Air ventilation in heated chamber?

Posted by repdesign

|

Air ventilation in heated chamber? September 19, 2015 12:43PM |

Registered: 11 years ago Posts: 70 |

Hi there,

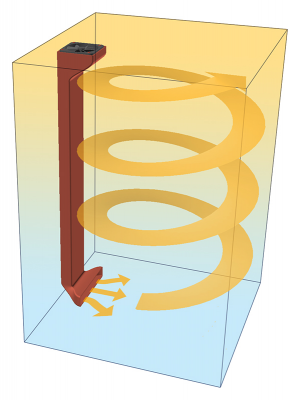

We are planning on building a new 3d printer with an enclosed build chamber. My latest printer already achieved about 50 °C, for the new one we want to go up to 60 or 70 °C. We'll see. Anyways, regarding the new design I guess the temperature gradient from the bottom of the chamber to the top is much more noticeable and I expect a difference from around 5 to 10 °C (the chamber is around 70 cm tall) which means the air in the lower regions is colder than that in the higher regions. The build platform moves from top to bottom (like Ultimaker). With a more even air temperature in the entire print chamber I expect better print results. My idea is to put in a kind of 3d printed fan duct that sucks the air from the top and blows it out at the bottom (see attachment). This ventilation would lead to a recirculating air flow and a stable air temperature in the entire chamber. What do you think of this idea or do you don't see any positive effects with this design?

We are planning on building a new 3d printer with an enclosed build chamber. My latest printer already achieved about 50 °C, for the new one we want to go up to 60 or 70 °C. We'll see. Anyways, regarding the new design I guess the temperature gradient from the bottom of the chamber to the top is much more noticeable and I expect a difference from around 5 to 10 °C (the chamber is around 70 cm tall) which means the air in the lower regions is colder than that in the higher regions. The build platform moves from top to bottom (like Ultimaker). With a more even air temperature in the entire print chamber I expect better print results. My idea is to put in a kind of 3d printed fan duct that sucks the air from the top and blows it out at the bottom (see attachment). This ventilation would lead to a recirculating air flow and a stable air temperature in the entire chamber. What do you think of this idea or do you don't see any positive effects with this design?

|

Re: Air ventilation in heated chamber? September 19, 2015 05:42PM |

Registered: 11 years ago Posts: 1,171 |

It sounds good in theory but you will never know until you try.

It's possible prints would be worse with stirred up air but I just don't know. The heat bed basically bathes the part in hot air as it rises, but would the circulated air affect the thermistor on the bottom of the heated bed and actually lower the bed temperature by making it think it's hotter?

I would be interested in your findings. Though I must say my enclosure gets to around 50c where the parts are printed and I have no heat related problems (warping, cracking....).

It's possible prints would be worse with stirred up air but I just don't know. The heat bed basically bathes the part in hot air as it rises, but would the circulated air affect the thermistor on the bottom of the heated bed and actually lower the bed temperature by making it think it's hotter?

I would be interested in your findings. Though I must say my enclosure gets to around 50c where the parts are printed and I have no heat related problems (warping, cracking....).

|

Re: Air ventilation in heated chamber? September 19, 2015 11:18PM |

Registered: 11 years ago Posts: 5,780 |

We have a couple Stratasys FDM printers at the makerspace that operate the enclosure at 70C and the extruders at 270C (for printing ABS). The chamber is heated with 2x 400W resistive heaters with heatsinks and there are fans that circulate the air, though I'm not sure what the overall airflow arrangement is. I'll take a look at them tomorrow and post whatever I find.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Air ventilation in heated chamber? September 21, 2015 11:44AM |

Registered: 11 years ago Posts: 253 |

The stratasys design has the air intake in the lower section, blows over a heater element, then exhausts with a thin blade-like vent pointed across build layer.

there are two blower systems, one on each side, blowing at each other, which creates a temperature controlled bath at the point of depositing.

The chamber thermocouple probe is located in the lower corner. no thermistors are used by stratasys.

these heaters are very slow to react and heat. From cold, my Uprint takes about 20-30 minutes to reach 70C. Everything needs to heat up, including all the frame, mechanics, walls, door, etc. I think they do a slow heat so everything grows in size gradually. I assume that reaching a steady temperature for the entire printer is better than just measuring the air output and then starting the print. Over time there would be thermal expansion reflected in the parts dimensions.

another reason they use small watt heaters is to use 110V wall sockets. If they chose two 1000W heaters, they'd quickly exceed a typical home circuit amperage.

think about a hair dryer. it takes cold air, uses about 800+ watts over a 3 inch long coil arrangement, and you can feel the energy added, without a question.

From cold, as the machine is warming up, putting your hand in front of the exhaust, you can barely feel any warmth. I don't think they are aggressively adding power to the air, which supports the slow warm up theory. I'd guess they power those heaters with 25 watts to 50 or so.....complete SWAG....

there are two blower systems, one on each side, blowing at each other, which creates a temperature controlled bath at the point of depositing.

The chamber thermocouple probe is located in the lower corner. no thermistors are used by stratasys.

these heaters are very slow to react and heat. From cold, my Uprint takes about 20-30 minutes to reach 70C. Everything needs to heat up, including all the frame, mechanics, walls, door, etc. I think they do a slow heat so everything grows in size gradually. I assume that reaching a steady temperature for the entire printer is better than just measuring the air output and then starting the print. Over time there would be thermal expansion reflected in the parts dimensions.

another reason they use small watt heaters is to use 110V wall sockets. If they chose two 1000W heaters, they'd quickly exceed a typical home circuit amperage.

think about a hair dryer. it takes cold air, uses about 800+ watts over a 3 inch long coil arrangement, and you can feel the energy added, without a question.

From cold, as the machine is warming up, putting your hand in front of the exhaust, you can barely feel any warmth. I don't think they are aggressively adding power to the air, which supports the slow warm up theory. I'd guess they power those heaters with 25 watts to 50 or so.....complete SWAG....

|

Re: Air ventilation in heated chamber? September 21, 2015 10:41PM |

Registered: 9 years ago Posts: 93 |

I think your idea is okay but a bit of extra work. I have a single 115v 400w chamber heater mounted on the (cold)bottom of the case forcing (hot)air up- no ducts anywhere. I agree with most of what has been said... yep heats up the air quick but as the chamber as a whole warms the bed level changes and runs different overall than @room temp. without a doubt(not a reprap design fyi).

Even though I have more power and can heat the chamber air to 55c within ...~2minutes (i think was the time), I still let it 'soak' for ~20-30min. before I start printing. Nothing scientific about that btw... I just set the temp and a timer.

Even though I have more power and can heat the chamber air to 55c within ...~2minutes (i think was the time), I still let it 'soak' for ~20-30min. before I start printing. Nothing scientific about that btw... I just set the temp and a timer.

|

Re: Air ventilation in heated chamber? September 21, 2015 10:49PM |

Registered: 11 years ago Posts: 5,780 |

I start up my printer and close the side panel. It starts printing about 5 minutes after I hit the go button. The enclosure warms up over the next 15 minutes or so from the bed heater and that's fast enough because it takes that long to print the first few layers of most prints, and the first few laers aren't the problem. I have found that ABS starts delaminating about 3 cm or so above the bed, depending on the morphology of the object. Small prints don't really seem to need a warm enclosure, though shielding from air drafts is a good idea even for small prints.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.