Tinkerine Studio - Ditto 3D Printer

Posted by ECSuyu

|

Re: Tinkerine Studio - Ditto 3D Printer July 14, 2012 10:00PM |

Registered: 12 years ago Posts: 147 |

I don't want this to become a debate about achievable print speed and the quality impact that it has. As you say printing at 100mm/s is not twice as fast as 50mm/s, especially with that print over such a small distance.

However, it should be safe to say that a Mendel can hit 100mm/s infill without an issue, depending on the number of perimeters that the resonance may overlap. Printing perimeters is a different argument, one where a lightweight head without* resonance clearly has the advantage if you want to take the prize for speed.

My point was more of a comparison, which is hard to quantify. A lightweight head can print faster whilst attaining the same quality as compared to a heavier axis. If there are any problems with this statement then please feel free to open a new topic, I think we have gotten a little off topic!

However, it should be safe to say that a Mendel can hit 100mm/s infill without an issue, depending on the number of perimeters that the resonance may overlap. Printing perimeters is a different argument, one where a lightweight head without* resonance clearly has the advantage if you want to take the prize for speed.

My point was more of a comparison, which is hard to quantify. A lightweight head can print faster whilst attaining the same quality as compared to a heavier axis. If there are any problems with this statement then please feel free to open a new topic, I think we have gotten a little off topic!

|

Re: Tinkerine Studio - Ditto 3D Printer July 15, 2012 10:35AM |

Registered: 12 years ago Posts: 313 |

billyzelsnack Wrote:

> This is the best evidence I have found.

> [www.youtube.com]

> It is printing very fast at "only" 100mm/s and the

> quality looks decent with good fill too, but I

> wonder how often the print is actually achieving

> 100mm/s. If that print took 5 minutes then how

> long would the print of taken at 50mm/s? Overall

> print time and quality is all that matters.

I have a Prusa with a 8mm acrylic plate firmly bolted to the frame (as electronics mount and frame stiffener) and it's not showing any significant vibration at any speed (up to 300 mm/s) - but this is with gentle 1500 mm/s*s acceleration.

I just printed two identical objects, straight pipes with a somewhat complicated internal structures, and these took 3:48 at 50 mm/s and 3:13 at 100 mm/s. They look almost identical (the 100 mm/s is just a little rougher) but the plastic fusion is noticeably worse in the 100 mm/s one, especially in the outer perimeter where the extruder actually ran at that speed. In fact it broke when I used a bit of force to check the strength. So I saved an insignificant amount of time and produced an unusable object. This is why I have been printing at 50 mm/s. (This was with natural 3mm ABS, 265 C, 0.35mm Arcol V4, 0.225 layers and 2.0 W/T)

> Also in my experience even if you can get the

> correct volume of plastic out of the hotend that

> does not mean it is going to properly adhere to

> the layer below at higher speeds. Thread overhangs

> and cornering are particularly troublesome. This

> means the slicing software needs to be smarter

> about going slower in trouble spots and going

> slower of course increases build time.

Exactly. As does using a conservative acceleration value.

> This is the best evidence I have found.

> [www.youtube.com]

> It is printing very fast at "only" 100mm/s and the

> quality looks decent with good fill too, but I

> wonder how often the print is actually achieving

> 100mm/s. If that print took 5 minutes then how

> long would the print of taken at 50mm/s? Overall

> print time and quality is all that matters.

I have a Prusa with a 8mm acrylic plate firmly bolted to the frame (as electronics mount and frame stiffener) and it's not showing any significant vibration at any speed (up to 300 mm/s) - but this is with gentle 1500 mm/s*s acceleration.

I just printed two identical objects, straight pipes with a somewhat complicated internal structures, and these took 3:48 at 50 mm/s and 3:13 at 100 mm/s. They look almost identical (the 100 mm/s is just a little rougher) but the plastic fusion is noticeably worse in the 100 mm/s one, especially in the outer perimeter where the extruder actually ran at that speed. In fact it broke when I used a bit of force to check the strength. So I saved an insignificant amount of time and produced an unusable object. This is why I have been printing at 50 mm/s. (This was with natural 3mm ABS, 265 C, 0.35mm Arcol V4, 0.225 layers and 2.0 W/T)

> Also in my experience even if you can get the

> correct volume of plastic out of the hotend that

> does not mean it is going to properly adhere to

> the layer below at higher speeds. Thread overhangs

> and cornering are particularly troublesome. This

> means the slicing software needs to be smarter

> about going slower in trouble spots and going

> slower of course increases build time.

Exactly. As does using a conservative acceleration value.

|

Re: Tinkerine Studio - Ditto 3D Printer July 19, 2012 08:09PM |

Registered: 13 years ago Posts: 141 |

For everyone wondering the effects of print speed vs time and print quality we will be doing a test of this today and will be posting the results once we have them. It is something that we believe should be documented and test and I'm sure the community would be interested in it as well.

But we would like to take this time to tell everyone that Ditto is now on indiegogo for anyone that is interested. Support us if you can, as we have tried to incorporate pledges that are meant to benefit everyone at least a little bit.

Ditto - Indiegogo Campaign

___________________________________________________

Kreativ-e

Tinkerine Studio

But we would like to take this time to tell everyone that Ditto is now on indiegogo for anyone that is interested. Support us if you can, as we have tried to incorporate pledges that are meant to benefit everyone at least a little bit.

Ditto - Indiegogo Campaign

___________________________________________________

Kreativ-e

Tinkerine Studio

|

Re: Tinkerine Studio - Ditto 3D Printer July 20, 2012 03:47PM |

Registered: 13 years ago Posts: 141 |

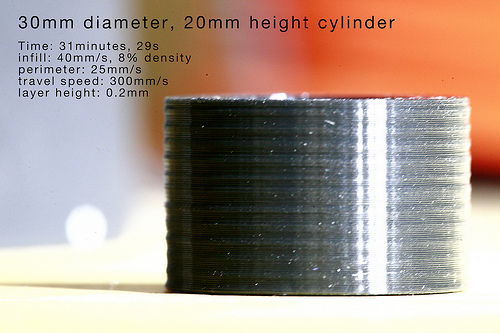

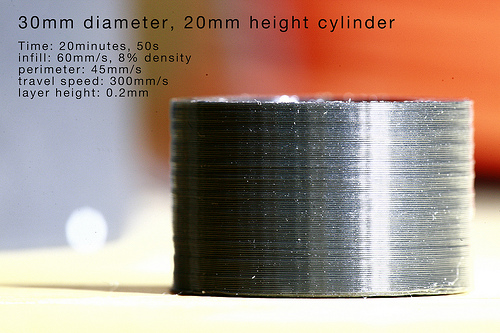

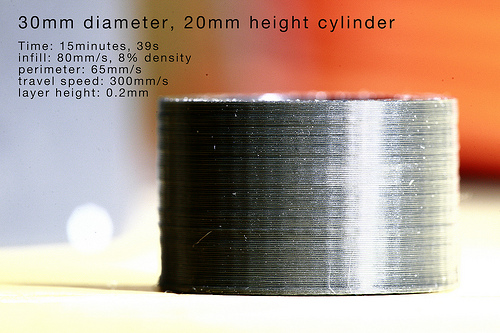

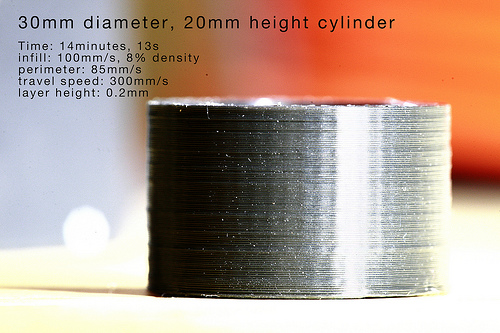

I hope this sheds some light in terms of print speed to quality and time saving that has been discussed here.

Our findings are pretty interesting: At 80mm/s infill speed, Ditto delivers better quality prints than at 40mm/s, and thats at half the print time. However, the time saving from 80mm/s to 100mm/s is only 1 minute on this small object. On top of that, there is significantly more banding when printing at slower speeds.

Though this test is only on a small object, we can say that at this moment Ditto doesn't do well at slower speeds. Around 60-80mm/s is the optimal speed in which we believe Ditto performs the best in terms of both print speed and quality. This might not be the case for other printers, and we will conduct another experiment on the Mendels we have once we get them back up and running.

Speed vs Quality test 1 by Tinkerine Studio, on Flickr

Speed vs Quality test 2 by Tinkerine Studio, on Flickr

Speed vs Quality test 3 by Tinkerine Studio, on Flickr

Speed vs Quality test 4 by Tinkerine Studio, on Flickr

Edited 2 time(s). Last edit at 07/20/2012 03:57PM by ECSuyu.

___________________________________________________

Kreativ-e

Tinkerine Studio

Our findings are pretty interesting: At 80mm/s infill speed, Ditto delivers better quality prints than at 40mm/s, and thats at half the print time. However, the time saving from 80mm/s to 100mm/s is only 1 minute on this small object. On top of that, there is significantly more banding when printing at slower speeds.

Though this test is only on a small object, we can say that at this moment Ditto doesn't do well at slower speeds. Around 60-80mm/s is the optimal speed in which we believe Ditto performs the best in terms of both print speed and quality. This might not be the case for other printers, and we will conduct another experiment on the Mendels we have once we get them back up and running.

Speed vs Quality test 1 by Tinkerine Studio, on Flickr

Speed vs Quality test 2 by Tinkerine Studio, on Flickr

Speed vs Quality test 3 by Tinkerine Studio, on Flickr

Speed vs Quality test 4 by Tinkerine Studio, on Flickr

Edited 2 time(s). Last edit at 07/20/2012 03:57PM by ECSuyu.

___________________________________________________

Kreativ-e

Tinkerine Studio

|

Re: Tinkerine Studio - Ditto 3D Printer July 20, 2012 05:11PM |

Registered: 13 years ago Posts: 301 |

|

Re: Tinkerine Studio - Ditto 3D Printer July 20, 2012 05:36PM |

Registered: 13 years ago Posts: 141 |

In terms of tessellation we are not sure how tessellated it is. The model was quickly done for testing purposes. It could be that the speed is smoothing out from the jerk value set inside marlin. But we want to do more tests with other objects.

Yup, these print are single perimeter prints, nozzle size of 0.35mm, and slic3rs default thread width.

___________________________________________________

Kreativ-e

Tinkerine Studio

Yup, these print are single perimeter prints, nozzle size of 0.35mm, and slic3rs default thread width.

___________________________________________________

Kreativ-e

Tinkerine Studio

|

Re: Tinkerine Studio - Ditto 3D Printer July 20, 2012 05:41PM |

Registered: 12 years ago Posts: 147 |

I was thinking of putting a test together on my MendelMax and Prusa to show my max speed vs quality (and hopefully get others to post their results). Some of the things I said were somewhat unfounded and I would be curious to see the result vs my expectations.

I still think that infill speed can be set very very high if using multiple perimeters without impacting quality (as long as there is minimal resonance in the XY planes - so expect my MendelMax to outperform the Prusa). I am mostly curious to see maximum perimeter speed vs quality which I don't think your test highlights very well. I would prefer to see a model with sharp corners and multiple islands.

I will try to put a test together in the coming week and start a new thread, as I think it will be interesting and its one of the most common questions for newcomers.

In response to your test, I am surprised to see that all speeds show inconsistent stacking of layers and question whether you currently have backlash or Z wobble in your setup. Perhaps you just need to tighten your belts a touch more.

I still think that infill speed can be set very very high if using multiple perimeters without impacting quality (as long as there is minimal resonance in the XY planes - so expect my MendelMax to outperform the Prusa). I am mostly curious to see maximum perimeter speed vs quality which I don't think your test highlights very well. I would prefer to see a model with sharp corners and multiple islands.

I will try to put a test together in the coming week and start a new thread, as I think it will be interesting and its one of the most common questions for newcomers.

In response to your test, I am surprised to see that all speeds show inconsistent stacking of layers and question whether you currently have backlash or Z wobble in your setup. Perhaps you just need to tighten your belts a touch more.

|

Re: Tinkerine Studio - Ditto 3D Printer July 20, 2012 05:44PM |

Registered: 11 years ago Posts: 939 |

|

Re: Tinkerine Studio - Ditto 3D Printer July 20, 2012 06:15PM |

Registered: 13 years ago Posts: 141 |

The banding and inconsistent layers are a result of the acme threaded rods we used for the beta machines. They had quite a bit of bend to them and the results are the banding and z wobble that you guys see. This test was also done on the first beta machine with pulleys printed from ABS which didnt have very deep tooth profiles so these prints will show some signs of backlash because of that. We have fully printed PLA pulleys waiting for him as an upgrade, but also need to upgrade the delrin bushings along side to make the time worth while.

@yydoctt- it would be interesting to see some results, I agree that this is probably one of the most lacking in documentation aspects for the community,one that novice users would benefit from.

___________________________________________________

Kreativ-e

Tinkerine Studio

@yydoctt- it would be interesting to see some results, I agree that this is probably one of the most lacking in documentation aspects for the community,one that novice users would benefit from.

___________________________________________________

Kreativ-e

Tinkerine Studio

|

Re: Tinkerine Studio - Ditto 3D Printer July 21, 2012 03:33PM |

Registered: 11 years ago Posts: 939 |

Out of interest I printed a 40mm cylinder on my mendelmax which has some slight ZWobble, with perimeter speeds of 20mm/s 40mm/s 60mm/s and 80mm/s.

I see a similar pattern to the banding, faster print speeds show less, but I think it's primarilly because of the temperature of the previous layer as the next is deposited.

I did the 40mm/s print first and didn't turn the fan on, it shows almost no Z banding, but there were some layer inconsistencies as the hotend cooled from it's initial layer temperature.

For the subsequent prints I ran with a fan on and with the same base layer temperature as subsequent layers.

the 80mm/sec print with cooling also shows almost no Z banding, but the backside of the print is extremely uneven becasue the fan doesn't get enough air there to cool it enough before the next layer goes down.

The 60mm/sec print has less banding than the 20mm/sec print both with cooling.

So I'd surmise that it's mostly a function of the temperature of the previous layer as the next is deposited, and although an interesting effect, it's only applicable where layer times are very short.

I see a similar pattern to the banding, faster print speeds show less, but I think it's primarilly because of the temperature of the previous layer as the next is deposited.

I did the 40mm/s print first and didn't turn the fan on, it shows almost no Z banding, but there were some layer inconsistencies as the hotend cooled from it's initial layer temperature.

For the subsequent prints I ran with a fan on and with the same base layer temperature as subsequent layers.

the 80mm/sec print with cooling also shows almost no Z banding, but the backside of the print is extremely uneven becasue the fan doesn't get enough air there to cool it enough before the next layer goes down.

The 60mm/sec print has less banding than the 20mm/sec print both with cooling.

So I'd surmise that it's mostly a function of the temperature of the previous layer as the next is deposited, and although an interesting effect, it's only applicable where layer times are very short.

|

Re: Tinkerine Studio - Ditto 3D Printer July 30, 2012 02:53PM |

Registered: 13 years ago Posts: 141 |

In case anyone has missed the launch of our Indiegogo campaign, here's a list of perks for all your honorable pledges. We appreciate any form of support, so please check us out at [www.indiegogo.com] . Thanks!

___________________________________________________

Kreativ-e

Tinkerine Studio

___________________________________________________

Kreativ-e

Tinkerine Studio

|

Re: Tinkerine Studio - Ditto 3D Printer August 15, 2012 03:51PM |

Registered: 13 years ago Posts: 141 |

Here's an update as our indiegogo comes near the end of its campaign. We have been working hard to try and bring down the cost of our machine, and with our on going relationship with our parts suppliers we are now able to offer Ditto at at a lower price. As promised we are passing these savings onto you guys.

So the prices now stand as the following for the machine kits:

Edited 2 time(s). Last edit at 08/15/2012 03:53PM by ECSuyu.

___________________________________________________

Kreativ-e

Tinkerine Studio

So the prices now stand as the following for the machine kits:

Edited 2 time(s). Last edit at 08/15/2012 03:53PM by ECSuyu.

___________________________________________________

Kreativ-e

Tinkerine Studio

Sorry, only registered users may post in this forum.