Extruder performance - can it be measured?

Posted by dzach

|

Extruder performance - can it be measured? June 25, 2012 06:37PM |

Registered: 12 years ago Posts: 88 |

Apologies for the long post.

Most (new) 3D printer owners would like to know what the maximum print speed of their printer is. So what's easier, we set the feed rate high, choose a nice object or one made for calibration and print we go. If the object prints nicely and there are no missing steps at the extruder or any other motor, then declare the new record and live happily ever after. Or not?

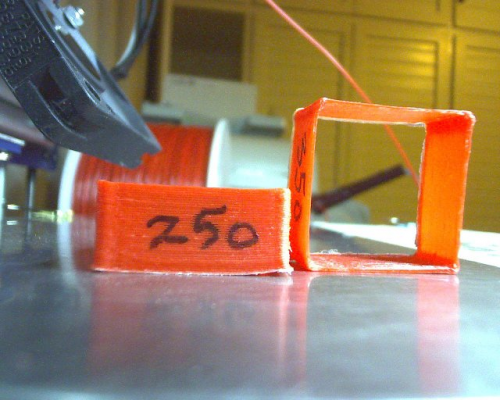

Unfortunately not. The 0.5mm single wall box printed nicely at a 350mm/s feed rate. Only ... I noticed something strange: it took exactly the same time to complete as it did at 250mm/s ! So something was not right; something was limiting the print and I needed to know what.

Here are the basic formulas for some simple speed/acceleration calculations :

The test box had dimensions 20x20x10mm therefore the accelerating travel along a 20mm edge (allowing for an equal deceleration before the head reached the end of the distance, if I get this right, at least with firmware without a look-ahead feature enabled) would be:

The printer was set to:

The velocity at the middle of the 20mm side would then be:

Clearly, the print head did not reach the requested feed rate of 250mm/s; instead, it momentarily reached 245.7mm/s at the middle of the box's edge. The limiting factor was the short travel which, at the given initial speed and acceleration, did not allow the print head to reach max speed.

What is the travel at which the print head could reach a feed rate of, e.g. 350mm/s?

Solving for s we get:

therefore a distance of 2 * 20.35mm = 40.7mm is needed for the print head to accelerate, reach a speed of 350mm/s and decelerate.

Trying to lift this limitation I created another version of the box, by elongating one side along the X axis, so that the print head would have the time to reach maximum speed and also have enough time to extrude some quantity of plastic and thus upset more the thermal conditions in the melt chamber.

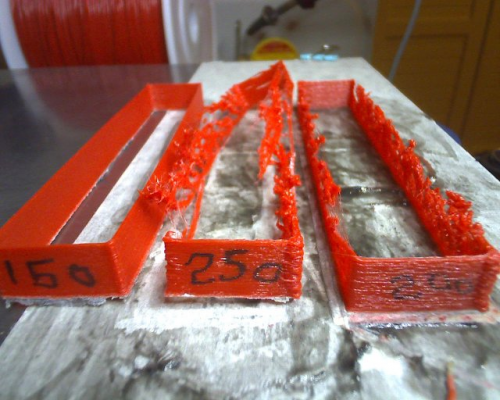

Here are the results:

At 250mm/s my DIY extruder simply did not perform, period. Although the short sides printed a lot better, the long sides were just crap. This proved in practice the theoretical calculations outlined above. The 200mm/s print showed some improvement, but it was still unacceptable, while the 150mm/s print was almost perfect. So, clearly, the limit of my DIY extruder lies somewhere between 150mm/s and 200mm/s.

There is a lot of talk about the best/fastest/sleekest/newest extruder/hotend/pinch-wheel/hobbed-screw design. New and cheap extruder designs emerge every other day, though no real performance data is ever published. But if we could give this quest some backup from measured data, things would be easier for the users and better for the developers, since knowing the standard against which they compete would lead to better designs or at least better prices for similar extruder performances.

So, here are some questions:

One measure of an extruder's performance is undoubtedly speed. Speed gets the job done faster, it allows the user to watch a greater portion or all of the print, it allows faster design iterations to achieve the optimum result.

As a first thought, a really simple set of tests could be devised:

In my mind, the "dynamic range" of an extruder can tell something about its performance, but this may well be just a projection from other disciplines

This is the STL file with a 0.5mm single wall box that I used for the speed test.

0.5mmx100x20-thin-wall.stl

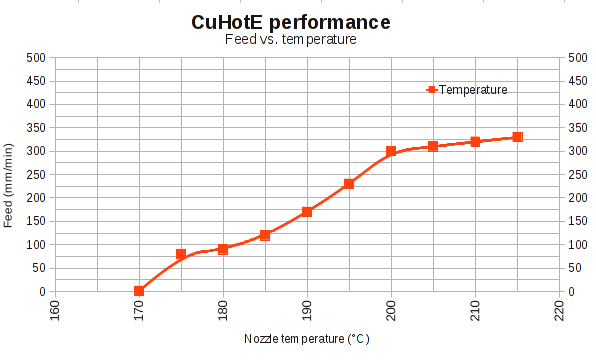

And this is showing my DIY extruder's performance as feed rate vs temperature graph.For each measurement, I extruded 100mm of PLA and accepted the measurement only if there was no missed steps:

More of my adventures with extruder performance in my ORDbot build log

If there is consensus on a minimal set of tests then the main concepts could be posted on the RepRap wiki as a guide for extruder performance.

Any thoughts?

Edited 1 time(s). Last edit at 06/25/2012 06:56PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Most (new) 3D printer owners would like to know what the maximum print speed of their printer is. So what's easier, we set the feed rate high, choose a nice object or one made for calibration and print we go. If the object prints nicely and there are no missing steps at the extruder or any other motor, then declare the new record and live happily ever after. Or not?

Unfortunately not. The 0.5mm single wall box printed nicely at a 350mm/s feed rate. Only ... I noticed something strange: it took exactly the same time to complete as it did at 250mm/s ! So something was not right; something was limiting the print and I needed to know what.

Here are the basic formulas for some simple speed/acceleration calculations :

v = sqrt( u^2 + 2 * a * s ) where: v = final velocity (mm/s) u = initial velocity (mm/s) a = acceleration (mm/s^2) s = travel (mm) t = time (s)

The test box had dimensions 20x20x10mm therefore the accelerating travel along a 20mm edge (allowing for an equal deceleration before the head reached the end of the distance, if I get this right, at least with firmware without a look-ahead feature enabled) would be:

s = 20mm/2 = 10mm

The printer was set to:

u = 20mm/s, initial speed a = 3000mm/s^2, acceleration

The velocity at the middle of the 20mm side would then be:

v = sqrt( (20mm/s)^2 + 2*3000mm/s^2*10mm = 245.7 mm/s

Clearly, the print head did not reach the requested feed rate of 250mm/s; instead, it momentarily reached 245.7mm/s at the middle of the box's edge. The limiting factor was the short travel which, at the given initial speed and acceleration, did not allow the print head to reach max speed.

What is the travel at which the print head could reach a feed rate of, e.g. 350mm/s?

Solving for s we get:

s = (v^2 - u^2) / (2 * a) s = ((350mm/s)^2 - (20mm/s)^2) / (2 * 3000mm/s^2) = 20.35mm

therefore a distance of 2 * 20.35mm = 40.7mm is needed for the print head to accelerate, reach a speed of 350mm/s and decelerate.

Trying to lift this limitation I created another version of the box, by elongating one side along the X axis, so that the print head would have the time to reach maximum speed and also have enough time to extrude some quantity of plastic and thus upset more the thermal conditions in the melt chamber.

Here are the results:

At 250mm/s my DIY extruder simply did not perform, period. Although the short sides printed a lot better, the long sides were just crap. This proved in practice the theoretical calculations outlined above. The 200mm/s print showed some improvement, but it was still unacceptable, while the 150mm/s print was almost perfect. So, clearly, the limit of my DIY extruder lies somewhere between 150mm/s and 200mm/s.

There is a lot of talk about the best/fastest/sleekest/newest extruder/hotend/pinch-wheel/hobbed-screw design. New and cheap extruder designs emerge every other day, though no real performance data is ever published. But if we could give this quest some backup from measured data, things would be easier for the users and better for the developers, since knowing the standard against which they compete would lead to better designs or at least better prices for similar extruder performances.

So, here are some questions:

- - What is considered good extruder performance?

- Can we measure extruder performance?

- Can we publish the tested performance of various extruder designs and see which of them offer what advantages?

- Can we produce a diagram showing the performance of an extruder at different temperatures, so that users can easily adjust speed/temperature?

One measure of an extruder's performance is undoubtedly speed. Speed gets the job done faster, it allows the user to watch a greater portion or all of the print, it allows faster design iterations to achieve the optimum result.

As a first thought, a really simple set of tests could be devised:

- - High Extrusion Speed: one test for a travel of 100mm and one for a travel of 200mm, for small and large print beds respectively. The tests do not aim to show anything else but hotend/extruder performance, that is, neither warping nor Z-axis wobble or anything else not related to the extruder, but affecting print quality, should count.

- Low Extrusion Speed: this may be needed for small objects that cannot print in higher speeds, due to plastic not having time to cool between layers.

In my mind, the "dynamic range" of an extruder can tell something about its performance, but this may well be just a projection from other disciplines

This is the STL file with a 0.5mm single wall box that I used for the speed test.

0.5mmx100x20-thin-wall.stl

And this is showing my DIY extruder's performance as feed rate vs temperature graph.For each measurement, I extruded 100mm of PLA and accepted the measurement only if there was no missed steps:

More of my adventures with extruder performance in my ORDbot build log

If there is consensus on a minimal set of tests then the main concepts could be posted on the RepRap wiki as a guide for extruder performance.

Any thoughts?

Edited 1 time(s). Last edit at 06/25/2012 06:56PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 25, 2012 06:47PM |

Registered: 13 years ago Posts: 2,947 |

You never address quality? I have built hotneds that print at 350mm/s but they could never print a part like ones that can not print at those speeds.

The J-head Mk-iVb and Mk-Vb both have speed limitations but print really well. The Arcol prints really fast but is known for ooze. How do you call one better then the other when they have different properties.

The J-head Mk-iVb and Mk-Vb both have speed limitations but print really well. The Arcol prints really fast but is known for ooze. How do you call one better then the other when they have different properties.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 25, 2012 07:01PM |

Registered: 13 years ago Posts: 301 |

|

Re: Extruder performance - can it be measured? June 25, 2012 07:48PM |

Registered: 12 years ago Posts: 88 |

Sublime Wrote:

-------------------------------------------------------

> You never address quality?

Ah, but then we have to establish some criteria about the quality of a print. As the objective of these tests is extruder performance at an acceptable quality, quality could be a pass or fail criterion taking 3 values if passed: low, average, high. The intention is not to reject designs but to try establish some hard data for each at different conditions. Searching the internet for data one finds that very few people do actually publish numerical data for their extruders.

While documenting extruder performance, a number of setup parameters should be made known, together with some pictures showing the test object as successfully printed with that particular setup and some of the next higher but failed test. Sounds like a lot, but I think it's actually what most people do when describing their efforts with their extruders. What makes it a little different is the formalized procedure, test objects and the expectation of specific numerical data from the test.

billyzelsnack Wrote:

-------------------------------------------------------

> The limit is the volume of plastic extruded not

> the speed at which the nozzle moves.

Yes, that's why I posted the feed vs temperature graph (btw, the units on it are wrong, it should be mm/s on the Y axis); it is the extruder feed, not the head speed.

I think mm^3 is harder to understand physically than mm/s and that's what most people post when bragging about their designs. In any case you can't go 350mm/s on bed and extrude less plastic than necessary, or maybe the other way around, in order to have an acceptable print @350mm/s you have to extrude the necessary plastic.

-------------------------------------------------------

> You never address quality?

Ah, but then we have to establish some criteria about the quality of a print. As the objective of these tests is extruder performance at an acceptable quality, quality could be a pass or fail criterion taking 3 values if passed: low, average, high. The intention is not to reject designs but to try establish some hard data for each at different conditions. Searching the internet for data one finds that very few people do actually publish numerical data for their extruders.

While documenting extruder performance, a number of setup parameters should be made known, together with some pictures showing the test object as successfully printed with that particular setup and some of the next higher but failed test. Sounds like a lot, but I think it's actually what most people do when describing their efforts with their extruders. What makes it a little different is the formalized procedure, test objects and the expectation of specific numerical data from the test.

billyzelsnack Wrote:

-------------------------------------------------------

> The limit is the volume of plastic extruded not

> the speed at which the nozzle moves.

Yes, that's why I posted the feed vs temperature graph (btw, the units on it are wrong, it should be mm/s on the Y axis); it is the extruder feed, not the head speed.

I think mm^3 is harder to understand physically than mm/s and that's what most people post when bragging about their designs. In any case you can't go 350mm/s on bed and extrude less plastic than necessary, or maybe the other way around, in order to have an acceptable print @350mm/s you have to extrude the necessary plastic.

|

Re: Extruder performance - can it be measured? June 25, 2012 08:11PM |

Registered: 13 years ago Posts: 2,947 |

dzach Wrote:

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

> -----

> > You never address quality?

>

> Ah, but then we have to establish some criteria

> about the quality of a print. As the objective of

> these tests is extruder performance at an

> acceptable quality, quality could be a pass or

> fail criterion taking 3 values if passed: low,

> average, high. The intention is not to reject

> designs but to try establish some hard data for

> each at different conditions. Searching the

> internet for data one finds that very few people

> do actually publish numerical data for their

> extruders.

>

> While documenting extruder performance, a number

> of setup parameters should be made known, together

> with some pictures showing the test object as

> successfully printed with that particular setup

> and some of the next higher but failed test.

> Sounds like a lot, but I think it's actually what

> most people do when describing their efforts with

> their extruders. What makes it a little different

> is the formalized procedure, test objects and the

> expectation of specific numerical data from the

> test.

I do believe what you are looking for is something important and it would be great if we could make some standard to judge these things by. But I also believe we would need to have one machine to test them all. Not individuals with different parts and firmware settings and even the plastic being used would have to come from the same batch and have been kept in the exact same way.

I think it is more important to establish a standard for quality first (and only the best quality prints should even be considered). At that point when we have a few hotneds capable of printing parts with a finish that's acceptable in a retail market can we then measure their performance.

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

> -----

> > You never address quality?

>

> Ah, but then we have to establish some criteria

> about the quality of a print. As the objective of

> these tests is extruder performance at an

> acceptable quality, quality could be a pass or

> fail criterion taking 3 values if passed: low,

> average, high. The intention is not to reject

> designs but to try establish some hard data for

> each at different conditions. Searching the

> internet for data one finds that very few people

> do actually publish numerical data for their

> extruders.

>

> While documenting extruder performance, a number

> of setup parameters should be made known, together

> with some pictures showing the test object as

> successfully printed with that particular setup

> and some of the next higher but failed test.

> Sounds like a lot, but I think it's actually what

> most people do when describing their efforts with

> their extruders. What makes it a little different

> is the formalized procedure, test objects and the

> expectation of specific numerical data from the

> test.

I do believe what you are looking for is something important and it would be great if we could make some standard to judge these things by. But I also believe we would need to have one machine to test them all. Not individuals with different parts and firmware settings and even the plastic being used would have to come from the same batch and have been kept in the exact same way.

I think it is more important to establish a standard for quality first (and only the best quality prints should even be considered). At that point when we have a few hotneds capable of printing parts with a finish that's acceptable in a retail market can we then measure their performance.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 25, 2012 09:01PM |

Registered: 12 years ago Posts: 88 |

Sublime Wrote:

-------------------------------------------------------

> I have built hotneds that print at 350mm/s

I would be very interested in the details of their design.

My printer can move reliably @350mm/s but my DIY extruder is way slower at 150mm/s. I did think it was doing 350mm/s but was forced to realize that was just my wishful thinking I realize that many experts will smile at these statements, but that's how many of the rest of us think

I realize that many experts will smile at these statements, but that's how many of the rest of us think

Sublime Wrote:

-------------------------------------------------------

> [...] it would be great if we could make some standard to judge these things by. But I also believe we would need to have one machine to test them all.

> [...] I think it is more important to establish a standard for quality first (and only the best quality prints should even be considered).

Yes, you are right. Though there are some qualities that may be measured independently, like pinch gear/hobbed bolt grip, quality of extrusion at various extruder feed rates etc, length of ooze after a given time, etc.

Take for instance quality of extrusion. It is a quality that can be documented with numbers and pictures independently of the quality of print. It can also be contested by anyone having the same extruder.

I see, for instance, some new extruder designs with a very deep grip on the plastic, so deep that I feel there is a risk to get air trapped in the extrusion at higher speeds. Measuring the grip force of such an extruder would give it a high score but measuring the quality of extrusion at various speeds and temperatures might negate the good results of the former measurement. Quality of extrusion is different than quality of print, it is like a subset of it and thus, maybe, easier to measure.

I realize that this is a big subject. Taking at it piece by piece may make it easier to handle, and also give useful partial results.

-------------------------------------------------------

> I have built hotneds that print at 350mm/s

I would be very interested in the details of their design.

My printer can move reliably @350mm/s but my DIY extruder is way slower at 150mm/s. I did think it was doing 350mm/s but was forced to realize that was just my wishful thinking

I realize that many experts will smile at these statements, but that's how many of the rest of us think

I realize that many experts will smile at these statements, but that's how many of the rest of us think

Sublime Wrote:

-------------------------------------------------------

> [...] it would be great if we could make some standard to judge these things by. But I also believe we would need to have one machine to test them all.

> [...] I think it is more important to establish a standard for quality first (and only the best quality prints should even be considered).

Yes, you are right. Though there are some qualities that may be measured independently, like pinch gear/hobbed bolt grip, quality of extrusion at various extruder feed rates etc, length of ooze after a given time, etc.

Take for instance quality of extrusion. It is a quality that can be documented with numbers and pictures independently of the quality of print. It can also be contested by anyone having the same extruder.

I see, for instance, some new extruder designs with a very deep grip on the plastic, so deep that I feel there is a risk to get air trapped in the extrusion at higher speeds. Measuring the grip force of such an extruder would give it a high score but measuring the quality of extrusion at various speeds and temperatures might negate the good results of the former measurement. Quality of extrusion is different than quality of print, it is like a subset of it and thus, maybe, easier to measure.

I realize that this is a big subject. Taking at it piece by piece may make it easier to handle, and also give useful partial results.

|

Re: Extruder performance - can it be measured? June 25, 2012 09:11PM |

Registered: 13 years ago Posts: 301 |

> > The limit is the volume of plastic extruded not

> > the speed at which the nozzle moves.

>

> Yes, that's why I posted the feed vs temperature

> graph (btw, the units on it are wrong, it should

> be mm/s on the Y axis); it is the extruder feed,

> not the head speed.

>

> I think mm^3 is harder to understand physically

> than mm/s and that's what most people post when

> bragging about their designs. In any case you

> can't go 350mm/s on bed and extrude less plastic

> than necessary, or maybe the other way around, in

> order to have an acceptable print @350mm/s you

> have to extrude the necessary plastic.

At thinner layer heights less plastic is needed so it is possible to go faster. For fair comparisons thread width and layer height would also need to be specified so you're back to volume.

Update.. Nevermind the above comment. I went and had another look at your graph. I think we still would need to know the free air extrusion diameter. It does bring up another question though. Is there non-negligible added pressure requirements from the act of smashing the filament against a prior layer during typical printing?

Edited 1 time(s). Last edit at 06/25/2012 09:32PM by billyzelsnack.

> > the speed at which the nozzle moves.

>

> Yes, that's why I posted the feed vs temperature

> graph (btw, the units on it are wrong, it should

> be mm/s on the Y axis); it is the extruder feed,

> not the head speed.

>

> I think mm^3 is harder to understand physically

> than mm/s and that's what most people post when

> bragging about their designs. In any case you

> can't go 350mm/s on bed and extrude less plastic

> than necessary, or maybe the other way around, in

> order to have an acceptable print @350mm/s you

> have to extrude the necessary plastic.

At thinner layer heights less plastic is needed so it is possible to go faster. For fair comparisons thread width and layer height would also need to be specified so you're back to volume.

Update.. Nevermind the above comment. I went and had another look at your graph. I think we still would need to know the free air extrusion diameter. It does bring up another question though. Is there non-negligible added pressure requirements from the act of smashing the filament against a prior layer during typical printing?

Edited 1 time(s). Last edit at 06/25/2012 09:32PM by billyzelsnack.

|

Re: Extruder performance - can it be measured? June 25, 2012 09:52PM |

Registered: 13 years ago Posts: 2,947 |

dzach Wrote:

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

> -----

> > I have built hotneds that print at 350mm/s

>

> I would be very interested in the details of their

> design.

>

> My printer can move reliably @350mm/s but my DIY

> extruder is way slower at 150mm/s. I did think it

> was doing 350mm/s but was forced to realize that

> was just my wishful thinking I realize that

I realize that

> many experts will smile at these statements, but

> that's how many of the rest of us think

The key to fast printing is a long melt chamber and a short nozzle hole.

This is the set of instructions I created but have since hide from view as they can not achieve high quality prints which I believe are more important.

[geometricobjectdepositiontool.blogspot.ca]

>

> Sublime Wrote:

> --------------------------------------------------

> -----

> > [...] it would be great if we could make some

> standard to judge these things by. But I also

> believe we would need to have one machine to test

> them all.

> > [...] I think it is more important to establish

> a standard for quality first (and only the best

> quality prints should even be considered).

>

> Yes, you are right. Though there are some

> qualities that may be measured independently, like

> pinch gear/hobbed bolt grip, quality of extrusion

> at various extruder feed rates etc, length of ooze

> after a given time, etc.

Nophead did some good testing of pinch wheel design a few years back and has a good method documented to measure the grip.

>

> Take for instance quality of extrusion. It is a

> quality that can be documented with numbers and

> pictures independently of the quality of print. It

> can also be contested by anyone having the same

> extruder.

I am not sure how we would mesure quality of a free air extrusion but could see measuring the free air diameter as Nophead always suggests. But if the plastic is coming out anything but smooth and round it is not a successful hotend.

>

> I see, for instance, some new extruder designs

> with a very deep grip on the plastic, so deep that

> I feel there is a risk to get air trapped in the

> extrusion at higher speeds. Measuring the grip

> force of such an extruder would give it a high

> score but measuring the quality of extrusion at

> various speeds and temperatures might negate the

> good results of the former measurement. Quality of

> extrusion is different than quality of print, it

> is like a subset of it and thus, maybe, easier to

> measure.

I agree that the new pinch wheels being developed may cause problems in the future. My thoughts are more on the volume change that the notches create. I see them as a possible cause of pulsing extrusion.

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

> -----

> > I have built hotneds that print at 350mm/s

>

> I would be very interested in the details of their

> design.

>

> My printer can move reliably @350mm/s but my DIY

> extruder is way slower at 150mm/s. I did think it

> was doing 350mm/s but was forced to realize that

> was just my wishful thinking

I realize that

I realize that> many experts will smile at these statements, but

> that's how many of the rest of us think

The key to fast printing is a long melt chamber and a short nozzle hole.

This is the set of instructions I created but have since hide from view as they can not achieve high quality prints which I believe are more important.

[geometricobjectdepositiontool.blogspot.ca]

>

> Sublime Wrote:

> --------------------------------------------------

> -----

> > [...] it would be great if we could make some

> standard to judge these things by. But I also

> believe we would need to have one machine to test

> them all.

> > [...] I think it is more important to establish

> a standard for quality first (and only the best

> quality prints should even be considered).

>

> Yes, you are right. Though there are some

> qualities that may be measured independently, like

> pinch gear/hobbed bolt grip, quality of extrusion

> at various extruder feed rates etc, length of ooze

> after a given time, etc.

Nophead did some good testing of pinch wheel design a few years back and has a good method documented to measure the grip.

>

> Take for instance quality of extrusion. It is a

> quality that can be documented with numbers and

> pictures independently of the quality of print. It

> can also be contested by anyone having the same

> extruder.

I am not sure how we would mesure quality of a free air extrusion but could see measuring the free air diameter as Nophead always suggests. But if the plastic is coming out anything but smooth and round it is not a successful hotend.

>

> I see, for instance, some new extruder designs

> with a very deep grip on the plastic, so deep that

> I feel there is a risk to get air trapped in the

> extrusion at higher speeds. Measuring the grip

> force of such an extruder would give it a high

> score but measuring the quality of extrusion at

> various speeds and temperatures might negate the

> good results of the former measurement. Quality of

> extrusion is different than quality of print, it

> is like a subset of it and thus, maybe, easier to

> measure.

I agree that the new pinch wheels being developed may cause problems in the future. My thoughts are more on the volume change that the notches create. I see them as a possible cause of pulsing extrusion.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 26, 2012 03:00PM |

Registered: 12 years ago Posts: 88 |

Thanks a lot for the replies!

billyzelsnack Wrote:

-------------------------------------------------------

> I think we still would need to know the free air extrusion diameter.

Free extrusion is IMO one of the two parameters affecting extrusion that can be easily measured by the end user, the other one being filament diameter.

Sublime Wrote:

--------------------------------------------------

> The key to fast printing is a long melt chamber and a short nozzle hole.

> This is the set of instructions I created [...]

Thanks for the link! This is an awesome work you have done there! I guess long melt chamber is needed to produce more hot plastic and short nozzle to minimize friction at the exit?

High quality prints are undoubtedly the goal, especially if the parts are for sale, but there are other occasions where an average quality print can be acceptable if for example doing fast prototyping. It seems to me that this argument will never have a single/simple answer and a compromise will always be needed.

Indeed extrusion quality is difficult to measure.

To sum up the discussion so far:

Phew! this is becoming quite formal now

Are there more parameters/clauses needed?

EDIT: Added 3.7.3, the failed photos.

Edited 1 time(s). Last edit at 06/26/2012 03:51PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

billyzelsnack Wrote:

-------------------------------------------------------

> I think we still would need to know the free air extrusion diameter.

Free extrusion is IMO one of the two parameters affecting extrusion that can be easily measured by the end user, the other one being filament diameter.

Sublime Wrote:

--------------------------------------------------

> The key to fast printing is a long melt chamber and a short nozzle hole.

> This is the set of instructions I created [...]

Thanks for the link! This is an awesome work you have done there! I guess long melt chamber is needed to produce more hot plastic and short nozzle to minimize friction at the exit?

High quality prints are undoubtedly the goal, especially if the parts are for sale, but there are other occasions where an average quality print can be acceptable if for example doing fast prototyping. It seems to me that this argument will never have a single/simple answer and a compromise will always be needed.

Indeed extrusion quality is difficult to measure.

To sum up the discussion so far:

1. Formalized tests require well calibrated machines and standard/known quality of filament.

2. Test conditions that must be stated:

2.1 - X,Y,Z axis feed rate, mm/s

2.2 - X,Y,Z acceleration, mm/s^2

2.3 - Filament average diameter, mm

2.4 - Die swell (mid air extrusion diameter), mm

2.5 - Ambient temperature, °C

2.6 - Ambient humidity, %

3. Test results should include the following:

3.1 - Quality grade, [1,2,3] or [low, average, high]

3.2 - Minimum Usable Feed Rate, FRMN, mm/s

3.3 - Maximum Usable Feed Rate , FRMX, mm/s

3.4 - Recommended Feed Rate, FR, mm/s

3.5 - Filament Grip Force, GF, N or kp

3.6 - Filament Grip Deformation, GD, %

3.7 - Description of grip failure reason, [slippage, filament break, other]

3.7 - Photographs for each of FRMN, FRMX, FR, as follows:

3.7.1 - Overview of print

3.7.2 - Closeups of the four test box corners

3.7.3 - Overview of failed test box, where test ended

Phew! this is becoming quite formal now

Are there more parameters/clauses needed?

EDIT: Added 3.7.3, the failed photos.

Edited 1 time(s). Last edit at 06/26/2012 03:51PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 26, 2012 03:11PM |

Registered: 13 years ago Posts: 2,947 |

dzach Wrote:

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

>

> > The key to fast printing is a long melt chamber

> and a short nozzle hole.

> > This is the set of instructions I created [...]

>

> Thanks for the link! This is an awesome work you

> have done there! I guess long melt chamber is

> needed to produce more hot plastic and short

> nozzle to minimize friction at the exit?

I believe what I have read (don't quote me on it) was that the force required to extrude goes up by a fourth power as the nozzle exit hole length doubles.

The long melt zone is to keep the time the plastic is in contact with the heat the same as in a short melt zone at slower speeds. The problem then becomes friction increases as more filament is at the glass transition temperature, this then requires you to raise the temperature a lot so the entire melt zone melts the plastic which as a fluid does not have much friction again. Also the long melt zone creates hysteresis because the plastic becomes a little compressible.

This is why I am trying a copper hotend with a medium length melt zone and long exit hole right now. I hope the copper will transfer the heat to the plastic faster so the medium length melt zone will have the same effect as the long one with the brass barrel. And the long exit hole is to increase the back pressure which allows us to use reversal to stop the flow of plastic while preventing ooze.

-------------------------------------------------------

> Sublime Wrote:

> --------------------------------------------------

>

> > The key to fast printing is a long melt chamber

> and a short nozzle hole.

> > This is the set of instructions I created [...]

>

> Thanks for the link! This is an awesome work you

> have done there! I guess long melt chamber is

> needed to produce more hot plastic and short

> nozzle to minimize friction at the exit?

I believe what I have read (don't quote me on it) was that the force required to extrude goes up by a fourth power as the nozzle exit hole length doubles.

The long melt zone is to keep the time the plastic is in contact with the heat the same as in a short melt zone at slower speeds. The problem then becomes friction increases as more filament is at the glass transition temperature, this then requires you to raise the temperature a lot so the entire melt zone melts the plastic which as a fluid does not have much friction again. Also the long melt zone creates hysteresis because the plastic becomes a little compressible.

This is why I am trying a copper hotend with a medium length melt zone and long exit hole right now. I hope the copper will transfer the heat to the plastic faster so the medium length melt zone will have the same effect as the long one with the brass barrel. And the long exit hole is to increase the back pressure which allows us to use reversal to stop the flow of plastic while preventing ooze.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 26, 2012 03:31PM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

I believe what I have read (don't quote me on it) was that the force required to extrude goes up by a fourth power as the nozzle exit hole length doubles.

I think the pressure goes up linearly with the nozzle hole length but with the inverse fourth power of the diameter. The force required is much more complicated because a lot of it comes from the transition zone as well as the nozzle temperature.

[www.hydraraptor.blogspot.com]

|

Re: Extruder performance - can it be measured? June 26, 2012 03:42PM |

Registered: 12 years ago Posts: 88 |

Very informative!

What is the length of the shortl/medium/long melt zone?

I'm asking for a reason

When finished, it will have a name: CuHotE

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

What is the length of the shortl/medium/long melt zone?

I'm asking for a reason

When finished, it will have a name: CuHotE

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 26, 2012 03:55PM |

Registered: 13 years ago Posts: 2,947 |

The melt zone on the fast ones were about 40mm long. The melt zone on a J-head Mk-IVb is 10mm and the J-head Mk-Vb is 25mm.

The nozzle lengths of a few hotends were meausured by Brian at Hotends.com

I have built copper barrel and aluminium heater block ones with a melt zone of 25mm and nozzle hole of around 0.5 and they printed well up to about 200mm/s but still had some ooze issues.

The nozzle lengths of a few hotends were meausured by Brian at Hotends.com

Quote

J-head blog [url]http://jheadnozzle.blogspot.com/[/url]

This will leave the following nozzle orifice lengths:

Budaschnozzle: 0.0095 (0.24mm) Prints fast but known for ooze

MakerBot Mk V: 0.0515 (1.32mm) Prints well but known for not going fast

MakerGear: 0.0335 (0.85mm) Known as an all around good hotend

J-Head: 0.0495 (1.26mm) Prints well but known to have speed limitations

I have built copper barrel and aluminium heater block ones with a melt zone of 25mm and nozzle hole of around 0.5 and they printed well up to about 200mm/s but still had some ooze issues.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 26, 2012 04:58PM |

Registered: 12 years ago Posts: 88 |

I revised the text, it now includes nozzle data. Removed feed rate from the conditions since it is required in the results:

Ideally all tests should be performed with a "standard" machine, and anyone with a "standard" machine should be able to repeat them and get the same results. Alternatively, someone who is in possession of a number of well known extruders/hotends could perform a series of tests on them, or, a certification authority could be formed to perform the tests on standard equipment .

.

It looks like the Filament Grip data belongs to a mechanical section and it should be separated from the thermal part, the hot+cold end.

Draft Extruder Performance Test, rev. 0.2

-----------------------------------------

1. Formalized tests require well calibrated machines and standard/known quality of filament.

2. Test conditions that must be stated for each test:

2.1 - Filament

2.1.1 - Material, [PLA, ABS, other]

2.1.2 - Filament average diameter, mm

2.1.3 - Die swell (mid air extrusion diameter), mm

2.2 - Thermal conditions

2.2.1 - Melt zone temperature, °C

2.2.2 - Temperature fluctuation, %

2.2.3 - Ambient temperature, °C

2.2.4 - Ambient humidity, %

2.3 - Mechanical conditions

2.3.1 - X,Y,Z acceleration, mm/s^2

2.4 - Nozzle data

2.4.1 - Nozzle orifice diameter, mm

2.4.2 - Nozzle orifice length, mm

3. Test results should include the following:

3.1 - Quality grade, [1,2,3] or [low, average, high]

3.2 - Minimum Usable Feed Rate, FRMN, mm/s

3.3 - Maximum Usable Feed Rate , FRMX, mm/s

3.4 - Recommended Feed Rate, FRR, mm/s

3.5 - Filament Grip Force, GF, N or kp

3.6 - Filament Grip Deformation, GD, %

3.7 - Description of grip failure reason, [slippage, filament break, other]

3.7 - Photographs for each of 3.2, 3.3, 3.4, as follows:

3.7.1 - Overview of print

3.7.2 - Closeups of the four test box corners

3.7.3 - Overview of failed test box, where test ended

Ideally all tests should be performed with a "standard" machine, and anyone with a "standard" machine should be able to repeat them and get the same results. Alternatively, someone who is in possession of a number of well known extruders/hotends could perform a series of tests on them, or, a certification authority could be formed to perform the tests on standard equipment

.

. It looks like the Filament Grip data belongs to a mechanical section and it should be separated from the thermal part, the hot+cold end.

|

Re: Extruder performance - can it be measured? June 26, 2012 05:14PM |

Admin Registered: 17 years ago Posts: 7,879 |

The problem with printing at high speed is the retract speed needs to be made correspondingly faster or the ooze will increase. That means less gearing and a bigger motor. Perhaps a servo is needed. I have some I have been meaning to try for a about 3 years!

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Extruder performance - can it be measured? June 26, 2012 05:37PM |

Registered: 12 years ago Posts: 88 |

Thanks for the data Sublime!

Can we design a test object that would test both speed and ooze? For example have one long dimension, say 100 or 200mm for the speed portion and on the orhter dimension something to test oozing?

Or maybe a separate test that will extrude e.g. 10mm if filament and then wait for 60s before turning the heater off?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Can we design a test object that would test both speed and ooze? For example have one long dimension, say 100 or 200mm for the speed portion and on the orhter dimension something to test oozing?

Or maybe a separate test that will extrude e.g. 10mm if filament and then wait for 60s before turning the heater off?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 26, 2012 05:48PM |

Registered: 13 years ago Posts: 2,947 |

A small letter "i" would be a good test part for this. A long straight section, a short straight section, a circle and a space. But it should also have bridge because fast hotends are hotter and bridging gets harder. So maybe the long part of the "i" could have a space under the middle of it for the first mm or 2 in height by most of its length.

Could you make that data a spreadsheet so we can easily track the info and maybe more people will participate?

Could you make that data a spreadsheet so we can easily track the info and maybe more people will participate?

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 26, 2012 06:41PM |

Admin Registered: 17 years ago Posts: 7,879 |

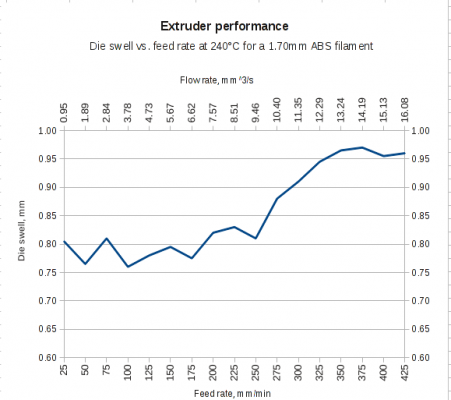

2.1.3 - Die swell (mid air extrusion diameter), mm

Die swell is very dependent on flow rate, so without that stated is pretty meaningless. It would need to be a graph against flow rate.

I don't think feed rates are relevant to extruder performance, it should be flow rate.

[www.hydraraptor.blogspot.com]

Die swell is very dependent on flow rate, so without that stated is pretty meaningless. It would need to be a graph against flow rate.

I don't think feed rates are relevant to extruder performance, it should be flow rate.

[www.hydraraptor.blogspot.com]

|

Re: Extruder performance - can it be measured? June 26, 2012 06:54PM |

Registered: 12 years ago Posts: 88 |

dzach Wrote:

-------------------------------------------------------

> (btw, the units on it are wrong, it should be mm/s on the Y axis)

I rechecked this and the units in the graph are correct, mm/min. It is from the "Extrude" button units in Pronterface.

I think a graph of feed rate vs. temperature might be a useful indicator or could even be used by the end users to calibrate their extruders.

I was planning on making a Word document but I'll make an Excel sheet with the data. I'll be happy to see more people participating. Maybe at some point we could send this to those who make/sell extruders/hotends and ask them to comment it and/or perform the test.

It now looks like it should include a section describing the procedure, to reduce misunderstandings.

Here is the Excel file:

Draft_Extruder_Performance_Test.xls

Edited 1 time(s). Last edit at 06/26/2012 07:23PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> (btw, the units on it are wrong, it should be mm/s on the Y axis)

I rechecked this and the units in the graph are correct, mm/min. It is from the "Extrude" button units in Pronterface.

I think a graph of feed rate vs. temperature might be a useful indicator or could even be used by the end users to calibrate their extruders.

Draft Extruder Performance Test, rev. 0.3 1 Procedure 1.1 Formalized tests require well calibrated machines and standard/known quality of filament. 2 Test conditions 2.1 Filament 2.1.1 Material [PLA, ABS, other] 2.1.2 Filament average diameter mm 2.1.3 Die swell (mid air extrusion diameter) mm 2.2 Thermal 2.2.1 Melt zone temperature °C 2.2.2 Temperature fluctuation % 2.2.3 Ambient temperature °C 2.2.4 Ambient humidity % 2.3 Mechanical 2.3.1 X,Y,Z acceleration mm/s^2 2.4 Nozzle data 2.4.1 Nozzle orifice diameter mm 2.4.2 Nozzle orifice length mm 3 Test results 3.1 Quality 3.1.1 Quality grade [low, average, high] 3.2 Speed 3.2.1 Minimum Usable Feed Rate, FRMN mm/s 3.2.2 Maximum Usable Feed Rate , FRMX mm/s 3.2.3 Recommended Feed Rate, FRR mm/s 3.3 Mechanical 3.3.1 Filament Grip Force, GF N 3.3.2 Filament Grip Deformation, GD % 3.3.3 Description of grip failure reason [slippage, break, motor, other] 3.4 Photographs 3.4.1 Overview of print [photo] 3.4.2 Closeups of the four test box corners [photo] 3.4.3 Overview of failed test box, where test ended [photo]

I was planning on making a Word document but I'll make an Excel sheet with the data. I'll be happy to see more people participating. Maybe at some point we could send this to those who make/sell extruders/hotends and ask them to comment it and/or perform the test.

It now looks like it should include a section describing the procedure, to reduce misunderstandings.

Here is the Excel file:

Draft_Extruder_Performance_Test.xls

Edited 1 time(s). Last edit at 06/26/2012 07:23PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 26, 2012 07:21PM |

Registered: 12 years ago Posts: 88 |

Quote

nophead

I don't think feed rates are relevant to extruder

performance, it should be flow rate.

Pronterface, which I used to produce the feed rate vs. temperature graph has feed rate units next to the button "Extrude" and I thought that others could use the same method to produce such graphs. Since flow rate is feed rate times filament cross-section, all data for the transformation between the two units is available.

Flow rate feels indeed better suited, but I've seen it only in Skeinforge, and there it is used it without any units.

So the question is which units will be more useful to the end user.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 26, 2012 07:53PM |

Registered: 12 years ago Posts: 88 |

I did a little test with my DIY extruder:

I don't have experience other than with my DIY extruder. I suppose that not all extruders give the same ooze. Is the test I described an indication for the oozing property? If not, what would be a test for it, that would not involve other settings except temperature?

Maybe doing a print test for oozing, like with a lower case "i", would involve other settings (slicer dependent) and would be difficult to isolate the oozing property from that.

EDIT:

In any case, I inserted an Ooze length measurement to the test.

Draft_Extruder_Performance_Test.xls

Edited 1 time(s). Last edit at 06/26/2012 08:26PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

- Set the temperature to 185°C - Extracted 10mm of filament - Cut the extrusion at the nozzle - Waited for 60s - Turned off the heater - Waited for it to cool to ambient temperature - Cut the ooze at the nozzle and straightened it - Measured the oozeIt measured 16.5mm in length, ϕ0.98mm.

I don't have experience other than with my DIY extruder. I suppose that not all extruders give the same ooze. Is the test I described an indication for the oozing property? If not, what would be a test for it, that would not involve other settings except temperature?

Maybe doing a print test for oozing, like with a lower case "i", would involve other settings (slicer dependent) and would be difficult to isolate the oozing property from that.

EDIT:

In any case, I inserted an Ooze length measurement to the test.

Draft Extruder Performance Test, rev. 0.4 3.3 Thermal 3.3.1 Ooze length mm 3.4 Mechanical 3.4.1 Filament Grip Force, GF N

Draft_Extruder_Performance_Test.xls

Edited 1 time(s). Last edit at 06/26/2012 08:26PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 26, 2012 08:27PM |

Registered: 13 years ago Posts: 2,947 |

dzach Wrote:

-------------------------------------------------------

> I did a little test with my DIY extruder:

>

>

> - Set the temperature to 185°C

You would need to confirm the temperature with a thermocouple before each test.

> - Extracted 10mm of filament

I don't think the exact length would be important but I do believe it would need to be more like 50mm to be sure all air and molten plastic have been purged and you are at normal extrusion conditions in a long print.

> - Cut the extrusion at the nozzle

> - Waited for 60s

This seems excessive, I think 1sec would be a better test but that would be hard to get accurate.

These two I would not worry about

> - Turned off the heater

> - Waited for it to cool to ambient temperature

> - Cut the ooze at the nozzle and straightened it

> - Measured the ooze

This would need to be done at the end of the wait time.

> Maybe doing a print test for oozing, like with a

> lower case "i", would involve other settings

> (slicer dependent) and would be difficult to

> isolate the oozing property from that.

True but if one individual can get no ooze with one hotend and lots with another it would be clear.

-------------------------------------------------------

> I did a little test with my DIY extruder:

>

>

> - Set the temperature to 185°C

You would need to confirm the temperature with a thermocouple before each test.

> - Extracted 10mm of filament

I don't think the exact length would be important but I do believe it would need to be more like 50mm to be sure all air and molten plastic have been purged and you are at normal extrusion conditions in a long print.

> - Cut the extrusion at the nozzle

> - Waited for 60s

This seems excessive, I think 1sec would be a better test but that would be hard to get accurate.

These two I would not worry about

> - Turned off the heater

> - Waited for it to cool to ambient temperature

> - Cut the ooze at the nozzle and straightened it

> - Measured the ooze

This would need to be done at the end of the wait time.

> Maybe doing a print test for oozing, like with a

> lower case "i", would involve other settings

> (slicer dependent) and would be difficult to

> isolate the oozing property from that.

True but if one individual can get no ooze with one hotend and lots with another it would be clear.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? June 27, 2012 03:31AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

So the question is which units will be more useful to the end user.

When comparing performance it is the output rate of the extruder that is relevant, especially if you are comparing a 1.75mm extruder with a 3mm one. However the measurement will always be the input rate, but it should be converted to flow for comparison.

[www.hydraraptor.blogspot.com]

|

Re: Extruder performance - can it be measured? June 27, 2012 06:49AM |

Registered: 12 years ago Posts: 88 |

nophead Wrote:

-------------------------------------------------------

> So the question is which units will be more useful

> to the end user.

>

> When comparing performance it is the output rate

> of the extruder that is relevant, especially if

> you are comparing a 1.75mm extruder with a 3mm

> one. However the measurement will always be the

> input rate, but it should be converted to flow for

> comparison.

You are right, in that case plotting feed rate would put the two curves quite apart. We might use multiple X or Y axes to plot both parameters on the same graph.

I created a github repository to keep track of the revisions of the test. Please feel free to comment and contribute in any way you can.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> So the question is which units will be more useful

> to the end user.

>

> When comparing performance it is the output rate

> of the extruder that is relevant, especially if

> you are comparing a 1.75mm extruder with a 3mm

> one. However the measurement will always be the

> input rate, but it should be converted to flow for

> comparison.

You are right, in that case plotting feed rate would put the two curves quite apart. We might use multiple X or Y axes to plot both parameters on the same graph.

I created a github repository to keep track of the revisions of the test. Please feel free to comment and contribute in any way you can.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 27, 2012 07:37AM |

Registered: 12 years ago Posts: 88 |

Sublime Wrote:

-------------------------------------------------------

> You would need to confirm the temperature with a

> thermocouple before each test.

Yes, my thermistor is already of questionable performance. This brings up again the issue of standardized equipment/materials. I consider most temperature values rather relative, due to the variations in filament quality, but I don't have data to see what that means in reality.

>

> > - Extracted 10mm of filament

> I don't think the exact length would be important

> but I do believe it would need to be more like

> 50mm to be sure all air and molten plastic have

> been purged and you are at normal extrusion

> conditions in a long print.

>

Ok, 50mm.

> > - Cut the extrusion at the nozzle

> > - Waited for 60s

> This seems excessive, I think 1sec would be a

> better test but that would be hard to get

> accurate.

I observed that my extruder keeps oozing for more than 45s after the last extrusion and I prefer to have a greater length to measure than a shorter one.

> These two I would not worry about

> > - Turned off the heater

> > - Waited for it to cool to ambient temperature

Gone.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> You would need to confirm the temperature with a

> thermocouple before each test.

Yes, my thermistor is already of questionable performance. This brings up again the issue of standardized equipment/materials. I consider most temperature values rather relative, due to the variations in filament quality, but I don't have data to see what that means in reality.

>

> > - Extracted 10mm of filament

> I don't think the exact length would be important

> but I do believe it would need to be more like

> 50mm to be sure all air and molten plastic have

> been purged and you are at normal extrusion

> conditions in a long print.

>

Ok, 50mm.

> > - Cut the extrusion at the nozzle

> > - Waited for 60s

> This seems excessive, I think 1sec would be a

> better test but that would be hard to get

> accurate.

I observed that my extruder keeps oozing for more than 45s after the last extrusion and I prefer to have a greater length to measure than a shorter one.

> These two I would not worry about

> > - Turned off the heater

> > - Waited for it to cool to ambient temperature

Gone.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 27, 2012 09:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

The slow ooze you get after the pressure is removed is not that important as it isn't significant in the time it takes for the head to move from one side of the bed to the other. It mainly depends on the viscosity of the plastic, What is important is how fast you can dump the pressure at the end of a length of fast extrusion which is a combination of the hot end and the motor and gearing.

Another quality is how fast the filament comes out when you fast forward. For some extruders I have a small delay after fast forwarding to give the filament time to hit the object. I then get a perfect line start. With a J-head I find it comes out too fast and I get a blob because I can't fast forward fast enough. I would need to start moving before the end of the fast forward to get good results, or use a faster motor.

[www.hydraraptor.blogspot.com]

Another quality is how fast the filament comes out when you fast forward. For some extruders I have a small delay after fast forwarding to give the filament time to hit the object. I then get a perfect line start. With a J-head I find it comes out too fast and I get a blob because I can't fast forward fast enough. I would need to start moving before the end of the fast forward to get good results, or use a faster motor.

[www.hydraraptor.blogspot.com]

|

Re: Extruder performance - can it be measured? June 27, 2012 07:22PM |

Registered: 12 years ago Posts: 88 |

In that case the test procedure I described for measuring ooze is not going to give any useful results. My DIY hotend has too a delay in fast forward that I believe is causing some minor problems.

Sublime suggested that a long object in the shape of an "i" could probably uncover ooze problems. I'll create one such test object and give it a try.

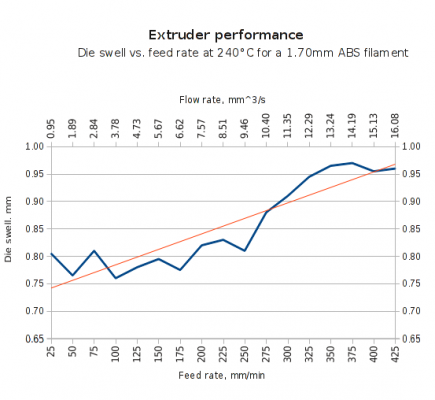

In the meanwhile I did a test of flow vs. die swell. It wasn't as easy as I thought it would be, because gravity plays a significant role in the shape of the extrusion, and I only realized that after plotting the data. Did the test again trying to find a consistent way to lay the extrusion , but not with great success. Maybe it shouldn't be a "mid air" extrusion and should actually lay on the bed; the nozzle could be 2mm above the bed.

Anyhow, here is a plot of the results. LibreOffice gave me a hard time trying to plot the two X axes. I also tried gnuplot but needed a lot of reading and decided to do a little cut and paste to get both feed and flow rates on the same plot.

It looks like a greater flow causes more swell and the order seems exponential:

I did the test by setting the temperature to 240°C and then set the feed rate and extrude 50mm of filament for feed rates 25mm/s apart. Above about 350mm/min the stepper started skipping, but not at the beginning so there was some well extruded section that I could measure.

Edited 3 time(s). Last edit at 06/27/2012 07:49PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Sublime suggested that a long object in the shape of an "i" could probably uncover ooze problems. I'll create one such test object and give it a try.

In the meanwhile I did a test of flow vs. die swell. It wasn't as easy as I thought it would be, because gravity plays a significant role in the shape of the extrusion, and I only realized that after plotting the data. Did the test again trying to find a consistent way to lay the extrusion , but not with great success. Maybe it shouldn't be a "mid air" extrusion and should actually lay on the bed; the nozzle could be 2mm above the bed.

Anyhow, here is a plot of the results. LibreOffice gave me a hard time trying to plot the two X axes. I also tried gnuplot but needed a lot of reading and decided to do a little cut and paste to get both feed and flow rates on the same plot.

It looks like a greater flow causes more swell and the order seems exponential:

I did the test by setting the temperature to 240°C and then set the feed rate and extrude 50mm of filament for feed rates 25mm/s apart. Above about 350mm/min the stepper started skipping, but not at the beginning so there was some well extruded section that I could measure.

Edited 3 time(s). Last edit at 06/27/2012 07:49PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 28, 2012 04:25AM |

Admin Registered: 17 years ago Posts: 7,879 |

Interesting. I did some tests with HDPE a long time ago and got a more linear relationship [hydraraptor.blogspot.co.uk].

If you lay it on the bed then I think the speed the bed moves will influence it. Perhaps run it a few cm above and get it to form a coil.

[www.hydraraptor.blogspot.com]

If you lay it on the bed then I think the speed the bed moves will influence it. Perhaps run it a few cm above and get it to form a coil.

[www.hydraraptor.blogspot.com]

|

Re: Extruder performance - can it be measured? June 28, 2012 06:56AM |

Registered: 12 years ago Posts: 88 |

It did form a coil and it could be the curvature that made it difficult to get consistent readings with digital calipers.

I took so many measurements in hope that a trend would reveal itself, but this "S" curve leaves it open to interpretation.

What's peculiar with my 0.4mm hotend and its short length of the orifice is the excessive die swell it produces.

The measurements are min-max averages. If the 3 lowest measurements are not considered then it looks like a linear relationship, but I don't like that much of an uncertainty. I also need to have a look at my thermistor, as it seems to have deteriorated over time.

EDIT:

Excessive die swell? Looking at your results, nophead, I'd call it rather normal.

Edited 3 time(s). Last edit at 06/28/2012 07:12AM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

I took so many measurements in hope that a trend would reveal itself, but this "S" curve leaves it open to interpretation.

What's peculiar with my 0.4mm hotend and its short length of the orifice is the excessive die swell it produces.

The measurements are min-max averages. If the 3 lowest measurements are not considered then it looks like a linear relationship, but I don't like that much of an uncertainty. I also need to have a look at my thermistor, as it seems to have deteriorated over time.

EDIT:

Excessive die swell? Looking at your results, nophead, I'd call it rather normal.

Edited 3 time(s). Last edit at 06/28/2012 07:12AM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 28, 2012 07:37AM |

Admin Registered: 17 years ago Posts: 7,879 |

My graph was HDPE and that has more die swell than ABS, which has more than PLA.

People have said the a longer orifice gives less die swell. I am not sure why as the pressure will be higher, so the plastic compressed more. Having said that I don't think the plastic compressing and expanding is the whole cause of die swell. I think the viscosity makes the outside of the flow much slower than the inside. That causes the edges of the flow to curl outwards as it leaves the nozzle exit. So I think die swell is mainly due to viscosity, so it will be temperature dependent as well.

[www.hydraraptor.blogspot.com]

People have said the a longer orifice gives less die swell. I am not sure why as the pressure will be higher, so the plastic compressed more. Having said that I don't think the plastic compressing and expanding is the whole cause of die swell. I think the viscosity makes the outside of the flow much slower than the inside. That causes the edges of the flow to curl outwards as it leaves the nozzle exit. So I think die swell is mainly due to viscosity, so it will be temperature dependent as well.

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.