EEVBlog rPrint Project

Posted by Dust

|

EEVBlog rPrint Project January 22, 2016 01:49AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: EEVBlog rPrint Project January 24, 2016 07:51AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: EEVBlog rPrint Project January 24, 2016 09:40AM |

Registered: 11 years ago Posts: 5,780 |

Unfortunately, we don't get to see if it actually prints, and they don't show any prints, so like many kickstarter projects, this may be in that dark place that lies somewhere between a vaporware and a prototype.

I'm not a fan of cantilevered designs, but maybe he built it stiff enough to work. The bubble is going to make working on the thing a PITA.

1) his own extruder design- does it work? It looks like it uses a cheapo brush-type DC motor. How long will that last?

2) the bed lifting mechanism- is it precise enough to work or will slop in the joints/flexibility cause problems?

3) his own controller design and code- does it work?

Based on my limited experience building a machine using off-the-shelf parts and controller, and playing with extruder design/construction, I'd say he has a few years worth of development work ahead of him. Maybe he's already tested the individual parts and got them working and now he's finishing the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm not a fan of cantilevered designs, but maybe he built it stiff enough to work. The bubble is going to make working on the thing a PITA.

1) his own extruder design- does it work? It looks like it uses a cheapo brush-type DC motor. How long will that last?

2) the bed lifting mechanism- is it precise enough to work or will slop in the joints/flexibility cause problems?

3) his own controller design and code- does it work?

Based on my limited experience building a machine using off-the-shelf parts and controller, and playing with extruder design/construction, I'd say he has a few years worth of development work ahead of him. Maybe he's already tested the individual parts and got them working and now he's finishing the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: EEVBlog rPrint Project January 24, 2016 04:28PM |

Registered: 11 years ago Posts: 1,277 |

|

Re: EEVBlog rPrint Project January 25, 2016 02:27AM |

Registered: 10 years ago Posts: 580 |

I watched it through. It's a big feat, I hope it works.

I hope he publishes the test results on all the things he re-invented, including his fast code libraries. That will be progress one way or another.

Other than that, he's learned a lot, good for him!

Edited 1 time(s). Last edit at 01/25/2016 02:27AM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I hope he publishes the test results on all the things he re-invented, including his fast code libraries. That will be progress one way or another.

Other than that, he's learned a lot, good for him!

Edited 1 time(s). Last edit at 01/25/2016 02:27AM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: EEVBlog rPrint Project January 25, 2016 06:42AM |

Registered: 11 years ago Posts: 1,277 |

Being the code was written right by using C++ he surely could but remember it has very little checking in it so is just made for these purposes. How will those routines fair in the real world? Not certain but should be okay just never know. I would love to get those fast routines on a 2560 but honestly I am not certain what the 2560 uses for atol, atoi, atof etc...?Quote

Paul Wanamaker

I watched it through. It's a big feat, I hope it works.

I hope he publishes the test results on all the things he re-invented, including his fast code libraries. That will be progress one way or another.

Other than that, he's learned a lot, good for him!

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: EEVBlog rPrint Project January 25, 2016 07:29AM |

Registered: 8 years ago Posts: 3,525 |

I wonder how his extruder compares to the flex3drive? This is also direct drive, very light and uses a standard (but stationary) nema 17 which makes it easy to use and familiar and no doubt reliable.

Is anyone familiar with the bed levelling system? Is there any merit in it?

Edited 1 time(s). Last edit at 01/25/2016 07:30AM by DjDemonD.

Is anyone familiar with the bed levelling system? Is there any merit in it?

Edited 1 time(s). Last edit at 01/25/2016 07:30AM by DjDemonD.

|

Re: EEVBlog rPrint Project January 25, 2016 07:38AM |

Registered: 11 years ago Posts: 5,780 |

It wasn't actually a leveling system- I didn't see any means of leveling it. The visible mechanism was the bed lifting mechanism. When he pushed on the bed you could see it move, so I'd say there isn't much merit in it, but maybe when it's loaded with just a print it will be OK. There are plenty of cheap printers around whose beds move when you push on them and they seem to be workable.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: EEVBlog rPrint Project January 25, 2016 07:48AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: EEVBlog rPrint Project January 25, 2016 07:51AM |

Registered: 8 years ago Posts: 1,671 |

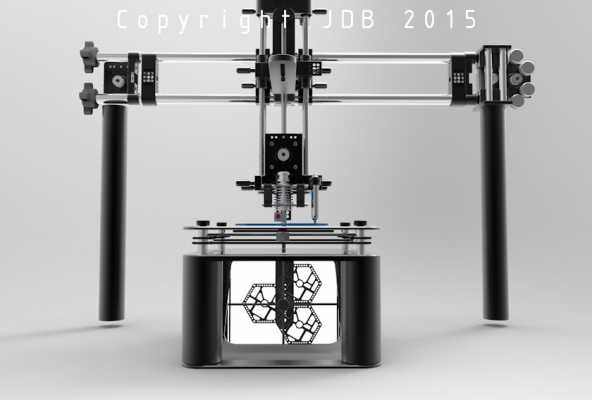

Interesting video, 11k prototype wow now I feel happy, though he has a few more extra's left over, $1400 in parts even at the 100 rate, I think mine was halve that at the retail rate, though for the price I paid for X&Y, linear rails is a future option for other builds, tiny dd extruder great, hopefully more will follow soon, new board & code, i'd like an all in one, but what if it blows, a lot of extra brain work in the coding I couldn't attempt, ramping & encoders cool, looking forward to updates to that, and a sarrus bed, which reminded me of the post from 6 months back which I hadn't realized had been updated,

which I would have driven with a leadscrew probably at one corner, maybe 2.

the 2 fat cylinders remind me of an old/early design I did a year or 2 ago, I knew I had these black 35mm tubes lying around and wanted to incorporate, they did get used in the current design, but not in the same way as in the earlier render.

this was a few designs in one render so dont get confused why the bed looks out of place or unfunctional

Edited 2 time(s). Last edit at 01/25/2016 08:36AM by MechaBits.

Quote

realthor

Hi MechaBits, the sarrus linkage has been tried before for lifting purposes in the 3d printing community (http://forums.reprap.org/read.php?185,450966) and several design variations have been proposed in the "Solutions for Wally" (a simplified version of the Compact Space Crank) or even this Delta Sarrus Linkage concept. But none of them address the further questions: how are they going to be moved, how are the dead spots addressed and what solution for reduction are they going to use and where will that fit in the 3d printer's volume.

- How would the sarrus linkage you propose be actuated? Would you put a motor at each elbow joint? That would be the only way to avoid dead spots/singularities.

- How would you gear down a stepper to obtain a resolution that is 3d printing acceptable?

- If you need a large red printing bed, you get to put the green pairs at the center of the red bed's sides, so you end up needing more than two green pairs, which will get it closer to my design above. This will also increase the need to put a motor at each green pair.

There has been one concept on this forum I really liked and that is Nic Stewart's Modified Sarrus Idea, which has a higher range of Z translation than the normal sarrus. The same thing I am trying to do with my design but the issue I am having is a simple way to avoid the ded points/ singularities in a simple manner. That I didn't find so far.

Thanks.

which I would have driven with a leadscrew probably at one corner, maybe 2.

the 2 fat cylinders remind me of an old/early design I did a year or 2 ago, I knew I had these black 35mm tubes lying around and wanted to incorporate, they did get used in the current design, but not in the same way as in the earlier render.

this was a few designs in one render so dont get confused why the bed looks out of place or unfunctional

Edited 2 time(s). Last edit at 01/25/2016 08:36AM by MechaBits.

|

Re: EEVBlog rPrint Project January 25, 2016 07:51AM |

Registered: 11 years ago Posts: 1,277 |

As most kickstarter ideas I doubt it but his fast ascii/string to math functions is what I really want to investigate. Saving clock cycles (if it works for our needs) is the biggest new thing on that printer imo.Quote

Dust

You guys are so negative..

it a prototype!

And I think it has lots of interesting ideas.

Is it practical?... far to soon to tell.

Negative? A realist is most certainly negative to a perpetual optimist so in your eyes we are.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: EEVBlog rPrint Project January 27, 2016 06:16AM |

Registered: 12 years ago Posts: 227 |

|

Re: EEVBlog rPrint Project January 27, 2016 12:15PM |

Registered: 10 years ago Posts: 580 |

He mentioned in the video that the extruder flow rate was tested off the machine - it looks like he is still doing unit testing.

It is not apparent that he has printed anything at all yet, so for everything he has done it's not possible to judge yet... Hopefully (now that he has finished his degree) he will still have the motivation and energy to complete the project. IMHO it would have been better for him to have waited a month or three, and show it working.

He still has an astounding amount of work to do to test this. This is a huge project for one person - he has re-invented everything in what he considers to be the perfect way (and most complicated). Just debugging the firmware will be a huge task. I think this is too much for one person.

He mentions that the microcontroller he chose doesn't have enough RAM for him to turn on all the features at once... This is something I hope all controller developers will pay attention to - plan for 3x feature growth, and not just choose a core based on brand loyalty or a couple $. There are some great processors out now (like the dual core Cortex M4/M0) with much more RAM and flash, and that will eliminate timing problems. I like the direction that Smoothie is taking with the Smoothieboard v2.

It is not apparent that he has printed anything at all yet, so for everything he has done it's not possible to judge yet... Hopefully (now that he has finished his degree) he will still have the motivation and energy to complete the project. IMHO it would have been better for him to have waited a month or three, and show it working.

He still has an astounding amount of work to do to test this. This is a huge project for one person - he has re-invented everything in what he considers to be the perfect way (and most complicated). Just debugging the firmware will be a huge task. I think this is too much for one person.

He mentions that the microcontroller he chose doesn't have enough RAM for him to turn on all the features at once... This is something I hope all controller developers will pay attention to - plan for 3x feature growth, and not just choose a core based on brand loyalty or a couple $. There are some great processors out now (like the dual core Cortex M4/M0) with much more RAM and flash, and that will eliminate timing problems. I like the direction that Smoothie is taking with the Smoothieboard v2.

|

Re: EEVBlog rPrint Project January 27, 2016 01:19PM |

Registered: 11 years ago Posts: 5,780 |

Quote

karabas

BTW what is the lightweghtest extruder now proven to work?

I don't know how much it weighs, but this is probably close. It is one of the dual extruders in a Stratasys FDM1600 printer. The focus is a little off, but the silver and black cylinders are the filament drive and pinch wheels. The silver wheel has a urethane(?) surface and the two wheels are at a fixed spacing so there is no adjustment for pinch wheel tension- just the deformation of the urethane surface to provide the push against the drive gear.

From the looks of this thing you'd think they were concerned about the size and moving mass, but nooooo... the extruder carriage with the heaters and other stuff is big and very heavy.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: EEVBlog rPrint Project January 27, 2016 01:45PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: EEVBlog rPrint Project January 27, 2016 02:03PM |

Registered: 11 years ago Posts: 5,780 |

They apparently don't care too much about mass or print speed. These machines are driven by NEMA-23 size motors and they print very slowly. I have an XY assembly from a different, more modern Stratasys machine with a NEMA-23 motor to drive the extruder carriage and the motor is mounted on the carriage!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.