Perfactory Machine: Can we make one?

Posted by makeit

|

Re: Perfactory Machine: Can we make one? July 16, 2008 08:45AM |

Registered: 15 years ago Posts: 35 |

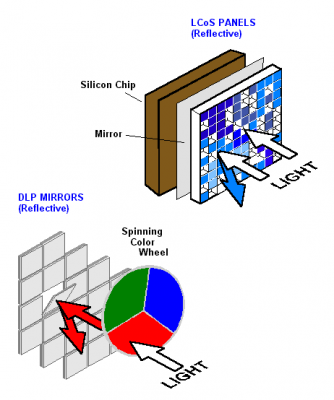

Theres another projection chip system based on LCD technology called LCos. It seems to offer the same possibilities of DMD. Not sure about the lumen power being comparable in the mini versions to the DLP Projectors used. If it is this might be the tech worth seeking out for the projection system since it is so small and seems to eliminate the need for a fan and other things.

[www.youtube.com]

[www.youtube.com]

/\ Cool links showing how small the entire unit is and how small it will eventually be.

I'm wondering if the light source is a laser. I hope it is since that might bring the lumen power close to a conventional projector bulb tech depending on it's distance from the observation area. The housing unit if we could build the system this way could be much smaller as well. No fans needs to move the heat out of the system cause by the light source. Less space needed inside to house it all.

This is the company that makes it.

[www.aurora-sys.com]

I think Perfactory is also looking into using this tech to replace what they are using now. I could have sworn I read something about it somewhere.

[www.youtube.com]

[www.youtube.com]

/\ Cool links showing how small the entire unit is and how small it will eventually be.

I'm wondering if the light source is a laser. I hope it is since that might bring the lumen power close to a conventional projector bulb tech depending on it's distance from the observation area. The housing unit if we could build the system this way could be much smaller as well. No fans needs to move the heat out of the system cause by the light source. Less space needed inside to house it all.

This is the company that makes it.

[www.aurora-sys.com]

I think Perfactory is also looking into using this tech to replace what they are using now. I could have sworn I read something about it somewhere.

|

Re: Perfactory Machine: Can we make one? July 16, 2008 12:23PM |

Registered: 17 years ago Posts: 550 |

Those chips look very interesting and the look very expensive!

Now I'm wondering if it isn't much easier to just take some sort of

readily available Monitor to make such perfactory.

Or even a digital pictureframe.

That way you can easily fit the size to your needs.

Let's say I have some 7" digital pictureframe laying around,

I build the Z Axis and the Bed to be filled with the polymer.

I load the slices to the SD Card, and set the "change intervall" of the pictureframe to ten seconds.

Done.

Now I need some bigger objects.

I mount a new Z-Plate (should be cheap)

change the outerline of the polymer bed (shouldn't be expensive too)

And get myself a 10" pictureframe

DONE.

Or, I can hook up my 22" Monitor and let my OS generate the slideshow...

Would be some sort of that much easier and cheaper to build ?

'sid

Now I'm wondering if it isn't much easier to just take some sort of

readily available Monitor to make such perfactory.

Or even a digital pictureframe.

That way you can easily fit the size to your needs.

Let's say I have some 7" digital pictureframe laying around,

I build the Z Axis and the Bed to be filled with the polymer.

I load the slices to the SD Card, and set the "change intervall" of the pictureframe to ten seconds.

Done.

Now I need some bigger objects.

I mount a new Z-Plate (should be cheap)

change the outerline of the polymer bed (shouldn't be expensive too)

And get myself a 10" pictureframe

DONE.

Or, I can hook up my 22" Monitor and let my OS generate the slideshow...

Would be some sort of that much easier and cheaper to build ?

'sid

|

Re: Perfactory Machine: Can we make one? July 16, 2008 12:38PM |

Registered: 16 years ago Posts: 361 |

Quote

Would be some sort of that much easier and cheaper to build ?

Well, of course. The importat question is, "will it work?" I doubt you'll get anything like the same intensity from a digital picture frame as you would from a projector. A nice big CRT is better, but still nothing like the amount of light a projector is kicking out.

You'll need that bright light to make the photopolymer congeal rapidly; the faster the better, I'd guess.

There's nothing to stop you making a cheaper projector, of course. But I don't think its a component you can avoid altogether.

|

Re: Perfactory Machine: Can we make one? July 16, 2008 12:38PM |

Registered: 16 years ago Posts: 370 |

|

Re: Perfactory Machine: Can we make one? July 16, 2008 12:39PM |

sid Wrote:

-------------------------------------------------------

> Now I'm wondering if it isn't much easier to just

> take some sort of

> readily available Monitor to make such

> perfactory.

> Or even a digital pictureframe.

You mean something like the Lumenlab projectors? They're computer projectors home made from lcd monitors. See [www.lumenlab.com]

-------------------------------------------------------

> Now I'm wondering if it isn't much easier to just

> take some sort of

> readily available Monitor to make such

> perfactory.

> Or even a digital pictureframe.

You mean something like the Lumenlab projectors? They're computer projectors home made from lcd monitors. See [www.lumenlab.com]

|

Re: Perfactory Machine: Can we make one? July 16, 2008 12:40PM |

Registered: 16 years ago Posts: 370 |

Ru Wrote:

-------------------------------------------------------

> Would be some sort of that much easier and cheaper

> to build ?

>

> Well, of course. The importat question is, "will

> it work?" I doubt you'll get anything like the

> same intensity from a digital picture frame as you

> would from a projector. A nice big CRT is better,

> but still nothing like the amount of light a

> projector is kicking out.

>

> You'll need that bright light to make the

> photopolymer congeal rapidly; the faster the

> better, I'd guess.

>

> There's nothing to stop you making a cheaper

> projector, of course. But I don't think its a

> component you can avoid altogether.

Right, I thought he was talking about one of the home-made projector hacks that takes an LCD screen out of its frame and shines a halogen bulb through it. I agree that an LCD on its own almost certainly won't put out enough energy to rapidly polymerize the plastic.

-------------------------------------------------------

> Would be some sort of that much easier and cheaper

> to build ?

>

> Well, of course. The importat question is, "will

> it work?" I doubt you'll get anything like the

> same intensity from a digital picture frame as you

> would from a projector. A nice big CRT is better,

> but still nothing like the amount of light a

> projector is kicking out.

>

> You'll need that bright light to make the

> photopolymer congeal rapidly; the faster the

> better, I'd guess.

>

> There's nothing to stop you making a cheaper

> projector, of course. But I don't think its a

> component you can avoid altogether.

Right, I thought he was talking about one of the home-made projector hacks that takes an LCD screen out of its frame and shines a halogen bulb through it. I agree that an LCD on its own almost certainly won't put out enough energy to rapidly polymerize the plastic.

|

Re: Perfactory Machine: Can we make one? July 16, 2008 01:36PM |

Registered: 17 years ago Posts: 550 |

Depending on how sensible the photopolymer is, maybe a tft is bright enough,

maybe it needs to be a crt.

But removing a backlight from a tft and adding a bright light behind is not considered magic

I just thought, It's way easier to reuse all the monitors electronics too.

And yes like the lumenlab projectors do.

Maybe simpler

If a crt is bright enough to do the job,

then we're half way through, not?

And if not, we still can hack an ordinary tft with some lightsource

peel of the reflective layer from the el-film and put a lamp behind.

In both cases we don't need to care much about electronics,

almost everything is already system integrated, except the z-Axis control,

that will need to be synchronized with the slideshow;

again this shouldn't be hard to do with let's say our arduino.

I'd like to know how much energy will be required...

maybe it's just the wavelength, like those uv-polymers...

or both?

Does someone know about things like that?

'sid

But as long as I'm not done with my repstrap I won't start building another device

(I got four open projects at this time, I'd love to reduce, not increase )

)

Edited 2 time(s). Last edit at 07/16/2008 01:39PM by sid.

maybe it needs to be a crt.

But removing a backlight from a tft and adding a bright light behind is not considered magic

I just thought, It's way easier to reuse all the monitors electronics too.

And yes like the lumenlab projectors do.

Maybe simpler

If a crt is bright enough to do the job,

then we're half way through, not?

And if not, we still can hack an ordinary tft with some lightsource

peel of the reflective layer from the el-film and put a lamp behind.

In both cases we don't need to care much about electronics,

almost everything is already system integrated, except the z-Axis control,

that will need to be synchronized with the slideshow;

again this shouldn't be hard to do with let's say our arduino.

I'd like to know how much energy will be required...

maybe it's just the wavelength, like those uv-polymers...

or both?

Does someone know about things like that?

'sid

But as long as I'm not done with my repstrap I won't start building another device

(I got four open projects at this time, I'd love to reduce, not increase

)

)Edited 2 time(s). Last edit at 07/16/2008 01:39PM by sid.

|

Re: Perfactory Machine: Can we make one? July 16, 2008 01:51PM |

Registered: 17 years ago Posts: 550 |

Sorry, I forgot:

Kyle Corbitt Wrote:

-------------------------------------------------------

> I don't know whether those chips are more

> expensive than a 22" monitor or not right now, but

> I suspect that with all the projectors you see

> everywhere these days, they're falling fast.

Well a 22" Monitor starting at ~200 bucks (depending on resolution, speed and brightness)

A "give it a testrun" 7" tft is less than 70 Euro.

For this project we don't really care about the speed, and if we have to add a lightsource we don't even care about brightness.

A projector with the same resolution is about four to six times higher in price.

I don't know how much the chip itself is, but if you only buy a chip you'll have to spend money and time on electronics again.

'sid

Kyle Corbitt Wrote:

-------------------------------------------------------

> I don't know whether those chips are more

> expensive than a 22" monitor or not right now, but

> I suspect that with all the projectors you see

> everywhere these days, they're falling fast.

Well a 22" Monitor starting at ~200 bucks (depending on resolution, speed and brightness)

A "give it a testrun" 7" tft is less than 70 Euro.

For this project we don't really care about the speed, and if we have to add a lightsource we don't even care about brightness.

A projector with the same resolution is about four to six times higher in price.

I don't know how much the chip itself is, but if you only buy a chip you'll have to spend money and time on electronics again.

'sid

|

Re: Perfactory Machine: Can we make one? July 16, 2008 03:01PM |

> Cool video. It looks like the arm goes up and then

> back down again. Is that how it releases the new

> layer from the lower tray before it resets itself

> the next build?

There are two parts that move.

The "arm" which is a glass plate which the build object "grows out of". This plate can only move up and down.

The rear edge of the tray that holds the liquid can be raised and lowered.

The movement is to accomplish three things.

Separate the just build layer from the tray but not the arm.

Allow liquid to flow between the just build layer and the bottom of the tray.

Position the just build layer so the next layer can be built.

I believe the arm raising and lowering is to allow liquid to flow in and then positionning for the next layer. By this point the rear edge of the tray has been lowered. The lowering of the tray is where the just build layer is separated.

> The table/housing has to be perfectly level. A simple bubble level system is built into the table to adjust it to insure that it is level before the build is carried out.

If you have a tray full of liquid then it needs to be fairly level. Otherwise liquid will spill out or there will be dry areas. I don't believe the overall level of the table needs to be any more precise than that.

What is important is that the glass plate on the arm is parallel with the tray and the correct distance from the tray when a layer is built.

The amount of light is important. It needs to be bright enough to set the required thickness of liquild in a short time but not too bright. If the light is too bright it can set too much liquid.

> back down again. Is that how it releases the new

> layer from the lower tray before it resets itself

> the next build?

There are two parts that move.

The "arm" which is a glass plate which the build object "grows out of". This plate can only move up and down.

The rear edge of the tray that holds the liquid can be raised and lowered.

The movement is to accomplish three things.

Separate the just build layer from the tray but not the arm.

Allow liquid to flow between the just build layer and the bottom of the tray.

Position the just build layer so the next layer can be built.

I believe the arm raising and lowering is to allow liquid to flow in and then positionning for the next layer. By this point the rear edge of the tray has been lowered. The lowering of the tray is where the just build layer is separated.

> The table/housing has to be perfectly level. A simple bubble level system is built into the table to adjust it to insure that it is level before the build is carried out.

If you have a tray full of liquid then it needs to be fairly level. Otherwise liquid will spill out or there will be dry areas. I don't believe the overall level of the table needs to be any more precise than that.

What is important is that the glass plate on the arm is parallel with the tray and the correct distance from the tray when a layer is built.

The amount of light is important. It needs to be bright enough to set the required thickness of liquild in a short time but not too bright. If the light is too bright it can set too much liquid.

|

Re: Perfactory Machine: Can we make one? July 16, 2008 05:56PM |

Registered: 15 years ago Posts: 35 |

The simple lcd screen layed over a projector won't work. The reason it wont work is because the black pixel color will still have light/lumen power going through it. The black pixel value wont cure the resin as thickly as the white light value, but it will still cure the resin to some extent. This is if you used white pixel information for the solid shape you want to make. The black pixel image info will cure in thinner sheets around the edges of the thicker white pixel info. Now you have to sand or cut these thinner sheets off of the main piece after the build is done. Wasting material, reducing accuracy and adding more steps to finalize your RP parts. Not fun.

Heres an image to better explain whats going on with the DMD chip.

It's not just projecting an image. It's projecting it as a shape of pure light. This shape is caused by the pixel value that those mirrors on the chip are told to represent and ignore.

The cost wont be too bad if you buy a used or broken 1 chip DLP projector on Ebay. These projectors already have the power supply unit, the DMI cable connector, the lens and the bulb holder, a working bulb if your lucky.

So The Controlboard and maybe the DMD chip is all you'll have to swap out if you go that route. We sorta don't want to use the preinstalled DMD chip and controlboard= Since they will vary from all the available projector models.

We want to install our own, unless this issue of controlling the ones inside are all the same no matter which projector you buy so long as it's from the same company and has the same pixel display resolution.

The program we create will most likely be much easier to make if it's based on the same chip with a fixed resolution and controlboard that comes form the same manufacturer.

You can't promise other builders theyre build will work, if you tell them to hunt down a used projector since these 2 critical parts may vary.

Maybe we can replace the projection bulb with an ultra bright LED. Improving it's lifecycle and reducing the need to constantly readjust it from the effect caused by the burn off effect.

This is a Mod Project. How bad and involved that Modwork is remains unknown right now.

Theres a software program out there already to control the DMD chip and the Controlboard from that Pixel Perfect site.

One thing we might have to do is place a Potentiometer system going to the projection bulb or remoded Ultra Bright LED bulb so we can change the power going to it to reduce/intensify/control the lumen power it sends out.

When we go about building this we have to see how well we can time the arm to do it's task since it goes up and returns back down. Up high enough to pull in more resin and or break/lift the RP'd part from the lower tray to prepare it for the the next layer. Get it down to 15 seconds or so per layer.

Then we use the pixel perfect program to send the images to the DMD chip- not over a network- Lets keep the memory the program and task management stuff on our PC's. We will probably need a graphics card With an HDMI port to send the data.

We tell the DMD chip to start it's mirror flip into the image we sent to it- after the arm resets and returns to build new layer position. We send this image of light to this resin for 8 seconds. Then the program tells the DMD chip to shut off the mirrors completely- Not the bulb! The bulb is always on. It only lets light go to the projector when the mirrors tilt into an on position.

Then the arm raises it pulls the materials off the lower tray somehow. More resin is sent to the build tray when the clip is pulled back. And we are doing the whole process all over again.

Images should be sent from a folder. labeled 001 002 003 and so one. Program sends them. They are 2 bit color images. Gif file format is fine. SVG graphics is fine if you can change it to 2 bit color. Any color outside of blackest black and whitest white is not wanted. Lighter values of each color will cause resin cure issues against the stronger values before them. The images layers on the screen will look like they don't have aliasing to them. since they are only two color values used to make them.

The pixel perfect program should be pretty straight forward as far as representing the image by color and length of time. You don't turn off the bulb when the projects getting built. If you did that you would reduce it's lifecycle and possibly damage it. You turn the mirrors into the off position between layers. The LCOS chip works the same way but instead of mirrors it uses little led's to block the entire mirror behind them.

Edited 1 time(s). Last edit at 07/16/2008 06:26PM by makeit.

Heres an image to better explain whats going on with the DMD chip.

It's not just projecting an image. It's projecting it as a shape of pure light. This shape is caused by the pixel value that those mirrors on the chip are told to represent and ignore.

The cost wont be too bad if you buy a used or broken 1 chip DLP projector on Ebay. These projectors already have the power supply unit, the DMI cable connector, the lens and the bulb holder, a working bulb if your lucky.

So The Controlboard and maybe the DMD chip is all you'll have to swap out if you go that route. We sorta don't want to use the preinstalled DMD chip and controlboard= Since they will vary from all the available projector models.

We want to install our own, unless this issue of controlling the ones inside are all the same no matter which projector you buy so long as it's from the same company and has the same pixel display resolution.

The program we create will most likely be much easier to make if it's based on the same chip with a fixed resolution and controlboard that comes form the same manufacturer.

You can't promise other builders theyre build will work, if you tell them to hunt down a used projector since these 2 critical parts may vary.

Maybe we can replace the projection bulb with an ultra bright LED. Improving it's lifecycle and reducing the need to constantly readjust it from the effect caused by the burn off effect.

This is a Mod Project. How bad and involved that Modwork is remains unknown right now.

Theres a software program out there already to control the DMD chip and the Controlboard from that Pixel Perfect site.

One thing we might have to do is place a Potentiometer system going to the projection bulb or remoded Ultra Bright LED bulb so we can change the power going to it to reduce/intensify/control the lumen power it sends out.

When we go about building this we have to see how well we can time the arm to do it's task since it goes up and returns back down. Up high enough to pull in more resin and or break/lift the RP'd part from the lower tray to prepare it for the the next layer. Get it down to 15 seconds or so per layer.

Then we use the pixel perfect program to send the images to the DMD chip- not over a network- Lets keep the memory the program and task management stuff on our PC's. We will probably need a graphics card With an HDMI port to send the data.

We tell the DMD chip to start it's mirror flip into the image we sent to it- after the arm resets and returns to build new layer position. We send this image of light to this resin for 8 seconds. Then the program tells the DMD chip to shut off the mirrors completely- Not the bulb! The bulb is always on. It only lets light go to the projector when the mirrors tilt into an on position.

Then the arm raises it pulls the materials off the lower tray somehow. More resin is sent to the build tray when the clip is pulled back. And we are doing the whole process all over again.

Images should be sent from a folder. labeled 001 002 003 and so one. Program sends them. They are 2 bit color images. Gif file format is fine. SVG graphics is fine if you can change it to 2 bit color. Any color outside of blackest black and whitest white is not wanted. Lighter values of each color will cause resin cure issues against the stronger values before them. The images layers on the screen will look like they don't have aliasing to them. since they are only two color values used to make them.

The pixel perfect program should be pretty straight forward as far as representing the image by color and length of time. You don't turn off the bulb when the projects getting built. If you did that you would reduce it's lifecycle and possibly damage it. You turn the mirrors into the off position between layers. The LCOS chip works the same way but instead of mirrors it uses little led's to block the entire mirror behind them.

Edited 1 time(s). Last edit at 07/16/2008 06:26PM by makeit.

|

Re: Perfactory Machine: Can we make one? July 16, 2008 07:25PM |

Registered: 16 years ago Posts: 370 |

|

Re: Perfactory Machine: Can we make one? July 17, 2008 06:25AM |

Registered: 17 years ago Posts: 550 |

Well thinking of what Fernando achieved

[forums.reprap.org]

I think there's only the machine left

'sid

[forums.reprap.org]

I think there's only the machine left

'sid

|

Re: Perfactory Machine: Can we make one? July 17, 2008 10:24AM |

Registered: 16 years ago Posts: 370 |

|

Re: Perfactory Machine: Can we make one? July 17, 2008 11:01AM |

Registered: 15 years ago Posts: 35 |

I called up DL innovations. and asked about they're

[www.dlinnovations.com]

They asked what resolution and wavelength -

UV cost more.

10,000 dollars for the starter kit at 1280x1024 resolution using regular projector bulb. Ummmmm....

It does however come with everything needed to control the chip- not sure if the light source/bulb is included in this price. The UV version at this resolution is much more $. I didn't have it in me to ask.

The Pixel Percision software that will control the boards they offer cost 3,500 dollars. Ouch!

They have a deadline coming up the 1100 going End of Life Soon. Told me I'd have to sign a license agreement and all sorts of stuff. WTH?!?!?!?

Wow back to square one again. I guess this means moding a used or broken DLP model now.

back to square one again. I guess this means moding a used or broken DLP model now.

Edited 1 time(s). Last edit at 07/17/2008 11:11AM by makeit.

[www.dlinnovations.com]

They asked what resolution and wavelength -

UV cost more.

10,000 dollars for the starter kit at 1280x1024 resolution using regular projector bulb. Ummmmm....

It does however come with everything needed to control the chip- not sure if the light source/bulb is included in this price. The UV version at this resolution is much more $. I didn't have it in me to ask.

The Pixel Percision software that will control the boards they offer cost 3,500 dollars. Ouch!

They have a deadline coming up the 1100 going End of Life Soon. Told me I'd have to sign a license agreement and all sorts of stuff. WTH?!?!?!?

Wow

back to square one again. I guess this means moding a used or broken DLP model now.

back to square one again. I guess this means moding a used or broken DLP model now.Edited 1 time(s). Last edit at 07/17/2008 11:11AM by makeit.

|

Re: Perfactory Machine: Can we make one? July 17, 2008 11:04AM |

Registered: 15 years ago Posts: 35 |

|

Re: Perfactory Machine: Can we make one? July 17, 2008 11:22AM |

Registered: 15 years ago Posts: 35 |

[www.pixelprecision.net]

[www.pixelprecision.net]

Supports bitmap and jpeg image importing. Don't see why anyone would want to use the pixel by pixel image creation suite they offer. Program allows the creation of animation files as well- that would have solved the timing routine. Image shape for certain number of frames. Then blank image to turn of mirrors for certain number of frames.

But even this way and how you generate all that seems like a big P.I.A! Too much mula for what it does and it sounds like a slow painful way to do a simple batch process!

You should be able to drag or import a folder with the all image files in it created in the native resolution that the chip display in (pov-ray slice feature) if need be they can be batch files dragged into paintshop to reduce them to 2 bit black and white images before you do this. Very fast and done like that.

So you import or drag the folder with these already scaled to match mirror resolution files into the build/task window. A window pops up and ask if you want to insert a blank image between each image file sent (blank image is the turn off mirror command) You click yes. Time for each frame button comes up or is selectable

You enter in the time value you need to work with whatever time corresponds with the arm and cure rate. Something like that.

Edited 1 time(s). Last edit at 07/17/2008 11:40AM by makeit.

[www.pixelprecision.net]

Supports bitmap and jpeg image importing. Don't see why anyone would want to use the pixel by pixel image creation suite they offer. Program allows the creation of animation files as well- that would have solved the timing routine. Image shape for certain number of frames. Then blank image to turn of mirrors for certain number of frames.

But even this way and how you generate all that seems like a big P.I.A! Too much mula for what it does and it sounds like a slow painful way to do a simple batch process!

You should be able to drag or import a folder with the all image files in it created in the native resolution that the chip display in (pov-ray slice feature) if need be they can be batch files dragged into paintshop to reduce them to 2 bit black and white images before you do this. Very fast and done like that.

So you import or drag the folder with these already scaled to match mirror resolution files into the build/task window. A window pops up and ask if you want to insert a blank image between each image file sent (blank image is the turn off mirror command) You click yes. Time for each frame button comes up or is selectable

You enter in the time value you need to work with whatever time corresponds with the arm and cure rate. Something like that.

Edited 1 time(s). Last edit at 07/17/2008 11:40AM by makeit.

|

Re: Perfactory Machine: Can we make one? July 17, 2008 11:43AM |

Registered: 17 years ago Posts: 550 |

10.000 US$ ? for the starterkit ?

Well this is just a little over what is suitable for a 600US$ limit isn't it?

makeit, I'd love to see the projectors you mentioned.

I looked around and most consumergrade projectors do have some sort of lcd/tft solution, or just tubes like a crt.

I don't find anything that has a dmd chip installed.

even the highest priced model I could find right now (Epson EMP-8300NL) has nothing but a small (1.4") tft inside

'sid

[EDIT]

Never mind, I've found some...

Edited 1 time(s). Last edit at 07/17/2008 12:00PM by sid.

Well this is just a little over what is suitable for a 600US$ limit isn't it?

makeit, I'd love to see the projectors you mentioned.

I looked around and most consumergrade projectors do have some sort of lcd/tft solution, or just tubes like a crt.

I don't find anything that has a dmd chip installed.

even the highest priced model I could find right now (Epson EMP-8300NL) has nothing but a small (1.4") tft inside

'sid

[EDIT]

Never mind, I've found some...

Edited 1 time(s). Last edit at 07/17/2008 12:00PM by sid.

|

Re: Perfactory Machine: Can we make one? July 17, 2008 12:32PM |

Registered: 15 years ago Posts: 35 |

[www.viewsonic.com]

[www.superwarehouse.com]

Saw an even cheaper price but not sure if it's the same unit.

[www.superwarehouse.com]

Saw an even cheaper price but not sure if it's the same unit.

|

Re: Perfactory Machine: Can we make one? July 17, 2008 12:36PM |

Registered: 15 years ago Posts: 35 |

|

Re: Perfactory Machine: Can we make one? July 17, 2008 12:42PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Perfactory Machine: Can we make one? July 17, 2008 02:20PM |

Registered: 15 years ago Posts: 35 |

What are those lcd clear windows called. You know the ones those folks used for privacy in japan. They go all blue colored when a charge goes through them.

Maybe those could be the answer. You could use them to make a block out shape.

The Lcos chip is another alternative.

Worst case alternative: We use a hand crank system and a plate loader.

We print our layers out on transparent overhead sheets in a standard printer. We replace the ink in the cartridge with something that has more opacity to it so the light wont shine through.

We load these 8x10 printed on transparency sheet into the plate loader.

Then we remove a cover plate covering the light source. The light goes through the printed on overhead transparency sheet under the glass table. Under the resin holding vat. We expose the resin for a certain length of time.

Place the light plate cover back over the light source again.

Hand crank our build arm up a tiny bit for the next layer.

Release more resin into the building vat.

Then we load our next image into the plate loader and we are ready to do it all over again.

It would be midevil as all hell, but it could work.

Hehehehehehe I'm just joshing with ya, but hey I might go there maybe...

Edited 1 time(s). Last edit at 07/17/2008 02:26PM by makeit.

Maybe those could be the answer. You could use them to make a block out shape.

The Lcos chip is another alternative.

Worst case alternative: We use a hand crank system and a plate loader.

We print our layers out on transparent overhead sheets in a standard printer. We replace the ink in the cartridge with something that has more opacity to it so the light wont shine through.

We load these 8x10 printed on transparency sheet into the plate loader.

Then we remove a cover plate covering the light source. The light goes through the printed on overhead transparency sheet under the glass table. Under the resin holding vat. We expose the resin for a certain length of time.

Place the light plate cover back over the light source again.

Hand crank our build arm up a tiny bit for the next layer.

Release more resin into the building vat.

Then we load our next image into the plate loader and we are ready to do it all over again.

It would be midevil as all hell, but it could work.

Hehehehehehe I'm just joshing with ya, but hey I might go there maybe...

Edited 1 time(s). Last edit at 07/17/2008 02:26PM by makeit.

|

Re: Perfactory Machine: Can we make one? July 17, 2008 02:58PM |

Registered: 15 years ago Posts: 35 |

|

Re: Perfactory Machine: Can we make one? July 17, 2008 03:26PM |

Registered: 15 years ago Posts: 251 |

Greetings all,

For the above "Primative but Functional" design to work, the light would have to be well collimated (parallel rays) and quite uniform. Even then, the transpariencies should be as close as possible to the resin, to minimize diffraction.

Exposing an entire layer at once (many voxells in parallel) is attractive, but isn't the only way to go. One could imagine a raster-scan system, based on two tilting mirrors to "paint" each layer. If the light source were of sufficient power, that approach might be competitive on speed. One can also imagine more than one beam -- maybe one for coarse features and another for the fine ones.....

Alternatively, the transparencies might be replaced by two plates, one with a slit (parallel to Y) that moves only in X, the second the same thing, rotated by 90 degrees. That's just another way of exposing one X, Y area at a time. (Though it does waste most of the light.)

This limits us to a single size of voxell, but uses pure translation instead of rotations (which can induce trig terms -- distortion if not accounted for.)

Are the resins for this approach available, and what's the ballpark cost/volume, anybody know? Ditto patent/IP status.

-- Larry

For the above "Primative but Functional" design to work, the light would have to be well collimated (parallel rays) and quite uniform. Even then, the transpariencies should be as close as possible to the resin, to minimize diffraction.

Exposing an entire layer at once (many voxells in parallel) is attractive, but isn't the only way to go. One could imagine a raster-scan system, based on two tilting mirrors to "paint" each layer. If the light source were of sufficient power, that approach might be competitive on speed. One can also imagine more than one beam -- maybe one for coarse features and another for the fine ones.....

Alternatively, the transparencies might be replaced by two plates, one with a slit (parallel to Y) that moves only in X, the second the same thing, rotated by 90 degrees. That's just another way of exposing one X, Y area at a time. (Though it does waste most of the light.)

This limits us to a single size of voxell, but uses pure translation instead of rotations (which can induce trig terms -- distortion if not accounted for.)

Are the resins for this approach available, and what's the ballpark cost/volume, anybody know? Ditto patent/IP status.

-- Larry

|

Re: Perfactory Machine: Can we make one? July 17, 2008 04:03PM |

Registered: 16 years ago Posts: 370 |

Larry_Pfeffer Wrote:

-------------------------------------------------------

> Exposing an entire layer at once (many voxells in

> parallel) is attractive, but isn't the only way to

> go. One could imagine a raster-scan system, based

> on two tilting mirrors to "paint" each layer. If

> the light source were of sufficient power, that

> approach might be competitive on speed. One can

> also imagine more than one beam -- maybe one for

> coarse features and another for the fine

> ones.....

Now we're back to "standard" UV-printing, except with the innovation of having a thin layer of monomer instead of flooding the build area. Not the end of the world, but takes about half the innovation out of the design.

> Are the resins for this approach available, and

> what's the ballpark cost/volume, anybody know?

> Ditto patent/IP status.

>

> -- Larry

Commercial resins are mega-expensive. Fernando seems to think you can do the same thing on the cheap, but he isn't there quite yet.

For patent stuff... I think it's pretty new. Considering they use a projector, it's nowhere near the 20-years-old that a patent has to be to expire. So yeah, what Forrest said.

-------------------------------------------------------

> Exposing an entire layer at once (many voxells in

> parallel) is attractive, but isn't the only way to

> go. One could imagine a raster-scan system, based

> on two tilting mirrors to "paint" each layer. If

> the light source were of sufficient power, that

> approach might be competitive on speed. One can

> also imagine more than one beam -- maybe one for

> coarse features and another for the fine

> ones.....

Now we're back to "standard" UV-printing, except with the innovation of having a thin layer of monomer instead of flooding the build area. Not the end of the world, but takes about half the innovation out of the design.

> Are the resins for this approach available, and

> what's the ballpark cost/volume, anybody know?

> Ditto patent/IP status.

>

> -- Larry

Commercial resins are mega-expensive. Fernando seems to think you can do the same thing on the cheap, but he isn't there quite yet.

For patent stuff... I think it's pretty new. Considering they use a projector, it's nowhere near the 20-years-old that a patent has to be to expire. So yeah, what Forrest said.

|

Re: Perfactory Machine: Can we make one? July 17, 2008 06:00PM |

Registered: 15 years ago Posts: 199 |

Larry_Pfeffer Wrote:

-------------------------------------------------------

> Are the resins for this approach available, and

> what's the ballpark cost/volume, anybody know?

[www.prototypemagazine.com]

"In terms of consumables, the first thing to consider is the material. This is priced at

-------------------------------------------------------

> Are the resins for this approach available, and

> what's the ballpark cost/volume, anybody know?

[www.prototypemagazine.com]

"In terms of consumables, the first thing to consider is the material. This is priced at

|

Re: Perfactory Machine: Can we make one? July 17, 2008 06:12PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Perfactory Machine: Can we make one? July 18, 2008 09:28AM |

Forrest Higgs Wrote:

-------------------------------------------------------

> Traditionally, the problem with photolithography

> type prototypes that depend on radiation in one

> form or another to polymerize monomers has been

> the cost of the monomer.

True, but one advantage of this approach is that it uses less of it than the alternatives which normally involve flooding the whole work area.

-------------------------------------------------------

> Traditionally, the problem with photolithography

> type prototypes that depend on radiation in one

> form or another to polymerize monomers has been

> the cost of the monomer.

True, but one advantage of this approach is that it uses less of it than the alternatives which normally involve flooding the whole work area.

|

Re: Perfactory Machine: Can we make one? July 18, 2008 10:07AM |

Admin Registered: 17 years ago Posts: 1,915 |

When I worked in the Symbiotic Processes Laboratory at UTAustin back in the early 1970's, we were interested in printing using light beams to polymerize methyl methacrylate into acrylic plastic. It would do it, but the monomer was a serious irritant and required lots of ventilation to work with. On the plus side it was about the only plastic that I've ever heard of that could be reduced to its monomer chemically without a lot of losses.

I just checked the pricing for methyl methacrylate. It appears that in very large lots it is selling for about $1.25-1.50/lb these days. If you buy it from chemical supply labs, however, you can play on paying about $25/lb for it in bottles. It hasn't seen the price rises that many polymers have since it is largely produced form natural gas rather than oil.

I just checked the pricing for methyl methacrylate. It appears that in very large lots it is selling for about $1.25-1.50/lb these days. If you buy it from chemical supply labs, however, you can play on paying about $25/lb for it in bottles. It hasn't seen the price rises that many polymers have since it is largely produced form natural gas rather than oil.

|

Re: Perfactory Machine: Can we make one? July 22, 2008 04:10AM |

Registered: 16 years ago Posts: 120 |

I think the transparency should be placed between the light source and the lens. Then you could have a knob to adjust focus just like an old fashioned Overhead- or Dia- projector.

If you used a Dia projector you could load its magasine with 24 pictures and change for each exposure with the remote control :-)

Doensn't glass block UV-light BTW?

If you used a Dia projector you could load its magasine with 24 pictures and change for each exposure with the remote control :-)

Doensn't glass block UV-light BTW?

|

Re: Perfactory Machine: Can we make one? July 22, 2008 04:47AM |

Registered: 16 years ago Posts: 361 |

Quote

Doensn't glass block UV-light BTW?

Yes, mostly. It seems most things do. You can mitigate the problem somewhat by doing longer exposure times or using a super-powerful light source. Some glass will of course be better than others in this regard, and you're likely to get different effect from different wavelengths of UV, but this starts to drift out of my limited area of knowledge

(I briefly played with UV photography. It's tricky, practically impossible with CMOS digital camera sensors, and UV-transaprent quartz lenses are horrifyingly expensive.)

Sorry, only registered users may post in this forum.