Vision 3d Printer - A Quick Build RepRap Prusa Mendel

Posted by Beekeeper

|

Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 27, 2012 03:09AM |

Registered: 12 years ago Posts: 115 |

I just posted my RepRap Prusa Mendel variant on Kickstarter. I like the Prusa Mendel in all it's flavors, a LOT. It is simple enough that most people could build one with most parts that they could have in 3 days, but it takes a long time to assemble and it still looks too hobbiest for most people to consider. Most people that I show my original Prusa Mendel to are unimpressed... until they see what it can do. I have never seen a machine that has everyone from small children to senior citizens entranced. This is the magic of RepRap. I have showed my original Prusa with only a Gen6 board and printing on Blue Tape in grade schools, at a local Mini Makerfaire, and to friends. The response is always the same, once it starts moving people can't get enough of it.

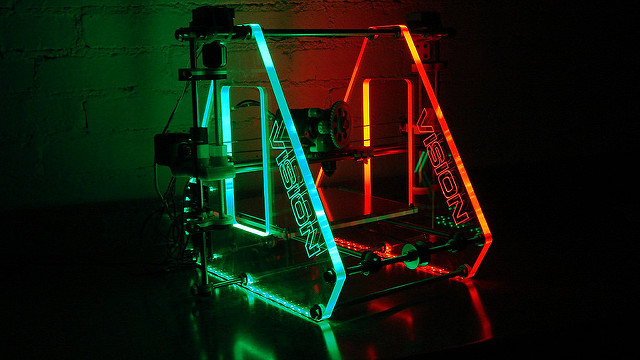

My Vision 3d Printer is a Fork of the RepRap Prusa Mendel Iteration 2. My goal was to produce a kit that builds in 1/3 the time of a normal Prusa Mendel while looking as cools as RepRap is. I hope you like it. The 12mm Acrylic Sidewalls make it much more rigid than a traditional Prusa Mendel Iteration 2. I tightened up a lot of tolerances and CNC machined the sidewalls. They could be made out of any other 12mm panels like Aluminum or MDF (although MDF will warp over time especially with humidity and under a load). I will publish all of my work either once I start shipping, or if the Kickstarter campaign is a bust. It comes with a fully built extruder, fully assembled electronics, all tools needed to assemble it, and all wires with connectors already installed, no soldering needed.

You can find it at:

[www.kickstarter.com]

I am also going to offer lower cost (but high quality) filament here in the US in a larger variety of colors then is currently available. I have a heavy background in plastics and plastic processing, and will set up a couple of extruder lines in-house. I hope to eventually lower the price from the amount in the Kickstarter campaign, but don't know how many people will even be interested. Either way, I will continue to work on all of the things in the Kickstarter listing.

I have been working on new materials for filament. The plastics world is filled with other great resins, With more machines to try them out, I can speed up development considerably. I have also been working with non plastic materials too, more about that on a later date.

I am very thankful for the RepRap community, and hope this machine helps.

As a disclaimer, I will release the source files and design files for everything in the machine(s) once I start shipping. That said, it is Open Source Hardware (as defined by when I ship, the files will be posted for all to have). If you are one of the few that don't like this policy, you can freely develop your own RepRap machine and post it for all to enjoy. I'm not out to please everyone (no one has that power), I am looking to make a positive difference.

Thank You,

Matt Underwood

aka beekeeper

My Vision 3d Printer is a Fork of the RepRap Prusa Mendel Iteration 2. My goal was to produce a kit that builds in 1/3 the time of a normal Prusa Mendel while looking as cools as RepRap is. I hope you like it. The 12mm Acrylic Sidewalls make it much more rigid than a traditional Prusa Mendel Iteration 2. I tightened up a lot of tolerances and CNC machined the sidewalls. They could be made out of any other 12mm panels like Aluminum or MDF (although MDF will warp over time especially with humidity and under a load). I will publish all of my work either once I start shipping, or if the Kickstarter campaign is a bust. It comes with a fully built extruder, fully assembled electronics, all tools needed to assemble it, and all wires with connectors already installed, no soldering needed.

You can find it at:

[www.kickstarter.com]

I am also going to offer lower cost (but high quality) filament here in the US in a larger variety of colors then is currently available. I have a heavy background in plastics and plastic processing, and will set up a couple of extruder lines in-house. I hope to eventually lower the price from the amount in the Kickstarter campaign, but don't know how many people will even be interested. Either way, I will continue to work on all of the things in the Kickstarter listing.

I have been working on new materials for filament. The plastics world is filled with other great resins, With more machines to try them out, I can speed up development considerably. I have also been working with non plastic materials too, more about that on a later date.

I am very thankful for the RepRap community, and hope this machine helps.

As a disclaimer, I will release the source files and design files for everything in the machine(s) once I start shipping. That said, it is Open Source Hardware (as defined by when I ship, the files will be posted for all to have). If you are one of the few that don't like this policy, you can freely develop your own RepRap machine and post it for all to enjoy. I'm not out to please everyone (no one has that power), I am looking to make a positive difference.

Thank You,

Matt Underwood

aka beekeeper

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 27, 2012 04:50AM |

Registered: 15 years ago Posts: 123 |

You want to show off how cool reprap is.. by making a machine that is not a reprap? Besides dude, this already exists: [reprap.org]

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 27, 2012 09:52AM |

Registered: 11 years ago Posts: 10 |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 28, 2012 04:00PM |

Registered: 12 years ago Posts: 115 |

@harodwilliams: Thanks!

@destroyer2012: Ouch! I don't know where the rules are that officially designates one design a RepRap an another as not. All the RP parts in the Vision 3d Printer require another 3d Printer to print them. All RP parts are either Prusa parts, Greg's accessible extruder parts, or working derivitives of those parts. There doesn't seem to be a formula to say what percentage of parts need to be RP parts. There doesn't seem to be a panel to even present a design to for any "official" designation.

If you need to have more RP parts to be an official RepRap, then you can certainly still build a Darwin or Sell's Mendel, but the part count of other vitamin parts skyrockets also. With larger part counts comes longer build times and poorer success rates. I don't think even 10 Darwins were ever built.

My version of of the Prusa Mendel is a logical extension of reducing part count and dramatically reducing build time. This increases the chance of success, what RepRap needs in order to grow. My machine also reduces the RP parts by 8 (no verticies, and 2 fewer bar clamps). The RP count alone saves on printing time by several hours.

About the link to:

Prusa Air

They are not even close to structurally the same.

I did a bit of research, and although the 6mm panel acrylic version of the Prusa Air is still in deveopment, it appears to still be vaperware. Although it has a lot of "likes" and downloads on Thingiverse, it appears no one ever completed one. The Prusa Air is still in active development, but only a couple of people have actually made one that works. Yamagata and Illius, but they ditched the acrylic and made their machines out of ALUMINUM or MDF. 6mm acrylic where you cut out one side of the triangle, would require much more structure to be added, in order to keep the machine from wobbling. The reason for the thin acrylic is probably because most laser cutters can't handle thicker sheets. (As a side note, Yamagata's Greg's Extruder is machined out of aluminum - quite impressive.) Don't get me wrong, I am not knocking their machine, they are making their machine better every day through actively improving it. To each their own. ALL MACHINES have their strengths and their weaknesses. It is great that we have choices.

I would think that you above most, would realize this. Your first post on Reprap forums was on July 18, 2008 where you had assembled a McWire (except for the extruder). But you didn't have it running until 3 months ago? It took you 4 YEARS to build a machine that gives you a maximum build speed of 4mm/sec??? Again, I am not knocking the machine, it was the state of RepRap 4 years ago, but when you make a machine hard to build, they don't get built.

Our local Fab Lab purchased a Makerbot Cupcake 2 to 3 years ago, but it came with a large amount of bad electronics and missing hardware. It took them 2 years to get Makerbot to replace the parts. By the time Makerbot did, Makerbot had officially stop supporting the Cupcake. Again, state of the art 3 years ago, but not where Reprap is now. I'm sure a lot of the first Makerbots never even made parts, it is just the way it was. But to Makerbot's credit, they have helped grow the community both in terms of the number of Makerbot's that made Reprap parts, and the overall first exposure of people to 3d printing. Zack Smith's (Makerbot Co-Founder) direct involvement with Reprap in the early days helped everybody.

That being said, try and find your own happiness. If the Vision 3d Prusa Mendel isn't for you, keep looking.

Take Care,

Matt Underwood

Vision 3D Printer

@destroyer2012: Ouch! I don't know where the rules are that officially designates one design a RepRap an another as not. All the RP parts in the Vision 3d Printer require another 3d Printer to print them. All RP parts are either Prusa parts, Greg's accessible extruder parts, or working derivitives of those parts. There doesn't seem to be a formula to say what percentage of parts need to be RP parts. There doesn't seem to be a panel to even present a design to for any "official" designation.

If you need to have more RP parts to be an official RepRap, then you can certainly still build a Darwin or Sell's Mendel, but the part count of other vitamin parts skyrockets also. With larger part counts comes longer build times and poorer success rates. I don't think even 10 Darwins were ever built.

My version of of the Prusa Mendel is a logical extension of reducing part count and dramatically reducing build time. This increases the chance of success, what RepRap needs in order to grow. My machine also reduces the RP parts by 8 (no verticies, and 2 fewer bar clamps). The RP count alone saves on printing time by several hours.

About the link to:

Prusa Air

They are not even close to structurally the same.

I did a bit of research, and although the 6mm panel acrylic version of the Prusa Air is still in deveopment, it appears to still be vaperware. Although it has a lot of "likes" and downloads on Thingiverse, it appears no one ever completed one. The Prusa Air is still in active development, but only a couple of people have actually made one that works. Yamagata and Illius, but they ditched the acrylic and made their machines out of ALUMINUM or MDF. 6mm acrylic where you cut out one side of the triangle, would require much more structure to be added, in order to keep the machine from wobbling. The reason for the thin acrylic is probably because most laser cutters can't handle thicker sheets. (As a side note, Yamagata's Greg's Extruder is machined out of aluminum - quite impressive.) Don't get me wrong, I am not knocking their machine, they are making their machine better every day through actively improving it. To each their own. ALL MACHINES have their strengths and their weaknesses. It is great that we have choices.

I would think that you above most, would realize this. Your first post on Reprap forums was on July 18, 2008 where you had assembled a McWire (except for the extruder). But you didn't have it running until 3 months ago? It took you 4 YEARS to build a machine that gives you a maximum build speed of 4mm/sec??? Again, I am not knocking the machine, it was the state of RepRap 4 years ago, but when you make a machine hard to build, they don't get built.

Our local Fab Lab purchased a Makerbot Cupcake 2 to 3 years ago, but it came with a large amount of bad electronics and missing hardware. It took them 2 years to get Makerbot to replace the parts. By the time Makerbot did, Makerbot had officially stop supporting the Cupcake. Again, state of the art 3 years ago, but not where Reprap is now. I'm sure a lot of the first Makerbots never even made parts, it is just the way it was. But to Makerbot's credit, they have helped grow the community both in terms of the number of Makerbot's that made Reprap parts, and the overall first exposure of people to 3d printing. Zack Smith's (Makerbot Co-Founder) direct involvement with Reprap in the early days helped everybody.

That being said, try and find your own happiness. If the Vision 3d Prusa Mendel isn't for you, keep looking.

Take Care,

Matt Underwood

Vision 3D Printer

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 28, 2012 07:17PM |

Registered: 15 years ago Posts: 123 |

My position is this: I don't see how your design improves on what has been done. What I see is a ploy to make money off people who will spring to buy a 3d printer that "looks good". Please, prove me wrong.

I agree I was being too harsh by not calling it a reprap. When I see those huge plexiglass panels though, my mind jumps immediately to "you made a 3d printer out of plexiglass". I don't think that when people see your "vision" they will immediately connect it with "this printer can make its own parts". So the concept of having THIS design to show off how cool REPrap is, seems flimsy in my opinion.

I bring up the prusa air to say that this concept of replacing the prusa triangles with plexiglass has been thought of and done, so I personally don't see where your design is improving from theirs. "Not even structurally the same"? Are we looking at different machines?

As far as I can see, the difference is your panels are shaped differently. Yes they are more substatial, but I think it's only a minor improvement when compared to the fact that most forces on the machine during fast builds are in the direction perpendicular to those panels. Your design has no cross bracing like the mendelmax has. Your design has those leadscrew stabilizers which over-constrain the z axis making it more likely to bind. Your design includes nothing to stabilize the triangles from being rotated relative to each other. Your design still has the z-steppers on top where they are more likely to wobble back and forth. These are the specific reasons why I think your design is not a significant enough improvement over the prusa air to justify calling it something new.

I'm glad you bring up my reprap history because I see that what I've done in the past is very important to our conversation about your mendel design. I'm sure you think I was just twiddling my thumbs for four years refreshing the reprap wiki page, and if it helps your ego to think that then go ahead, sure, I'm a loser. You caught me! Clearly only those people that have successfully designed and built their own 3d printers should comment in this forum at all.

I remember at some point in the past people were content with putting up their reprap designs (in their entirety) on the reprap wiki, allowing others to criticize and modify their work, instead of putting "new 3d printers" up on kickstarter and asking for money.

But I'm just a loser, so forget I said anything.

I agree I was being too harsh by not calling it a reprap. When I see those huge plexiglass panels though, my mind jumps immediately to "you made a 3d printer out of plexiglass". I don't think that when people see your "vision" they will immediately connect it with "this printer can make its own parts". So the concept of having THIS design to show off how cool REPrap is, seems flimsy in my opinion.

I bring up the prusa air to say that this concept of replacing the prusa triangles with plexiglass has been thought of and done, so I personally don't see where your design is improving from theirs. "Not even structurally the same"? Are we looking at different machines?

As far as I can see, the difference is your panels are shaped differently. Yes they are more substatial, but I think it's only a minor improvement when compared to the fact that most forces on the machine during fast builds are in the direction perpendicular to those panels. Your design has no cross bracing like the mendelmax has. Your design has those leadscrew stabilizers which over-constrain the z axis making it more likely to bind. Your design includes nothing to stabilize the triangles from being rotated relative to each other. Your design still has the z-steppers on top where they are more likely to wobble back and forth. These are the specific reasons why I think your design is not a significant enough improvement over the prusa air to justify calling it something new.

I'm glad you bring up my reprap history because I see that what I've done in the past is very important to our conversation about your mendel design. I'm sure you think I was just twiddling my thumbs for four years refreshing the reprap wiki page, and if it helps your ego to think that then go ahead, sure, I'm a loser. You caught me! Clearly only those people that have successfully designed and built their own 3d printers should comment in this forum at all.

I remember at some point in the past people were content with putting up their reprap designs (in their entirety) on the reprap wiki, allowing others to criticize and modify their work, instead of putting "new 3d printers" up on kickstarter and asking for money.

But I'm just a loser, so forget I said anything.

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 28, 2012 08:48PM |

Registered: 11 years ago Posts: 10 |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 28, 2012 08:54PM |

Admin Registered: 15 years ago Posts: 1,470 |

haroldwilliams Wrote:

-------------------------------------------------------

> From what I have read, this is getting close to

> the other thread. Why not appreciate another

> design and the new reprappers it will bring.

Exactly. Many people have developed Mendel-variants and sell them. And this RepRap definitely does look cooler than a standard Prusa Mendel. What I am most interested in is having another filament supplier, especially if he can compete on price and still have a good quality product.

-------------------------------------------------------

> From what I have read, this is getting close to

> the other thread. Why not appreciate another

> design and the new reprappers it will bring.

Exactly. Many people have developed Mendel-variants and sell them. And this RepRap definitely does look cooler than a standard Prusa Mendel. What I am most interested in is having another filament supplier, especially if he can compete on price and still have a good quality product.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 29, 2012 05:39AM |

Registered: 13 years ago Posts: 60 |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 30, 2012 10:22AM |

Registered: 12 years ago Posts: 127 |

I think it looks great... If they like it they will buy it... If they dont they wont... So why worry?

Ryan

Quality Engineer & Hobbyist

thingsandtrains.blogspot.com

Ryan

Quality Engineer & Hobbyist

thingsandtrains.blogspot.com

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 30, 2012 04:06PM |

Admin Registered: 15 years ago Posts: 1,470 |

banthafodder7400 Wrote:

-------------------------------------------------------

> I think it looks great... If they like it they

> will buy it... If they dont they wont... So why

> worry?

Exactly. This is the beauty of a free market. BTW, I think it looks pretty neat.

-------------------------------------------------------

> I think it looks great... If they like it they

> will buy it... If they dont they wont... So why

> worry?

Exactly. This is the beauty of a free market. BTW, I think it looks pretty neat.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 30, 2012 05:31PM |

Registered: 12 years ago Posts: 60 |

You missed out on one chance for improvement, Z height...

You are no longer constrained by equalateral triangles, so why not make it taller while keeping the existing footprint? Looks like you will have a mx z height of 100mm, why not go 200mm?

This is a movement in the reprap community, more height for larger prints is a premium. To get more height with this system you would have to re-order the frame sides, ouch!

You are no longer constrained by equalateral triangles, so why not make it taller while keeping the existing footprint? Looks like you will have a mx z height of 100mm, why not go 200mm?

This is a movement in the reprap community, more height for larger prints is a premium. To get more height with this system you would have to re-order the frame sides, ouch!

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 30, 2012 08:13PM |

Registered: 12 years ago Posts: 115 |

WildBill,

"You missed out on one chance for improvement, Z height...

You are no longer constrained by equalateral triangles, so why not make it taller while keeping the existing footprint? Looks like you will have a mx z height of 100mm, why not go 200mm? "

Actually, no I didn't. Good of you to notice though. The 2 larger Vision Printer (the Vision "Plus" and the Vision "BigFoot") are not Equillateral Triangles, They ARE Isosceles, and I stretched the Z Height in order to do just that. Since, it is an optimized RepRap Prusa Mendel, the small size Vision 3d Printer is the exact same locational dimensions as the Prusa Mendel. I haven't shown them yet because it isn't June (see below). The Vision+ raises the Z height to 8.9" (225mm) which to most people seems pretty tall. The Vision+ is an extra $125 (because it uses more material, I get a much poorer yield of parts per sheet, costs me more to ship the larger box, and it requires me to refixture the plates a couple of times to get them cut on my machine).

Also, I no longer build the Vision printers with upper end Z Rod contraints or with 8mm-1.25 threaded rods for the Z axis, I switched to 6mm-1 threaded rod and found the Z Rod contraints are no longer needed since they don't fight with the 8mm smooth rods (although I am keeping the bottom one, for safety / looks & to keep the 6mm rod from getting bent). By eliminating the upper Z rod contraints, I gain back the extra 40mm of Z height.

I have been waiting for June to roll around and am going to post something new each day on Thingiverse - my part of the 30 Days of Creativity in June. Including 5 - 3D Printer Designs (That I Machine, Print RP Parts, Assemble, Tweak, and print parts for a the complete printer all within 1 day each - Not just build the printer in under a day, which is easy enough if you already have the parts). Check out Richrap's Blog for more information abou the 30 Days of Creativity.

The Kickstarter Campaign ends on June 28th (I should have waited 2 days to start the campaign - oh well, that's life).

Take Care,

Matt

"You missed out on one chance for improvement, Z height...

You are no longer constrained by equalateral triangles, so why not make it taller while keeping the existing footprint? Looks like you will have a mx z height of 100mm, why not go 200mm? "

Actually, no I didn't. Good of you to notice though. The 2 larger Vision Printer (the Vision "Plus" and the Vision "BigFoot") are not Equillateral Triangles, They ARE Isosceles, and I stretched the Z Height in order to do just that. Since, it is an optimized RepRap Prusa Mendel, the small size Vision 3d Printer is the exact same locational dimensions as the Prusa Mendel. I haven't shown them yet because it isn't June (see below). The Vision+ raises the Z height to 8.9" (225mm) which to most people seems pretty tall. The Vision+ is an extra $125 (because it uses more material, I get a much poorer yield of parts per sheet, costs me more to ship the larger box, and it requires me to refixture the plates a couple of times to get them cut on my machine).

Also, I no longer build the Vision printers with upper end Z Rod contraints or with 8mm-1.25 threaded rods for the Z axis, I switched to 6mm-1 threaded rod and found the Z Rod contraints are no longer needed since they don't fight with the 8mm smooth rods (although I am keeping the bottom one, for safety / looks & to keep the 6mm rod from getting bent). By eliminating the upper Z rod contraints, I gain back the extra 40mm of Z height.

I have been waiting for June to roll around and am going to post something new each day on Thingiverse - my part of the 30 Days of Creativity in June. Including 5 - 3D Printer Designs (That I Machine, Print RP Parts, Assemble, Tweak, and print parts for a the complete printer all within 1 day each - Not just build the printer in under a day, which is easy enough if you already have the parts). Check out Richrap's Blog for more information abou the 30 Days of Creativity.

The Kickstarter Campaign ends on June 28th (I should have waited 2 days to start the campaign - oh well, that's life).

Take Care,

Matt

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 30, 2012 08:23PM |

Registered: 12 years ago Posts: 115 |

The Vision BigFoot can go up to 12.5" (311mm) Z height. I am working on a video that shows 1 continuous print that lasts 50 hours and burns a couple lbs of filament (more on that later).

I do wonder what the longest running print is. I remember in the early days of Makerbot, they had their "Makerbot world records" and Zach had it at just over 2 hours with a Cupcake, in just 3 years, times have really changed.

I do wonder what the longest running print is. I remember in the early days of Makerbot, they had their "Makerbot world records" and Zach had it at just over 2 hours with a Cupcake, in just 3 years, times have really changed.

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 30, 2012 11:13PM |

Admin Registered: 15 years ago Posts: 1,470 |

Beekeeper Wrote:

-------------------------------------------------------

I am working on a video that shows 1

> continuous print that lasts 50 hours and burns a

> couple lbs of filament (more on that later).

That's crazy. I think my longest prints are around 12 hours. I don't like going much longer because there's a chance of something stupid ruining the whole print.

-------------------------------------------------------

I am working on a video that shows 1

> continuous print that lasts 50 hours and burns a

> couple lbs of filament (more on that later).

That's crazy. I think my longest prints are around 12 hours. I don't like going much longer because there's a chance of something stupid ruining the whole print.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel May 31, 2012 08:25PM |

Registered: 12 years ago Posts: 31 |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel June 06, 2012 01:26AM |

Registered: 11 years ago Posts: 16 |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel June 06, 2012 02:57AM |

Registered: 12 years ago Posts: 115 |

|

Re: Vision 3d Printer - A Quick Build RepRap Prusa Mendel June 06, 2012 04:05AM |

Registered: 12 years ago Posts: 93 |

Sorry, only registered users may post in this forum.