Maximum weight of moving print bed?

Posted by loco

|

Maximum weight of moving print bed? January 02, 2014 11:14AM |

Registered: 10 years ago Posts: 1,103 |

Hi there,

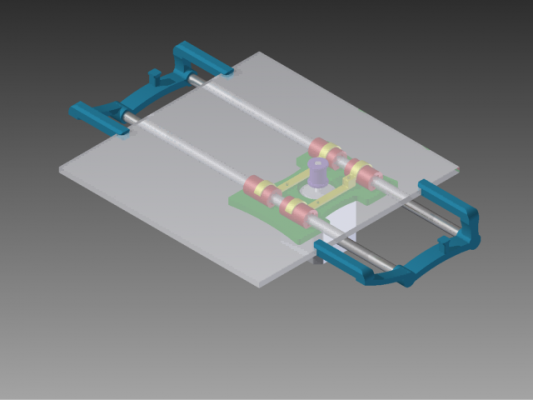

i'd like to introduce you to my new project. I really like the design of the Smartrap Mini, but unfortunately it's print size is only 150x150x150 mm.

I do want at least 200x200x200mm, so i'm designing a bigger Smartrap-like printer.

I just finished designing the first X-axis prototype, but i'm concerned about it's weight.

Since i plan to use 8mm steel rods and 5 mm acrylic glass, the moving mass on this axis would be about 500g.

For now i only have a rostock delta, so i can't even guess if it will be too much.

How much does the bed of for example a Mendel90 weigh and how fast can it print?

Regards from Germany

Marco

i'd like to introduce you to my new project. I really like the design of the Smartrap Mini, but unfortunately it's print size is only 150x150x150 mm.

I do want at least 200x200x200mm, so i'm designing a bigger Smartrap-like printer.

I just finished designing the first X-axis prototype, but i'm concerned about it's weight.

Since i plan to use 8mm steel rods and 5 mm acrylic glass, the moving mass on this axis would be about 500g.

For now i only have a rostock delta, so i can't even guess if it will be too much.

How much does the bed of for example a Mendel90 weigh and how fast can it print?

Regards from Germany

Marco

|

Re: Maximum weight of moving print bed? January 02, 2014 11:29AM |

Registered: 10 years ago Posts: 3 |

Try to gear the system down if you can. The small stepper motors will see a large inertia and will stall when accelerating.

The other option is to use lower acceleration rates.... so you can have reasonably large loads, but won't be able to accelerate hard.

If you do gear it down, remember that the torque from stepper motors will decrease at higher rpm. From memory, most will start to drop their torque output from 10 or 15 revs/sec. One way to overcome this is to use a higher supply voltage for the stepper drivers.

The other option is to use lower acceleration rates.... so you can have reasonably large loads, but won't be able to accelerate hard.

If you do gear it down, remember that the torque from stepper motors will decrease at higher rpm. From memory, most will start to drop their torque output from 10 or 15 revs/sec. One way to overcome this is to use a higher supply voltage for the stepper drivers.

|

Re: Maximum weight of moving print bed? January 02, 2014 12:22PM |

Admin Registered: 11 years ago Posts: 3,096 |

Well, I am using 2 aluminum plates, both 220x220mm with a heatbed mounted under the top one. I think I would've even made the design lighter, but it works so ok.

The bottom one has a lot of holes made in them to remove material in unneccesary areas, this is a 4mm thick plate of aluminum, the top plate is a solid 3mm thick alu plate covered with kapton tape where I print PLA on, yes PLA stick great on the kapton

I hope this gives you a bit of insight on whats possible however I would want it to be lighter, so will probably move on to a 2mm thick printing bed of aluminum covered with kapton, and an even more trimmed bottom-plate. The bottom plate will however still be a 4mm one, but with even less material and the smooth rods that it slides on will be placed to the outermost sides of the plate and the top plate will have trimmed-away edges in-between the screws that hold it together because I can't print there anyway.

The bottom one has a lot of holes made in them to remove material in unneccesary areas, this is a 4mm thick plate of aluminum, the top plate is a solid 3mm thick alu plate covered with kapton tape where I print PLA on, yes PLA stick great on the kapton

I hope this gives you a bit of insight on whats possible however I would want it to be lighter, so will probably move on to a 2mm thick printing bed of aluminum covered with kapton, and an even more trimmed bottom-plate. The bottom plate will however still be a 4mm one, but with even less material and the smooth rods that it slides on will be placed to the outermost sides of the plate and the top plate will have trimmed-away edges in-between the screws that hold it together because I can't print there anyway.

|

Re: Maximum weight of moving print bed? January 03, 2014 05:23AM |

Registered: 10 years ago Posts: 273 |

|

Re: Maximum weight of moving print bed? January 03, 2014 08:09PM |

Registered: 10 years ago Posts: 1,103 |

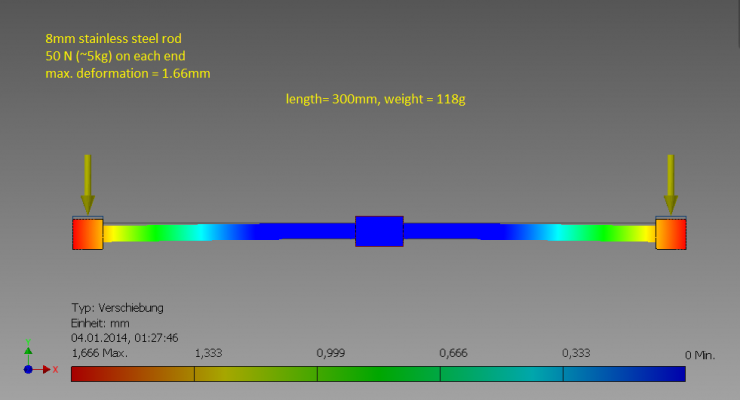

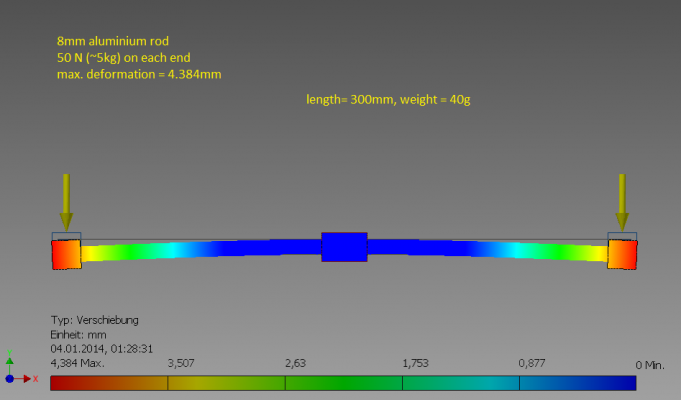

Why should i use even heavier 10mm or 12mm rods?

I'm considering to use printed PLA bushings, so i could use aluminium rods.

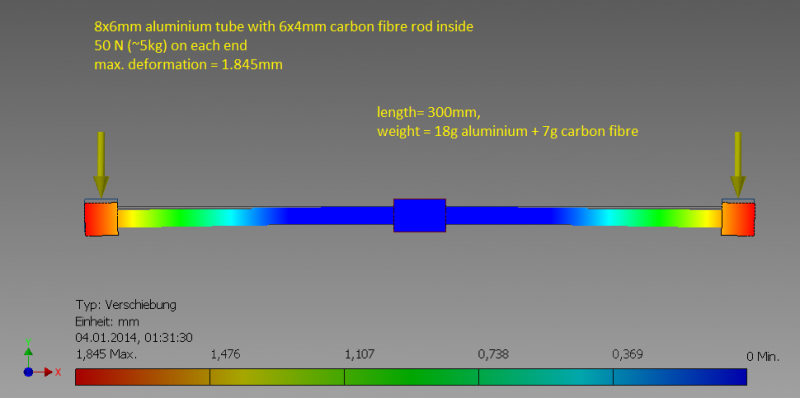

Because i didn't know if aluminium would be stiff enough and to get even lower weight i did some analysis with 8x6mm aluminium tube with a 6x4mm carbon fibre tube inside of it.

It almost reaches the strength of the steel rod, but weighs just ~20% of it. In combination with a 4mm instead of 5mm acrylic glass bed, the X-axis should weigh about 250g.

I'm considering to use printed PLA bushings, so i could use aluminium rods.

Because i didn't know if aluminium would be stiff enough and to get even lower weight i did some analysis with 8x6mm aluminium tube with a 6x4mm carbon fibre tube inside of it.

It almost reaches the strength of the steel rod, but weighs just ~20% of it. In combination with a 4mm instead of 5mm acrylic glass bed, the X-axis should weigh about 250g.

Sorry, only registered users may post in this forum.