Extruder performance - can it be measured?

Posted by dzach

|

Re: Extruder performance - can it be measured? June 28, 2012 10:12AM |

Registered: 12 years ago Posts: 88 |

Sublime's suggestion for revealing ooze problems seems to be right.

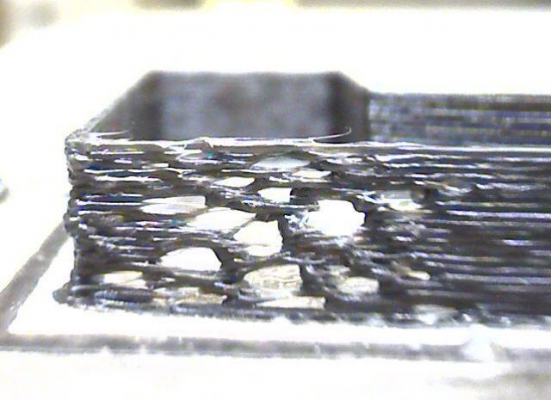

I can't remember if/what I've changed since I did the tests in the beginning of this thread, it might be my setting for retraction of 13mm/s, but here is a new test that shows many ooze problems:

ooze-j-test.stl

It was sliced by Skeinforge like this:

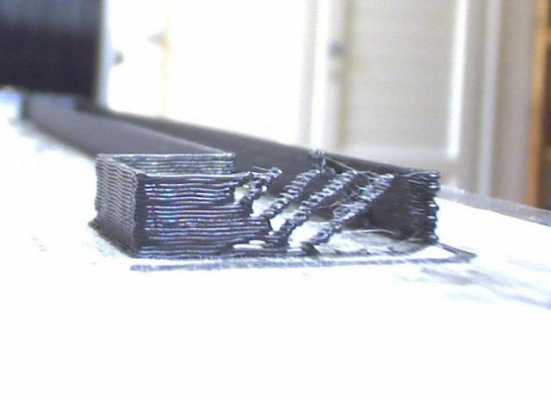

My extruder + current Skeinforge settings printed this test object like this:

In upcoming posts I'll try to do some analysis of the problems as I understand them. The ooze-j-test.stl is now included in github.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

I can't remember if/what I've changed since I did the tests in the beginning of this thread, it might be my setting for retraction of 13mm/s, but here is a new test that shows many ooze problems:

ooze-j-test.stl

It was sliced by Skeinforge like this:

My extruder + current Skeinforge settings printed this test object like this:

In upcoming posts I'll try to do some analysis of the problems as I understand them. The ooze-j-test.stl is now included in github.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? June 28, 2012 01:32PM |

Registered: 13 years ago Posts: 301 |

I don't understand how this tests ooze. The only difficulty in this print is that it is quite long in one axis making bed leveling more important for first layer adhesion. The jump to the circle is no big deal. Is the idea to keep increasing speed until the jump can no longer be made?

btw. That circle is subdivided a bit too much and communications slows down the nozzle dramatically at 115200 which is a pretty common baudrate for running Marlin.

btw. That circle is subdivided a bit too much and communications slows down the nozzle dramatically at 115200 which is a pretty common baudrate for running Marlin.

|

Re: Extruder performance - can it be measured? June 28, 2012 04:45PM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Extruder performance - can it be measured? July 01, 2012 01:32PM |

Registered: 12 years ago Posts: 88 |

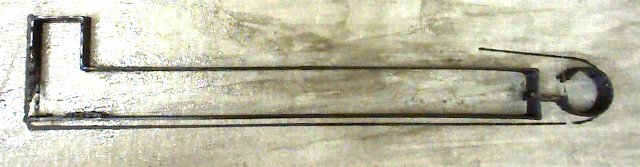

I will try to illustrate the problems this simple oozing test file revealed for my DIY extruder and/or setup. Obviously the slicer settings are not correct and the printer is not well calibrated, which is a prerequisite for proper testing of extruder performance, but nonetheless the problems show some of the inherent characteristics of this particular extruder. I believe that by isolating problematic areas the various problems will manifest themselves and that will make their correction easier. I haven't tried to apply a correction yet, but will do so after I post some of the minor problems too.

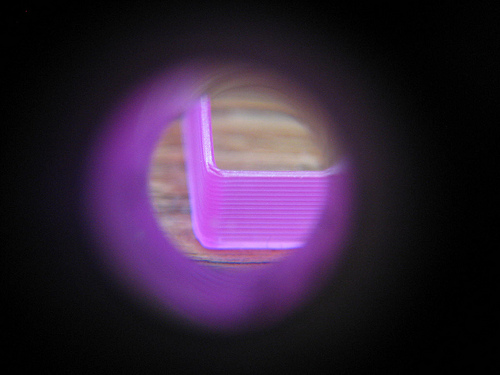

There are a number of problems evident on coarse inspection and other that need a closer look. The "closer look" in this post is achieved with a Philips SPZ-5000 webcam and Cheese and v4l2ucp running on Linux. This camera's lens can focus really close but it is a wide field lens so the edges come out blurred when the center is in focus.

Problems:

A. Gap with angular deposits

An animation showing this part of the gcode, from skeinleyer:

Explanation:

There is a problem with delayed fast forward before the start of extrusion. The nozzle arrives at the corner and the extruder fast forwards and starts to extrude. However, due to the problematic setup, it doesn't push out plastic immediately, but squirts out a little, before the bulk of it comes. This little plastic accumulates opposite to the direction of movement, since each time it gets deposited at the front of the forming bulge.

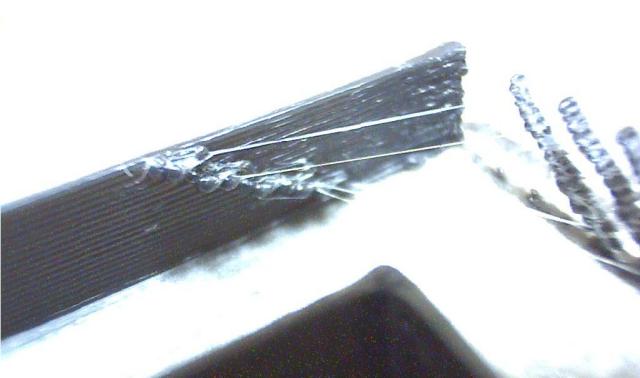

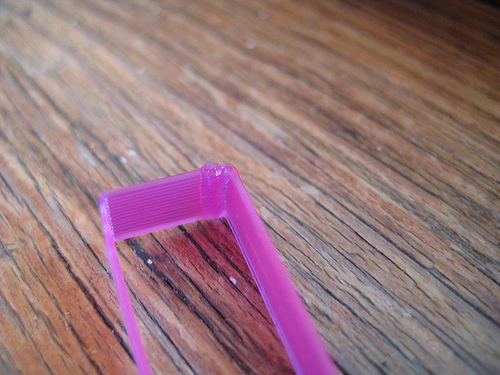

B. Angular bulge with strings

Explanation:

There is a problem with oozing and retraction. The long travel from the circular shape (areas C & D ) to this corner (areas A & B ) results in some ooze squirting out of the nozzle, which as soon as it touches the already laid wall it gets deposited there. The angle of the bulge shows the direction of movement: each time the ooze is deposited, the bulge extends to the side that first meets the nozzle. From there it goes to the start of the wall and fast forwards while stringing because there is no plastic underneath it to stick.

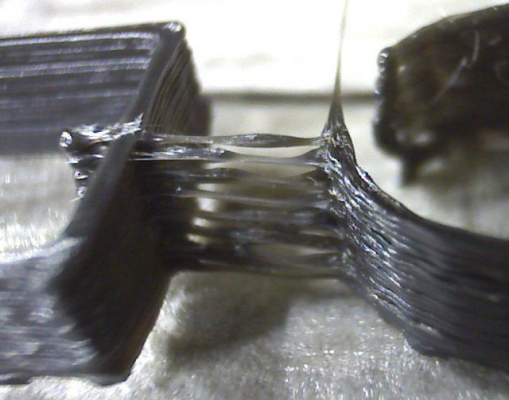

C. Bulge and strings

An animation showing the gcode, from skeinleyer:

Strings

Explanation:

This is an indication of bad retraction. As soon as the extruder finishes the circle, it retracts (too little) the filament and starts moving fast for the next layer. Due to the slow retraction, some plastic oozes out of the nozzle and forms a string before it meets the already laid wall. Some mm after meeting the wall the plastic is exhausted and the ooze stops. The fact that the bulge does not grow in an angle inside the wall supports this explanation.

D. Gap

The circle was supposed to be closed:

Explanation:

This is an indication of the problem in fast forward. As soon as the head reaches the start of the circle it is supposed to start extruding plastic. Due to the problematic settup however, it does not do it immediately but after a delay. Due to the slower extrusion feed along the circle there is no deposition of plastic during this delay. As soon as the bulk of it comes out it starts building the layer.

P. No skirt

In the marked photo there is a dashed line, named P, connecting the missing skirt. The single perimeter skirt was supposed to start at the corner in area A and go around the test object, but it only started after about half of the skirt perimeter was traveled. An indication of the fast forward delay problem.

Hopefully the explanations given tell the true story. Any comments or other explanations are very welcome.

More forensics coming soon

Edited 3 time(s). Last edit at 07/01/2012 08:36PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

There are a number of problems evident on coarse inspection and other that need a closer look. The "closer look" in this post is achieved with a Philips SPZ-5000 webcam and Cheese and v4l2ucp running on Linux. This camera's lens can focus really close but it is a wide field lens so the edges come out blurred when the center is in focus.

Problems:

A. Gap with angular deposits

An animation showing this part of the gcode, from skeinleyer:

Explanation:

There is a problem with delayed fast forward before the start of extrusion. The nozzle arrives at the corner and the extruder fast forwards and starts to extrude. However, due to the problematic setup, it doesn't push out plastic immediately, but squirts out a little, before the bulk of it comes. This little plastic accumulates opposite to the direction of movement, since each time it gets deposited at the front of the forming bulge.

B. Angular bulge with strings

Explanation:

There is a problem with oozing and retraction. The long travel from the circular shape (areas C & D ) to this corner (areas A & B ) results in some ooze squirting out of the nozzle, which as soon as it touches the already laid wall it gets deposited there. The angle of the bulge shows the direction of movement: each time the ooze is deposited, the bulge extends to the side that first meets the nozzle. From there it goes to the start of the wall and fast forwards while stringing because there is no plastic underneath it to stick.

C. Bulge and strings

An animation showing the gcode, from skeinleyer:

Strings

Explanation:

This is an indication of bad retraction. As soon as the extruder finishes the circle, it retracts (too little) the filament and starts moving fast for the next layer. Due to the slow retraction, some plastic oozes out of the nozzle and forms a string before it meets the already laid wall. Some mm after meeting the wall the plastic is exhausted and the ooze stops. The fact that the bulge does not grow in an angle inside the wall supports this explanation.

D. Gap

The circle was supposed to be closed:

Explanation:

This is an indication of the problem in fast forward. As soon as the head reaches the start of the circle it is supposed to start extruding plastic. Due to the problematic settup however, it does not do it immediately but after a delay. Due to the slower extrusion feed along the circle there is no deposition of plastic during this delay. As soon as the bulk of it comes out it starts building the layer.

P. No skirt

In the marked photo there is a dashed line, named P, connecting the missing skirt. The single perimeter skirt was supposed to start at the corner in area A and go around the test object, but it only started after about half of the skirt perimeter was traveled. An indication of the fast forward delay problem.

Hopefully the explanations given tell the true story. Any comments or other explanations are very welcome.

More forensics coming soon

Edited 3 time(s). Last edit at 07/01/2012 08:36PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Attachments:

open | download - problematic_areas.png (218 KB)

open | download - A.jpg (47.6 KB)

open | download - B.jpg (23.2 KB)

open | download - CD.jpg (49.2 KB)

open | download - D.jpg (54.3 KB)

open | download - C-2.jpg (21.7 KB)

open | download - A_skein.gif (24.8 KB)

open | download - CD_skein.gif (10.6 KB)

open | download - problematic_areas.png (218 KB)

open | download - A.jpg (47.6 KB)

open | download - B.jpg (23.2 KB)

open | download - CD.jpg (49.2 KB)

open | download - D.jpg (54.3 KB)

open | download - C-2.jpg (21.7 KB)

open | download - A_skein.gif (24.8 KB)

open | download - CD_skein.gif (10.6 KB)

|

Re: Extruder performance - can it be measured? July 01, 2012 03:27PM |

Registered: 13 years ago Posts: 301 |

What speed are you printing at? If you can't get a near perfect print at 20mm/s for everything then don't go any faster until you can. I'd also recommend using Slic3r or KISSlicer because there are just way too many nobs in Skeinforge that IMO are only useful once you have a well tuned printer.

|

Re: Extruder performance - @150mm/s July 01, 2012 08:32PM |

Registered: 12 years ago Posts: 88 |

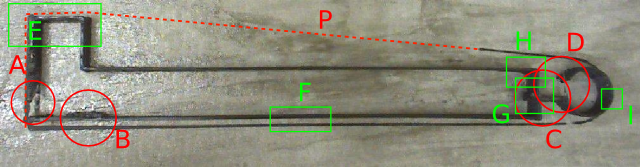

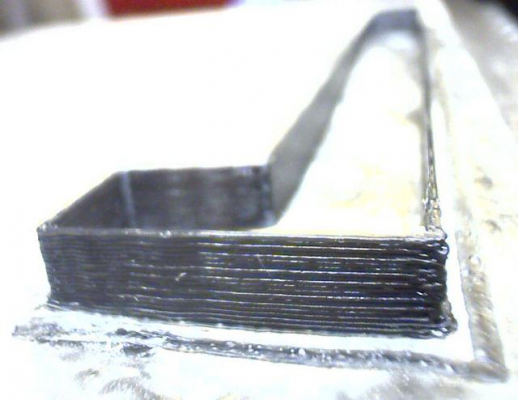

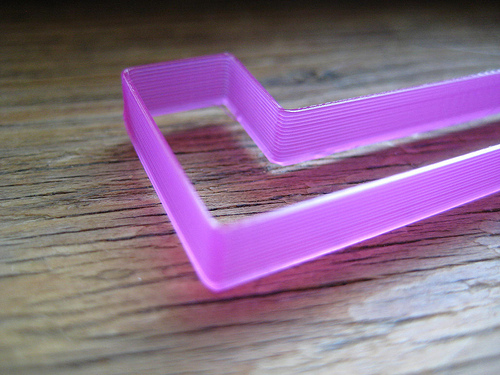

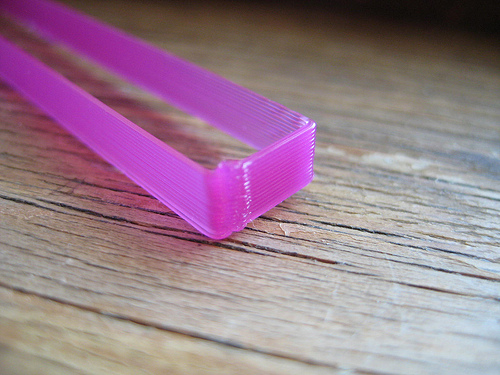

The ooze_j_test.stl printed at 150mm//s proved to be good in revealing some more minor problems. All walls have 0.5mm nominal thickness and 5mm height.

Minor problems:

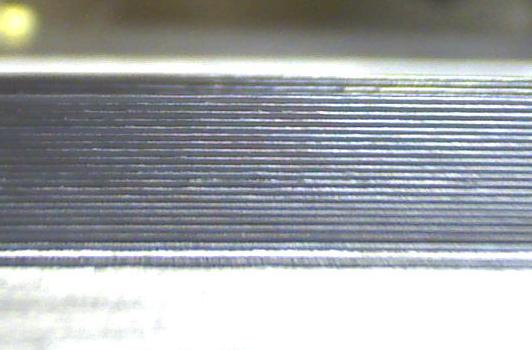

E. Waves

The same object, now detached from the bed and cropped, from a different angle to show the extent of the waves.

Explanation:

Maybe an acceleration / deceleration issue?

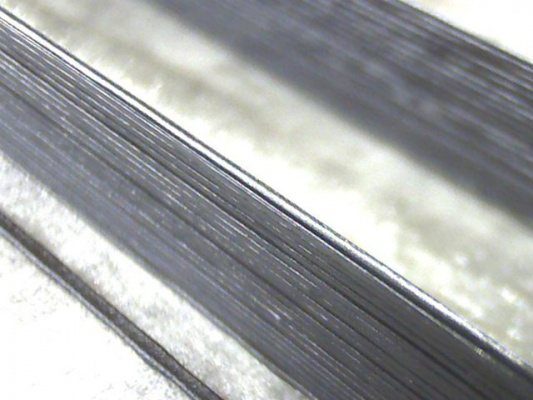

F. Z axis wobble

This is not an extruder problem.

Although the long side looks perfect...

... illuminating the wall with a small incident angle to create shadows reveals a minor problem along the Z direction every 5 layers. I measured the 4 layers 0.50mm and the whole wall thickness 0.52mm so it looks like the wobble is ~20μm.

G-H. Acceleration / deceleration

The close-up photo makes it easier to measure; the vertical side in the picture is deceleration and the horizontal is acceleration:

The wall thickness at full speed in the middle of the long wall is 0.50mm. If we assume that the thickness in the middle of the short wall is also 0.5mm, then the corner has a thickness of 0.9mm.

Explanation:

Sprinter, AFAIK, does not use look ahead so the head has to decelerate and stop at the corners and then start again, accelerate, et.c. This shows clearly in the pictures above. I haven't used Marlin successfully yet due to it reporting some thermistor errors, which strangely enough do not show up with Sprinter. It would be interesting to see how Marlin prints these corners.

I. Bulges and waves

Explanation:

I believe the small bulges and waves are due to the same acceleration / deceleration issue as above.

I would love to see the test file printed with Marlin at high speed, close to 150mm/s if possible. Or for that matter, with any firmware at high speed.

Please post your results with this test if you print it. It only takes a few minutes to print.

Edited 2 time(s). Last edit at 07/02/2012 07:29AM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Minor problems:

E. Waves

The same object, now detached from the bed and cropped, from a different angle to show the extent of the waves.

Explanation:

Maybe an acceleration / deceleration issue?

F. Z axis wobble

This is not an extruder problem.

Although the long side looks perfect...

... illuminating the wall with a small incident angle to create shadows reveals a minor problem along the Z direction every 5 layers. I measured the 4 layers 0.50mm and the whole wall thickness 0.52mm so it looks like the wobble is ~20μm.

G-H. Acceleration / deceleration

The close-up photo makes it easier to measure; the vertical side in the picture is deceleration and the horizontal is acceleration:

The wall thickness at full speed in the middle of the long wall is 0.50mm. If we assume that the thickness in the middle of the short wall is also 0.5mm, then the corner has a thickness of 0.9mm.

Explanation:

Sprinter, AFAIK, does not use look ahead so the head has to decelerate and stop at the corners and then start again, accelerate, et.c. This shows clearly in the pictures above. I haven't used Marlin successfully yet due to it reporting some thermistor errors, which strangely enough do not show up with Sprinter. It would be interesting to see how Marlin prints these corners.

I. Bulges and waves

Explanation:

I believe the small bulges and waves are due to the same acceleration / deceleration issue as above.

I would love to see the test file printed with Marlin at high speed, close to 150mm/s if possible. Or for that matter, with any firmware at high speed.

Please post your results with this test if you print it. It only takes a few minutes to print.

Edited 2 time(s). Last edit at 07/02/2012 07:29AM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Attachments:

open | download - E.jpg (24.4 KB)

open | download - nice_but.jpg (25.3 KB)

open | download - F.jpg (50.2 KB)

open | download - waves.jpg (13.3 KB)

open | download - G.jpg (48.5 KB)

open | download - H.jpg (26.8 KB)

open | download - accel-decel.jpg (30 KB)

open | download - I.jpg (24.4 KB)

open | download - E.jpg (24.4 KB)

open | download - nice_but.jpg (25.3 KB)

open | download - F.jpg (50.2 KB)

open | download - waves.jpg (13.3 KB)

open | download - G.jpg (48.5 KB)

open | download - H.jpg (26.8 KB)

open | download - accel-decel.jpg (30 KB)

open | download - I.jpg (24.4 KB)

|

Re: Extruder performance - can it be measured? July 02, 2012 05:08AM |

Registered: 11 years ago Posts: 129 |

Hi dzach

First I'd like to thank you for your efforts.

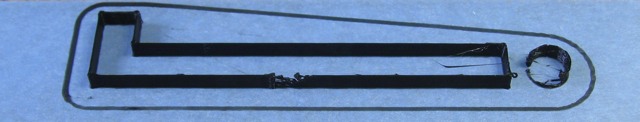

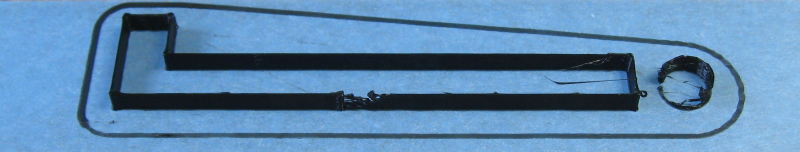

Here is my test result using Marlin 1.0.0 RC2.

The other parameters are:

Extruder: MakerGear Stepper Plastruder

Slicer Software: Slic3r, Version 0.8.4

Filament: PLA

Nozzle [mm] : 0.35

Temperature [°C]: 195 (185)

Layer height [mm]: 0.25

Print Speed (all settings, Perimeters .. Travel) [mm/s]: 150

First Layer speed [mm/s]: 75

Accelaretion [mm/s^2]: 3000

Edited 5 time(s). Last edit at 07/02/2012 05:43AM by flurin.

First I'd like to thank you for your efforts.

Here is my test result using Marlin 1.0.0 RC2.

The other parameters are:

Extruder: MakerGear Stepper Plastruder

Slicer Software: Slic3r, Version 0.8.4

Filament: PLA

Nozzle [mm] : 0.35

Temperature [°C]: 195 (185)

Layer height [mm]: 0.25

Print Speed (all settings, Perimeters .. Travel) [mm/s]: 150

First Layer speed [mm/s]: 75

Accelaretion [mm/s^2]: 3000

Edited 5 time(s). Last edit at 07/02/2012 05:43AM by flurin.

|

Re: Extruder performance - can it be measured? July 02, 2012 03:38PM |

Registered: 12 years ago Posts: 88 |

Hi flurin

Thank you for following this and printing the test object. Although the circle is not complete Marlin seems to print it smoother than Sprinter. There is also some more plastic at the corners of your print.

I managed to correct my settings with Skeinforge easily. I hadn't really set any retraction before so by setting it to 3mm it immediately improved everything, except for the part right after the fast forward after a layer change.

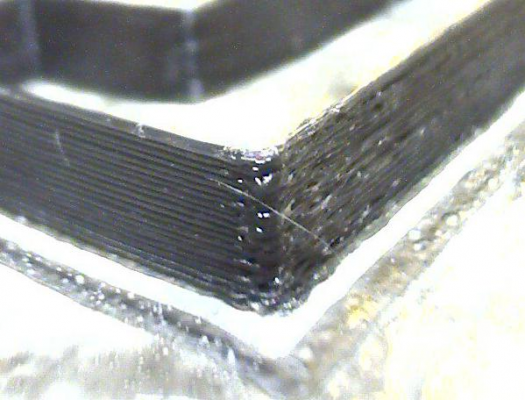

So it seemed it needed just a little more plastic right after fast forward. I changed the Restart Extra Distance from 0.0 to 0.09mm and this is what I'm now getting at 150mm/s:

Area A:

Area B:

Areas C & D:

There are still some strings but nothing compared with what it was before. The test print took 1:12", with the nozzle already hot.

I believe that having the wall thickness correct is very important because it shows that the plastic extruded is what the slicer calculated. In this case it should be 0.5mm:

Looking at the results I think it's worth repeating the test at a higher speed.

Skeinforge gives amazing control over a print, one just need to know what the problem is that needs correction.

Edited 2 time(s). Last edit at 07/02/2012 03:51PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Thank you for following this and printing the test object. Although the circle is not complete Marlin seems to print it smoother than Sprinter. There is also some more plastic at the corners of your print.

I managed to correct my settings with Skeinforge easily. I hadn't really set any retraction before so by setting it to 3mm it immediately improved everything, except for the part right after the fast forward after a layer change.

So it seemed it needed just a little more plastic right after fast forward. I changed the Restart Extra Distance from 0.0 to 0.09mm and this is what I'm now getting at 150mm/s:

Area A:

Area B:

Areas C & D:

There are still some strings but nothing compared with what it was before. The test print took 1:12", with the nozzle already hot.

I believe that having the wall thickness correct is very important because it shows that the plastic extruded is what the slicer calculated. In this case it should be 0.5mm:

Looking at the results I think it's worth repeating the test at a higher speed.

Skeinforge gives amazing control over a print, one just need to know what the problem is that needs correction.

Edited 2 time(s). Last edit at 07/02/2012 03:51PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 02, 2012 06:17PM |

Registered: 12 years ago Posts: 88 |

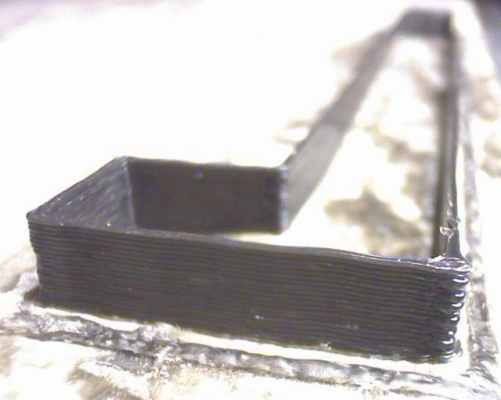

And this is what I'm getting at 300mm/s:

All problematic areas now print acceptably and even the strings have disappeared.

However I seem to have hit a limit again since printing at 300, 350 and 400mm/s doesn't make a difference in actual print time. They all print in 1:08". The print at 250mm/s lasted 1:17". All prints were timed with Pronterface with the nozzle hot.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

All problematic areas now print acceptably and even the strings have disappeared.

However I seem to have hit a limit again since printing at 300, 350 and 400mm/s doesn't make a difference in actual print time. They all print in 1:08". The print at 250mm/s lasted 1:17". All prints were timed with Pronterface with the nozzle hot.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 03, 2012 02:17PM |

Registered: 15 years ago Posts: 123 |

dzach a lot of your problems appear hardware related. You should never have to fast forward extra filament when retracting; if you do it means you are losing some by leakage/oozage and that needs to be addressed in your hardware (print at lower temps, get a nozzle with a longer orifice). Also, it seems to me that you should aim for fixing big problems (gaps in the structure) before fixing small problems (slight z-axis issues).

In my experience once your hardware works properly it is a simple matter of figuring out your E steps/mm and filament thickness to make for a good print at a slow speed. This means you should work to eliminate filament grinding, filament getting stuck in the nozzle because the heat travels up too far, filament leaking out the tip of the nozzle because the orifice is too short or your temp is too high; things like that before messing with slicer settings. Use a decent slicer like KISSlicer or slic3r to try to isolate the problem. If you know whether its your hardware or your software which are producing bad prints that would help a lot more than just printing things and looking at the result, which in my opinion helps very little unless you are aware of where the problem is.

Given a good performance at low speed (eg 20mm/s as mentioned), performace change at higher speed is the more interesting aspect of this thread in my opinion. But I think all this screwing around with speed caps needs to stop. I don't give a crap what your printer is set to I care about what speed it actually goes. So if you are reporting building at a speed I want to see either a video or a calculation that proves you are actually going the speed you say. Many factors drop the printer's actual speed: Minimum layer time, acceleration, cornering are just a few.

In my experience once your hardware works properly it is a simple matter of figuring out your E steps/mm and filament thickness to make for a good print at a slow speed. This means you should work to eliminate filament grinding, filament getting stuck in the nozzle because the heat travels up too far, filament leaking out the tip of the nozzle because the orifice is too short or your temp is too high; things like that before messing with slicer settings. Use a decent slicer like KISSlicer or slic3r to try to isolate the problem. If you know whether its your hardware or your software which are producing bad prints that would help a lot more than just printing things and looking at the result, which in my opinion helps very little unless you are aware of where the problem is.

Given a good performance at low speed (eg 20mm/s as mentioned), performace change at higher speed is the more interesting aspect of this thread in my opinion. But I think all this screwing around with speed caps needs to stop. I don't give a crap what your printer is set to I care about what speed it actually goes. So if you are reporting building at a speed I want to see either a video or a calculation that proves you are actually going the speed you say. Many factors drop the printer's actual speed: Minimum layer time, acceleration, cornering are just a few.

|

Re: Extruder performance - can it be measured? July 03, 2012 08:00PM |

Registered: 12 years ago Posts: 88 |

@destroyer2012

I am sorry to see you annoyed so much. Were you not, you would have read a little more of this thread and your advice could have been a little more relevant. Thank you in any case.

Calculations you can find in the beginning of this thread. I dont sell extruders or anything 3D related and have no interest whatsoever in persuading or entertaining you with videos. With the help of other people that care, a test object and a test procedure were drafted that are open to discussion and criticism. You are very welcome to print it and report your results if you want.

Skeinforge has given me excelent results, you may try it yourself and see if you can improve your extruder`s performance too. If you do, please report back for the rest of us to see.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

I am sorry to see you annoyed so much. Were you not, you would have read a little more of this thread and your advice could have been a little more relevant. Thank you in any case.

Calculations you can find in the beginning of this thread. I dont sell extruders or anything 3D related and have no interest whatsoever in persuading or entertaining you with videos. With the help of other people that care, a test object and a test procedure were drafted that are open to discussion and criticism. You are very welcome to print it and report your results if you want.

Skeinforge has given me excelent results, you may try it yourself and see if you can improve your extruder`s performance too. If you do, please report back for the rest of us to see.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 04, 2012 05:04PM |

Registered: 13 years ago Posts: 2,947 |

I have been away for a while and am just coming back to this but I have to agree with Destroyer for the most part. You need to be able to print a flawless part before increasing the speed. Then only increase the speed after that point and until it starts to cause issues. There is absolutely no reason to attempt to print fast if you are getting those results.

Further more the idea behind the i or j shape test part to test for ooze was to turn off retract and see how much ooze you get between the dot and the straight part. At normal speeds and temperatures with a fast travel you should be able to print that with little to no ooze. If you can't it is time to get a new hotend.

Further more the idea behind the i or j shape test part to test for ooze was to turn off retract and see how much ooze you get between the dot and the straight part. At normal speeds and temperatures with a fast travel you should be able to print that with little to no ooze. If you can't it is time to get a new hotend.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Extruder performance - can it be measured? July 04, 2012 07:09PM |

Registered: 12 years ago Posts: 88 |

Quote

There is absolutely no reason to attempt to print fast if you are getting those results.

I just realized what the problem you both see in the photos is, that I can't see. Please take into account that the photos show a part that's 5mm tall, i.e. they are almost microscopic views, so defects that are usually invisible are accentuated. Moreover, I chose lighting angles such that those problems stand out as much as possible, so no wonder why you say that. I now see why destroyer2012 took my tests as bragging about achieving high speeds, but with such awful results.

When seen from a normal distance and lighting or photographed to size, the last results, though not perfect, look very acceptable to me.

Which brings back the question about what is "acceptable quality" for this test. It seems to me that "photo proofing" will have to include photographs taken at standard angles and with the same standard magnification, otherwise the eye+brain may not be very successful in extrapolating the optical impression to the real size of a part, and some photos may not do justice to the results. Even better, the test should probably ask for proof at some standard speeds, e.g. 25, 50, 75, 100, 150, 200, 300mm/s et.c. so speed and photos of different extruders will be comparable.

I think the best interest for the end user is to see and judge for himself if an extruder is performing acceptably for him at a given speed. To do that, an end user should have all results of the test, including the failed, and not just the best. I chose to show magnifications and not normal photos exactly for showing as many otherwise hidden details as possible. My failed tests were shown at the beginning of this thread. After calibrating the extruder better, I don't get such obvious failures any more, even at 350mm/s, but the quality might not be considered acceptable. But that's exactly what my DIY extruder is capable of.

In any case, since I might not have printed a test of real good quality yet, I'm begging to see what somebody else can achieve with this test and how it will look under this kind of magnification at whatever speed best quality can be achieved.

Edited 2 time(s). Last edit at 07/04/2012 07:24PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 04, 2012 07:21PM |

Registered: 12 years ago Posts: 88 |

Sublime Wrote:

-------------------------------------------------------

> Further more the idea behind the i or j shape test

> part to test for ooze was to turn off retract and

> see how much ooze you get between the dot and the

> straight part. At normal speeds and temperatures

> with a fast travel you should be able to print

> that with little to no ooze.

That was a very good idea indeed.

All my tests before the final calibration had retract turned off. Ooze was all but negligible, but is difficult to quantify it.

> If you can't it is

> time to get a new hotend.

But I'll stick with it for now and try to calibrate it better.

and try to calibrate it better.

Edited 1 time(s). Last edit at 07/04/2012 07:22PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> Further more the idea behind the i or j shape test

> part to test for ooze was to turn off retract and

> see how much ooze you get between the dot and the

> straight part. At normal speeds and temperatures

> with a fast travel you should be able to print

> that with little to no ooze.

That was a very good idea indeed.

All my tests before the final calibration had retract turned off. Ooze was all but negligible, but is difficult to quantify it.

> If you can't it is

> time to get a new hotend.

But I'll stick with it for now

and try to calibrate it better.

and try to calibrate it better.Edited 1 time(s). Last edit at 07/04/2012 07:22PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 04, 2012 07:43PM |

Registered: 13 years ago Posts: 301 |

This is from the day the test model was posted. I just grabbed it out of my junk prints box. I printed it with whatever my printer was set at the time and likely at 40mm/s.

|

Re: Extruder performance - can it be measured? July 04, 2012 08:16PM |

Registered: 12 years ago Posts: 88 |

Thank you billyzelsnack.

Can you post a photo of the corner close to the circle and the circle too?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Can you post a photo of the corner close to the circle and the circle too?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 04, 2012 08:43PM |

Registered: 13 years ago Posts: 301 |

KISSlicer does not have jittering so all the retract starts are on top of each other. I can't find the circle bit in my junk box. There was zero oozing between the stick and the circle. The circle was not the nicest due to the it being subdivided so much and my 115200 Marlin baudrate not able to keep up.

The translucent PLA also shows off a little bit too low of flow around the corner section. Kinda strange considering just after the retract starts it was fine.

Edited 3 time(s). Last edit at 07/04/2012 09:00PM by billyzelsnack.

The translucent PLA also shows off a little bit too low of flow around the corner section. Kinda strange considering just after the retract starts it was fine.

Edited 3 time(s). Last edit at 07/04/2012 09:00PM by billyzelsnack.

|

Re: Extruder performance - can it be measured? July 05, 2012 06:55AM |

Registered: 12 years ago Posts: 88 |

Thanks again billyzelsnack. If you can spare the time, could you please post any of the details below that you may happen to know?

Trying to build procedures for extruder performance testing is not an easy task after all. I realize now that mixing my calibration efforts with the test results in the same thread may have been totally confusing.

Also, this is supposed to be a performance measurement test and not a beauty contest. In general, people tend to show their best print with photographs taken from the best possible angle, but the purpose of a performance test, as far as I understand it, is not to make or break a record but to record the extruder's behaviour in various conditions. With some specific settings an extruder will give its best quality prints while with some other it will be faster of fail entirely. I think these are to be recorded and form the extruder's performance record. Experts in this field may find the failed tests more informative than the best quality ones.

As it looks now, this is not something one can deal with in a matter of minutes. It needs preparation time, a well calibrated printer and extruder (or else the test will end up being a calibration adventure like mine above), a camera for taking consistent close up photographs, meticulous application of proper test procedures and detailed reporting. In other words, not many people will be willing to spend the time to perform such a test with their extruder. But maybe those who design new extruders and/or those who sell them should.

I have an interest to see how far my DIY extruder can go and compare that with how other extruders do. Before setting out to make a DIY extruder I tried to find some hard data that would help me decide which one to buy, but there was none. Maybe due to the open source nature of these projects people hesitate to criticize other people's extruder designs, out of respect for the effort. Few pioneers in the field have published most of the data that exists in the internet for their own designs, but there is no comprehensive "buyer's guide" for the end user and there already exists a sizeable worldwide 3D printer market where a lot of money is being made. An extruder's performance record could probably form the basis of such a "buyer's guide". This is my two cents contribution to that.

I will try to eat my own dog food and post a full report for my DIY extruder in accordance with the test procedure being drafted. Before that, there are still some issues with properties that are difficult to measure, namely quality of print, oozing and maybe a few more. These could be broken down to more items which would then be easier to quantify.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Extruder name [DIY, other] 2 Test conditions 2.1 Filament 2.1.1 Material [PLA, ABS, other] 2.1.2 Filament average diameter mm 2.1.3 Die swell (mid air extrusion diameter) mm 2.2 Thermal 2.2.1 Melt zone temperature °C 2.2.2 Temperature fluctuation % 2.2.3 Ambient temperature °C 2.2.4 Ambient humidity % 2.3 Mechanical 2.3.1 X,Y,Z acceleration mm/s^2 2.4 Nozzle data 2.4.1 Nozzle orifice diameter mm 2.4.2 Nozzle orifice length mm

Trying to build procedures for extruder performance testing is not an easy task after all. I realize now that mixing my calibration efforts with the test results in the same thread may have been totally confusing.

Also, this is supposed to be a performance measurement test and not a beauty contest. In general, people tend to show their best print with photographs taken from the best possible angle, but the purpose of a performance test, as far as I understand it, is not to make or break a record but to record the extruder's behaviour in various conditions. With some specific settings an extruder will give its best quality prints while with some other it will be faster of fail entirely. I think these are to be recorded and form the extruder's performance record. Experts in this field may find the failed tests more informative than the best quality ones.

As it looks now, this is not something one can deal with in a matter of minutes. It needs preparation time, a well calibrated printer and extruder (or else the test will end up being a calibration adventure like mine above), a camera for taking consistent close up photographs, meticulous application of proper test procedures and detailed reporting. In other words, not many people will be willing to spend the time to perform such a test with their extruder. But maybe those who design new extruders and/or those who sell them should.

I have an interest to see how far my DIY extruder can go and compare that with how other extruders do. Before setting out to make a DIY extruder I tried to find some hard data that would help me decide which one to buy, but there was none. Maybe due to the open source nature of these projects people hesitate to criticize other people's extruder designs, out of respect for the effort. Few pioneers in the field have published most of the data that exists in the internet for their own designs, but there is no comprehensive "buyer's guide" for the end user and there already exists a sizeable worldwide 3D printer market where a lot of money is being made. An extruder's performance record could probably form the basis of such a "buyer's guide". This is my two cents contribution to that.

I will try to eat my own dog food and post a full report for my DIY extruder in accordance with the test procedure being drafted. Before that, there are still some issues with properties that are difficult to measure, namely quality of print, oozing and maybe a few more. These could be broken down to more items which would then be easier to quantify.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 05, 2012 12:24PM |

Registered: 13 years ago Posts: 301 |

My print is just ok. My hotend/extruder is designed to be compact and lightweight and not a speed king. It was printed with however my machine was setup using whatever my settings were when I saw the model posted. I could spend some time tweaking the print for this specific model and get it nicer, but that might make my regular prints less nice.

I think some of the backlash you are seeing is that people regularly quote ridiculously high speeds without any concept or evidence of quality or general usability. This sets unrealistic expectations especially for people getting their printers setup for the first time and it causes all sorts of issues. If you can't get a decent print at 20mm/s then you're not going to get one at higher speed.

What I'd like to see is a quality progression starting at 20mm/s and not 150mm/s. Can you post a pic of your print at 20mm/s so we have a baseline comparison?

Extruder name Printxel

2.1.1 Material PLA

2.1.2 Filament average diameter 2.85

2.1.3 Die swell (mid air extrusion diameter) 0.9

2.2.1 Melt zone temperature 190

2.2.2 Temperature fluctuation 0.5

2.2.3 Ambient temperature 80

2.2.4 Ambient humidity ? air-conditioner

2.3.1 X,Y,Z acceleration Marlin defaults

2.4.1 Nozzle orifice diameter 0.5?? but probably bigger

2.4.2 Nozzle orifice length 0.5?? but this is difficult to measure

I don't remember the overall build time, but if you're going to track things that is probably the most important issue for your test.

I think some of the backlash you are seeing is that people regularly quote ridiculously high speeds without any concept or evidence of quality or general usability. This sets unrealistic expectations especially for people getting their printers setup for the first time and it causes all sorts of issues. If you can't get a decent print at 20mm/s then you're not going to get one at higher speed.

What I'd like to see is a quality progression starting at 20mm/s and not 150mm/s. Can you post a pic of your print at 20mm/s so we have a baseline comparison?

Extruder name Printxel

2.1.1 Material PLA

2.1.2 Filament average diameter 2.85

2.1.3 Die swell (mid air extrusion diameter) 0.9

2.2.1 Melt zone temperature 190

2.2.2 Temperature fluctuation 0.5

2.2.3 Ambient temperature 80

2.2.4 Ambient humidity ? air-conditioner

2.3.1 X,Y,Z acceleration Marlin defaults

2.4.1 Nozzle orifice diameter 0.5?? but probably bigger

2.4.2 Nozzle orifice length 0.5?? but this is difficult to measure

I don't remember the overall build time, but if you're going to track things that is probably the most important issue for your test.

|

Re: Extruder performance - can it be measured? July 05, 2012 06:22PM |

Registered: 15 years ago Posts: 123 |

Sorry if I sounded overly negative, I just want to say that it is probably not the speed you set that matters but the speed that is acheived. The relevant statistic is where does the printer travel that fast and what does the part look like in those areas.

The reason why I suggest making a video is because we can see where the print head is and hear (by the stepper sound) how fast it's going. In fact the sound of the steppers (frequency) combined with axis steps/mm should be all we need to know to calculate instantaneous speed. I'm going to try that when I get home, could be a useful tool to once and for all end this "I'm printing at 400mm/s" silliness.

I think the most important statistic for print quality is: Is the extrudate coming out exactly as expected? The slicer assumes zero ooze and perfect extruder/filament traction, so no strings and no blobs should be the ideal print quality. Not visible ridges which are unfortunately what is the most striking when looking at prints.

I agree that looking at pictures is not a great method of measuring extruder performance, what we need instead is something that produces hard numbers like for example weighing the printed parts. You could also cut the part up and weigh it in pieces to see if there is over/under extrusion concentrated to a specific area. Combined with a video you can tell what speed the printer was travelling in that area for example along the long part of the j shape we have now. That would be an interesting data set.

The reason why I suggest making a video is because we can see where the print head is and hear (by the stepper sound) how fast it's going. In fact the sound of the steppers (frequency) combined with axis steps/mm should be all we need to know to calculate instantaneous speed. I'm going to try that when I get home, could be a useful tool to once and for all end this "I'm printing at 400mm/s" silliness.

I think the most important statistic for print quality is: Is the extrudate coming out exactly as expected? The slicer assumes zero ooze and perfect extruder/filament traction, so no strings and no blobs should be the ideal print quality. Not visible ridges which are unfortunately what is the most striking when looking at prints.

I agree that looking at pictures is not a great method of measuring extruder performance, what we need instead is something that produces hard numbers like for example weighing the printed parts. You could also cut the part up and weigh it in pieces to see if there is over/under extrusion concentrated to a specific area. Combined with a video you can tell what speed the printer was travelling in that area for example along the long part of the j shape we have now. That would be an interesting data set.

|

Re: Extruder performance - can it be measured? July 05, 2012 06:42PM |

Registered: 12 years ago Posts: 88 |

Thanks again for the data.

billyzelsnack Wrote:

-------------------------------------------------------

> What I'd like to see is a quality progression

> starting at 20mm/s and not 150mm/s. Can you post a

> pic of your print at 20mm/s so we have a baseline

> comparison?

Yes, as I said I'll do a full test starting from 20mm/s, then 40, 60, 80 100, 150, 200, 250, 300, 350mm/s. That's 10 tests all together. Before I do that I would like to have some way to define acceptability of a print, as well as low, average and high quality, and then some way to measure ooze that will be meaningful, if it is to be considered a performance indicator.

Today I received a thermocouple and checked my thermistor that I suspected had gone bad. Indeed, it was way off (ABS was boiling at 220°C) and needs to be replaced immediately.

Stay tuned for more.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

billyzelsnack Wrote:

-------------------------------------------------------

> What I'd like to see is a quality progression

> starting at 20mm/s and not 150mm/s. Can you post a

> pic of your print at 20mm/s so we have a baseline

> comparison?

Yes, as I said I'll do a full test starting from 20mm/s, then 40, 60, 80 100, 150, 200, 250, 300, 350mm/s. That's 10 tests all together. Before I do that I would like to have some way to define acceptability of a print, as well as low, average and high quality, and then some way to measure ooze that will be meaningful, if it is to be considered a performance indicator.

Today I received a thermocouple and checked my thermistor that I suspected had gone bad. Indeed, it was way off (ABS was boiling at 220°C) and needs to be replaced immediately.

Stay tuned for more.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 05, 2012 07:36PM |

Registered: 12 years ago Posts: 88 |

destroyer2012 Wrote:

-------------------------------------------------------

> Sorry if I sounded overly negative, I just want to

> say that it is probably not the speed you set that

> matters but the speed that is acheived.

No problem from my side, I didn't realize I sounded like I was bragging, since most pictures I posted were with problems.

The calculations posted in the beginning of this thread as well as the test object were intended to show exactly that: it's not the speed you set but the actual speed achieved that matters. But despite these calculations showing a plausible head speed of 350mm/s I seem to have hit another limit at about 300mm/s. How do I know? by timing the test prints at 200,250, 300, and 350mm/s. Both 300 and 350mm/s print out at the same duration, 250 and 300 were different. And how do I know that the speed at 250 is really 250mm/s? That I don't know. I would expect that when the gcode says F15000 and there are no missing steps or other limitations, the stepper would actually do 15000mm/min, or the print will come out with the wrong dimensions. But this doesn't explain why the gcode says F21000 and the print at 350mm/s lasts the same as the one at 300mm/s.

Are these prints acceptable or usable? It remains to be seen. I would accept a print if:

1. The part measured as per the design. If it didn't then the extruder was not calibrated properly or if it were then the part failed.

2. There was absolutely no gap on the surfaces, not only for aesthetic reasons but because the part seems to be a lot weaker when there are even small gaps in it.

Regarding quality, I see 3 values for acceptable parts: low, average and high. I wouldn't mind having my prints low quality, if all I needed was fast prototyping of a part. I'd print it fast and if everything came out ok then I'd print it at a lower speed for best quality. It all depends on the intended use. It's like printing in draft mode with a 2D printer. I think it matters though if my draft mode is 10 times faster than my best quality one.

If it is for measurements I'll try to make a video with the fastest acceptable print I can get, when I replace my thermistor.

Edited 1 time(s). Last edit at 07/05/2012 07:42PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> Sorry if I sounded overly negative, I just want to

> say that it is probably not the speed you set that

> matters but the speed that is acheived.

No problem from my side, I didn't realize I sounded like I was bragging, since most pictures I posted were with problems.

The calculations posted in the beginning of this thread as well as the test object were intended to show exactly that: it's not the speed you set but the actual speed achieved that matters. But despite these calculations showing a plausible head speed of 350mm/s I seem to have hit another limit at about 300mm/s. How do I know? by timing the test prints at 200,250, 300, and 350mm/s. Both 300 and 350mm/s print out at the same duration, 250 and 300 were different. And how do I know that the speed at 250 is really 250mm/s? That I don't know. I would expect that when the gcode says F15000 and there are no missing steps or other limitations, the stepper would actually do 15000mm/min, or the print will come out with the wrong dimensions. But this doesn't explain why the gcode says F21000 and the print at 350mm/s lasts the same as the one at 300mm/s.

Are these prints acceptable or usable? It remains to be seen. I would accept a print if:

1. The part measured as per the design. If it didn't then the extruder was not calibrated properly or if it were then the part failed.

2. There was absolutely no gap on the surfaces, not only for aesthetic reasons but because the part seems to be a lot weaker when there are even small gaps in it.

Regarding quality, I see 3 values for acceptable parts: low, average and high. I wouldn't mind having my prints low quality, if all I needed was fast prototyping of a part. I'd print it fast and if everything came out ok then I'd print it at a lower speed for best quality. It all depends on the intended use. It's like printing in draft mode with a 2D printer. I think it matters though if my draft mode is 10 times faster than my best quality one.

If it is for measurements I'll try to make a video with the fastest acceptable print I can get, when I replace my thermistor.

Edited 1 time(s). Last edit at 07/05/2012 07:42PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 12, 2012 09:29AM |

Registered: 12 years ago Posts: 88 |

Unfortunately replacing the thermistor proved fatal for the heater:

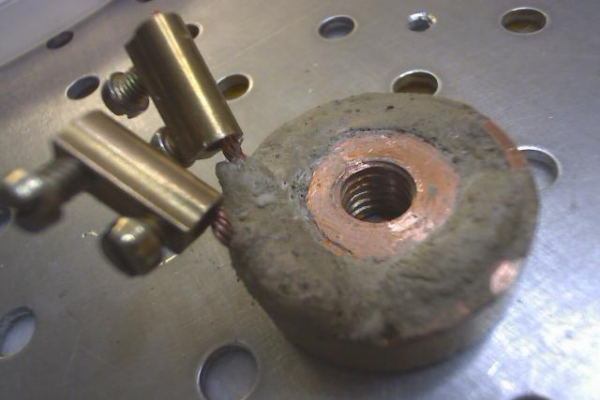

In any case, I wanted to try another hotend so I proceeded with a new heater, based on a 22mmx6.3mm piece of round copper rod, quite heavier than the previous super light aluminum one:

This is the final assembly. Notice the position of the thermistor, between the copper heater and a threaded washer screwed on the nozzle:

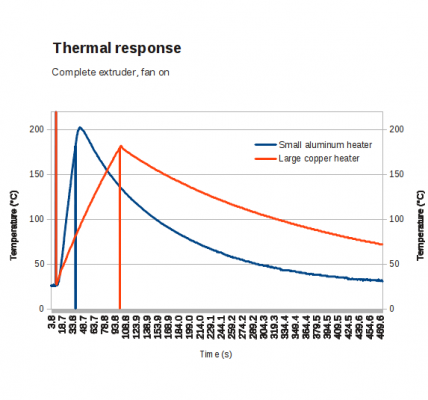

Tuning is not finished yet, but here is a graph comparing the thermal response of old/new extruders:

Two things to note, at a first glance:

1. The heavier Cu heater takes about 3 times longer to reach final temperature

2. The new Cu hotend + thermistor has a much smaller overshoot, possibly due to lower thermal resistance of the junctions in the new system and/or different position of the thermistor.

I'm not satisfied with the position of the thermistor on the Cu heater as it doesn't measure actual nozzle temperature so I'll try different positions and see what happens.

Regarding the thermistors, I still have problems with them.

Initially it seemed like any temperature higher than 250°C would destroy a thermistor. I got one malfunctioning right after I tried to set temperature to 250°C. After I replaced it and before I tighten the nut holding the new one on the barrel, it was reading the correct temperature, checked with a thermocouple. After just tightening it, it started reading about 5 °C lower at room temperature. I think I applied more pressure on the thermistor than it could take and, though not broken, the mechanical distortion of the glass encapsulation caused permanent change of the NTC element characteristics.

I'm still waiting (30 days and counting) for some thermocouple amplifiers ICs (MAX6675ISA) to be delivered from China, so hopefully I'll soon get rid of the thermistors all together.

Edited 2 time(s). Last edit at 07/12/2012 09:42AM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

In any case, I wanted to try another hotend so I proceeded with a new heater, based on a 22mmx6.3mm piece of round copper rod, quite heavier than the previous super light aluminum one:

This is the final assembly. Notice the position of the thermistor, between the copper heater and a threaded washer screwed on the nozzle:

Tuning is not finished yet, but here is a graph comparing the thermal response of old/new extruders:

Two things to note, at a first glance:

1. The heavier Cu heater takes about 3 times longer to reach final temperature

2. The new Cu hotend + thermistor has a much smaller overshoot, possibly due to lower thermal resistance of the junctions in the new system and/or different position of the thermistor.

I'm not satisfied with the position of the thermistor on the Cu heater as it doesn't measure actual nozzle temperature so I'll try different positions and see what happens.

Regarding the thermistors, I still have problems with them.

Initially it seemed like any temperature higher than 250°C would destroy a thermistor. I got one malfunctioning right after I tried to set temperature to 250°C. After I replaced it and before I tighten the nut holding the new one on the barrel, it was reading the correct temperature, checked with a thermocouple. After just tightening it, it started reading about 5 °C lower at room temperature. I think I applied more pressure on the thermistor than it could take and, though not broken, the mechanical distortion of the glass encapsulation caused permanent change of the NTC element characteristics.

I'm still waiting (30 days and counting) for some thermocouple amplifiers ICs (MAX6675ISA) to be delivered from China, so hopefully I'll soon get rid of the thermistors all together.

Edited 2 time(s). Last edit at 07/12/2012 09:42AM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 14, 2012 01:52PM |

Registered: 12 years ago Posts: 313 |

The extruder's job is to produce an accurate track of plastic as commanded by the G-code, so why not measure the extruder performance by feeding it a square waveform by turning the extrusion on and off while moving it in a straight line at constant speed? Doing that at different speeds would allow measuring the extrusion system's frequency response.

Running a test G-code which contains such test lines with increasing speeds should show pretty clearly what the extruder is capable of.

Running a test G-code which contains such test lines with increasing speeds should show pretty clearly what the extruder is capable of.

|

Re: Extruder performance - can it be measured? July 15, 2012 05:05PM |

Registered: 12 years ago Posts: 88 |

@ttsalo

That would be interesting if it weren't for all that software trying to compensate for the mechanical and thermal limitations, e.g. acceleration limits, retracts e.t.c

destroyer2012 Wrote:

-------------------------------------------------------

> The reason why I suggest making a video is because

> we can see where the print head is and hear (by

> the stepper sound) how fast it's going. In fact

> the sound of the steppers (frequency) combined

> with axis steps/mm should be all we need to know

> to calculate instantaneous speed. I'm going to try

> that when I get home, could be a useful tool to

> once and for all end this "I'm printing at

> 400mm/s" silliness.

>[...] Combined with a

> video you can tell what speed the printer was

> travelling in that area for example along the long

> part of the j shape we have now. That would be an

> interesting data set.

So, here is a video of a print @300mm/s, with the new heater.

The video was taken with a Philips SPZ5000 webcam, that's the only one I have available here.

What do you see in that video, with regard to speed?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

That would be interesting if it weren't for all that software trying to compensate for the mechanical and thermal limitations, e.g. acceleration limits, retracts e.t.c

destroyer2012 Wrote:

-------------------------------------------------------

> The reason why I suggest making a video is because

> we can see where the print head is and hear (by

> the stepper sound) how fast it's going. In fact

> the sound of the steppers (frequency) combined

> with axis steps/mm should be all we need to know

> to calculate instantaneous speed. I'm going to try

> that when I get home, could be a useful tool to

> once and for all end this "I'm printing at

> 400mm/s" silliness.

>[...] Combined with a

> video you can tell what speed the printer was

> travelling in that area for example along the long

> part of the j shape we have now. That would be an

> interesting data set.

So, here is a video of a print @300mm/s, with the new heater.

The video was taken with a Philips SPZ5000 webcam, that's the only one I have available here.

What do you see in that video, with regard to speed?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 15, 2012 09:31PM |

Registered: 13 years ago Posts: 301 |

|

Re: Extruder performance - can it be measured? July 16, 2012 03:44AM |

Registered: 12 years ago Posts: 88 |

billyzelsnack Wrote:

-------------------------------------------------------

> Looks good. Do you have some close-up pics?

When I get the time, I'll do a full test starting from slow speeds. In the meanwhile I'm waiting for Destroyer2012's forensics analysis

Since a video seems to be desirable/persuading, I may add the requirement for one, with sound, in the performance test draft. Hopefully Destroyer2012 can come up with some procedure for analysing the sound of the stepper as a proof of speed.

On the test side, a third criterion for acceptability would be for the part not to de-laminate. So the criteria, at the moment, that I would consider to accept a test part are:

1. The printed part dimensions must be as per the design (+/- 0.01mm ?).

2. There is no visible gap on any surface.

3. The part does not de-laminate when put under shear force (numbers ?).

These would make a part acceptable, but the quality would still need to be defined as low, average, high.

Or, even better, draft, normal, high.

I like the term "draft" in a 3D context. It may help people see more than "best quality" possibilities in their 3D printers. It may even someday become trendy:

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> Looks good. Do you have some close-up pics?

When I get the time, I'll do a full test starting from slow speeds. In the meanwhile I'm waiting for Destroyer2012's forensics analysis

Since a video seems to be desirable/persuading, I may add the requirement for one, with sound, in the performance test draft. Hopefully Destroyer2012 can come up with some procedure for analysing the sound of the stepper as a proof of speed.

On the test side, a third criterion for acceptability would be for the part not to de-laminate. So the criteria, at the moment, that I would consider to accept a test part are:

1. The printed part dimensions must be as per the design (+/- 0.01mm ?).

2. There is no visible gap on any surface.

3. The part does not de-laminate when put under shear force (numbers ?).

These would make a part acceptable, but the quality would still need to be defined as low, average, high.

Or, even better, draft, normal, high.

I like the term "draft" in a 3D context. It may help people see more than "best quality" possibilities in their 3D printers. It may even someday become trendy:

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: Extruder performance - can it be measured? July 16, 2012 11:57AM |

Registered: 13 years ago Posts: 301 |

> 3. The part does not de-laminate when put under

> shear force (numbers ?).

Is the part you printed above seem nice and strong? I grabbed the one out of my junk box and because it is not tall and deforms so easily I could not get it to delaminate at all using my fingers. Maybe the test part needs to be twice or so as tall to better showcase ease of delamination.

> shear force (numbers ?).

Is the part you printed above seem nice and strong? I grabbed the one out of my junk box and because it is not tall and deforms so easily I could not get it to delaminate at all using my fingers. Maybe the test part needs to be twice or so as tall to better showcase ease of delamination.

|

Re: Extruder performance - can it be measured? July 16, 2012 03:30PM |

Registered: 12 years ago Posts: 313 |

dzach Wrote:

-------------------------------------------------------

> @ttsalo

> That would be interesting if it weren't for all

> that software trying to compensate for the

> mechanical and thermal limitations, e.g.

> acceleration limits, retracts e.t.c

I was thinking of doing it with custom generated G-code, with a sequence of constant speed moves on each line, alternating with extruder on and off. That should eliminate retracts and most of acceleration effects (at least if E acceleration is high enough). After that there shouldn't be much software effects and the test should show more or less the raw extruder capabilities with the given temperature and material. It should show accurate extruding at slower speeds, then lag and fuzzy starts and stops, and eventually insufficient extrusion.

-------------------------------------------------------

> @ttsalo

> That would be interesting if it weren't for all

> that software trying to compensate for the

> mechanical and thermal limitations, e.g.

> acceleration limits, retracts e.t.c

I was thinking of doing it with custom generated G-code, with a sequence of constant speed moves on each line, alternating with extruder on and off. That should eliminate retracts and most of acceleration effects (at least if E acceleration is high enough). After that there shouldn't be much software effects and the test should show more or less the raw extruder capabilities with the given temperature and material. It should show accurate extruding at slower speeds, then lag and fuzzy starts and stops, and eventually insufficient extrusion.

|

Re: Extruder performance - can it be measured? July 16, 2012 04:08PM |

Registered: 12 years ago Posts: 88 |

That part in the video was, I think, the best I've printed so far at that speed, I couldn't break it or de-laminate it by hand. Before that, while trying to calibrate the new hot end I got a few parts that would de-laminate by hand force, because they were printed at lower temperatures. As the speed increases the temperature has to follow so I end up printing at higher than normal temperatures or the extruder will start missing steps.

With the new heater I get less oozing and the strings that were forming between the circle and the rectangular body have now disappeared. Calibrating for higher speeds makes underlying problems very obvious and with Skeinforge it is very easy to correct them one at a time, once you get to know the peculiarities of the software.

But I believe these high speed/draft mode business got us a off track, measuring other parameters that are not directly related to the extruder. They may be a subject for another thread.

Back to the extruder, the temperature overshoot is one indicator showing how fast the hot end can respond to changes in the flow of plastic. Materials with high thermal conductivity, e.g. copper and aluminium and hot ends with few thermal junctions, e.g. heater and nozzle in the same block of highly conductive metal, should show a lower overshoot and respond better even with bang-bang temperature control. So this could be a good parameter to measure.

So far, oozing has been elusive, filament deformation can be measured, max flow and flow vs. temperature is also measurable, die swell is measurable (but I had difficulties measuring it reliably).

Are the above adequate and necessary hard numbers to go into an extruder performance test? What else is needed?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

With the new heater I get less oozing and the strings that were forming between the circle and the rectangular body have now disappeared. Calibrating for higher speeds makes underlying problems very obvious and with Skeinforge it is very easy to correct them one at a time, once you get to know the peculiarities of the software.

But I believe these high speed/draft mode business got us a off track, measuring other parameters that are not directly related to the extruder. They may be a subject for another thread.

Back to the extruder, the temperature overshoot is one indicator showing how fast the hot end can respond to changes in the flow of plastic. Materials with high thermal conductivity, e.g. copper and aluminium and hot ends with few thermal junctions, e.g. heater and nozzle in the same block of highly conductive metal, should show a lower overshoot and respond better even with bang-bang temperature control. So this could be a good parameter to measure.

So far, oozing has been elusive, filament deformation can be measured, max flow and flow vs. temperature is also measurable, die swell is measurable (but I had difficulties measuring it reliably).

Are the above adequate and necessary hard numbers to go into an extruder performance test? What else is needed?

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Sorry, only registered users may post in this forum.