KickStarter Campaign For Dual Extruder

Posted by Idolcrasher

|

KickStarter Campaign For Dual Extruder June 11, 2012 08:29PM |

Registered: 12 years ago Posts: 539 |

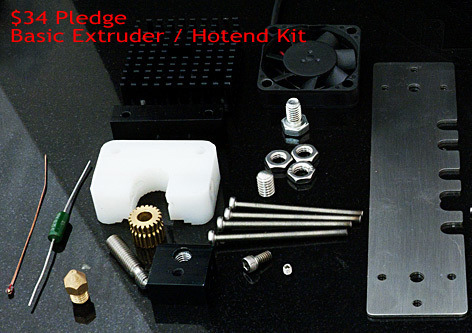

Saw this on kickstarter and thought the community should know: KickStarter Campaign For Dual Extruder

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 07:33AM |

Registered: 11 years ago Posts: 329 |

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 04:32PM |

Registered: 12 years ago Posts: 140 |

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 05:53PM |

Registered: 13 years ago Posts: 818 |

I decided to go for the dual kit with resistors a few days back, it looks like the MK7/8 so should work ok, I'm not a fan of direct drive, but it's quite a nice setup for dual extrusion and very reasonable cost, it's looks like they are doing very well with the campaign, so should be able to get these machined nicely.

[richrap.blogspot.com]

[richrap.blogspot.com]

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 06:53PM |

Admin Registered: 17 years ago Posts: 7,879 |

I could never understand how dual extruders side by side would work. I.e. what stops one nozzle dribbling while the other is extruding. I saw a Makerbot Replicator working the other day. The answer is nothing. It completely failed to print a ball because each nozzle dribbled, so when it was its turn to extrude it was short of plastic and left gaps so the other filament had nothing to stick to so got dragged around and so it went on. It just made two plastic spaghetti.

Anybody seen one working? How does it manage to not dribble on the model and have enough plastic to be ready to extrude?

[www.hydraraptor.blogspot.com]

Anybody seen one working? How does it manage to not dribble on the model and have enough plastic to be ready to extrude?

[www.hydraraptor.blogspot.com]

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 07:10PM |

Registered: 11 years ago Posts: 939 |

KisSlicer has a setting for it, and though I've never seen it run, what it appears to do is draw a cylinder next to the model retract and wipe the nozzle on the cylinder on color/material changes.

I agree though, unless you have a very high pressure nozzle, it's still going to leak on things, plus your dragging a second hotend over the part while printing.

I agree though, unless you have a very high pressure nozzle, it's still going to leak on things, plus your dragging a second hotend over the part while printing.

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 08:31PM |

Registered: 12 years ago Posts: 108 |

nophead Wrote:

> Anybody seen one working? How does it manage to

> not dribble on the model and have enough plastic

> to be ready to extrude?

Not personally, but I found this video. It's strange that the first 4 pages of videos looking for printing examples are completely dominated by commercials uploaded by Makerbot, trade show presentation uploaded by just about everyone, and support videos intended for purchasers. Of those videos, I hadn't seen any that were actually using both extruders except the one I just linked.

Cleaned up pretty well IMO, even though it did look quite awkward with long tails on the 3 side from the less-used extruder. I wonder if the retraction when switching nozzles is just a regular travel retraction or if they use a longer retraction but it drools anyway. I suppose it's better than retracting too much and then causing a blob when the filament is pushed in suddenly.

> Anybody seen one working? How does it manage to

> not dribble on the model and have enough plastic

> to be ready to extrude?

Not personally, but I found this video. It's strange that the first 4 pages of videos looking for printing examples are completely dominated by commercials uploaded by Makerbot, trade show presentation uploaded by just about everyone, and support videos intended for purchasers. Of those videos, I hadn't seen any that were actually using both extruders except the one I just linked.

Cleaned up pretty well IMO, even though it did look quite awkward with long tails on the 3 side from the less-used extruder. I wonder if the retraction when switching nozzles is just a regular travel retraction or if they use a longer retraction but it drools anyway. I suppose it's better than retracting too much and then causing a blob when the filament is pushed in suddenly.

|

Re: KickStarter Campaign For Dual Extruder June 14, 2012 10:55PM |

Registered: 11 years ago Posts: 939 |

|

Re: KickStarter Campaign For Dual Extruder June 15, 2012 03:41AM |

Admin Registered: 17 years ago Posts: 7,879 |

I found it doesn't matter how far you retract it will still ooze very slowly due to gravity.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: KickStarter Campaign For Dual Extruder June 15, 2012 04:26AM |

Registered: 13 years ago Posts: 818 |

I also saw a replicator operating last month, and it was not doing a great job of handling either one or two extruder's, but I expect that was down to the way it had been setup. I was also rather shocked how slow it was printing, especially the first layer, that was going at about 5mm/sec.

Maybe printing reasonably fast and drop the temperature of the non printing extruder back by ~20 degrees, you would still need to re-heat and prime/wipe both nozzles at change-over time to ensure a clean model.

[richrap.blogspot.com]

Maybe printing reasonably fast and drop the temperature of the non printing extruder back by ~20 degrees, you would still need to re-heat and prime/wipe both nozzles at change-over time to ensure a clean model.

[richrap.blogspot.com]

|

Re: KickStarter Campaign For Dual Extruder June 23, 2012 06:48PM |

Registered: 12 years ago Posts: 60 |

Horrible design for a dual extruder.

sure lets use only 1/3 of the print bed and have leveling nozzle issues and print at a max speed of 30mm/s and be limited to 1.75mm filament oh and weigh the x axis down a ton...

Smart...

I feel sorry for you backers who are about to be dissapointed...

sure lets use only 1/3 of the print bed and have leveling nozzle issues and print at a max speed of 30mm/s and be limited to 1.75mm filament oh and weigh the x axis down a ton...

Smart...

I feel sorry for you backers who are about to be dissapointed...

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 02:06AM |

Registered: 12 years ago Posts: 93 |

Are there any inherent design flaws with it as a single extruder? Any critique can help us improve products in the future.

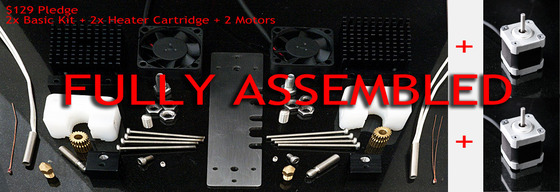

Two extruders mounted side by side does take up more room than a single extruder, its a trade-off for having two extruders. The 42mm on a side NEMA 17 motors are your limiting factor there; a bowden cable style extruder could be used side by side to minimize the decrease in build area but there are greater oozing issues present. The standard linear bearing x-carraige for a Prusa Mendel is actually slightly wider than two of the extruders mounted side by side so the only build area decrease you have is the distance between the two nozzle orifices which is ~33mm, leaving you with 5/6 of the print bed usable (assuming my math is right...its late!).

The nozzles do have to be level in order to get high-quality prints, however that would be the case with any dual extrusion package (at least one that uses two separate nozzles). Assuming your x-carraige is level relative to your print bed, the two nozzles are very easy to get lined up.

1.75mm filament compatibility was a choice that we made as it allowed for a smaller motor than a 3mm version in order to reduce moving mass. Due to the demand for a 3mm version, however, we will be looking into that in the future, although it will require a longer NEMA 17 motor.

The reason we decided to use the grooved spur gear in order to increase grip which allows a higher speed to be maintained without slipping. In our testing we have been able to achieve significantly faster extrusion speeds than 30mm/s. Because it is able to extrude and retract with such speed, oozing is very limited although as Nophead mentioned earlier, gravity does always play a role, however but by keeping the speeds up dripping can be minimized. It really depends on what you are printing...the dice in the above video would have more dripping because one of the nozzles sits idle for several layers at a time between dots, whereas a globe that is using both colors on the same layer would minimize any issues. In testing limiting factor of the speed of extruder has been the rigidity of the 3D printer, not the extruder itself.

Thank you for your feedback; its always good to start a dialog and get questions answered!

-Chelsea

Two extruders mounted side by side does take up more room than a single extruder, its a trade-off for having two extruders. The 42mm on a side NEMA 17 motors are your limiting factor there; a bowden cable style extruder could be used side by side to minimize the decrease in build area but there are greater oozing issues present. The standard linear bearing x-carraige for a Prusa Mendel is actually slightly wider than two of the extruders mounted side by side so the only build area decrease you have is the distance between the two nozzle orifices which is ~33mm, leaving you with 5/6 of the print bed usable (assuming my math is right...its late!).

The nozzles do have to be level in order to get high-quality prints, however that would be the case with any dual extrusion package (at least one that uses two separate nozzles). Assuming your x-carraige is level relative to your print bed, the two nozzles are very easy to get lined up.

1.75mm filament compatibility was a choice that we made as it allowed for a smaller motor than a 3mm version in order to reduce moving mass. Due to the demand for a 3mm version, however, we will be looking into that in the future, although it will require a longer NEMA 17 motor.

The reason we decided to use the grooved spur gear in order to increase grip which allows a higher speed to be maintained without slipping. In our testing we have been able to achieve significantly faster extrusion speeds than 30mm/s. Because it is able to extrude and retract with such speed, oozing is very limited although as Nophead mentioned earlier, gravity does always play a role, however but by keeping the speeds up dripping can be minimized. It really depends on what you are printing...the dice in the above video would have more dripping because one of the nozzles sits idle for several layers at a time between dots, whereas a globe that is using both colors on the same layer would minimize any issues. In testing limiting factor of the speed of extruder has been the rigidity of the 3D printer, not the extruder itself.

Thank you for your feedback; its always good to start a dialog and get questions answered!

-Chelsea

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 08:56AM |

Registered: 12 years ago Posts: 539 |

richrap Wrote:

-------------------------------------------------------

> I decided to go for the dual kit with resistors a

> few days back, it looks like the MK7/8 so should

> work ok, I'm not a fan of direct drive, but it's

> quite a nice setup for dual extrusion and very

> reasonable cost, it's looks like they are doing

> very well with the campaign, so should be able to

> get these machined nicely.

Rich,

I put in for the double extruder pre-made. Any chance your quick fit x-Carriage could get an adapter to carry one ore two of these extruders?

I think it would be akin to carrying the same extruder as attached to the Replicator.

-------------------------------------------------------

> I decided to go for the dual kit with resistors a

> few days back, it looks like the MK7/8 so should

> work ok, I'm not a fan of direct drive, but it's

> quite a nice setup for dual extrusion and very

> reasonable cost, it's looks like they are doing

> very well with the campaign, so should be able to

> get these machined nicely.

Rich,

I put in for the double extruder pre-made. Any chance your quick fit x-Carriage could get an adapter to carry one ore two of these extruders?

I think it would be akin to carrying the same extruder as attached to the Replicator.

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 12:15PM |

Registered: 12 years ago Posts: 60 |

It is a poor design all together, the motor selection is wrong the spacing is huge the direction of nozzles is wrong, sure it will work fine on a replicator with space next to a bed or a bed moving in x and y but not only y. You added a ton of moving mass, and moving mass is a reprap's primary enemy. Your motors are limited on torque becaues a direct drive solution needs to be geared to get decent print speeds.

Just an all around poor design for a reprap, may be fine for makerbot but not us.

Plus the fact that you basically reverse engineered someonelse's work to under cut them is kinda low in my book. Why not design a new version that would work on reprap instead of trying to shove a square peg into a round hole.

Have you put one of these monstrosities on a prusa frame and tried to print yet? how much new resonance are you seeing, how many new modes of resonance failure have you introduced? what has you z height been reduced to? Did you do any simulations or modal studies? Do you have engineers or just people with calipers?

Like I said poor design for a reprap, maybe a repstrap or ordbot is fine, but anyone putting this on a prusa frame is going to be sorely dissapointed.

If you want to go in a new direction look at what Stratysis does and how small and close together their system is compared to yours, er MakerBot's. Who you need to credit by the way with the design.

All current opensource designs for dual extrusion (other than reprap pro's bowden system) are a nightmare for a reprap and are designed in the wrong direction for the wrong machine.

Edited 3 time(s). Last edit at 06/24/2012 03:23PM by WildBill.

Just an all around poor design for a reprap, may be fine for makerbot but not us.

Plus the fact that you basically reverse engineered someonelse's work to under cut them is kinda low in my book. Why not design a new version that would work on reprap instead of trying to shove a square peg into a round hole.

Have you put one of these monstrosities on a prusa frame and tried to print yet? how much new resonance are you seeing, how many new modes of resonance failure have you introduced? what has you z height been reduced to? Did you do any simulations or modal studies? Do you have engineers or just people with calipers?

Like I said poor design for a reprap, maybe a repstrap or ordbot is fine, but anyone putting this on a prusa frame is going to be sorely dissapointed.

If you want to go in a new direction look at what Stratysis does and how small and close together their system is compared to yours, er MakerBot's. Who you need to credit by the way with the design.

All current opensource designs for dual extrusion (other than reprap pro's bowden system) are a nightmare for a reprap and are designed in the wrong direction for the wrong machine.

Edited 3 time(s). Last edit at 06/24/2012 03:23PM by WildBill.

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 05:30PM |

Registered: 12 years ago Posts: 93 |

Ok folks, I have had my coffee!

Our goal with this design was to offer a high-quality extruder at the lowest price possible.

Looking at the weight of our single extruder vs. a single Wade's geared extruder there is actually LESS weight on our cold end. Our hot end is also LESS weight than the traditional popular hot ends (j-head etc.).

The motor is sized appropriately for the extruder. The limiting factor on extrusion speed is not the motor, or the extruder, it is a factor of how rigid the 3D printer is and the speed at which the carraige is moving. Having a geared motor does not offer any advantages (except resolution that we found does not really translate into improved print quality at this level) over the one we specified, the only thing it does is add cost which we would have to pass on.

We have two Prusa Mendels at the shop and the extruders have been tested on them.

On the cold end side, there is actually MORE room on Z than a Wade's Geared extruder. On the hot end side, the overall length when compared to a j-head is SHORTER. Overall you GAIN Z travel (not very much).

The beauty of open-source is that everyone is free to take other's designs and modify, improve and commercialize them. This spawns tons of innovation and in this case reduces costs a HUGE amount which helps the community. We have mentioned quite a few times here, on our website and the Kickstarter campaign that it is derivative of Makerbot's design which in turn is derived from UP!'s. When the files are uploaded to thingiverse, they will include that info as well. What doesn't work with Reprap is high cost, we helped reduce that significantly.

-Chelsea

Our goal with this design was to offer a high-quality extruder at the lowest price possible.

Looking at the weight of our single extruder vs. a single Wade's geared extruder there is actually LESS weight on our cold end. Our hot end is also LESS weight than the traditional popular hot ends (j-head etc.).

The motor is sized appropriately for the extruder. The limiting factor on extrusion speed is not the motor, or the extruder, it is a factor of how rigid the 3D printer is and the speed at which the carraige is moving. Having a geared motor does not offer any advantages (except resolution that we found does not really translate into improved print quality at this level) over the one we specified, the only thing it does is add cost which we would have to pass on.

We have two Prusa Mendels at the shop and the extruders have been tested on them.

On the cold end side, there is actually MORE room on Z than a Wade's Geared extruder. On the hot end side, the overall length when compared to a j-head is SHORTER. Overall you GAIN Z travel (not very much).

The beauty of open-source is that everyone is free to take other's designs and modify, improve and commercialize them. This spawns tons of innovation and in this case reduces costs a HUGE amount which helps the community. We have mentioned quite a few times here, on our website and the Kickstarter campaign that it is derivative of Makerbot's design which in turn is derived from UP!'s. When the files are uploaded to thingiverse, they will include that info as well. What doesn't work with Reprap is high cost, we helped reduce that significantly.

-Chelsea

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 05:44PM |

Registered: 13 years ago Posts: 818 |

Idolcrasher Wrote:

-------------------------------------------------------

>

> Rich,

>

> I put in for the double extruder pre-made. Any

> chance your quick fit x-Carriage could get an

> adapter to carry one ore two of these extruders?

>

> I think it would be akin to carrying the same

> extruder as attached to the Replicator.

That was my thinking also, I think this extruder will be fine on a MendelMax, should still be able to get more speed out of it than the Replicator does.

I was thinking about a neat way to adjust the level/angle of the nozzles on the X-carriage, I'll try to add something into the mounting plate.

[richrap.blogspot.com]

-------------------------------------------------------

>

> Rich,

>

> I put in for the double extruder pre-made. Any

> chance your quick fit x-Carriage could get an

> adapter to carry one ore two of these extruders?

>

> I think it would be akin to carrying the same

> extruder as attached to the Replicator.

That was my thinking also, I think this extruder will be fine on a MendelMax, should still be able to get more speed out of it than the Replicator does.

I was thinking about a neat way to adjust the level/angle of the nozzles on the X-carriage, I'll try to add something into the mounting plate.

[richrap.blogspot.com]

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 09:24PM |

Registered: 12 years ago Posts: 539 |

richrap Wrote:

-------------------------------------------------------

> Idolcrasher Wrote:

> --------------------------------------------------

> -----

> >

> > Rich,

> >

> > I put in for the double extruder pre-made. Any

> > chance your quick fit x-Carriage could get an

> > adapter to carry one ore two of these

> extruders?

> >

> > I think it would be akin to carrying the same

> > extruder as attached to the Replicator.

>

> That was my thinking also, I think this extruder

> will be fine on a MendelMax, should still be able

> to get more speed out of it than the Replicator

> does.

>

> I was thinking about a neat way to adjust the

> level/angle of the nozzles on the X-carriage, I'll

> try to add something into the mounting plate.

You the man Rich,

I would love to mount my new sexy double extruder on your quick fit rig!

-------------------------------------------------------

> Idolcrasher Wrote:

> --------------------------------------------------

> -----

> >

> > Rich,

> >

> > I put in for the double extruder pre-made. Any

> > chance your quick fit x-Carriage could get an

> > adapter to carry one ore two of these

> extruders?

> >

> > I think it would be akin to carrying the same

> > extruder as attached to the Replicator.

>

> That was my thinking also, I think this extruder

> will be fine on a MendelMax, should still be able

> to get more speed out of it than the Replicator

> does.

>

> I was thinking about a neat way to adjust the

> level/angle of the nozzles on the X-carriage, I'll

> try to add something into the mounting plate.

You the man Rich,

I would love to mount my new sexy double extruder on your quick fit rig!

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 09:44PM |

Registered: 12 years ago Posts: 539 |

WildBill Wrote:

-------------------------------------------------------

> It is a poor design all together, the motor

> selection is wrong the spacing is huge the

> direction of nozzles is wrong, sure it will work

> fine on a replicator with space next to a bed or a

> bed moving in x and y but not only y. You added a

> ton of moving mass, and moving mass is a reprap's

> primary enemy. Your motors are limited on torque

> becaues a direct drive solution needs to be geared

> to get decent print speeds.

>

> Just an all around poor design for a reprap, may

> be fine for makerbot but not us.

>

> Plus the fact that you basically reverse

> engineered someonelse's work to under cut them is

> kinda low in my book. Why not design a new version

> that would work on reprap instead of trying to

> shove a square peg into a round hole.

>

> Have you put one of these monstrosities on a prusa

> frame and tried to print yet? how much new

> resonance are you seeing, how many new modes of

> resonance failure have you introduced? what has

> you z height been reduced to? Did you do any

> simulations or modal studies? Do you have

> engineers or just people with calipers?

>

> Like I said poor design for a reprap, maybe a

> repstrap or ordbot is fine, but anyone putting

> this on a prusa frame is going to be sorely

> dissapointed.

>

> If you want to go in a new direction look at what

> Stratysis does and how small and close together

> their system is compared to yours, er MakerBot's.

> Who you need to credit by the way with the

> design.

>

> All current opensource designs for dual extrusion

> (other than reprap pro's bowden system) are a

> nightmare for a reprap and are designed in the

> wrong direction for the wrong machine.

Jesus Dude Chill Out,

Are you seriously taking time out of your day to scream at some folks who are selling extruders?

Plus you are yelling at them for modifying an open source design and commercializing it? I have no idea how you managed that one The MakerBot folks commercialized the entire RepRap project lol. With your attitude, I would think that you would hate the MakerBot guys most of all.

The MakerBot folks commercialized the entire RepRap project lol. With your attitude, I would think that you would hate the MakerBot guys most of all.

Then you recommend they take a look at Stratasys's design? So i guess you want them to look at the design, but not too close right? God knows we don't want them to be inspired by engineering ground work that has already been laid.

Your arguments are angry, unfocused and loud. I can fill in the blanks for the engineering arguments you were semi-posing; but you didn't actually pose any points of value. You also made no recomendations as to how the design should be improved.

*What spacing should the motors have?

*what direction should the nozzles be pointed?

*How much should it weigh?

You added nothing of value.

Yeah, my RepRapPro Bowden Extruder works great... I think I am cool with other designs existing as well.

I am going to roll the dice, get a new fancy pants extruder and have fun experimenting with it. If it doesn't work out at least I have the scrap parts to work with.

We need more people like QU-BD to compete with MakerBot so we can actually have reasonably priced well made equipment for our 3D printers. Personally I am tired of scrounging parts from Chinese EBay sellers.

Edited 4 time(s). Last edit at 06/24/2012 10:42PM by Idolcrasher.

-------------------------------------------------------

> It is a poor design all together, the motor

> selection is wrong the spacing is huge the

> direction of nozzles is wrong, sure it will work

> fine on a replicator with space next to a bed or a

> bed moving in x and y but not only y. You added a

> ton of moving mass, and moving mass is a reprap's

> primary enemy. Your motors are limited on torque

> becaues a direct drive solution needs to be geared

> to get decent print speeds.

>

> Just an all around poor design for a reprap, may

> be fine for makerbot but not us.

>

> Plus the fact that you basically reverse

> engineered someonelse's work to under cut them is

> kinda low in my book. Why not design a new version

> that would work on reprap instead of trying to

> shove a square peg into a round hole.

>

> Have you put one of these monstrosities on a prusa

> frame and tried to print yet? how much new

> resonance are you seeing, how many new modes of

> resonance failure have you introduced? what has

> you z height been reduced to? Did you do any

> simulations or modal studies? Do you have

> engineers or just people with calipers?

>

> Like I said poor design for a reprap, maybe a

> repstrap or ordbot is fine, but anyone putting

> this on a prusa frame is going to be sorely

> dissapointed.

>

> If you want to go in a new direction look at what

> Stratysis does and how small and close together

> their system is compared to yours, er MakerBot's.

> Who you need to credit by the way with the

> design.

>

> All current opensource designs for dual extrusion

> (other than reprap pro's bowden system) are a

> nightmare for a reprap and are designed in the

> wrong direction for the wrong machine.

Jesus Dude Chill Out,

Are you seriously taking time out of your day to scream at some folks who are selling extruders?

Plus you are yelling at them for modifying an open source design and commercializing it? I have no idea how you managed that one

The MakerBot folks commercialized the entire RepRap project lol. With your attitude, I would think that you would hate the MakerBot guys most of all.

The MakerBot folks commercialized the entire RepRap project lol. With your attitude, I would think that you would hate the MakerBot guys most of all.Then you recommend they take a look at Stratasys's design? So i guess you want them to look at the design, but not too close right? God knows we don't want them to be inspired by engineering ground work that has already been laid.

Your arguments are angry, unfocused and loud. I can fill in the blanks for the engineering arguments you were semi-posing; but you didn't actually pose any points of value. You also made no recomendations as to how the design should be improved.

*What spacing should the motors have?

*what direction should the nozzles be pointed?

*How much should it weigh?

You added nothing of value.

Yeah, my RepRapPro Bowden Extruder works great... I think I am cool with other designs existing as well.

I am going to roll the dice, get a new fancy pants extruder and have fun experimenting with it. If it doesn't work out at least I have the scrap parts to work with.

We need more people like QU-BD to compete with MakerBot so we can actually have reasonably priced well made equipment for our 3D printers. Personally I am tired of scrounging parts from Chinese EBay sellers.

Edited 4 time(s). Last edit at 06/24/2012 10:42PM by Idolcrasher.

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 11:19PM |

Registered: 12 years ago Posts: 60 |

Chelsea - QU-BD Wrote:

-------------------------------------------------------

> Ok folks, I have had my coffee!

>

> Our goal with this design was to offer a

> high-quality extruder at the lowest price

> possible.

An under powered motor is not high quality and the UP! system is not a good starting point for reprap improvement. You are undercutting a good company in the process and did not improve upon their design. You mention in passing it is a derivative but never actually say "This is a MakerBot Dual Extruder" becuase that is what it is, no?

> Looking at the weight of our single extruder vs. a

> single Wade's geared extruder there is actually

> LESS weight on our cold end. Our hot end is also

> LESS weight than the traditional popular hot ends

> (j-head etc.).

Um no, you are thinking along the lines of what exists on other machines. I'll be releasing a dual extruder that weighs 1/2 the weight of the MakerBot design and that takes up 1/2 the space of the one you are pushing. I'll also be solving all of the engineering problems I am posing in this thread as my system will be designed specifically with reprap and high quality high speed printing and at a lower cost than your solution. What's best is that my solution is unique and from my own drawing board and meant to spur improvement and development.

> The motor is sized appropriately for the extruder.

> The limiting factor on extrusion speed is not the

> motor, or the extruder, it is a factor of how

> rigid the 3D printer is and the speed at which the

> carraige is moving. Having a geared motor does

> not offer any advantages (except resolution that

> we found does not really translate into improved

> print quality at this level) over the one we

> specified, the only thing it does is add cost

> which we would have to pass on.

The motor is most definately not sized for the extruder, it is too heavey and too low on torque, I will say that over and over again. There is a good reason most serious users of a printer have a geared motor on the extruder. Also a geared motor does not add cost if you know how to do motor selection propperly.

> We have two Prusa Mendels at the shop and the

> extruders have been tested on them.

Dual setup? How much wider is the x carriage now? Did you have to widen the frame? What kind of print speeds are you seeing? What's you upper limit? Do you have video of this? The model that I am setting up to run a modal frequency test on it with the MK8 is showing me that we would need to widen our frame 40mm to use the entire print bed. I'm also seeing a Z crash in my model at around 85mm on the trapazoidal frame. I'll gladly share my engineering results with the community as they should know the problems associated with this type of setup.

> On the cold end side, there is actually MORE room

> on Z than a Wade's Geared extruder. On the hot

> end side, the overall length when compared to a

> j-head is SHORTER. Overall you GAIN Z travel (not

> very much).

Again, you are talking about an older design that will soon be defunct. Old design is not the de-facto best.

> The beauty of open-source is that everyone is free

> to take other's designs and modify, improve and

> commercialize them. This spawns tons of

> innovation and in this case reduces costs a HUGE

> amount which helps the community. We have

> mentioned quite a few times here, on our website

> and the Kickstarter campaign that it is derivative

> of Makerbot's design which in turn is derived from

> UP!'s. When the files are uploaded to

> thingiverse, they will include that info as well.

> What doesn't work with Reprap is high cost, we

> helped reduce that significantly.

>

> -Chelsea

If you want to reduce cost you should not be making it from billet alum and using nema17s.

-------------------------------------------------------

> Ok folks, I have had my coffee!

>

> Our goal with this design was to offer a

> high-quality extruder at the lowest price

> possible.

An under powered motor is not high quality and the UP! system is not a good starting point for reprap improvement. You are undercutting a good company in the process and did not improve upon their design. You mention in passing it is a derivative but never actually say "This is a MakerBot Dual Extruder" becuase that is what it is, no?

> Looking at the weight of our single extruder vs. a

> single Wade's geared extruder there is actually

> LESS weight on our cold end. Our hot end is also

> LESS weight than the traditional popular hot ends

> (j-head etc.).

Um no, you are thinking along the lines of what exists on other machines. I'll be releasing a dual extruder that weighs 1/2 the weight of the MakerBot design and that takes up 1/2 the space of the one you are pushing. I'll also be solving all of the engineering problems I am posing in this thread as my system will be designed specifically with reprap and high quality high speed printing and at a lower cost than your solution. What's best is that my solution is unique and from my own drawing board and meant to spur improvement and development.

> The motor is sized appropriately for the extruder.

> The limiting factor on extrusion speed is not the

> motor, or the extruder, it is a factor of how

> rigid the 3D printer is and the speed at which the

> carraige is moving. Having a geared motor does

> not offer any advantages (except resolution that

> we found does not really translate into improved

> print quality at this level) over the one we

> specified, the only thing it does is add cost

> which we would have to pass on.

The motor is most definately not sized for the extruder, it is too heavey and too low on torque, I will say that over and over again. There is a good reason most serious users of a printer have a geared motor on the extruder. Also a geared motor does not add cost if you know how to do motor selection propperly.

> We have two Prusa Mendels at the shop and the

> extruders have been tested on them.

Dual setup? How much wider is the x carriage now? Did you have to widen the frame? What kind of print speeds are you seeing? What's you upper limit? Do you have video of this? The model that I am setting up to run a modal frequency test on it with the MK8 is showing me that we would need to widen our frame 40mm to use the entire print bed. I'm also seeing a Z crash in my model at around 85mm on the trapazoidal frame. I'll gladly share my engineering results with the community as they should know the problems associated with this type of setup.

> On the cold end side, there is actually MORE room

> on Z than a Wade's Geared extruder. On the hot

> end side, the overall length when compared to a

> j-head is SHORTER. Overall you GAIN Z travel (not

> very much).

Again, you are talking about an older design that will soon be defunct. Old design is not the de-facto best.

> The beauty of open-source is that everyone is free

> to take other's designs and modify, improve and

> commercialize them. This spawns tons of

> innovation and in this case reduces costs a HUGE

> amount which helps the community. We have

> mentioned quite a few times here, on our website

> and the Kickstarter campaign that it is derivative

> of Makerbot's design which in turn is derived from

> UP!'s. When the files are uploaded to

> thingiverse, they will include that info as well.

> What doesn't work with Reprap is high cost, we

> helped reduce that significantly.

>

> -Chelsea

If you want to reduce cost you should not be making it from billet alum and using nema17s.

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 11:32PM |

Registered: 12 years ago Posts: 60 |

Idolcrasher Wrote:

> Jesus Dude Chill Out,

>

> Are you seriously taking time out of your day to

> scream at some folks who are selling extruders?

Yes, someone needs to tell them where they are going wrong. Why don't you come by my house and pat me on the back after I release a turd.

> Plus you are yelling at them for modifying an open

> source design and commercializing it? I have no

> idea how you managed that one The MakerBot

The MakerBot

> folks commercialized the entire RepRap project

> lol. With your attitude, I would think that you

> would hate the MakerBot guys most of all.

Um, they reverse engineered it and undercut the ones who did the actual development on it, as a dev I find this shady. No I don't hate MakerBot, they are actually trying to innovate and push 3D printing not copy a design and capitalize on it by undercutting a prominent member in the advancement of 3D printing. I hate buildatron botmill and techzone though because that is exactly what they did.

> Then you recommend they take a look at Stratasys's

> design? So i guess you want them to look at the

> design, but not too close right? God knows we

> don't want them to be inspired by engineering

> ground work that has already been laid.

I want them to actually come up with something better and use the Stratasys design as a jumping point, this is commonly done in engineering and would have possibly lead these guys to an original idea, other than re-use of intellectual property designed for a different system.

> Your arguments are angry, unfocused and loud. I

> can fill in the blanks for the engineering

> arguments you were semi-posing; but you didn't

> actually pose any points of value. You also made

> no recomendations as to how the design should be

> improved.

Not angry and unfocused or loud, these are engineering points consumers shouldn't have to think about because it should be done for them by an engineer. In this case this system was not designed for a reprap, and I'm not giving my ideas away to a company that will just undercut me. I'm trying to protect the consumers on this one, anyone with a trapazoidal threaded rod frame. There is alot that is a grey area on this extruder that has not been thought of for reprap specifically.,

> *What spacing should the motors have?

> *what direction should the nozzles be pointed?

> *How much should it weigh?

Mine will be much smaller, closer together and the nozzles aligned in the Y direction where we can over shoot to correct for nozzle displacement, as most prusa will allow over shoot in that direction.

> You added nothing of value.

I will be adding value, just not for this company, but for the reprap community.

> Yeah, my RepRapPro Bowden Extruder works great...

> I think I am cool with other designs existing as

> well.

>

> I am going to roll the dice, get a new fancy pants

> extruder and have fun experimenting with it. If

> it doesn't work out at least I have the scrap

> parts to work with.

More power to you, but maybe you should also consider the questions posed, do you know how much wider your carriage is about to become? Are you going to mod your frame in the x direction to make up for this? Also when you home a tall print over 80mm you will need special g code to keep you from running your extruder into the frame.

> We need more people like QU-BD to compete with

> MakerBot so we can actually have reasonably priced

> well made equipment for our 3D printers.

> Personally I am tired of scrounging parts from

> Chinese EBay sellers.

In my opinion QU-BD is just the same as the chinese, they did not care about the originator of the design or intellectual property, heck they are not even following the GNU GPL correctly. They are just producing good for a lower cost and undercutting another good company.

What they are doing is not helping the community, the green eyed monster is never a good thing.

> Jesus Dude Chill Out,

>

> Are you seriously taking time out of your day to

> scream at some folks who are selling extruders?

Yes, someone needs to tell them where they are going wrong. Why don't you come by my house and pat me on the back after I release a turd.

> Plus you are yelling at them for modifying an open

> source design and commercializing it? I have no

> idea how you managed that one

The MakerBot

The MakerBot> folks commercialized the entire RepRap project

> lol. With your attitude, I would think that you

> would hate the MakerBot guys most of all.

Um, they reverse engineered it and undercut the ones who did the actual development on it, as a dev I find this shady. No I don't hate MakerBot, they are actually trying to innovate and push 3D printing not copy a design and capitalize on it by undercutting a prominent member in the advancement of 3D printing. I hate buildatron botmill and techzone though because that is exactly what they did.

> Then you recommend they take a look at Stratasys's

> design? So i guess you want them to look at the

> design, but not too close right? God knows we

> don't want them to be inspired by engineering

> ground work that has already been laid.

I want them to actually come up with something better and use the Stratasys design as a jumping point, this is commonly done in engineering and would have possibly lead these guys to an original idea, other than re-use of intellectual property designed for a different system.

> Your arguments are angry, unfocused and loud. I

> can fill in the blanks for the engineering

> arguments you were semi-posing; but you didn't

> actually pose any points of value. You also made

> no recomendations as to how the design should be

> improved.

Not angry and unfocused or loud, these are engineering points consumers shouldn't have to think about because it should be done for them by an engineer. In this case this system was not designed for a reprap, and I'm not giving my ideas away to a company that will just undercut me. I'm trying to protect the consumers on this one, anyone with a trapazoidal threaded rod frame. There is alot that is a grey area on this extruder that has not been thought of for reprap specifically.,

> *What spacing should the motors have?

> *what direction should the nozzles be pointed?

> *How much should it weigh?

Mine will be much smaller, closer together and the nozzles aligned in the Y direction where we can over shoot to correct for nozzle displacement, as most prusa will allow over shoot in that direction.

> You added nothing of value.

I will be adding value, just not for this company, but for the reprap community.

> Yeah, my RepRapPro Bowden Extruder works great...

> I think I am cool with other designs existing as

> well.

>

> I am going to roll the dice, get a new fancy pants

> extruder and have fun experimenting with it. If

> it doesn't work out at least I have the scrap

> parts to work with.

More power to you, but maybe you should also consider the questions posed, do you know how much wider your carriage is about to become? Are you going to mod your frame in the x direction to make up for this? Also when you home a tall print over 80mm you will need special g code to keep you from running your extruder into the frame.

> We need more people like QU-BD to compete with

> MakerBot so we can actually have reasonably priced

> well made equipment for our 3D printers.

> Personally I am tired of scrounging parts from

> Chinese EBay sellers.

In my opinion QU-BD is just the same as the chinese, they did not care about the originator of the design or intellectual property, heck they are not even following the GNU GPL correctly. They are just producing good for a lower cost and undercutting another good company.

What they are doing is not helping the community, the green eyed monster is never a good thing.

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 11:36PM |

Registered: 11 years ago Posts: 16 |

|

Re: KickStarter Campaign For Dual Extruder June 24, 2012 11:47PM |

Registered: 12 years ago Posts: 60 |

kwando Wrote:

-------------------------------------------------------

> Idolcrasher Wrote:

>

> > We need more people like QU-BD to compete with

> > MakerBot so we can actually have reasonably

> priced

> > well made equipment for our 3D printers.

> > Personally I am tired of scrounging parts from

> > Chinese EBay sellers.

>

> Agree.

So compete by building a better mouse trap. Why is that so hard to understand? This is not a better dual extruder solution than raldrich's, and on top of that his is smaller and lighter and the nozzles are closer together than this design. Support that, it is true open source and already available, and a unique solution. It is different than my solution but still better than this one.

[www.thingiverse.com]

^ This is more along the lines of what a reprap needs than the MK8 for dual extrusion.

QU-BD is now making companies like MakerBot want to license intellectual property, I know I would be going after them for the GNU GPL violations.

The point of opensource is not to capitalize on others work as Chelsea mentioned but to help each other to improve a solution and avoid business greed. Capitalizing on others work is theft.

Edited 1 time(s). Last edit at 06/24/2012 11:54PM by WildBill.

-------------------------------------------------------

> Idolcrasher Wrote:

>

> > We need more people like QU-BD to compete with

> > MakerBot so we can actually have reasonably

> priced

> > well made equipment for our 3D printers.

> > Personally I am tired of scrounging parts from

> > Chinese EBay sellers.

>

> Agree.

So compete by building a better mouse trap. Why is that so hard to understand? This is not a better dual extruder solution than raldrich's, and on top of that his is smaller and lighter and the nozzles are closer together than this design. Support that, it is true open source and already available, and a unique solution. It is different than my solution but still better than this one.

[www.thingiverse.com]

^ This is more along the lines of what a reprap needs than the MK8 for dual extrusion.

QU-BD is now making companies like MakerBot want to license intellectual property, I know I would be going after them for the GNU GPL violations.

The point of opensource is not to capitalize on others work as Chelsea mentioned but to help each other to improve a solution and avoid business greed. Capitalizing on others work is theft.

Edited 1 time(s). Last edit at 06/24/2012 11:54PM by WildBill.

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:00AM |

Registered: 14 years ago Posts: 581 |

I 100% agree with Wildbill here. Kickstarter has a HORRIBLE track record of undelivered equip, and until a design has been open sourced & independently tested there is no way to judge the design, especially with an extruder.

Remember, Kickstarters are a gift & a promise , not a purchase.

Edited 1 time(s). Last edit at 06/25/2012 12:12AM by spacexula.

repraplogphase.blogspot.com

Remember, Kickstarters are a gift & a promise , not a purchase.

Edited 1 time(s). Last edit at 06/25/2012 12:12AM by spacexula.

repraplogphase.blogspot.com

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:06AM |

Registered: 12 years ago Posts: 29 |

I want to preface this by saying I am not trying to be combative...I apologize if I come off this way.

Mr Mild Bill,

It doesn't seem that you are actually listening to what the QU-BD folks are saying. I don't think it was their intention to release the end all most awesome, super, great extruder that DESTROYS ALL; I think they wanted to release something that is well made, reliable and most importantly cheap. By reducing the overall price of entry, I think that does more for the community than printing 10mm/s faster. In that regard they look to have succeeded.

Of course you are releasing your own extruder, perhaps that is the reasoning for some of the illogical complaints, you have a profit motive. The QU-BD folks were comparing theirs to a common setup, a Wade's w/ a J-Head, I think that's fair; of course there probably is a lighter weight, smaller extruder in someone's basement somewhere, but its not for sale, right now, at $34.00 or less.

Assuming that the geared extruder on Thingiverse under 'WildBill' is yours, I do inherently see a problem with it, it uses printed plastic parts. When I was putting together my Reprap I had to purchase the printed parts because I didn't have anyone near me that could print them for free...its nice to not have to deal with that for your first printer and end up spending more. I will take machined aluminum any day over printed ABS. Additionally unless I am reading it wrong, that motor maxes out at 50 degrees C...won't that cause some problems...I did hear mention of one of those motors used for an extruder and melting in the process...

Their extruder is a derivative work if they changed some of the parts. It also lists on their website, which parts are unaltered Makerbot's and which they have changed (mostly changed). They also list this in their campaign several times that the design is based off the Makerbot MK7. I don't really see what the problem is, its not like they are trying to pass it off as their own.

Until you release your (1/2 weight, 1/2 size) extruder and price it with a hot end and all the parts that go with it for less than $34, the older, soon to be defunct designs are still valid. If you do release your extruder and it does what you say it can, I will be first in line to buy it.

What is the pricing and time frame on your extruder, with a hot end and the motor?

Mr Mild Bill,

It doesn't seem that you are actually listening to what the QU-BD folks are saying. I don't think it was their intention to release the end all most awesome, super, great extruder that DESTROYS ALL; I think they wanted to release something that is well made, reliable and most importantly cheap. By reducing the overall price of entry, I think that does more for the community than printing 10mm/s faster. In that regard they look to have succeeded.

Of course you are releasing your own extruder, perhaps that is the reasoning for some of the illogical complaints, you have a profit motive. The QU-BD folks were comparing theirs to a common setup, a Wade's w/ a J-Head, I think that's fair; of course there probably is a lighter weight, smaller extruder in someone's basement somewhere, but its not for sale, right now, at $34.00 or less.

Assuming that the geared extruder on Thingiverse under 'WildBill' is yours, I do inherently see a problem with it, it uses printed plastic parts. When I was putting together my Reprap I had to purchase the printed parts because I didn't have anyone near me that could print them for free...its nice to not have to deal with that for your first printer and end up spending more. I will take machined aluminum any day over printed ABS. Additionally unless I am reading it wrong, that motor maxes out at 50 degrees C...won't that cause some problems...I did hear mention of one of those motors used for an extruder and melting in the process...

Their extruder is a derivative work if they changed some of the parts. It also lists on their website, which parts are unaltered Makerbot's and which they have changed (mostly changed). They also list this in their campaign several times that the design is based off the Makerbot MK7. I don't really see what the problem is, its not like they are trying to pass it off as their own.

Until you release your (1/2 weight, 1/2 size) extruder and price it with a hot end and all the parts that go with it for less than $34, the older, soon to be defunct designs are still valid. If you do release your extruder and it does what you say it can, I will be first in line to buy it.

What is the pricing and time frame on your extruder, with a hot end and the motor?

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:26AM |

Registered: 12 years ago Posts: 60 |

vulcanrd Wrote:

-------------------------------------------------------

> I want to preface this by saying I am not trying

> to be combative...I apologize if I come off this

> way.

Not at all, this is an open discussion and people are entitled to their opinions.

> Mr Mild Bill,

>

> It doesn't seem that you are actually listening to

> what the QU-BD folks are saying. I don't think it

> was their intention to release the end all most

> awesome, super, great extruder that DESTROYS ALL;

> I think they wanted to release something that is

> well made, reliable and most importantly cheap.

> By reducing the overall price of entry, I think

> that does more for the community than printing

> 10mm/s faster. In that regard they look to have

> succeeded.

I listend closely, but put the mk7 or mk8 dual extruder on a CAD model of a prusa and tell me you don't feel scared. I'm not talking about 10mm/s, lets see their extruder do 200mm/s cleanly, my single extruder design can do this easily and is much smaller than a NEMA17 solution, geared or not. My point is there are more reliable, cheaper, and reprap specific solutions already available. They may have suceeded in producing a cheaper extruder with the same design but is that really a good thing to copy a poor design?

> Of course you are releasing your own extruder,

> perhaps that is the reasoning for some of the

> illogical complaints, you have a profit motive.

> The QU-BD folks were comparing theirs to a common

> setup, a Wade's w/ a J-Head, I think that's fair;

> of course there probably is a lighter weight,

> smaller extruder in someone's basement somewhere,

> but its not for sale, right now, at $34.00 or

> less.

No, my motive is not profit driven, when I release my extruder design all funding will go towards prototyping and development for reprap betterment. This will help all, not my financial situation. Currently you actually can buy a more efficient solution from ezmobius for around that price that will print faster cleaner and weigh 1/4 of the weight of the posted single extruder. It's not on his site yet, the motor is, but he will gladly work with you in IRC to get the combo.

[store.trinitylabs.com]

> Assuming that the geared extruder on Thingiverse

> under 'WildBill' is yours, I do inherently see a

> problem with it, it uses printed plastic parts.

> When I was putting together my Reprap I had to

> purchase the printed parts because I didn't have

> anyone near me that could print them for

> free...its nice to not have to deal with that for

> your first printer and end up spending more. I

> will take machined aluminum any day over printed

> ABS. Additionally unless I am reading it wrong,

> that motor maxes out at 50 degrees C...won't that

> cause some problems...I did hear mention of one of

> those motors used for an extruder and melting in

> the process...

Yes, that is my geared extruder. Name a single reprapper that thinks more printed parts is a bad thing. I didn't get my plastic for free and not many actually do, so this is a non-issue. Also if you go into the IRC as suggested on the wiki you can get all of your plastics printed cheaply by many of us. Additionally it costs me $.40 to print my extruder housing, how much does it cost for custom machined billet alum? The motor is fine with a heatsink, ezmobius is working with Mineaba to stock reprap specific PG35L-048 motors that will run cooler. There has only been report of one melting and it was due to not having it cooled. My printer runs more than 8 hours every day and in a 90* F garage and I have had no issues with overheating and have not maintenanced my extruder since installing it. I'll take printed ABS any day over expensive un-needed hard to modify aluminum. To each their own.

> Their extruder is a derivative work if they

> changed some of the parts. It also lists on their

> website, which parts are unaltered Makerbot's and

> which they have changed (mostly changed). They

> also list this in their campaign several times

> that the design is based off the Makerbot MK7. I

> don't really see what the problem is, its not like

> they are trying to pass it off as their own.

According to GNU GPL they need to give propper attribution, it is the least they can do after they under cut them so badly.

> Until you release your (1/2 weight, 1/2 size)

> extruder and price it with a hot end and all the

> parts that go with it for less than $34, the

> older, soon to be defunct designs are still valid.

> If you do release your extruder and it does what

> you say it can, I will be first in line to buy

> it.

Sounds great, I look forward to your support.

> What is the pricing and time frame on your

> extruder, with a hot end and the motor?

I'm going to be releasing the kickstarter for the research next week after I get quotes back, people who fund me will recieve a gift of a working solution based on the researched parts they funded. My lead times are a bit longer becuase I want to propperly vent the design. I'll be sharing thermal simulation and avoidable resonance frequencies when it is all ready.

In other words, I'm a mechiancal engineer doing this the propper way to improve the reprap design. Not a CNC programmer with a caliper that re-coded someone elses g-code to undercut a good company. MakerBot charges so much becuase they need to pay engineers to design their products for MakerBot equipment, a commercial product. I'm willing to bet not a single engineer works at QU-BD, but machine operators and customer service. When you have an actuall engineering concern do you want support from a profit driven company with no engineers or support in the IRC from someone who is an engineer and reprap-dev and enthusiast?

Edited 3 time(s). Last edit at 06/25/2012 12:39AM by WildBill.

-------------------------------------------------------

> I want to preface this by saying I am not trying

> to be combative...I apologize if I come off this

> way.

Not at all, this is an open discussion and people are entitled to their opinions.

> Mr Mild Bill,

>

> It doesn't seem that you are actually listening to

> what the QU-BD folks are saying. I don't think it

> was their intention to release the end all most

> awesome, super, great extruder that DESTROYS ALL;

> I think they wanted to release something that is

> well made, reliable and most importantly cheap.

> By reducing the overall price of entry, I think

> that does more for the community than printing

> 10mm/s faster. In that regard they look to have

> succeeded.

I listend closely, but put the mk7 or mk8 dual extruder on a CAD model of a prusa and tell me you don't feel scared. I'm not talking about 10mm/s, lets see their extruder do 200mm/s cleanly, my single extruder design can do this easily and is much smaller than a NEMA17 solution, geared or not. My point is there are more reliable, cheaper, and reprap specific solutions already available. They may have suceeded in producing a cheaper extruder with the same design but is that really a good thing to copy a poor design?

> Of course you are releasing your own extruder,

> perhaps that is the reasoning for some of the

> illogical complaints, you have a profit motive.

> The QU-BD folks were comparing theirs to a common

> setup, a Wade's w/ a J-Head, I think that's fair;

> of course there probably is a lighter weight,

> smaller extruder in someone's basement somewhere,

> but its not for sale, right now, at $34.00 or

> less.

No, my motive is not profit driven, when I release my extruder design all funding will go towards prototyping and development for reprap betterment. This will help all, not my financial situation. Currently you actually can buy a more efficient solution from ezmobius for around that price that will print faster cleaner and weigh 1/4 of the weight of the posted single extruder. It's not on his site yet, the motor is, but he will gladly work with you in IRC to get the combo.

[store.trinitylabs.com]

> Assuming that the geared extruder on Thingiverse

> under 'WildBill' is yours, I do inherently see a

> problem with it, it uses printed plastic parts.

> When I was putting together my Reprap I had to

> purchase the printed parts because I didn't have

> anyone near me that could print them for

> free...its nice to not have to deal with that for

> your first printer and end up spending more. I

> will take machined aluminum any day over printed

> ABS. Additionally unless I am reading it wrong,

> that motor maxes out at 50 degrees C...won't that

> cause some problems...I did hear mention of one of

> those motors used for an extruder and melting in

> the process...

Yes, that is my geared extruder. Name a single reprapper that thinks more printed parts is a bad thing. I didn't get my plastic for free and not many actually do, so this is a non-issue. Also if you go into the IRC as suggested on the wiki you can get all of your plastics printed cheaply by many of us. Additionally it costs me $.40 to print my extruder housing, how much does it cost for custom machined billet alum? The motor is fine with a heatsink, ezmobius is working with Mineaba to stock reprap specific PG35L-048 motors that will run cooler. There has only been report of one melting and it was due to not having it cooled. My printer runs more than 8 hours every day and in a 90* F garage and I have had no issues with overheating and have not maintenanced my extruder since installing it. I'll take printed ABS any day over expensive un-needed hard to modify aluminum. To each their own.

> Their extruder is a derivative work if they

> changed some of the parts. It also lists on their

> website, which parts are unaltered Makerbot's and

> which they have changed (mostly changed). They

> also list this in their campaign several times

> that the design is based off the Makerbot MK7. I

> don't really see what the problem is, its not like

> they are trying to pass it off as their own.

According to GNU GPL they need to give propper attribution, it is the least they can do after they under cut them so badly.

> Until you release your (1/2 weight, 1/2 size)

> extruder and price it with a hot end and all the

> parts that go with it for less than $34, the

> older, soon to be defunct designs are still valid.

> If you do release your extruder and it does what

> you say it can, I will be first in line to buy

> it.

Sounds great, I look forward to your support.

> What is the pricing and time frame on your

> extruder, with a hot end and the motor?

I'm going to be releasing the kickstarter for the research next week after I get quotes back, people who fund me will recieve a gift of a working solution based on the researched parts they funded. My lead times are a bit longer becuase I want to propperly vent the design. I'll be sharing thermal simulation and avoidable resonance frequencies when it is all ready.

In other words, I'm a mechiancal engineer doing this the propper way to improve the reprap design. Not a CNC programmer with a caliper that re-coded someone elses g-code to undercut a good company. MakerBot charges so much becuase they need to pay engineers to design their products for MakerBot equipment, a commercial product. I'm willing to bet not a single engineer works at QU-BD, but machine operators and customer service. When you have an actuall engineering concern do you want support from a profit driven company with no engineers or support in the IRC from someone who is an engineer and reprap-dev and enthusiast?

Edited 3 time(s). Last edit at 06/25/2012 12:39AM by WildBill.

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:36AM |

Registered: 12 years ago Posts: 29 |

spacexula....I think you are confusing them with someone else...how can they have a horrible track record if this is their first product (correct me if I missed something)?

wildbill...so you starting a Kickstarter for 'research' and are wanting to collect money before the design has been 'vented', why not wait till you have all the kinks worked out before asking for funding? What is your estimated price point for the extruder, hotend and motor?

Edited 1 time(s). Last edit at 06/25/2012 12:40AM by vulcanrd.

wildbill...so you starting a Kickstarter for 'research' and are wanting to collect money before the design has been 'vented', why not wait till you have all the kinks worked out before asking for funding? What is your estimated price point for the extruder, hotend and motor?

Edited 1 time(s). Last edit at 06/25/2012 12:40AM by vulcanrd.

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:44AM |

Registered: 12 years ago Posts: 60 |

He is talking about kickstarter projects in general not delivering on promises. Like the promise that this system is compatible with a prusa frame or carriage. Oh or the promise that you will not lose out on print area or print height. Basically anyone can promise anything on kickstarter and get funding true or not is what spacexula is saying. This system will kill your x axis acceleration too, no mention of that here though, that is just too much moving mass for a prusa threaded rod frame.

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:49AM |

Registered: 12 years ago Posts: 60 |

vulcanrd Wrote:

-------------------------------------------------------

> spacexula....I think you are confusing them with

> someone else...how can they have a horrible track

> record if this is their first product (correct me

> if I missed something)?

>

> wildbill...so you starting a Kickstarter for

> 'research' and are wanting to collect money before

> the design has been 'vented', why not wait till

> you have all the kinks worked out before asking

> for funding? What is your estimated price point

> for the extruder, hotend and motor?

There is nothing wrong with crowd sourcing funding for open source development. I will have the kinks worked out before sending out the rewards, trust me, and all data will be open and shared. I'm going all out on this and not cutting corners and have already invested a ton of my personal time into it. That is what opensource is all about. My research will then be shared with the community. I'll have a better number on price point this coming week, but don't expect it to cost anywhere near a MakerBot extruder. Realistically the development systems that are sent as gifts will be slightly more expensive than a commercial offering. (not even sure if I will offer a commercial product or just share the research and give away the working prototypes). This is the meaning of bettering a product through open source. I'm doing it becuase I can and have the energy to devote to it. Unfortunately since I have to outsource the machining there will be that one markup, but I am trying to keep machined parts to a minimum. I will gladly be transparent with engineering design, sourcing costs and open and in constant contact with those investing in the research.

Edited 1 time(s). Last edit at 06/25/2012 01:06AM by WildBill.

-------------------------------------------------------

> spacexula....I think you are confusing them with

> someone else...how can they have a horrible track

> record if this is their first product (correct me

> if I missed something)?

>

> wildbill...so you starting a Kickstarter for

> 'research' and are wanting to collect money before

> the design has been 'vented', why not wait till

> you have all the kinks worked out before asking

> for funding? What is your estimated price point

> for the extruder, hotend and motor?

There is nothing wrong with crowd sourcing funding for open source development. I will have the kinks worked out before sending out the rewards, trust me, and all data will be open and shared. I'm going all out on this and not cutting corners and have already invested a ton of my personal time into it. That is what opensource is all about. My research will then be shared with the community. I'll have a better number on price point this coming week, but don't expect it to cost anywhere near a MakerBot extruder. Realistically the development systems that are sent as gifts will be slightly more expensive than a commercial offering. (not even sure if I will offer a commercial product or just share the research and give away the working prototypes). This is the meaning of bettering a product through open source. I'm doing it becuase I can and have the energy to devote to it. Unfortunately since I have to outsource the machining there will be that one markup, but I am trying to keep machined parts to a minimum. I will gladly be transparent with engineering design, sourcing costs and open and in constant contact with those investing in the research.

Edited 1 time(s). Last edit at 06/25/2012 01:06AM by WildBill.

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 12:49AM |

Registered: 12 years ago Posts: 29 |

You're right I just reread what he said that Kickstarter in general has a horrible track record not necessarily them in particular.

If what they say is true about it weighing less and taking up less space (in single form) than a Wade's / J-head that a lot of people are running successfully...how can you say its too much mass for the Prusa frame?

If what they say is true about it weighing less and taking up less space (in single form) than a Wade's / J-head that a lot of people are running successfully...how can you say its too much mass for the Prusa frame?

|

Re: KickStarter Campaign For Dual Extruder June 25, 2012 01:01AM |

Registered: 12 years ago Posts: 60 |

it is simple physics, I'll release modal results tomorrow for this system if you want to see what a frame will do when throwing that much mass around. There is no way two nema17, and all of that billet alum is lighter than a single nema17 and some printed ABS... That sounds far fetched to me.

If they based it on the MK7/8 like they say and things are identical, I challenge you to prove it to me in CAD that it is smaller and prove it to me in simulated weight that it is lighter... I see it differently in my math. They say it weighs 12 oz with a single motor and extruder, my single combo weighs about 7 oz. with the old mkiv jhead, double it all up and you can see where the weight savings will be huge.

Look at the torque ratings for these motors, do you really want to max them out with moving mass?

If they based it on the MK7/8 like they say and things are identical, I challenge you to prove it to me in CAD that it is smaller and prove it to me in simulated weight that it is lighter... I see it differently in my math. They say it weighs 12 oz with a single motor and extruder, my single combo weighs about 7 oz. with the old mkiv jhead, double it all up and you can see where the weight savings will be huge.

Look at the torque ratings for these motors, do you really want to max them out with moving mass?

Sorry, only registered users may post in this forum.