut traps in the X/Y axis ends

> which are need to hold the nuts because you can

> not hold them with a wrench even if you wanted

> to.

hm ok - well i'll have a closer look as soon as the files are released. Would be good if everything metric fits well so i just have to find out where to get 5/16" rods or bearings that fit on 8mm ones.

btw regarding all other posts on that topic here in the thread: I have several different rods in different quality and they all measure 7,99mm to 8,01mm - maybe you have to by worse quality to get that 7,95 ones

> If anyone finds that a metric size will not work

> they can post in the support forum

> [forums.reprap.org] and I will

> most likely be able to make the change if they are

> not able to.

That's a good deal - thank you.

Frank

Frank

|

Re: Tantillus portable 3D printer May 19, 2012 05:11AM |

Registered: 13 years ago Posts: 2,947 |

Helmi Wrote:

-------------------------------------------------------

> I guess i have to have a closer look at blender.

> Working with google sketchup and OpenSCAD only so

> far. didn't even know blender makes it possible to

> make things parametric.

Its not a well known fact. But blender uses "modifiers" which can be left un-applied. These modifiers are things like Boolean (union, difference and intersect), bevels, subdividing and smoothing, etc

If you ever want to learn Blender I suggest Blendercookie.com . They have lots of tutorials (some apply to what we do and some don't) and after doing 4-5 of them you will have a grasp on the basics. Just remember it can do a lot that other programs can not. Like boolean any two objects together regardless of manifoldedness.

> btw regarding all other posts on that topic here

> in the thread: I have several different rods in

> different quality and they all measure 7,99mm to

> 8,01mm - maybe you have to by worse quality to get

> that 7,95 ones

Since the bushings that ride on the shafts that turn in the 608's are printed you can use regular 8mm round stock that usually comes in around 7.9 and just print the bushings a little smaller.

-------------------------------------------------------

> I guess i have to have a closer look at blender.

> Working with google sketchup and OpenSCAD only so

> far. didn't even know blender makes it possible to

> make things parametric.

Its not a well known fact. But blender uses "modifiers" which can be left un-applied. These modifiers are things like Boolean (union, difference and intersect), bevels, subdividing and smoothing, etc

If you ever want to learn Blender I suggest Blendercookie.com . They have lots of tutorials (some apply to what we do and some don't) and after doing 4-5 of them you will have a grasp on the basics. Just remember it can do a lot that other programs can not. Like boolean any two objects together regardless of manifoldedness.

> btw regarding all other posts on that topic here

> in the thread: I have several different rods in

> different quality and they all measure 7,99mm to

> 8,01mm - maybe you have to by worse quality to get

> that 7,95 ones

Since the bushings that ride on the shafts that turn in the 608's are printed you can use regular 8mm round stock that usually comes in around 7.9 and just print the bushings a little smaller.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Tantillus portable 3D printer May 19, 2012 06:14AM |

Admin Registered: 17 years ago Posts: 7,879 |

I have been looking at bearing and rod tolerances. The datasheet for my precision rods is here: [www.zappautomation.co.uk]. That shows two tolerance standards g6(Asian) that is -5 to -14um and h6(European) 0 to -9um. It is not clear if it is two products or a single product that complies to both standards, i.e. -5 to -9um.

Bearings seem to be 0 to -8um as standard so odds are that it will fit, but not guaranteed. There is a nice tool here for checking: [www.skf.com]

There are bearing tolerance standards that would guarantee a fit.

The bottom line is I don't think even 5/16" is guaranteed to fit. You have to chose an actually bearing and shaft with compatible tolerance specifications or gamble.

[www.hydraraptor.blogspot.com]

Bearings seem to be 0 to -8um as standard so odds are that it will fit, but not guaranteed. There is a nice tool here for checking: [www.skf.com]

There are bearing tolerance standards that would guarantee a fit.

The bottom line is I don't think even 5/16" is guaranteed to fit. You have to chose an actually bearing and shaft with compatible tolerance specifications or gamble.

[www.hydraraptor.blogspot.com]

|

Re: Tantillus portable 3D printer May 19, 2012 06:15AM |

Admin Registered: 12 years ago Posts: 819 |

Guess i'll take some 608s out of the drawer and give the steel dealer a visit next week - we will see ;-)

I still have to decide whether to use LM8UU (i have some of them here), printed ones or the IGUS RJMP-01-08 i use on the prusa. The latter do a really good job on my Prusa and are running completely soft and silent.

Thanks for your hints regarding blender - i'll give that a try some day soon.

Frank

I still have to decide whether to use LM8UU (i have some of them here), printed ones or the IGUS RJMP-01-08 i use on the prusa. The latter do a really good job on my Prusa and are running completely soft and silent.

Thanks for your hints regarding blender - i'll give that a try some day soon.

Frank

|

Anonymous User

Re: Tantillus portable 3D printer May 19, 2012 07:47AM |

|

Anonymous User

Re: Tantillus portable 3D printer May 19, 2012 07:50AM |

Quote

Sublime wrote

You're and idiot,

When you round 50 it goes down not up 50.1 goes up.

Nophead has been selling stuff since before you even heard about reprap and only uses his propriety software that he refuses to let anyone see. He refused to release the Mendel 90 files until he was able to sell them.

You obviously know nothing about reprap and are just a troll trying to screw all of us over and you DO NOT contribute at all.

Like I said before show some respect you troll.

And like I said I made this for myself and I'm only selling it because people wanted it. Not the other way around as you keep accusing me of.

Nice message in my inbox.

I am not a troll but feel you have overpriced your machine. Is that not allowed?

Also this fawning over the results. Please! It looks no different from others I have seen usng similar parts.

What is the cost for 100 hours of printing these days? Will your "reprap" buddies make minimum wage?

Also looking at the tornado print (which is easy to do quick) it looks like the gears arent perfectly round.

Edited 3 time(s). Last edit at 05/19/2012 10:14AM by gerards1111.

|

Re: Tantillus portable 3D printer May 19, 2012 09:49AM |

Registered: 13 years ago Posts: 123 |

Gerards1111,

Where did all that anger come from? Your profile says you've made 33 posts, and all of them I've seen have been complaints or criticism. Those are hallmarks of the general definition of a troll. Sublime and nophead have both made hundreds of posts each and have contributed not only lots of their time and discoveries to the community but also designed lots of things that they have freely contributed. I don't think it's unreasonable at all for them to get some compensation for their investment of time and energy into improving the community. If you don't like one design or the other, then that's your prerogative but why are you so vocal and antagonistic with the criticism?

Personally, I am in awe of the effort that went into both Tantillus and Mendel90, and plan to make one of each. They each have their attractions and the community is large enough for both to coexist.

Where did all that anger come from? Your profile says you've made 33 posts, and all of them I've seen have been complaints or criticism. Those are hallmarks of the general definition of a troll. Sublime and nophead have both made hundreds of posts each and have contributed not only lots of their time and discoveries to the community but also designed lots of things that they have freely contributed. I don't think it's unreasonable at all for them to get some compensation for their investment of time and energy into improving the community. If you don't like one design or the other, then that's your prerogative but why are you so vocal and antagonistic with the criticism?

Personally, I am in awe of the effort that went into both Tantillus and Mendel90, and plan to make one of each. They each have their attractions and the community is large enough for both to coexist.

|

Anonymous User

Re: Tantillus portable 3D printer May 19, 2012 10:13AM |

|

Re: Tantillus portable 3D printer May 19, 2012 10:28AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

He refused to release the Mendel 90 files until he was able to sell them.

Completely un-true. I released them when I had finished them, which was long before I sold any. In fact I have only sold a couple of sets of printed parts recently to people that requested them. I haven't actively marketed them because I haven't had time to complete the instructions yet. More people have printed their own parts and built machines, which is the whole point of RepRap.

Not that I support people baying for source code. It is entirely up to the author when and indeed if it is published if it isn't based on opensource code.

Edited 1 time(s). Last edit at 05/19/2012 10:42AM by nophead.

[www.hydraraptor.blogspot.com]

|

Anonymous User

Re: Tantillus portable 3D printer May 19, 2012 10:42AM |

|

Re: Tantillus portable 3D printer May 19, 2012 11:09AM |

Admin Registered: 17 years ago Posts: 7,879 |

They sell actual physical items but RepRap IP is given completely free. I.e. people freely give away 1000's of hours of their time, just like people in the opensource software world. The only difference is that in addition some people also sell hardware.

People can hardly be expected to give away hardware in addition to their time, or even supply it at cost. Once you have done design or research it doesn't cost anything to publish it as it is a one off operation. If you sell items made to that design each item costs time and money so has to be charged for. If the demand is such that you choose to give up your day job or rent premises then you have to charge commercial rates.

Sublime can charge whatever he wants. It is only too expensive if he could have sold more by selling it cheaper. All these campaigns end up over subscribed so demand exceeds supply, hence we see the prices we do.

[www.hydraraptor.blogspot.com]

People can hardly be expected to give away hardware in addition to their time, or even supply it at cost. Once you have done design or research it doesn't cost anything to publish it as it is a one off operation. If you sell items made to that design each item costs time and money so has to be charged for. If the demand is such that you choose to give up your day job or rent premises then you have to charge commercial rates.

Sublime can charge whatever he wants. It is only too expensive if he could have sold more by selling it cheaper. All these campaigns end up over subscribed so demand exceeds supply, hence we see the prices we do.

[www.hydraraptor.blogspot.com]

|

Re: Tantillus portable 3D printer May 19, 2012 02:23PM |

Registered: 13 years ago Posts: 2,947 |

nophead Wrote:

-------------------------------------------------------

> He refused to release the Mendel 90 files until he

> was able to sell them.

>

> Completely un-true. I released them when I had

> finished them, which was long before I sold any.

> In fact I have only sold a couple of sets of

> printed parts recently to people that requested

> them.

I stand corrected and apologize for my misunderstandings. I was trying to keep up with everything happening in the world of RepRap at once and miss understood why you waited to release them.

-------------------------------------------------------

> He refused to release the Mendel 90 files until he

> was able to sell them.

>

> Completely un-true. I released them when I had

> finished them, which was long before I sold any.

> In fact I have only sold a couple of sets of

> printed parts recently to people that requested

> them.

I stand corrected and apologize for my misunderstandings. I was trying to keep up with everything happening in the world of RepRap at once and miss understood why you waited to release them.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.