Puller for an extruder

Posted by IanJohnson

|

Puller for an extruder February 14, 2013 03:35AM |

Registered: 12 years ago Posts: 132 |

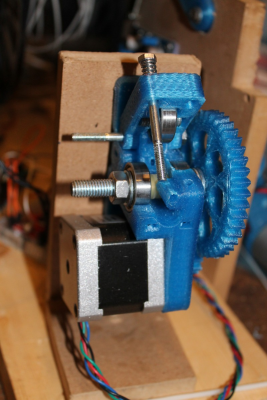

I am working on a puller for my Filastruder. The die opening is larger than the filament, and the filament gets stretched down to the needed diameter as it is pulled away toward the spool winder. The puller is a Greg's Wade's extruder mounted sideways, driven by an Arduino Uno. I put a small piece of latex tube over the bolt and tweaked the Wade's to make room for the wider diameter. I didn't hob the bolt because I'm concerned about putting teeth marks in it.

To keep the filament within tolerances, the tension needs to be absolutely constant, so the feed rate of the puller can't be allowed change. The problem I'm having is that the filament compresses the latex and changes the effective diameter of the roller, which changes the feed rate. Any variation in filament diameter varies the roller diameter, which varies the speed and causes variation in the filament diameter as it exits the extruder, which eventually reaches the roller and starts it all over again.

Any ideas on how I can grip the filament in the puller? It doesn't need a lot of force to push the filament since there is no hot end to force it into, but I want a tight grip. Ideally movement and tension on the spooling side won't be allowed to travel through the puller and affect the filament at the extruder.

Edited 1 time(s). Last edit at 02/14/2013 03:37AM by IanJohnson.

To keep the filament within tolerances, the tension needs to be absolutely constant, so the feed rate of the puller can't be allowed change. The problem I'm having is that the filament compresses the latex and changes the effective diameter of the roller, which changes the feed rate. Any variation in filament diameter varies the roller diameter, which varies the speed and causes variation in the filament diameter as it exits the extruder, which eventually reaches the roller and starts it all over again.

Any ideas on how I can grip the filament in the puller? It doesn't need a lot of force to push the filament since there is no hot end to force it into, but I want a tight grip. Ideally movement and tension on the spooling side won't be allowed to travel through the puller and affect the filament at the extruder.

Edited 1 time(s). Last edit at 02/14/2013 03:37AM by IanJohnson.

|

Re: Puller for an extruder February 14, 2013 03:51AM |

Registered: 11 years ago Posts: 251 |

|

Re: Puller for an extruder February 14, 2013 05:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Puller for an extruder February 14, 2013 12:06PM |

|

Re: Puller for an extruder February 14, 2013 05:04PM |

Registered: 11 years ago Posts: 79 |

|

Re: Puller for an extruder February 14, 2013 06:00PM |

Registered: 12 years ago Posts: 132 |

Does the puller put tension on the plastic at the die to size the wire? Or does it only push out and rest on the bottom of the trough before getting picked up by the roller?

The Filastruder will maintain a close enough tolerance if it just extrudes and lands on the floor or table. If the spooler takes up the filament without lifting it completely off of whatever it landed on, the tension at the die (and the filament size) will stay consistent. The challenge with that is maneuvering it to the puller without disturbing it enough to cause a kink which will jam the puller and cause more kinks. Also the speed of the puller has to exactly match the feedrate. If it's a little too fast, over several hours it will overtake the extruder and begin stretching the filament. A little too slow, and the filament will start piling up and might push back against the die and begin making plastic ramen noodles. I think it's ironic that Makibox is calling their extruder Ramen, when that is what we call it when the filament goes out of control.

The Filastruder will maintain a close enough tolerance if it just extrudes and lands on the floor or table. If the spooler takes up the filament without lifting it completely off of whatever it landed on, the tension at the die (and the filament size) will stay consistent. The challenge with that is maneuvering it to the puller without disturbing it enough to cause a kink which will jam the puller and cause more kinks. Also the speed of the puller has to exactly match the feedrate. If it's a little too fast, over several hours it will overtake the extruder and begin stretching the filament. A little too slow, and the filament will start piling up and might push back against the die and begin making plastic ramen noodles. I think it's ironic that Makibox is calling their extruder Ramen, when that is what we call it when the filament goes out of control.

Sorry, only registered users may post in this forum.