Printing nuts, bolts & screws - Is it possible? (Complete Newbie!)

Posted by Jon

|

Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 23, 2012 05:06AM |

Registered: 11 years ago Posts: 7 |

Hi All...

Just wondering if any of you could relate your experiences 3D-printing threaded components - bolts, screws, nuts etc. What is the smallest possible standard thread size, without the printer resolution compromising functionality? And what model printer would you recommend for this kind of job?

I'm thinking fairly seriously about buying/making a 3D printer to make components that will need to screw together and be user-adjustable. 3D printing might be much cheaper than getting them made by a pro manufacturer...

Cheers,

Jon.

Just wondering if any of you could relate your experiences 3D-printing threaded components - bolts, screws, nuts etc. What is the smallest possible standard thread size, without the printer resolution compromising functionality? And what model printer would you recommend for this kind of job?

I'm thinking fairly seriously about buying/making a 3D printer to make components that will need to screw together and be user-adjustable. 3D printing might be much cheaper than getting them made by a pro manufacturer...

Cheers,

Jon.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 23, 2012 05:15AM |

Registered: 12 years ago Posts: 30 |

[www.thingiverse.com] and [www.thingiverse.com] use printed threads. The planetary gear one probably gives the best impression of scale and usability. Also i think it's the smalles "usable" diameter/pitch

For holding stuff together self threading screws are way more useful than printed ones.

For holding stuff together self threading screws are way more useful than printed ones.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 23, 2012 05:29AM |

Registered: 11 years ago Posts: 7 |

Thanks joo

Yeah, I'm sure off-the-shelf (metal) bolts are much better quality - but i'm designing components that, if they were to require standard hardware, would require hours of complicated assembly. And I need to make hundreds of them...

But those examples look quite similar to my application... promising!

One thing that occurred to me, though: If I'm making many of these objects, do I need to physically remove each object from the printer bed after it has finished printing, or are some printer models capable of somehow "ejecting" the made object and starting with a new object with no user input?

Yeah, I'm sure off-the-shelf (metal) bolts are much better quality - but i'm designing components that, if they were to require standard hardware, would require hours of complicated assembly. And I need to make hundreds of them...

But those examples look quite similar to my application... promising!

One thing that occurred to me, though: If I'm making many of these objects, do I need to physically remove each object from the printer bed after it has finished printing, or are some printer models capable of somehow "ejecting" the made object and starting with a new object with no user input?

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 23, 2012 06:10AM |

Registered: 13 years ago Posts: 643 |

No current reprap has an eject feature. Makerbot has the Automated Build Platform, but I haven't seen it mentioned in a while. It seems fairly simple to add an eject to any reprap, just have a boom and a pair of screws to drive it across the print bed. Or, parts pop free when using a glass heat bed, if you let it cool enough. A mendel90 can be run on its back so the parts would fall clear. I don't know how reliable it is, you may need some way to detect a clear bed and call for help if it doesn't clear on its own.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 23, 2012 09:14AM |

Registered: 11 years ago Posts: 64 |

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 26, 2012 08:07PM |

Registered: 15 years ago Posts: 332 |

Unless you're printing things that take up a lot of the bed area, but have a small volume, you can just fill the bed with as many as possible, and you're easily talking 10+ hours of printing, so an eject thing is less useful. I frequently fill up my prusas bed with parts before I go to bed, and it's finishing printing the next morning, so it's no hassle or wasted time.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) July 27, 2012 12:38PM |

Registered: 11 years ago Posts: 283 |

I do this from time to time as well but sometimes, when I come down in the morning, said parts are either in a stringy mess on the floor or wrapped around the print head. It all adds to the excitement!

james glanville Wrote:

-------------------------------------------------------

> Unless you're printing things that take up a lot

> of the bed area, but have a small volume, you can

> just fill the bed with as many as possible, and

> you're easily talking 10+ hours of printing, so an

> eject thing is less useful. I frequently fill up

> my prusas bed with parts before I go to bed, and

> it's finishing printing the next morning, so it's

> no hassle or wasted time.

Using ABSPrusa Mendel Zaphod with Pronterface and slic3r 1.3.0. Printing well with 3mm PLA and ABS through 2 x J Head Mk IV b and Wade Geared Exruders. Controlled using RAMPS1.4 board running Marlin_v1.1.9

james glanville Wrote:

-------------------------------------------------------

> Unless you're printing things that take up a lot

> of the bed area, but have a small volume, you can

> just fill the bed with as many as possible, and

> you're easily talking 10+ hours of printing, so an

> eject thing is less useful. I frequently fill up

> my prusas bed with parts before I go to bed, and

> it's finishing printing the next morning, so it's

> no hassle or wasted time.

Using ABSPrusa Mendel Zaphod with Pronterface and slic3r 1.3.0. Printing well with 3mm PLA and ABS through 2 x J Head Mk IV b and Wade Geared Exruders. Controlled using RAMPS1.4 board running Marlin_v1.1.9

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) June 07, 2015 04:14AM |

Registered: 8 years ago Posts: 1 |

Hi.It sounds good and also interesting idea which you share with us.If you want to get information about bolts, nuts, then you go through on this fastener supplies. It has many good services regarding fastners and sure you will also like it. Good luck.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) June 09, 2015 12:54AM |

Registered: 9 years ago Posts: 705 |

I drew and printed a bolt and nut that was about 3/4" diameter. I had to scale and reprint the nut three times to get it to thread all the way down. With different printers getting different results (daily it seems) it would be tough to get consistant outcomes.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) June 09, 2015 07:57AM |

Registered: 11 years ago Posts: 5,780 |

If you're interested in the challenge of printing threaded parts that fit together, go for it, but, if you need parts to actually hold other things together, it's hard to argue with using hardware store nuts and bolts. Printed parts have to be BIG compared to something like a 6-32 screw, and a 1" printed nut/bolt won't come close to the strength of a little 15 cent, 6-32 screw and nut.

I use a lot of 6-32 hardware in the stuff I print. Printing holes at 4mm diam will let the screw just slide through, and printing at 3.2 mm lets a 6-32 screw bite into the plastic and thread itself in. I recently invested about $30 in several hundred 6-32 screws of different lengths, nuts, and washers, just to keep them around for printed parts. I keep a clearance drill, a tap drill, and 6-32 tap in the box with the screws in case I need to put a screw into an aluminum part. I made CAD models of all the different pieces I have to use when I'm designing things. 6-32 seems like a good size for screwing plastic parts together- if you need something bigger than 6-32 to hold things together, plastic may not be the right material to use. 6-32 is big enough that when it threads into the plastic the threads have some good grip.

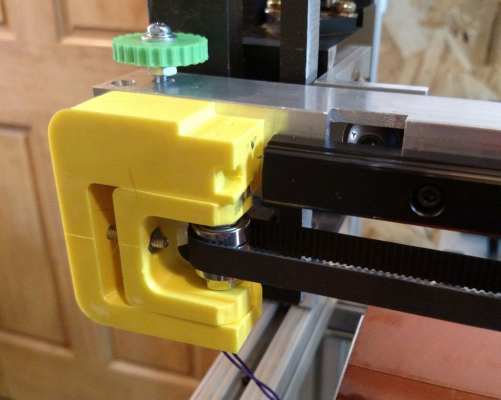

Here's a picture of the sort of stuff I do- it's the X axis belt tensioner in my printer. I used a 6-32 screw with a nut in the tensioner adjustment because I didn't want to take any chances on the threads in the plastic stripping out. The thumb-wheel turns a 6-32 screw to adjust the Z axis zero by bumping into a microswitch that isn't visible in the picture. I recently changed it for an opto-interruptor.

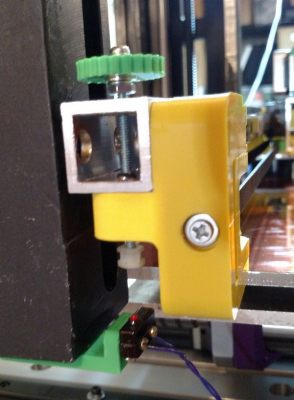

This photo shows the now depricated limit switch arrangement - that's a long 6-32 screw with a printed thumbwheel threaded right through the yellow plastic belt tensioner.

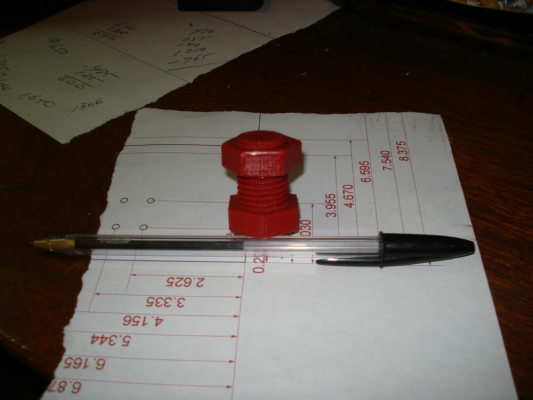

This is my first experiment at printing threaded parts- it's huge!

Eyepiece case

Edited 1 time(s). Last edit at 06/09/2015 07:57AM by the_digital_dentist.

I use a lot of 6-32 hardware in the stuff I print. Printing holes at 4mm diam will let the screw just slide through, and printing at 3.2 mm lets a 6-32 screw bite into the plastic and thread itself in. I recently invested about $30 in several hundred 6-32 screws of different lengths, nuts, and washers, just to keep them around for printed parts. I keep a clearance drill, a tap drill, and 6-32 tap in the box with the screws in case I need to put a screw into an aluminum part. I made CAD models of all the different pieces I have to use when I'm designing things. 6-32 seems like a good size for screwing plastic parts together- if you need something bigger than 6-32 to hold things together, plastic may not be the right material to use. 6-32 is big enough that when it threads into the plastic the threads have some good grip.

Here's a picture of the sort of stuff I do- it's the X axis belt tensioner in my printer. I used a 6-32 screw with a nut in the tensioner adjustment because I didn't want to take any chances on the threads in the plastic stripping out. The thumb-wheel turns a 6-32 screw to adjust the Z axis zero by bumping into a microswitch that isn't visible in the picture. I recently changed it for an opto-interruptor.

This photo shows the now depricated limit switch arrangement - that's a long 6-32 screw with a printed thumbwheel threaded right through the yellow plastic belt tensioner.

This is my first experiment at printing threaded parts- it's huge!

Eyepiece case

Edited 1 time(s). Last edit at 06/09/2015 07:57AM by the_digital_dentist.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) June 09, 2015 11:19PM |

Registered: 12 years ago Posts: 253 |

It can be done obviously. I tried this awhile back just to see and uploaded to Thingverse. [www.thingiverse.com] . The problem with printing real threads is you first have to model a real thread, thats not as easy as it sounds and if you are a novice at 3d modeling it will be a major obsticle. And as far as usefulness. Forget it, theres no use in a plastic bolt when you can go to the hardware store and buy a bag full of steel for $2. The strength of the plastic bolt and nut is a fraction of what a steel thread is. If you want to thread a bolt into a plastic printed part do what the dentist said, print the holes to the drill tap size and tap the threads by hand, that works very well for me.

|

Re: Printing nuts, bolts & screws - Is it possible? (Complete Newbie!) June 11, 2015 01:32AM |

Registered: 9 years ago Posts: 483 |

Sorry, only registered users may post in this forum.