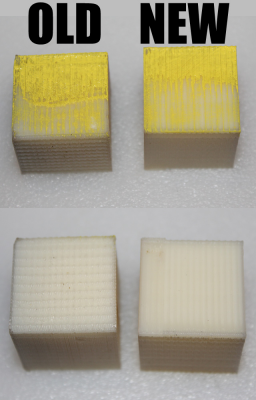

Z-axis Issue?

Posted by Zimtower

|

Z-axis Issue? June 26, 2012 07:49AM |

Registered: 11 years ago Posts: 44 |

|

Re: Z-axis Issue? June 26, 2012 09:42AM |

Registered: 14 years ago Posts: 689 |

If the ridges match the threads on the threaded rod on z, it could be the rod is not straight and is pulling the entire x gantry out of position.

Lube.

Check/adjust z couplings and trapped nuts.

Exchange bent z rod for a higher quality (=probably straigher) stainless steel rod.

Cool print though, my nieces would love that!

Edited 1 time(s). Last edit at 06/26/2012 09:44AM by Nudel.

--

-Nudel

Blog with RepRap Comic

Lube.

Check/adjust z couplings and trapped nuts.

Exchange bent z rod for a higher quality (=probably straigher) stainless steel rod.

Cool print though, my nieces would love that!

Edited 1 time(s). Last edit at 06/26/2012 09:44AM by Nudel.

--

-Nudel

Blog with RepRap Comic

|

Re: Z-axis Issue? June 27, 2012 09:15PM |

Registered: 16 years ago Posts: 824 |

This is likely Z_Axis wobble.

Show a picture of your printer, and it will help identify the culprit.

Usual suspects are captive z-motors (screwed down), captive lead screws (either by using two sets of nuts in the x-motor/idler ends, or using the printed 608 bearing holders at the top or bottom of the rods, or bent rods.

Show a picture of your printer, and it will help identify the culprit.

Usual suspects are captive z-motors (screwed down), captive lead screws (either by using two sets of nuts in the x-motor/idler ends, or using the printed 608 bearing holders at the top or bottom of the rods, or bent rods.

|

Re: Z-axis Issue? June 28, 2012 06:39AM |

Registered: 11 years ago Posts: 44 |

|

Re: Z-axis Issue? June 29, 2012 06:47AM |

Registered: 11 years ago Posts: 44 |

I just installed these very straight threaded rods and there is a tiny amount of improvement. I am also using the spiral couplers which I hear can be self-defeating.

[www.thingiverse.com]

I am guessing I should print these out?

|

Re: Z-axis Issue? June 29, 2012 10:10AM |

|

Re: Z-axis Issue? June 29, 2012 10:15AM |

Admin Registered: 17 years ago Posts: 7,879 |

There is no base on a standard Prusa. Yes the rods dangle from the motor.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Z-axis Issue? June 29, 2012 12:17PM |

Registered: 16 years ago Posts: 824 |

Helical flex coupling are meant to be used in situations where you have a captive rod and captive motor. The coupling then allows there to be misalignment without placing stress on the bearings.

In the case of repraps, the ideal solution would be a motor with a threaded shaft, but these are expensive.

Almost any solution will produce good results IF the mating of the rod to the motor is concentric, and the rod is straight.

In the case of repraps, the ideal solution would be a motor with a threaded shaft, but these are expensive.

Almost any solution will produce good results IF the mating of the rod to the motor is concentric, and the rod is straight.

Sorry, only registered users may post in this forum.