Larger printbed

Posted by Headbutt

|

Larger printbed June 23, 2012 05:18AM |

Registered: 11 years ago Posts: 3 |

Hi,

I am thinking of building a mendel but I would like it to have a larger printbed, I am pretty sure that I can do the mechanical side but what would I change on the software side so the computer knows that there is a larger print surface to use? Would I need to change something in the firmware that I load onto the arduino, or can I change the settings in a program like slic3r.

Headbutt

I am thinking of building a mendel but I would like it to have a larger printbed, I am pretty sure that I can do the mechanical side but what would I change on the software side so the computer knows that there is a larger print surface to use? Would I need to change something in the firmware that I load onto the arduino, or can I change the settings in a program like slic3r.

Headbutt

|

Re: Larger printbed June 23, 2012 05:26AM |

Registered: 14 years ago Posts: 689 |

The software side of things is super simple, building it without the entire frame wobbling is a whole other story.

Depending on the firmware you might have to adjust the soft endstops there. You also change the size of the build area in slic3r so you can center the objects. I don't know if there's any limits built into slic3r, but I'm guessing the plater tool wouldn't work very well with a wrong build plate config.

--

-Nudel

Blog with RepRap Comic

Depending on the firmware you might have to adjust the soft endstops there. You also change the size of the build area in slic3r so you can center the objects. I don't know if there's any limits built into slic3r, but I'm guessing the plater tool wouldn't work very well with a wrong build plate config.

--

-Nudel

Blog with RepRap Comic

|

Re: Larger printbed June 23, 2012 05:29AM |

Registered: 13 years ago Posts: 643 |

Which firmware? Some, such as marlin, have soft limits that you'll need to change, others don't.

The rest of the software won't care.

Also, if you are making a really large printbed, you'll run into problems as the firmware can't work with large enough numbers to handle the long axes. No reasonable printbed should run into those problems though.

The rest of the software won't care.

Also, if you are making a really large printbed, you'll run into problems as the firmware can't work with large enough numbers to handle the long axes. No reasonable printbed should run into those problems though.

|

Re: Larger printbed June 23, 2012 05:36AM |

Registered: 11 years ago Posts: 3 |

|

Re: Larger printbed June 23, 2012 05:49AM |

Registered: 13 years ago Posts: 643 |

|

Re: Larger printbed June 23, 2012 05:52AM |

Registered: 11 years ago Posts: 3 |

Hi,

Once again thanks for the quick response. So I was looking at slic3r and there are settings for the print bed size, are these all I have to change for a larger printbed?

I cant find setting on slic3r for changing the z axis dimensions, there are only setting for changing x and y, how would I achieve this?

Headbutt

Edited 1 time(s). Last edit at 06/23/2012 05:56AM by Headbutt.

Once again thanks for the quick response. So I was looking at slic3r and there are settings for the print bed size, are these all I have to change for a larger printbed?

I cant find setting on slic3r for changing the z axis dimensions, there are only setting for changing x and y, how would I achieve this?

Headbutt

Edited 1 time(s). Last edit at 06/23/2012 05:56AM by Headbutt.

|

Re: Larger printbed June 23, 2012 06:51AM |

Registered: 12 years ago Posts: 147 |

Hi Headbutt,

Firmwares, such as Marlin and Sprinter limit the possible Z height. There are no pre-warnings so don't try and print something too large for your printer (as defined in firmware) otherwise it will just stop.

You are going to run into stability issues with a Mendel design using threaded rods at those sizes, it will be fairly wobbly, limiting your speed or print quality significantly. I would look to increase the size of a standard MendelMax that uses aluminium extrusions, if I desired a print bed of that size. Else, you can adapt the Mendel (better is the Prusa Mendel as you will almost certainly need two Z motors) to use thicker threaded and smooth rods. I believe there is a design by Kliment called the Prusa12, which could help.

Whatever you choose, you will need a very rigid frame.

Also heating a bed of that size may prove to be problematic, although I'm sure there are people who would be willing to point you in the right direction.

Best of luck.

Firmwares, such as Marlin and Sprinter limit the possible Z height. There are no pre-warnings so don't try and print something too large for your printer (as defined in firmware) otherwise it will just stop.

You are going to run into stability issues with a Mendel design using threaded rods at those sizes, it will be fairly wobbly, limiting your speed or print quality significantly. I would look to increase the size of a standard MendelMax that uses aluminium extrusions, if I desired a print bed of that size. Else, you can adapt the Mendel (better is the Prusa Mendel as you will almost certainly need two Z motors) to use thicker threaded and smooth rods. I believe there is a design by Kliment called the Prusa12, which could help.

Whatever you choose, you will need a very rigid frame.

Also heating a bed of that size may prove to be problematic, although I'm sure there are people who would be willing to point you in the right direction.

Best of luck.

|

Re: Larger printbed June 23, 2012 06:58AM |

Registered: 12 years ago Posts: 147 |

Also are you absolutely sure you NEED a larger print bed? Splitting the model may prove to be quicker and less hassle than printing extremely large single prints. With a heated bed you still may get warping (prints lifting from the bed due to shrinking, especially if you are going slowly).

|

Re: Larger printbed June 23, 2012 06:58AM |

Registered: 13 years ago Posts: 1,780 |

Please note that just because you have a big print bed, it doesn't mean that you can build big parts. In fact, you can't even build a part as big as the current print bed (between 100 mm to 200 mm on each side) without it warping. You can build lots of small parts, but then you can do that with the standard bed too. You'll need to print inside a hot box to print large parts.

Edited 1 time(s). Last edit at 06/23/2012 09:16PM by brnrd.

Edited 1 time(s). Last edit at 06/23/2012 09:16PM by brnrd.

|

Re: Larger printbed June 23, 2012 07:34AM |

Registered: 14 years ago Posts: 689 |

My current printer is a oversized prusa, with a theoretical build volume of 33x40x20cm. The only changes I made was to use 12mm rods for the top parts of the triangles, and it's working pretty well. There's still quite a lot of wobble in the x direction, so my prints doesn't come out pristine, but it works fine as my daily printer.

I'm only using a close to standard prusa sized bed on it yet though, and haven't had any need for a larger build area, so there you go.

I wouldn't recommend building too far outside of the standards as your first printer, it does add a lot of unknown variables.

I've attached a few old pictures, I don't have any new ones after its completion, but can snap a few if there's interest. There's a video of it printing here. (Warning, chip-tune music).

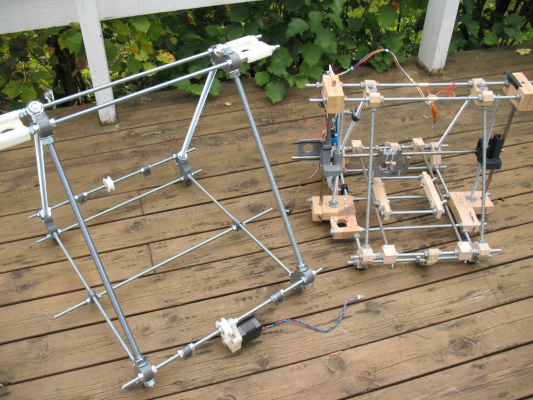

Here it is next to a standard sized sells mendel.

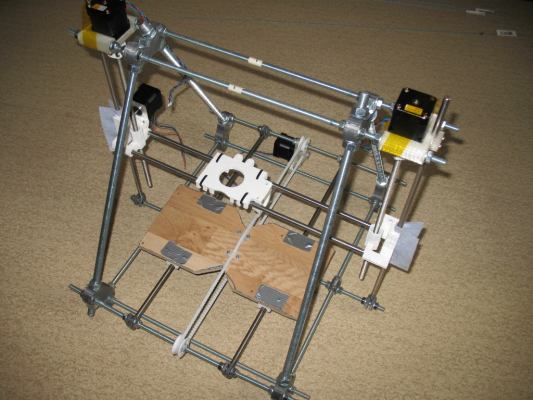

And here you can see the thicker triangle rods better.

--

-Nudel

Blog with RepRap Comic

I'm only using a close to standard prusa sized bed on it yet though, and haven't had any need for a larger build area, so there you go.

I wouldn't recommend building too far outside of the standards as your first printer, it does add a lot of unknown variables.

I've attached a few old pictures, I don't have any new ones after its completion, but can snap a few if there's interest. There's a video of it printing here. (Warning, chip-tune music).

Here it is next to a standard sized sells mendel.

And here you can see the thicker triangle rods better.

--

-Nudel

Blog with RepRap Comic

Sorry, only registered users may post in this forum.