FFC extruder / x carriage connectors idea (Flexible flat cables)

Posted by andy-net

|

FFC extruder / x carriage connectors idea (Flexible flat cables) May 18, 2014 08:34PM |

Registered: 12 years ago Posts: 46 |

Hey so I thought a nice easy / neat way to do the extruder / x carriage cables on non-delta bots might be to do something like this, maybe spread the heater over multiple pins for safety but I thought it would be tidy and stand up to a lot of punishment (its supposed to be flexible!)

has anyone tried this? I see a lot of IDE type cables used on the Mendel90 and I like that but I thought this would be a good idea as with some jumper cables it would make for a plug and play set up

I suppose you would need 7 pins if you used, but a 20 pin would leave 3 spare:

Hot End

4 x heater

2 x thermistor

Extruder Motor

4 x stepper

Auto Bed Level

2 x micro switch

3 x servo

Fan

2 x Fan

Edited 1 time(s). Last edit at 05/18/2014 09:02PM by andy-net.

has anyone tried this? I see a lot of IDE type cables used on the Mendel90 and I like that but I thought this would be a good idea as with some jumper cables it would make for a plug and play set up

I suppose you would need 7 pins if you used, but a 20 pin would leave 3 spare:

Hot End

4 x heater

2 x thermistor

Extruder Motor

4 x stepper

Auto Bed Level

2 x micro switch

3 x servo

Fan

2 x Fan

Edited 1 time(s). Last edit at 05/18/2014 09:02PM by andy-net.

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) May 18, 2014 10:34PM |

Registered: 12 years ago Posts: 46 |

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) May 18, 2014 11:02PM |

Registered: 10 years ago Posts: 18 |

These are commonly used in inkjet printers. if the setup is designed properly I'd expect it to work reasonably well.

Probably the biggest disadvantage of flex cables is the connectors-- in fact in a product I'm working on we were doing everything possible to avoid flex cables because the connectors fail so incredibly easily (though in the end, due to specific features, we did use a flex). The connectors also tend to be challenging to replace if they get damaged.

Another issue is that you need to be careful of force on the cable, and especially the bend radius - hugely important for moving parts. If you tear apart an inkjet printer, you'll see special gutters that the cable runs in and extra cable to decrease the forces on the cable. You would probably want the same thing -- a gutter for the flex to lay flat into beside the X carriage; if left dangling you'd face dangers both of snagging on things during moves, and of bending in ways that could damage the cable.

Regarding current - that could be calculated pretty easily. Heater current shouldn't be too much of a problem, though you'd want to order the signals (& possibly even run 2 cables) to minimize impact of the motor / hotend currents on servo control & thermistor signals.

Probably the biggest disadvantage of flex cables is the connectors-- in fact in a product I'm working on we were doing everything possible to avoid flex cables because the connectors fail so incredibly easily (though in the end, due to specific features, we did use a flex). The connectors also tend to be challenging to replace if they get damaged.

Another issue is that you need to be careful of force on the cable, and especially the bend radius - hugely important for moving parts. If you tear apart an inkjet printer, you'll see special gutters that the cable runs in and extra cable to decrease the forces on the cable. You would probably want the same thing -- a gutter for the flex to lay flat into beside the X carriage; if left dangling you'd face dangers both of snagging on things during moves, and of bending in ways that could damage the cable.

Regarding current - that could be calculated pretty easily. Heater current shouldn't be too much of a problem, though you'd want to order the signals (& possibly even run 2 cables) to minimize impact of the motor / hotend currents on servo control & thermistor signals.

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) May 19, 2014 10:09AM |

Registered: 11 years ago Posts: 253 |

check out Samtec ZF5S, in 30, 40 and 43 circuits.

about $1.5 a connector, 2.5 amps per circuit.

The cable is the cost, at around $4 per foot.

Simple strain reliefs near each cable end keep forces off the connectors.

The zero insertion force (ZIF) locking bar is tricky to get pushed in fully.

This leaves the cable free to pull out, but if its pushed down all the way, there is a great grip.

A push with a pocket screw driver seats the locking bar very easily, but it's very hard with fingers.

about $1.5 a connector, 2.5 amps per circuit.

The cable is the cost, at around $4 per foot.

Simple strain reliefs near each cable end keep forces off the connectors.

The zero insertion force (ZIF) locking bar is tricky to get pushed in fully.

This leaves the cable free to pull out, but if its pushed down all the way, there is a great grip.

A push with a pocket screw driver seats the locking bar very easily, but it's very hard with fingers.

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) May 19, 2014 10:26AM |

Registered: 10 years ago Posts: 869 |

Depending on what the size is of the wires, 4 may not be enough for your extruder heater. A standard 40 watt cartridge heater needs 3.3 amps @ 12V. 3 wires are needed with an IDC cable for both +12v and ground. Unless you use a large pitch FFC I doubt you'd be able to get away with just 2 wires each direction.Quote

andy-net

Hot End

4 x heater

2 x thermistor

Extruder Motor

4 x stepper

Auto Bed Level

2 x micro switch

3 x servo

Fan

2 x Fan

I'd also expand on just 20 conductors. I originally went with the 15 pin connector with my Mendel90 build but then have reworked it so that I have two 20 pin cables (7 of which get split off for the x-axis stepper and end stop) giving me a total of 33 pins on my x-carriage.

4 pins heater +12v

4 pins ground

1 pin empty

4 pins extruder stepper

2 pins thermistor

2 pins auto probe switch

2 pins hot end (E3D) fan

2 pins workpiece cooling fan

2 pins LED lighting

2 pin empty

2 pin empty

3 pins auto probe servo

3 pins empty

The IDC connectors make it nice to pop off the cable if need be, but they stay solidly connected. All the pins are connected to screw terminals or locking connectors so it's easy to add something if need be down the road.

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) June 23, 2014 10:41PM |

Registered: 12 years ago Posts: 46 |

Well its rare that you get to say this in the reprap world, but my plan worked flawlessly  I was worried that the cable might get hot but not at all, and its printing just as good as ever.

I was worried that the cable might get hot but not at all, and its printing just as good as ever.

The cable took a long time to arrive (they sent me three incorrect ones!!!) but other than that - I'm very happy.

So my bill of materials was simply:

1 x [www.ebay.com]

2 x [www.digikey.com]

The machine looks a lot tidier on top and I can think it down more I'm sure.

I hope this helps someone.

I was worried that the cable might get hot but not at all, and its printing just as good as ever.

I was worried that the cable might get hot but not at all, and its printing just as good as ever. The cable took a long time to arrive (they sent me three incorrect ones!!!) but other than that - I'm very happy.

So my bill of materials was simply:

1 x [www.ebay.com]

2 x [www.digikey.com]

The machine looks a lot tidier on top and I can think it down more I'm sure.

I hope this helps someone.

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) June 24, 2014 08:16AM |

Registered: 12 years ago Posts: 1,450 |

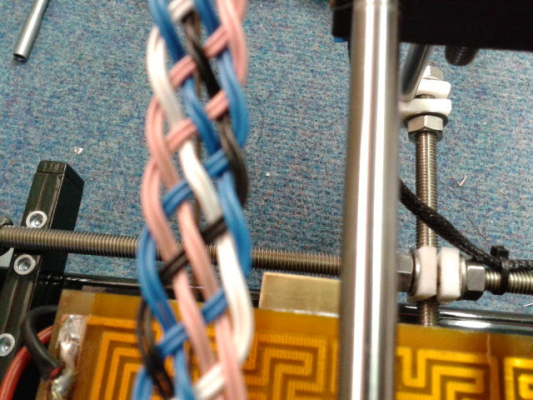

FFC has the advantage of being springy and can be relied not to flop into the mechanicals - such as extruder gears. Other flat cables such as ribbon cable are not nearly as good and anybody who has never had a snag with the just-plain-bundle-of-wires method is just plain lucky

A simple way of getting the same springiness but keeping to the RepRap philosophy of making with common materials is to flat braid thin cables and reinforce with a bit of springy wire

My apologies for the forum standard out-of-focus-pictures, bit I think it shows the idea. Wires are 10/01 (10 strands of copper of 0.1mm) two wires are O.K. for the hot-end heater and one each for every other function. The springy wire which you can just see in the middle of the braid was 0.6mm NiTiNol, but spring steel of phosphor bronze should also be O.K.

Mike

A simple way of getting the same springiness but keeping to the RepRap philosophy of making with common materials is to flat braid thin cables and reinforce with a bit of springy wire

My apologies for the forum standard out-of-focus-pictures, bit I think it shows the idea. Wires are 10/01 (10 strands of copper of 0.1mm) two wires are O.K. for the hot-end heater and one each for every other function. The springy wire which you can just see in the middle of the braid was 0.6mm NiTiNol, but spring steel of phosphor bronze should also be O.K.

Mike

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) July 01, 2014 01:27PM |

Registered: 12 years ago Posts: 46 |

Wow that's a really neat low-tech solution to the problem, thank you for sharing  that's very creative! and a lot less expensive I'm sure!

that's very creative! and a lot less expensive I'm sure!

Just to let you know the FFC cable is still doing really well, I've been printing with it for many hours now so I think this is a good option for anyone wanting to go the non-reprap-philosophy route.

that's very creative! and a lot less expensive I'm sure!

that's very creative! and a lot less expensive I'm sure!Just to let you know the FFC cable is still doing really well, I've been printing with it for many hours now so I think this is a good option for anyone wanting to go the non-reprap-philosophy route.

|

Re: FFC extruder / x carriage connectors idea (Flexible flat cables) July 01, 2014 09:50PM |

Registered: 10 years ago Posts: 80 |

Thats a neat idea. I'm using a short 3ft cat 5 cable and surprisingly i havn't had to replace it yet after hundred hours. Usually the patch cables are made using multi stranded copper for more flexibility than the solid core. I am running my steppers, fan, thermistor, and optical be sensor. I did use each pair per phase on the motor to safe on current. If my cable ever does fail i have a spare to plug right in for around a 1.50

Regards,

Greg

Regards,

Greg

Sorry, only registered users may post in this forum.