Calibration problem?

Posted by MrBlack

|

Calibration problem? May 30, 2012 06:25PM |

Registered: 12 years ago Posts: 19 |

Dear Community,

I'm almost finished with this printer I've been working on for about 11 months, but I'm having a problem.

I simply can't get my prints to come out correct or symmetrical, even though I've used a nickel calibration test to get just about as correct of calibration as I can.

I'm hoping that you have some suggestions: Here are some pictures of the problem:

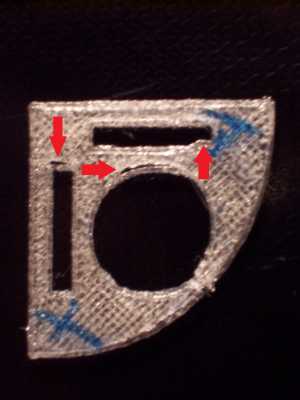

Here's the Nickel calibration test (http://www.thingiverse.com/thing:11261) I've been using to try to calibrate my X, Y, and Z axes.

Below are the photos of what the printer is doing, even though my measurements are calibrated seemingly as far as I can calibrate them within reasonable measuring error:

It appears that it's both not entirely symmetrical (though part of that is simply flashing) and that it's leaving a space between some of the extruded filament section.

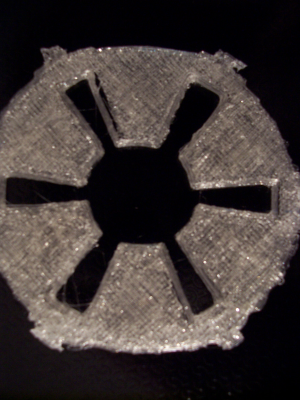

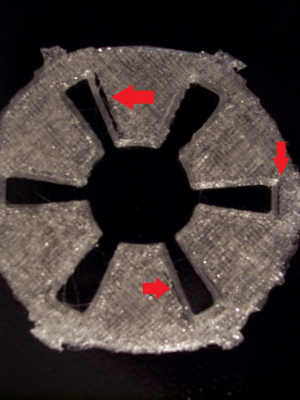

Also, I'm trying to make a Star Wars Imperial emblem (http://www.thingiverse.com/thing:17155) as a test print for my Slic3r settings, and it keeps coming out with the same issues as the calibration print (photos below)

Same thing: not entirely symmetrical (like it's supposed to be) and still has space between the sections where the printer extrudes in different ways.

I'm running a Botmill Axis 2.1 printer (Mendel) with a Wade's geared extruder that features a .35mm nozzle from MakerGear.

I've also tested my extruder to within my capacity for measurement error, and it seems to be pretty close to precisely extruding 5mm of plastic when I tell it to through Pronterface.

All help will be greatly appreciated as I'm so close to being finished after such a long fight (both with Botmill and the printer). . . at least I think. . .I just want this thing to work and be able to make some nice, symmetrical prints.

Thank you, thank you, thank you, to all of you who I lean on so heavily to get me to the end of this project.

Almost there. . .

Sincerely,

RR

I'm almost finished with this printer I've been working on for about 11 months, but I'm having a problem.

I simply can't get my prints to come out correct or symmetrical, even though I've used a nickel calibration test to get just about as correct of calibration as I can.

I'm hoping that you have some suggestions: Here are some pictures of the problem:

Here's the Nickel calibration test (http://www.thingiverse.com/thing:11261) I've been using to try to calibrate my X, Y, and Z axes.

Below are the photos of what the printer is doing, even though my measurements are calibrated seemingly as far as I can calibrate them within reasonable measuring error:

It appears that it's both not entirely symmetrical (though part of that is simply flashing) and that it's leaving a space between some of the extruded filament section.

Also, I'm trying to make a Star Wars Imperial emblem (http://www.thingiverse.com/thing:17155) as a test print for my Slic3r settings, and it keeps coming out with the same issues as the calibration print (photos below)

Same thing: not entirely symmetrical (like it's supposed to be) and still has space between the sections where the printer extrudes in different ways.

I'm running a Botmill Axis 2.1 printer (Mendel) with a Wade's geared extruder that features a .35mm nozzle from MakerGear.

I've also tested my extruder to within my capacity for measurement error, and it seems to be pretty close to precisely extruding 5mm of plastic when I tell it to through Pronterface.

All help will be greatly appreciated as I'm so close to being finished after such a long fight (both with Botmill and the printer). . . at least I think. . .I just want this thing to work and be able to make some nice, symmetrical prints.

Thank you, thank you, thank you, to all of you who I lean on so heavily to get me to the end of this project.

Almost there. . .

Sincerely,

RR

|

Re: Calibration problem? May 30, 2012 07:47PM |

Registered: 13 years ago Posts: 123 |

MrBlack,

Tell us a little more about the plastic (is it PLA or ABS) and your Slic3r settings. What indicated temperature are you printing at, do you have a thermocouple on a multimeter that confirmed your indicated temperate is close to what you are really extruding at, what speeds do you have Slic3r set for perimeters and infill? When you watch it print one of these objects, does it look to you like the nozzle is reaching the perimeter during the infill but pulling the plastic back away when it reverses direction? Do you get the same results when you slow down the print speeds and travel speeds?

What firmware are you using?

Tell us a little more about the plastic (is it PLA or ABS) and your Slic3r settings. What indicated temperature are you printing at, do you have a thermocouple on a multimeter that confirmed your indicated temperate is close to what you are really extruding at, what speeds do you have Slic3r set for perimeters and infill? When you watch it print one of these objects, does it look to you like the nozzle is reaching the perimeter during the infill but pulling the plastic back away when it reverses direction? Do you get the same results when you slow down the print speeds and travel speeds?

What firmware are you using?

|

Re: Calibration problem? May 30, 2012 08:23PM |

Registered: 12 years ago Posts: 19 |

1.) Tell us a little more about the plastic (is it PLA or ABS) and your Slic3r settings.

PLA, 3mm, natural color (no pigment.)

2.)What indicated temperature are you printing at?

I have Slic3r set for 185, and I preheat it through Pronterface manually every time I go to print.

3.) Do you have a thermocouple on a multimeter that confirmed your indicated temperate is close to what you are really extruding at?

I just have a thermistor/heater block setup. No multimeter, but the temperature doesn’t seem to be causing any problems so far.

4.) What speeds do you have Slic3r set for perimeters and infill?

On the nickel calibration test, I don’t know what the settings are, because I just downloaded the Gcode directly from the link in my original post.

Infill speed on the Imperial Emblem is 60.

Perimeter speed and Small Perimeter speed are set to 55.

I’ve also attached the notepad version of my Slic3r settings to this message.

5.) When you watch it print one of these objects, does it look to you like the nozzle is reaching the perimeter during the infill but pulling the plastic back away when it reverses direction?

It doesn’t look like it’s pulling the plastic away, it just seems like it never reaches those areas at all. . . Maybe because of the paths it’s taking?

6.) Do you get the same results when you slow down the print speeds and travel speeds?

I haven’t tested extensively yet, but I have operated at about half speed and it still does the same thing, as far as I could tell.

7.) What firmware are you using?

I use Printrun (Pronterface) and Slic3r. I have never used Skeinforge at all.

PLA, 3mm, natural color (no pigment.)

2.)What indicated temperature are you printing at?

I have Slic3r set for 185, and I preheat it through Pronterface manually every time I go to print.

3.) Do you have a thermocouple on a multimeter that confirmed your indicated temperate is close to what you are really extruding at?

I just have a thermistor/heater block setup. No multimeter, but the temperature doesn’t seem to be causing any problems so far.

4.) What speeds do you have Slic3r set for perimeters and infill?

On the nickel calibration test, I don’t know what the settings are, because I just downloaded the Gcode directly from the link in my original post.

Infill speed on the Imperial Emblem is 60.

Perimeter speed and Small Perimeter speed are set to 55.

I’ve also attached the notepad version of my Slic3r settings to this message.

5.) When you watch it print one of these objects, does it look to you like the nozzle is reaching the perimeter during the infill but pulling the plastic back away when it reverses direction?

It doesn’t look like it’s pulling the plastic away, it just seems like it never reaches those areas at all. . . Maybe because of the paths it’s taking?

6.) Do you get the same results when you slow down the print speeds and travel speeds?

I haven’t tested extensively yet, but I have operated at about half speed and it still does the same thing, as far as I could tell.

7.) What firmware are you using?

I use Printrun (Pronterface) and Slic3r. I have never used Skeinforge at all.

|

Re: Calibration problem? May 30, 2012 09:14PM |

Registered: 12 years ago Posts: 19 |

|

Re: Calibration problem? May 30, 2012 09:30PM |

Registered: 13 years ago Posts: 123 |

By firmware I meant the code that executes on your Arduino, something like Marlin, Sprinter, Teacup, 5D, or the like.

The temperature you are using is in the right ballpark for PLA, but if your firmware is using the wrong temperature table then it is possible that you are not getting as hot as you think and therefore may be stretching the filament around inside perimeters and/or not getting adhesion during infill when the filament touches the perimeter and the nozzle reverses direction.

I hadn't noticed that the nickel calibration link even had gcode attached. I downloaded the STL file, sliced it with Slic3r and got good results printing. I'm surprised you got as good a result as your photos show from looking at that gcode; it looks like it starts the first layer at 0.36mm, larger than your 0.35mm nozzle. I'm guessing that the author has a 0.50mm nozzle.

Try, for now, slowing down your perimeter speeds to say 30, increase your temperature by 5 or 10 degrees, and slice and print the nickel calibration piece (I'm assuming it will print faster than your other test object). Post some pictures of those results so we can see if that moves things in the right direction.

The temperature you are using is in the right ballpark for PLA, but if your firmware is using the wrong temperature table then it is possible that you are not getting as hot as you think and therefore may be stretching the filament around inside perimeters and/or not getting adhesion during infill when the filament touches the perimeter and the nozzle reverses direction.

I hadn't noticed that the nickel calibration link even had gcode attached. I downloaded the STL file, sliced it with Slic3r and got good results printing. I'm surprised you got as good a result as your photos show from looking at that gcode; it looks like it starts the first layer at 0.36mm, larger than your 0.35mm nozzle. I'm guessing that the author has a 0.50mm nozzle.

Try, for now, slowing down your perimeter speeds to say 30, increase your temperature by 5 or 10 degrees, and slice and print the nickel calibration piece (I'm assuming it will print faster than your other test object). Post some pictures of those results so we can see if that moves things in the right direction.

|

Re: Calibration problem? May 30, 2012 09:37PM |

Registered: 12 years ago Posts: 19 |

|

Re: Calibration problem? May 30, 2012 11:09PM |

Registered: 12 years ago Posts: 19 |

Alright, I ran 3 tests from your recommendations:

All had the heat at 195 (up from 185)

All had the perimeter and small perimeter speeds at 30 (down from 55)

Test 1 ( )

Had ONLY those settings modified.

Test 2 ( )

Additionally, I modified the infill speed and solid infill speed to 45 (down from 60 on both)

Test 3 ( )

Had the modified infill/solid infill speeds down to 45 from test 2

AND

Fill Density up from .4 to .5.

This print (Test 3) was far and away the worst copy, plus -even though I upped the fill density- it didn't do anything to fill those empty spaces.

It appears the first test came out the best, although they all still have little open places in them like before.

The prints are already much better with the higher heat and slower perimeter speed modifications, but I still don't quite know how to get rid of the empty spaces on the print. Could it be a calibration problem or a mechanical issue? The printer seems to be working fine outside of those places. Could it still be that infill speeds need to go lower?

Thoughts?

All had the heat at 195 (up from 185)

All had the perimeter and small perimeter speeds at 30 (down from 55)

Test 1 ( )

Had ONLY those settings modified.

Test 2 ( )

Additionally, I modified the infill speed and solid infill speed to 45 (down from 60 on both)

Test 3 ( )

Had the modified infill/solid infill speeds down to 45 from test 2

AND

Fill Density up from .4 to .5.

This print (Test 3) was far and away the worst copy, plus -even though I upped the fill density- it didn't do anything to fill those empty spaces.

It appears the first test came out the best, although they all still have little open places in them like before.

The prints are already much better with the higher heat and slower perimeter speed modifications, but I still don't quite know how to get rid of the empty spaces on the print. Could it be a calibration problem or a mechanical issue? The printer seems to be working fine outside of those places. Could it still be that infill speeds need to go lower?

Thoughts?

|

Re: Calibration problem? May 30, 2012 11:18PM |

Admin Registered: 15 years ago Posts: 1,470 |

Your infill speeds shouldn't need to be any slower. Your problem looks like backlash, either the belts aren't tight enough or they are not fitting the pulleys properly. With the motors on and not moving, are you able to move the x- and y- carriages back and forth by hand at all?

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Calibration problem? May 30, 2012 11:44PM |

Registered: 13 years ago Posts: 123 |

If I am looking at your photos correctly it looks like the infill not touching the perimeter is mostly on the Y direction, is that correct? Do you have springs on your printbed, and how much give do you have? Could it be the bed bouncing on the springs? Slowing down even more should confirm/deny that.

Another thought is that your nozzle is not as large as you may think. Perhaps it has gotten slightly clogged during your previous usage? If you raise the head to 20mm and extrude filament into the air, what is the diameter of the extruded filament? PLA doesn't have as large of die swell as ABS, but it should still be larger than the 0.35mm nozzle. I clogged my 0.35mm Makergear and am using a 0.50mm nozzle right now, but if I remember correctly you should see something like 0.4mm on the free-air extruded filament. If you have less, then when Slic3r does its calculations the width of each stripe it will be less than it thinks. You can compensate by telling Slic3r you have a smaller nozzle.

Lastly, try increasing the heat another 5 or 10 degrees. You don't want it drooling out of the nozzle in a semi-liquid form, but that additional die swell may close up the gaps.

Another thought is that your nozzle is not as large as you may think. Perhaps it has gotten slightly clogged during your previous usage? If you raise the head to 20mm and extrude filament into the air, what is the diameter of the extruded filament? PLA doesn't have as large of die swell as ABS, but it should still be larger than the 0.35mm nozzle. I clogged my 0.35mm Makergear and am using a 0.50mm nozzle right now, but if I remember correctly you should see something like 0.4mm on the free-air extruded filament. If you have less, then when Slic3r does its calculations the width of each stripe it will be less than it thinks. You can compensate by telling Slic3r you have a smaller nozzle.

Lastly, try increasing the heat another 5 or 10 degrees. You don't want it drooling out of the nozzle in a semi-liquid form, but that additional die swell may close up the gaps.

|

Re: Calibration problem? May 31, 2012 12:02AM |

Registered: 12 years ago Posts: 19 |

@NewPerfection: I know I can move at least the Y when the motors are on but not moving. I haven't tried the X, but I'll update tomorrow when I start testing again.

@Mkouri: that is correct, it appears that most of my infill not touching the perimeter is on my Y axis, although there is some space on the X as well.

Hm. Intriguing. I'll test whether my nozzle is clogged and up the heat tomorrow to see if that helps. Plus I'm going to recalibrate the Y, just a hair, to see if that does anything also.

I had calibrated the printer to where X and Y are not quite equal in my firmware, because that's what my measures told me, but i'll retest it and check the nozzle tomorrow. If nothing else, I'll at least try making them equal again.

Thanks for all the help so far, guys. My prints are looking much better already, even just from the few adjustments from your recommendations.

@Mkouri: that is correct, it appears that most of my infill not touching the perimeter is on my Y axis, although there is some space on the X as well.

Hm. Intriguing. I'll test whether my nozzle is clogged and up the heat tomorrow to see if that helps. Plus I'm going to recalibrate the Y, just a hair, to see if that does anything also.

I had calibrated the printer to where X and Y are not quite equal in my firmware, because that's what my measures told me, but i'll retest it and check the nozzle tomorrow. If nothing else, I'll at least try making them equal again.

Thanks for all the help so far, guys. My prints are looking much better already, even just from the few adjustments from your recommendations.

|

Re: Calibration problem? June 01, 2012 02:07AM |

Registered: 12 years ago Posts: 142 |

I agree with the suggestion of belt tension.

I was having problems with my prints printing the first layer ok then stepping up to 5 mm before the next layer. What frustrated me was that the rest of the print would turn out great.

Turns out the X belt was binding on the fender washer at the idler end and the Y belt was loose.

Fixed these up and it prints great.

I have to have my hotend at 200 for it to print and stick when using pla but I suspect my thermistor is not the correct type so play with the temp and see what happens. Too cold and it wont extrude or stick. Too hot and it will ooze over the sides of your print.

The temp is also dependent on room temperature. It is winter here and the air temp is about 10 deg c so I turn everything up 5 to 10 degrees.

I was having problems with my prints printing the first layer ok then stepping up to 5 mm before the next layer. What frustrated me was that the rest of the print would turn out great.

Turns out the X belt was binding on the fender washer at the idler end and the Y belt was loose.

Fixed these up and it prints great.

I have to have my hotend at 200 for it to print and stick when using pla but I suspect my thermistor is not the correct type so play with the temp and see what happens. Too cold and it wont extrude or stick. Too hot and it will ooze over the sides of your print.

The temp is also dependent on room temperature. It is winter here and the air temp is about 10 deg c so I turn everything up 5 to 10 degrees.

|

Re: Calibration problem? June 01, 2012 11:32AM |

Registered: 13 years ago Posts: 123 |

I agree now that backlash seems like the prime remaining suspect, and checking belt tightness and free play should help identify that.

Gregted, room temperature and humidity both have a part in the best extrusion temperature, as does the particular plastic. I've found that the Ultimachine transluscent PLA works best for me at 10-15 degrees cooler than their more heavily saturated colors, and in my experience their orange PLA is nearly impossible to get good quality prints from, it seems to need different temperatures along its length. That may just be a bad spool, but I won't buy their orange any longer. Transluscent green and blue have been very consistent across many spools.

Gregted, room temperature and humidity both have a part in the best extrusion temperature, as does the particular plastic. I've found that the Ultimachine transluscent PLA works best for me at 10-15 degrees cooler than their more heavily saturated colors, and in my experience their orange PLA is nearly impossible to get good quality prints from, it seems to need different temperatures along its length. That may just be a bad spool, but I won't buy their orange any longer. Transluscent green and blue have been very consistent across many spools.

|

Re: Calibration problem? June 01, 2012 12:40PM |

Registered: 11 years ago Posts: 79 |

Backlash seems likely but also check step loss or binding.

Are you sure your not loosing steps from binding or low current? Check the movement is smooth with power off.

Then Try printing in a different area of the bed. If there is one sticky spot it may loose steps there each time consistently. Making it run short.

Lastly I would up the current to the steppers and see if it improves at all. It may be loosing steps each time it acclerates/changes direction. So either up the current or reduce your acceleration settings.

Good luck.

Are you sure your not loosing steps from binding or low current? Check the movement is smooth with power off.

Then Try printing in a different area of the bed. If there is one sticky spot it may loose steps there each time consistently. Making it run short.

Lastly I would up the current to the steppers and see if it improves at all. It may be loosing steps each time it acclerates/changes direction. So either up the current or reduce your acceleration settings.

Good luck.

|

Re: Calibration problem? June 02, 2012 12:04AM |

Registered: 12 years ago Posts: 19 |

Sorry, only registered users may post in this forum.