An all metal hot-end design (Lots of Pics)

Posted by SanjayM

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 06:15AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 06:38AM |

Registered: 12 years ago Posts: 177 |

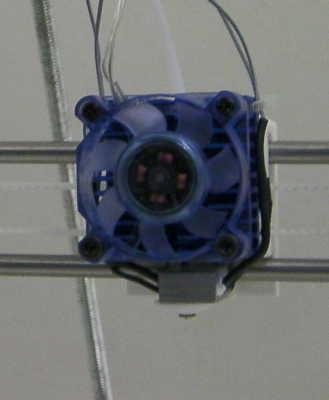

We are using screws through the fan/heatsink/cooler block to bind them tightly together.

The fan is still sucking. Will try blowing instead shortly.

Heatsink compound is being used - its white and greasy though - "Heat Sink Silicone Compound" with an 'SIL.MORE - Taiwan' logo. Is this stuff rubbish?

On our heater block we use a 300C rated boron nitride heatsink compound between heater resistor and the block, as well as the block. Its expensive, so we don't use it where we don't need the 300C rating, but if that might be better on the cold side than the white greasy stuff we could try it?

What type of compound would you recommend? Are any available at this store decent? [www.maplin.co.uk]

(There is a store locally I can pick up from today)

The fan is still sucking. Will try blowing instead shortly.

Heatsink compound is being used - its white and greasy though - "Heat Sink Silicone Compound" with an 'SIL.MORE - Taiwan' logo. Is this stuff rubbish?

On our heater block we use a 300C rated boron nitride heatsink compound between heater resistor and the block, as well as the block. Its expensive, so we don't use it where we don't need the 300C rating, but if that might be better on the cold side than the white greasy stuff we could try it?

What type of compound would you recommend? Are any available at this store decent? [www.maplin.co.uk]

(There is a store locally I can pick up from today)

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 06:42AM |

Registered: 11 years ago Posts: 1,277 |

Research this because I know for a fact screws are not enough for the best heat transfer. There are microscopic pits (no matter how much you think you made it flush or how much you lap either surface) and it has been proven beyond a shadow of a doubt that you lose a tremendous amount of heat transferring ability without heatsink compound. Tell you one thing after all of my reading on this subject over the years that when I build it the thing will have it and my temps will be the better for it.

Oh, another alternative is a heatsink pad just make sure it is rated for the temps you will be getting.

Edited 1 time(s). Last edit at 07/31/2012 06:44AM by Dark Alchemist.

Oh, another alternative is a heatsink pad just make sure it is rated for the temps you will be getting.

Edited 1 time(s). Last edit at 07/31/2012 06:44AM by Dark Alchemist.

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 06:59AM |

Registered: 12 years ago Posts: 177 |

We are using heatsink compound AND screws on the cooler-heatsink junction. My only concern was that the compound wasnt very good quality.

Problem solved though! Flipped the fan, now blowing into the heatsink, and I can hit temperatures of 250+ without going over body temp.

Right. Time for breakfast...

Problem solved though! Flipped the fan, now blowing into the heatsink, and I can hit temperatures of 250+ without going over body temp.

Right. Time for breakfast...

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 07:43AM |

Admin Registered: 17 years ago Posts: 7,879 |

I doubt you will notice much difference between one heatsink compound and another in this application. PC heatsinks are dissipating an order of magnitude more heat, so the temperature drop across the compound will be a lot more significant.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 08:51AM |

Registered: 11 years ago Posts: 1,277 |

@Sanjay ahhh, good.

@nophead The thing is that I am a perfectionist and a tweaker (I thought we all were around here) so even 1c less heat tickles me and allows me to go 1c higher on the head. Remember I am looking at all sorts of materials that need some serious hefty temps to melt them so anything to transfer more heat.

Now, do not get me wrong I am not saying run out and buy a 25 dollar .5oz tube of stuff I am just saying the heatsink grease from the likes of Radio Shack (meaning the old lithium grease white type heatsink compound) is not something I would ever use. I haven't touched that stuff since the 1980's for even my TO-220 work and I will also say the heatsink pads I have never been found of either.

@nophead The thing is that I am a perfectionist and a tweaker (I thought we all were around here) so even 1c less heat tickles me and allows me to go 1c higher on the head. Remember I am looking at all sorts of materials that need some serious hefty temps to melt them so anything to transfer more heat.

Now, do not get me wrong I am not saying run out and buy a 25 dollar .5oz tube of stuff I am just saying the heatsink grease from the likes of Radio Shack (meaning the old lithium grease white type heatsink compound) is not something I would ever use. I haven't touched that stuff since the 1980's for even my TO-220 work and I will also say the heatsink pads I have never been found of either.

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 10:19AM |

Admin Registered: 17 years ago Posts: 7,879 |

I still use a big syringe of it that I bought in the 1970s! It works fine for my needs. I am very much a don't fix what ain't broke sort of person.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 10:47AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 11:07AM |

Admin Registered: 17 years ago Posts: 7,879 |

The stuff in the syringe doesn't appear to have changed. When it is use for a long time the grease part dries out and leaves the white power but I think that is the active part anyway as silicone is not a great conductor.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 11:20AM |

Registered: 11 years ago Posts: 1,277 |

I know the better stuff has a shelf life of about 2 to a maximum (for the really pricey stuff) of 5 years after that you should buy more. I have a tube of that expensive stuff (Artic Silver) from a decade ago and it looks fine but I can tell you I do feel a difference when I applied it last so I know it is breaking down. I went and purchased something else that is even better but cost less. That lithium grease type stuff, if I remember right, has an extremely long shelf life but I dunno about almost 4 decades of one, heheh.

When I say breaks down I mean it loses much of its positives and what it turns into after that depends on what it is made of.

When I say breaks down I mean it loses much of its positives and what it turns into after that depends on what it is made of.

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 01:52PM |

Registered: 13 years ago Posts: 1,918 |

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 02:51PM |

Admin Registered: 17 years ago Posts: 7,879 |

Exactly. Designs should not be so marginal that it makes a difference. Otherwise they are not suitable to be replicated all over the world by amateur hobbyists.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 03:26PM |

Registered: 11 years ago Posts: 1,277 |

nophead Wrote:

-------------------------------------------------------

> Exactly. Designs should not be so marginal that it

> makes a difference. Otherwise they are not

> suitable to be replicated all over the world by

> amateur hobbyists.

I find that laughable that a hobbyist wouldn't understand about heatsink compound in this day and age of computers everywhere and if they don't then they need a premade device. No shame in that as that is what made Dell computers is the people who didn't know a harddrive ide connector from a sata connector.

-------------------------------------------------------

> Exactly. Designs should not be so marginal that it

> makes a difference. Otherwise they are not

> suitable to be replicated all over the world by

> amateur hobbyists.

I find that laughable that a hobbyist wouldn't understand about heatsink compound in this day and age of computers everywhere and if they don't then they need a premade device. No shame in that as that is what made Dell computers is the people who didn't know a harddrive ide connector from a sata connector.

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 03:46PM |

Admin Registered: 17 years ago Posts: 7,879 |

It not a question of understanding. If a design relies on a particular high grade compound to work then it is fragile and people will experience failures due to not applying it just right, using a cheap counterfeit brand, etc. Better to use a slightly bigger heatsink and then it will always work. It is probably a cheaper solution as well.

PCs need to use reasonably good compound because of the ridiculous amount of power the CPU uses running ridiculous software. We don't have the same constraints.

[www.hydraraptor.blogspot.com]

PCs need to use reasonably good compound because of the ridiculous amount of power the CPU uses running ridiculous software. We don't have the same constraints.

[www.hydraraptor.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) July 31, 2012 03:58PM |

Registered: 11 years ago Posts: 1,277 |

|

Re: An all metal hot-end design (Lots of Pics) August 01, 2012 06:05AM |

Admin Registered: 16 years ago Posts: 13,888 |

... regarding the life-time of really old heatsink grease I'll support nophead - but this is different for 'modern' compounds!

Some greases older than 1990 are usable, others, I've bought five years ago are dried out or starts 'smelling' as if they went rancid

So it's more the situation, that 'modern' heatsink greases (or their wrappings) are optimized to 'define' a specified durability date > <

<

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Some greases older than 1990 are usable, others, I've bought five years ago are dried out or starts 'smelling' as if they went rancid

So it's more the situation, that 'modern' heatsink greases (or their wrappings) are optimized to 'define' a specified durability date >

<

<Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An all metal hot-end design (Lots of Pics) August 01, 2012 06:27AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: An all metal hot-end design (Lots of Pics) August 04, 2012 04:59AM |

Registered: 11 years ago Posts: 2 |

|

Re: An all metal hot-end design (Lots of Pics) August 04, 2012 07:31AM |

Registered: 12 years ago Posts: 177 |

Hi Roland ,

We have indeed already filed flats onto the conical portion of the nozzle.

You need a pair of needle nosed pliers to hold and twist the nozzle and something like an adjustable spanner for the heater-block. It's just a matter of adding some heat and twisting out the nozzle and replacing with another.

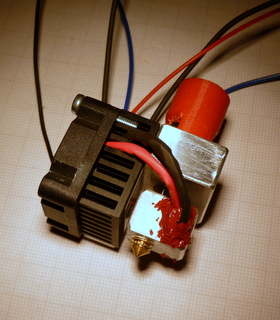

We've mounted this hot end to a printer successfully with the printed coupler as proposed, it prints absolutely beautifully, at both high resolutions as well as high extrusion speeds.

We feel our top extrusion speed is being limited by our 9mm melt zone, so we have a nozzle on the way with an extra 3mm of melt zone. Will report back what this does for extrusion rates with all else remaining equal.

We hope to be able to do 200mm/s infill. We can do 100mm/s infill on a 0.4mm layer presently without isue We hit 400mm/minute free air extrusion, which by my maths means our extrudate is exiting our 0.4mm nozzle at 125mm/s, how does this translate into true print speed of a 0.4mm layer height print, taking into account PWOT etc? More testing required to confirm.

We have indeed already filed flats onto the conical portion of the nozzle.

You need a pair of needle nosed pliers to hold and twist the nozzle and something like an adjustable spanner for the heater-block. It's just a matter of adding some heat and twisting out the nozzle and replacing with another.

We've mounted this hot end to a printer successfully with the printed coupler as proposed, it prints absolutely beautifully, at both high resolutions as well as high extrusion speeds.

We feel our top extrusion speed is being limited by our 9mm melt zone, so we have a nozzle on the way with an extra 3mm of melt zone. Will report back what this does for extrusion rates with all else remaining equal.

We hope to be able to do 200mm/s infill. We can do 100mm/s infill on a 0.4mm layer presently without isue We hit 400mm/minute free air extrusion, which by my maths means our extrudate is exiting our 0.4mm nozzle at 125mm/s, how does this translate into true print speed of a 0.4mm layer height print, taking into account PWOT etc? More testing required to confirm.

|

Re: An all metal hot-end design (Lots of Pics) August 04, 2012 10:35AM |

Registered: 11 years ago Posts: 2 |

|

Re: An all metal hot-end design (Lots of Pics) August 04, 2012 10:24PM |

Registered: 12 years ago Posts: 539 |

Nifty extruder

Check out the RepRap Pro hot end here:

RepRap Pro Hot End Assembly Instructions

Edited 2 time(s). Last edit at 08/05/2012 05:04PM by Idolcrasher.

Check out the RepRap Pro hot end here:

RepRap Pro Hot End Assembly Instructions

Edited 2 time(s). Last edit at 08/05/2012 05:04PM by Idolcrasher.

|

Re: An all metal hot-end design (Lots of Pics) August 06, 2012 11:48AM |

Registered: 12 years ago Posts: 177 |

Hi idolcrasher,

Yup, our first printer was a RRP Huxley, so we are very familiar with that design!

We wanted to take that compact assembly, eliminate the PTFE and simplify manufacture. The RRP stainless barrier is extremely thin and small, turned from M5 stud stock, so we use a more makerbot style stainless barrier with a RRP cooling arrangement, all adapted to work under a conventional direct extruder driven x carriage.

The hot end is still going strong and we have printed a few hundred metres of filament with it.

We are waiting on the final manufactured parts with slight amendments which should give a shorter transition zone and a higher extrude rate.

Yup, our first printer was a RRP Huxley, so we are very familiar with that design!

We wanted to take that compact assembly, eliminate the PTFE and simplify manufacture. The RRP stainless barrier is extremely thin and small, turned from M5 stud stock, so we use a more makerbot style stainless barrier with a RRP cooling arrangement, all adapted to work under a conventional direct extruder driven x carriage.

The hot end is still going strong and we have printed a few hundred metres of filament with it.

We are waiting on the final manufactured parts with slight amendments which should give a shorter transition zone and a higher extrude rate.

|

Re: An all metal hot-end design (Lots of Pics) August 08, 2012 02:25AM |

Registered: 12 years ago Posts: 539 |

|

Re: An all metal hot-end design (Lots of Pics) August 13, 2012 08:39AM |

Registered: 12 years ago Posts: 177 |

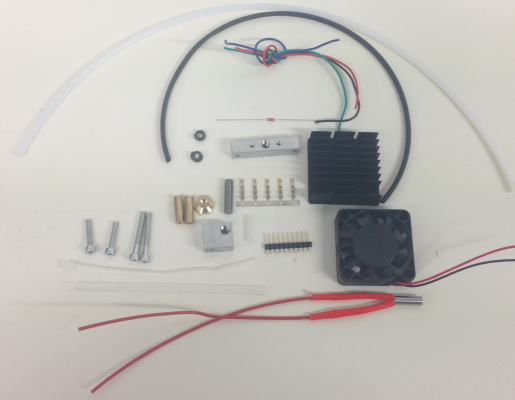

We are going to produce and sell kits, we should be able to keep prices low.

Our site is just getting up and running, extruders will be in stock SOON!

[e3d-online.com]

If there are any products you think we could/should offer, we are very open to suggestions/requests.

Our site is just getting up and running, extruders will be in stock SOON!

[e3d-online.com]

If there are any products you think we could/should offer, we are very open to suggestions/requests.

|

Re: An all metal hot-end design (Lots of Pics) August 18, 2012 11:38AM |

Registered: 11 years ago Posts: 2 |

After a good deal of testing, we have finally launched our new hot end on our website. SanjayM and I have put hours of work into making this hot end design. Along with helpful pointers from all the people on the forum, idolcrasher, dark alchemist, rolandL, hophead, NumberSix, to mention just a few. Thank you all!

We are selling a fully assembled version (£65 inc uk postage), and a kit (£50 inc uk postage).

If you are interested in buying one from outside the UK, we are happy to send internationally, we will only ever add on the exact extra postage costs. No more!

Check it out at www.e3d-online.com

Happy printing everyone!

Dave

E3d-online.com

Edited 1 time(s). Last edit at 08/18/2012 12:49PM by E3d-online.com.

We are selling a fully assembled version (£65 inc uk postage), and a kit (£50 inc uk postage).

If you are interested in buying one from outside the UK, we are happy to send internationally, we will only ever add on the exact extra postage costs. No more!

Check it out at www.e3d-online.com

Happy printing everyone!

Dave

E3d-online.com

Edited 1 time(s). Last edit at 08/18/2012 12:49PM by E3d-online.com.

|

Re: An all metal hot-end design (Lots of Pics) August 18, 2012 03:12PM |

Registered: 11 years ago Posts: 1,277 |

|

Re: An all metal hot-end design (Lots of Pics) August 18, 2012 03:51PM |

Registered: 13 years ago Posts: 248 |

That's shaped up nicely guys. Thanks for sharing your design evolution in such an open fashion. It's come together well now. It's great to see a 'simple' non-PEEK non-PTFE design out there.

If you don't mind sharing one last piece of information, how much care a are you taking when drilling out the stainless piece? Is it first drilled and then reamed to the required diam? Are you polishing the inside in any way after drilling, reaming?

Best of luck with sales.

Regards,

NumberSix

[numbersixreprap.blogspot.com]

If you don't mind sharing one last piece of information, how much care a are you taking when drilling out the stainless piece? Is it first drilled and then reamed to the required diam? Are you polishing the inside in any way after drilling, reaming?

Best of luck with sales.

Regards,

NumberSix

[numbersixreprap.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) August 19, 2012 02:10PM |

Registered: 11 years ago Posts: 2 |

When the stainless barrier is drilled, its done first with a 1.7mm drill, the reamed and polished to 2mm with a high quality tin tipped bit. iv attached some pics, i dont know if you can really see it very well, but its seriously smooth on the inside.

Hope this helps

Dave

E3D-Online.com

Hope this helps

Dave

E3D-Online.com

|

Re: An all metal hot-end design (Lots of Pics) August 19, 2012 03:37PM |

Admin Registered: 17 years ago Posts: 7,879 |

I found tapering the transition zone reduces the force needed to extrude greatly: [hydraraptor.blogspot.co.uk]

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: An all metal hot-end design (Lots of Pics) November 07, 2012 07:00PM |

Registered: 11 years ago Posts: 1 |

Sorry, only registered users may post in this forum.