Filament drive gear design

Posted by LoboCNC

|

Filament drive gear design May 09, 2013 03:08PM |

Registered: 10 years ago Posts: 564 |

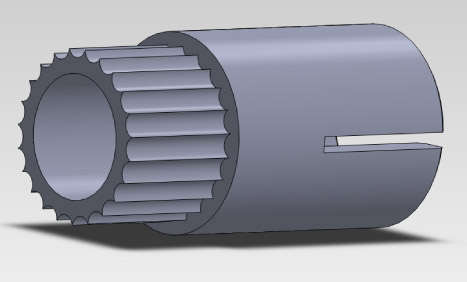

Here's a filament drive gear that seems to be less prone to clogging that the standard V-groove hobbed gears:

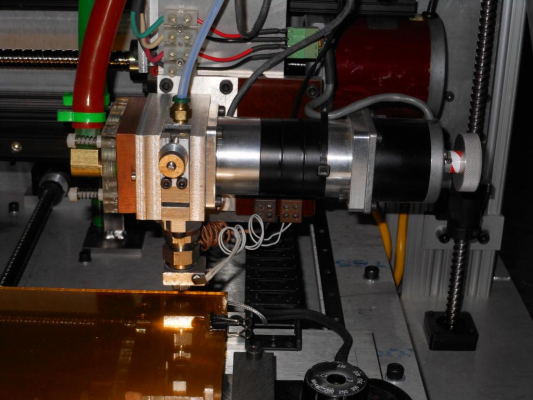

The teeth have a circular profile which seems to eject filament shavings better than the V-groove formed with a tap. I made this on my little CNC mill (Lobo CNC mill) using a 0.032" dia end mill . The OD of the toothed portion is 7mm. Overall, it seems pretty grippy.

The other innovation is the press-fit hub. I started with an 8mm rod, and then drilled and reamed it to 5mm. I then split the end of the hub about 0.25" deep on a bandsaw. Finally, I crimped the split end using a 0.182" dia drill bit as a mandrill to keep from over-squishing it. This gives a medium press-fit that you can tap on with a plastic mallet and pry off with a pair of screwdrivers. It's got way more grip than the motor torque.

If anyone's interested, I can provide more details.

-Jeff

Edited 1 time(s). Last edit at 05/09/2013 03:11PM by LoboCNC.

The teeth have a circular profile which seems to eject filament shavings better than the V-groove formed with a tap. I made this on my little CNC mill (Lobo CNC mill) using a 0.032" dia end mill . The OD of the toothed portion is 7mm. Overall, it seems pretty grippy.

The other innovation is the press-fit hub. I started with an 8mm rod, and then drilled and reamed it to 5mm. I then split the end of the hub about 0.25" deep on a bandsaw. Finally, I crimped the split end using a 0.182" dia drill bit as a mandrill to keep from over-squishing it. This gives a medium press-fit that you can tap on with a plastic mallet and pry off with a pair of screwdrivers. It's got way more grip than the motor torque.

If anyone's interested, I can provide more details.

-Jeff

Edited 1 time(s). Last edit at 05/09/2013 03:11PM by LoboCNC.

|

Re: Filament drive gear design May 09, 2013 06:53PM |

Registered: 11 years ago Posts: 254 |

|

Re: Filament drive gear design May 09, 2013 07:12PM |

Registered: 10 years ago Posts: 474 |

This is something else I came up with the idea of using a mig welder serrated wheel its way be too big for you guys but I have a much larger more powerful machine it does not clog it does not strip in fact so good as close as I can get the Teflon to the wheel it'll bend it and just push it out if there's a problem in the feeding of filament because of temperature or too close to bed my extruder motor is a Nema 23 and one hundred to one gearbox here is a pic of my large machine

https://www.facebook.com/photo.php?v=108932639308726&l=439374382398743664[www.facebook.com]

|

Re: Filament drive gear design May 09, 2013 07:39PM |

Registered: 10 years ago Posts: 564 |

Gerard Choinka Wrote:

-------------------------------------------------------

> Looks nice

> a traction test like this

> [hydraraptor.blogspot.de]-

> and-no-traction.html would be nice

Thanks for the link - this blog has just the sort of data I was looking for. I'll see if I can't rig up a test rig to get some numbers for comparison.

-------------------------------------------------------

> Looks nice

> a traction test like this

> [hydraraptor.blogspot.de]-

> and-no-traction.html would be nice

Thanks for the link - this blog has just the sort of data I was looking for. I'll see if I can't rig up a test rig to get some numbers for comparison.

|

Re: Filament drive gear design May 09, 2013 08:04PM |

Registered: 10 years ago Posts: 474 |

LoboCNC I think that the mig serrated drive wheels were actually printed in metal because they not have a radius a true v serrations not lined up to each other mail female and very had material my extruder probably ways1pound when I was testing it nothing elaborate as Hydra raptor I could grab onto the filament give myself approximately 2 feet of play with 1.75 ABS and literally throw it and it would not strip this could be because it's bigger diameter if I remember right I think it was 1.25 inch approximately and more teeth engaged

|

Re: Filament drive gear design May 09, 2013 08:23PM |

Registered: 10 years ago Posts: 474 |

|

Re: Filament drive gear design May 09, 2013 11:14PM |

Registered: 10 years ago Posts: 564 |

One interesting thing to think about with the tooth profile is the comparison with timing belts. Conventional trapezoidal tooth timing belts have a much lower load rating than the HTD style belts with the round tooth profile. I wonder if that applies to driving filament?

On the split hub, yes, doing the normal thing of using a hub collar over the split hub does make it foolproof. I'd seen the split-hub press-fit thing done with encoder wheels, and I though'd I'd see how well it worked for actually driving some torque.

-Jeff

On the split hub, yes, doing the normal thing of using a hub collar over the split hub does make it foolproof. I'd seen the split-hub press-fit thing done with encoder wheels, and I though'd I'd see how well it worked for actually driving some torque.

-Jeff

Sorry, only registered users may post in this forum.