High temperature stepper motor?

Posted by DingbatCA

|

High temperature stepper motor? October 08, 2013 02:21PM |

Registered: 10 years ago Posts: 7 |

I am looking to build a hot box/compartment/chamber style 3D printer. I have been able to engineer around most of the heat related issues, like parts melting. But I can not find a stepper motor rated to operated in a 100C environment. I have found plenty of sites that have them, but none that sell them.

Ideas?

Ideas?

|

Re: High temperature stepper motor? October 08, 2013 02:25PM |

Registered: 11 years ago Posts: 47 |

|

Re: High temperature stepper motor? October 08, 2013 02:55PM |

Registered: 10 years ago Posts: 7 |

|

Re: High temperature stepper motor? October 08, 2013 05:37PM |

Registered: 11 years ago Posts: 490 |

|

Re: High temperature stepper motor? October 08, 2013 05:40PM |

Registered: 11 years ago Posts: 544 |

|

Re: High temperature stepper motor? October 08, 2013 05:58PM |

Registered: 10 years ago Posts: 7 |

|

Re: High temperature stepper motor? October 09, 2013 03:40AM |

Registered: 11 years ago Posts: 544 |

|

Re: High temperature stepper motor? October 09, 2013 11:40AM |

Registered: 10 years ago Posts: 7 |

|

Re: High temperature stepper motor? October 09, 2013 01:24PM |

Registered: 11 years ago Posts: 19 |

Have a look at [kuehlingkuehling.de]

They went with a liquid cooled solution, I have to admit it seems more sensible than mechanical linkage transfer.

They went with a liquid cooled solution, I have to admit it seems more sensible than mechanical linkage transfer.

|

Re: High temperature stepper motor? October 09, 2013 01:40PM |

Registered: 10 years ago Posts: 7 |

|

Re: High temperature stepper motor? October 09, 2013 02:10PM |

Registered: 11 years ago Posts: 544 |

|

Re: High temperature stepper motor? October 09, 2013 02:22PM |

Registered: 10 years ago Posts: 7 |

|

Re: High temperature stepper motor? October 09, 2013 02:29PM |

Registered: 11 years ago Posts: 544 |

|

Re: High temperature stepper motor? October 09, 2013 02:36PM |

Registered: 10 years ago Posts: 7 |

|

Re: High temperature stepper motor? October 09, 2013 06:29PM |

Registered: 11 years ago Posts: 490 |

|

Re: High temperature stepper motor? October 09, 2013 10:07PM |

Registered: 11 years ago Posts: 544 |

yeah polycarb is really very expensive, and hard to print with. what parts do you need to have inside the build chamber? the extruder could be bowden to reduce weight and eliminate plastic parts inside the chamber. on my machine all of the frame vertexes are outside of the build chamber, so the only things that are exposed are the carriages and the z nut traps.

|

Re: High temperature stepper motor? October 10, 2013 04:52PM |

Registered: 11 years ago Posts: 490 |

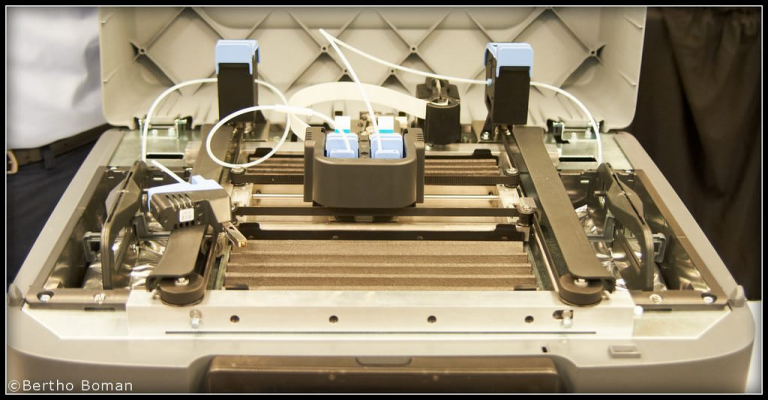

I am thinking of rebuilding my printer (currently a Mendel-Design) as an enclosed Bowden CoreXY-bot. The chamber itself is not a problem thanks to aluminium coated styrofoam, but the X and Y carriages and the Z assembly still pose problems. The build didn't start yet, as I am busy with other stuff at the moment, but the printer is constantly being developed in my head. Well, one possibility would be copying the heat barrier Stratasys put on their Mojo printer:

|

Re: High temperature stepper motor? October 10, 2013 09:07PM |

Registered: 11 years ago Posts: 544 |

|

Re: High temperature stepper motor? October 10, 2013 10:15PM |

Registered: 10 years ago Posts: 162 |

Look at the placement of the motors on the UConduit (http://www.thingiverse.com/thing:102972). It would be trivial to keep them out of the heated build chamber in this configuration.

|

Re: High temperature stepper motor? October 10, 2013 10:48PM |

Registered: 11 years ago Posts: 544 |

Sorry, only registered users may post in this forum.