Bed Adhesion Testing - Sitall and Wolfbite

Posted by Mutley3D

|

Bed Adhesion Testing - Sitall and Wolfbite January 11, 2015 08:14PM |

Registered: 9 years ago Posts: 425 |

Sitall Glass

They made the claim in a previous post that it was possible to print ABS onto this glass without any other substrate, no Kapton, no juice, no hairspray, glue etc. Hard to believe, so i thought i’d give it a go.

I was getting frustrated (although accepting) that i had to use substrates that caused the bottom of the print to become tarnished. Cloudy, imperfect.

I have been running the Sitall Glass now for about 3-4 weeks. It works well and “as advertised”. It took me a few goes and a little while to achieve reliability. It is sensitive to having the “ideal” zero Z height but once dialled in, it is good. It does also need to be clean clean (yes double clean). No greasy mit prints or other dirt.

PLA sticks very easily and very well indeed at 50-70Celsius, but then getting PLA to stick to plain glass is not that difficult, although it can be tricky.

ABS requires 110+ and the bed needs to be very, very level indeed. More so than if usually printing ABS with some form of substrate (ie Kapton and ABS Juice).

When the print is finished, the glass only needs to partially cool before the part releases itself, so you can heat up for the next print quicker.

The bottom of the print is perfectly flat with no lift or curl. The bottom has a glass like shine to it.

I have so far tested the following with success – Normal PLA, ABS, Nanotube ABS, PET (although the PET stuck too well so ill continue to use normal glass and glue stick for PET)

Ive tested Nylon and Acetal also on this glass and while they initially stick better than normal they do still warp fairly early into a print so Sitall is not good for these.

If your sitting on the fence with some spare cash and thinking about trying the Sitall Glass, id say its worth a try but your machine needs to be in good order with a level bed. And i don’t mean ABL level, i mean your bed needs to be flat level since it is easy to lift/drag the previous line of filament up if the nozzle catches it.

They will also cut to any custom size you require.

Ill post pics and more info soon. Im waiting on some WolfBite potion to arrive so will compare to this also and report back.

Edited 1 time(s). Last edit at 01/11/2015 08:39PM by Mutley3D.

They made the claim in a previous post that it was possible to print ABS onto this glass without any other substrate, no Kapton, no juice, no hairspray, glue etc. Hard to believe, so i thought i’d give it a go.

I was getting frustrated (although accepting) that i had to use substrates that caused the bottom of the print to become tarnished. Cloudy, imperfect.

I have been running the Sitall Glass now for about 3-4 weeks. It works well and “as advertised”. It took me a few goes and a little while to achieve reliability. It is sensitive to having the “ideal” zero Z height but once dialled in, it is good. It does also need to be clean clean (yes double clean). No greasy mit prints or other dirt.

PLA sticks very easily and very well indeed at 50-70Celsius, but then getting PLA to stick to plain glass is not that difficult, although it can be tricky.

ABS requires 110+ and the bed needs to be very, very level indeed. More so than if usually printing ABS with some form of substrate (ie Kapton and ABS Juice).

When the print is finished, the glass only needs to partially cool before the part releases itself, so you can heat up for the next print quicker.

The bottom of the print is perfectly flat with no lift or curl. The bottom has a glass like shine to it.

I have so far tested the following with success – Normal PLA, ABS, Nanotube ABS, PET (although the PET stuck too well so ill continue to use normal glass and glue stick for PET)

Ive tested Nylon and Acetal also on this glass and while they initially stick better than normal they do still warp fairly early into a print so Sitall is not good for these.

If your sitting on the fence with some spare cash and thinking about trying the Sitall Glass, id say its worth a try but your machine needs to be in good order with a level bed. And i don’t mean ABL level, i mean your bed needs to be flat level since it is easy to lift/drag the previous line of filament up if the nozzle catches it.

They will also cut to any custom size you require.

Ill post pics and more info soon. Im waiting on some WolfBite potion to arrive so will compare to this also and report back.

Edited 1 time(s). Last edit at 01/11/2015 08:39PM by Mutley3D.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite January 11, 2015 08:45PM |

Registered: 11 years ago Posts: 1,171 |

This sounds almost exactly like my experience with PEI plastic except that ABS does not pop off on it's own when cool though it's not too hard to remove. Most parts I can tap lightly with a small hammer and they come of easy while others (larger surface touching bed) I use a painters palette knife and still fairly easy.

There is one small issue with PEI that I discovered and that is that it's surface is not 100% level, it's very, very close but I notice a few spots that are high, like if I print with a very squished first layer it will skip in spots where it's a little high. If I had to guess, I would say the high spots are around 0.05mm and it's only in 2 spots about the size of a dime on my piece. With PLA I print with a higher nozzle (so the first layer is just touching) I don't see this issue at all, and using PLA most items I can just pull off by hand if I let the bed cool off.

Here is a video I did on PEI (before I noticed the high spots) [www.youtube.com]

There is one small issue with PEI that I discovered and that is that it's surface is not 100% level, it's very, very close but I notice a few spots that are high, like if I print with a very squished first layer it will skip in spots where it's a little high. If I had to guess, I would say the high spots are around 0.05mm and it's only in 2 spots about the size of a dime on my piece. With PLA I print with a higher nozzle (so the first layer is just touching) I don't see this issue at all, and using PLA most items I can just pull off by hand if I let the bed cool off.

Here is a video I did on PEI (before I noticed the high spots) [www.youtube.com]

|

Re: Bed Adhesion Testing - Sitall and Wolfbite January 17, 2015 06:45PM |

Registered: 10 years ago Posts: 8 |

|

Re: Bed Adhesion Testing - Sitall and Wolfbite January 18, 2015 01:40AM |

Registered: 11 years ago Posts: 1,171 |

|

Re: Bed Adhesion Testing - Sitall and Wolfbite February 02, 2015 03:10PM |

Registered: 9 years ago Posts: 5 |

Hi all !

My name is Dave, i live in Switzerland.

I have started printing in 3D about 3 months ago, with a Prusa i3 kit from china, self built.

Already from the beginning i have discovered the difficulties of getting a good adhesion, especially with ABS that is my favourite material.

I have started to print on the glass that has come with the machine kit (3mm standard glass), and off course it was a failure. Then i have tried with the black plastic that it is used to cover the cars windscreens, it is a PET tape. It has worked a little better, but only for small objects.

Then i have tried with abs slurry, this really has given me great results, but i have abandoned this thing because of the bad smell in my house and the fact that i had to clean the glass everytime, with other acetone... and other bad smell.

At the end, i have choose to use PLA with blue tape on the glass without heating, this was the only way i had to build something on my machine...

During my researches to a good solution, i have found the video's on Youtube of the member "Radusava". He has built is own prusa and he had the same issues, and he tried many ways to make the parts sticking on the bed. On one of the last videos i have know the existence of this "Sitall Glass".

I was suspicious when i have seen those videos... because it looks like simple glass, can't see the difference, but i have decided to try it because i was very worried by abs warping.

I have bought the glass on ebay, from the member mrblade777, from St.Petersburg. It has arrived after 2-3 weeks, because of the russian and swiss customs. Paid 25$ for the glass + 19$ for shipping.

I have tried to print the same day.

At first... i was disappointed... nothing was sticking on this glass... nor ABS or PLA... i have leveled my bed 4-5 times, checked and re-checked the distance from the nozzle to the bed with a depht meter. Tried to change the suggested temperature (110°C for abs) going from 90 to 120, nothing worked.

I have also cleaned with many pass of Acetone, nothing.

I was at the point of slam myself thinking that i have spent my money for a normal glass, when i have noticed one thing : on the videos that you see on the web, the first layer is going really slow ! And also on the website of unique3D it is indicated that the first layer should be printed at 20mm/s !!

I have tried 20mm/s, but it was already too fast for my machine, so i have slowed it again.

At 10mm/s , 110°C heated bed... it was a SUCCESS !! my abs was finally sticking to the bed !

The secret is : a leveled bed, a minimum of 110°C on the bed, and go slow !

I still had some little, but very little warping on the corners of square pieces, but only because the room where i have the machine is very ventilated and i always have problems on the right side of my parts. I have partially resolved building a shield with some cardboard.

The best thing to do when printing abs is to make a brim, like on radusava videos.

This is my review about this product SitGlass : it work, but you should follow the rules and try to slow the speed of the first, only the first layer.

best regards to all

Dave

My name is Dave, i live in Switzerland.

I have started printing in 3D about 3 months ago, with a Prusa i3 kit from china, self built.

Already from the beginning i have discovered the difficulties of getting a good adhesion, especially with ABS that is my favourite material.

I have started to print on the glass that has come with the machine kit (3mm standard glass), and off course it was a failure. Then i have tried with the black plastic that it is used to cover the cars windscreens, it is a PET tape. It has worked a little better, but only for small objects.

Then i have tried with abs slurry, this really has given me great results, but i have abandoned this thing because of the bad smell in my house and the fact that i had to clean the glass everytime, with other acetone... and other bad smell.

At the end, i have choose to use PLA with blue tape on the glass without heating, this was the only way i had to build something on my machine...

During my researches to a good solution, i have found the video's on Youtube of the member "Radusava". He has built is own prusa and he had the same issues, and he tried many ways to make the parts sticking on the bed. On one of the last videos i have know the existence of this "Sitall Glass".

I was suspicious when i have seen those videos... because it looks like simple glass, can't see the difference, but i have decided to try it because i was very worried by abs warping.

I have bought the glass on ebay, from the member mrblade777, from St.Petersburg. It has arrived after 2-3 weeks, because of the russian and swiss customs. Paid 25$ for the glass + 19$ for shipping.

I have tried to print the same day.

At first... i was disappointed... nothing was sticking on this glass... nor ABS or PLA... i have leveled my bed 4-5 times, checked and re-checked the distance from the nozzle to the bed with a depht meter. Tried to change the suggested temperature (110°C for abs) going from 90 to 120, nothing worked.

I have also cleaned with many pass of Acetone, nothing.

I was at the point of slam myself thinking that i have spent my money for a normal glass, when i have noticed one thing : on the videos that you see on the web, the first layer is going really slow ! And also on the website of unique3D it is indicated that the first layer should be printed at 20mm/s !!

I have tried 20mm/s, but it was already too fast for my machine, so i have slowed it again.

At 10mm/s , 110°C heated bed... it was a SUCCESS !! my abs was finally sticking to the bed !

The secret is : a leveled bed, a minimum of 110°C on the bed, and go slow !

I still had some little, but very little warping on the corners of square pieces, but only because the room where i have the machine is very ventilated and i always have problems on the right side of my parts. I have partially resolved building a shield with some cardboard.

The best thing to do when printing abs is to make a brim, like on radusava videos.

This is my review about this product SitGlass : it work, but you should follow the rules and try to slow the speed of the first, only the first layer.

best regards to all

Dave

|

Re: Bed Adhesion Testing - Sitall and Wolfbite March 05, 2015 05:04AM |

Registered: 10 years ago Posts: 8 |

|

Re: Bed Adhesion Testing - Sitall and Wolfbite March 19, 2015 03:20PM |

Registered: 9 years ago Posts: 26 |

Received my sitall glass 2 days ago an testing it now. THe results are pretty good!.

I finished building my printer 2 weeks ago, so I'm really new on this, but with the first level of the heatbed and taking in account that my bed barely gets to 95C. It's working great!

For long pieces I still have the wrapping problems, but it's great to print one piece after other without doing anything with the glass.

I'm doing the first layer at low speed (11mm/s)

I finished building my printer 2 weeks ago, so I'm really new on this, but with the first level of the heatbed and taking in account that my bed barely gets to 95C. It's working great!

For long pieces I still have the wrapping problems, but it's great to print one piece after other without doing anything with the glass.

I'm doing the first layer at low speed (11mm/s)

|

Re: Bed Adhesion Testing - Sitall and Wolfbite March 19, 2015 07:34PM |

Registered: 10 years ago Posts: 1,401 |

Sorry but I can't see the benefits of this glass, I might be just cheap or not printing 300 pieces a day.

For 8 dollars I get 8 cut to size pieces of glass from Lowe's 3 more dollars gives me 3 glue sticks.

I don't know how you guys are laying the glue? But I have never had a dull print due to the glue? Have never had a curl unless i'm printing with nylon, and since I have 8 glasses, I can leave the part cooling enough to come out simple, ABS detach by itself and PLA only need little force. Once the part comes off the glass I just spray some water and heat up the glass for the next print.

For 8 dollars I get 8 cut to size pieces of glass from Lowe's 3 more dollars gives me 3 glue sticks.

I don't know how you guys are laying the glue? But I have never had a dull print due to the glue? Have never had a curl unless i'm printing with nylon, and since I have 8 glasses, I can leave the part cooling enough to come out simple, ABS detach by itself and PLA only need little force. Once the part comes off the glass I just spray some water and heat up the glass for the next print.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite March 19, 2015 08:59PM |

Registered: 9 years ago Posts: 26 |

Well I think it´s only more confortable, I have not very much experience by now, but I don´t have to have 8 glasses, I don´t have to use glue , ABS juice, hairspray or tape (even if it´s cheap) and the best thing is that I don´t have to level my hotbed (not auto for now) when I change glasses several times because I really don´t touch the glass nor the bed, it´s allways clean and ready. I think it´s another improvement as many others that makes this hobby better everyday... ;-)

That´s all.

That´s all.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite March 20, 2015 05:53AM |

Registered: 10 years ago Posts: 82 |

I have been printing PLA on glass for the past year on my Prusa I3. I was using hair spray for adhesion but ran out and used ABS Goop instead. Surprised that it worked on PLA but it did so I kept on using it. Bought a new machine this year, a Wanhao Duplicator 4S (Makerbot Clone), and have been printing both ABS and PLA starting on glass. I want and need to print on a smooth, unlined surface, as the face of what I print matters so no tape solutions. I also like the idea of a wipe to clean rather than a retape.

My success rate printing on the glass bed that came with the Duplicator 4S has not been stellar. I get pretty good adhesion with ABS if I start from really clean glass with a very thin application of ABS Goop. And I mean really clean. With PLA I have just plain struggled to get good adhesion. Which I find strange given my experience over the past year with my Prusa I3.

While reading this and other forums I came across mention of the material FR-4. This is a fiberglass composite used for circuit boards. I bought a piece of it on eBay that measured 4x6 inches. This width is perfect but the length needed a trim. Stuff is not easy to cut.

Long story short. I absolutely love it. Both ABS and PLA adhere to it to the point of madness when the bed is hot. As in you will go mad trying to detach it. Then when the bed cools it can be easily pulled off...if in fact it does not slide off on its own. I have read that it loses this property after a while and I can not comment on this at this point...though I would say that if it does I will apply a little steel wool and then some fine emory paper and will be surprised if it does not come back.

My surface prep is to clean it with acetone. I am also using a thin film of ABS Goop as it seems to help though I have not done any science to prove this.

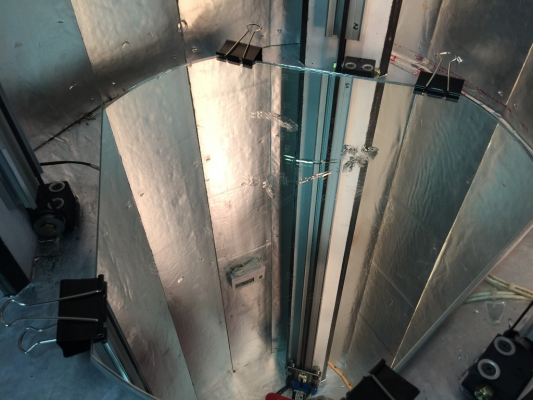

More herehttp://raspberrypirobot.blogspot.co.uk/2015/03/more-on-print-bonding-use-of-fr-4.html If you read this post you will also see the clips that I fabricated to hold FR-4 (or glass) to the build platform. I got tired of binder clips hitting the nozzle!

Wisar

My success rate printing on the glass bed that came with the Duplicator 4S has not been stellar. I get pretty good adhesion with ABS if I start from really clean glass with a very thin application of ABS Goop. And I mean really clean. With PLA I have just plain struggled to get good adhesion. Which I find strange given my experience over the past year with my Prusa I3.

While reading this and other forums I came across mention of the material FR-4. This is a fiberglass composite used for circuit boards. I bought a piece of it on eBay that measured 4x6 inches. This width is perfect but the length needed a trim. Stuff is not easy to cut.

Long story short. I absolutely love it. Both ABS and PLA adhere to it to the point of madness when the bed is hot. As in you will go mad trying to detach it. Then when the bed cools it can be easily pulled off...if in fact it does not slide off on its own. I have read that it loses this property after a while and I can not comment on this at this point...though I would say that if it does I will apply a little steel wool and then some fine emory paper and will be surprised if it does not come back.

My surface prep is to clean it with acetone. I am also using a thin film of ABS Goop as it seems to help though I have not done any science to prove this.

More here

Wisar

|

Re: Bed Adhesion Testing - Sitall and Wolfbite November 26, 2015 02:08AM |

Registered: 9 years ago Posts: 11 |

I got a piece of Sitall galss and all I can tell you is that it's a scam... PLA/ABS sticks better to glass than to this... I finally switched to PET surface on aluminium and it work the best!!!! Waste of money with Sitall....

Prusa i3 w/ Marlin firmware | Simplify3D | OctoPrint / Nautilus

Prusa i3 w/ Marlin firmware | Simplify3D | OctoPrint / Nautilus

|

Re: Bed Adhesion Testing - Sitall and Wolfbite November 26, 2015 03:45AM |

Registered: 9 years ago Posts: 26 |

I´m pretty sure you are not calibrating your printer in a good way.Quote

moonshine

I got a piece of Sitall galss and all I can tell you is that it's a scam... PLA/ABS sticks better to glass than to this... I finally switched to PET surface on aluminium and it work the best!!!! Waste of money with Sitall....

The bed has to bed setup properly, once you do that sitall glass does its job great. I´ve been using it for the past 6 months and it´s working like a charm.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite November 26, 2015 01:06PM |

Registered: 10 years ago Posts: 580 |

Mutley,

I was given a sample of Wolfbite by the manufacturer to try when I was exhibiting my printer at the World 3D Printer Expo early this year in Burbank.

I applied it exactly as directed on the custom cut mirror glass I use.

With ABS it made the print stick so well that every single time it pulled chunks of glass out of as the print was cooling. You would hear a "clink" sound and... oh no...

I spoke to someone from their company that was also exhibiting at a 3D printing/manufacturing conference in Riverside, and the woman told me that she thought I had an early batch, and it was too concentrated. She also said not to re-apply without cleaning the glass (it gets more concentrated if you don't)

So I cleaned the bed and tried it again, after diluting it 50%. Still lost chunks. Found that diluting it with 95% alcohol allowed it to spread the easiest and not bead up. Tried again at various lower percentages (I think 4 to 1 alcohol to Wolfbite) and it would still happen. Unacceptable. Switched to Aquanet.

Their tech support was extremely poor. I sent several emails, and after those were not answered I called and spoke to someone to leave a message for a tech to call me, and they still didn't contact me. I did finally get an email over a month later that was not in any way helpful. Exasperating.

So, if you use it, do be careful.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I was given a sample of Wolfbite by the manufacturer to try when I was exhibiting my printer at the World 3D Printer Expo early this year in Burbank.

I applied it exactly as directed on the custom cut mirror glass I use.

With ABS it made the print stick so well that every single time it pulled chunks of glass out of as the print was cooling. You would hear a "clink" sound and... oh no...

I spoke to someone from their company that was also exhibiting at a 3D printing/manufacturing conference in Riverside, and the woman told me that she thought I had an early batch, and it was too concentrated. She also said not to re-apply without cleaning the glass (it gets more concentrated if you don't)

So I cleaned the bed and tried it again, after diluting it 50%. Still lost chunks. Found that diluting it with 95% alcohol allowed it to spread the easiest and not bead up. Tried again at various lower percentages (I think 4 to 1 alcohol to Wolfbite) and it would still happen. Unacceptable. Switched to Aquanet.

Their tech support was extremely poor. I sent several emails, and after those were not answered I called and spoke to someone to leave a message for a tech to call me, and they still didn't contact me. I did finally get an email over a month later that was not in any way helpful. Exasperating.

So, if you use it, do be careful.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Bed Adhesion Testing - Sitall and Wolfbite November 29, 2015 12:48PM |

Registered: 12 years ago Posts: 1,450 |

I have been using Wolfbite for several months now and have had none of the problems that Paul Wannamaker had. The ABS print starts to loosen off a when the bed cools to about 80 degrees C and is completely loose by 40 degrees C. I do find that Wolfbite beads and does not take cleanly to glass when spread with the supplied sponge, but it does spread cleanly with a tissue pre-moistened with acetone.

I had previously discovered that some types of tissue, notably strengthened kitchen tissues, acetone dissolves some substance that inhibits proper adhesion of ABS even no Kapton film. ABS itself seems to poison the surface of a glass plate with what seems to be a second cousin of road film on a car windscreen - no solvent seems to clean it off but leaving it in bright sunlight on a shed roof does seem to re-invigorate it. Before noticing this poisoning effect I used print ABS on plain glass - no Wolfbite, ABS slurry or anything else.

Mike

I had previously discovered that some types of tissue, notably strengthened kitchen tissues, acetone dissolves some substance that inhibits proper adhesion of ABS even no Kapton film. ABS itself seems to poison the surface of a glass plate with what seems to be a second cousin of road film on a car windscreen - no solvent seems to clean it off but leaving it in bright sunlight on a shed roof does seem to re-invigorate it. Before noticing this poisoning effect I used print ABS on plain glass - no Wolfbite, ABS slurry or anything else.

Mike

|

Re: Bed Adhesion Testing - Sitall and Wolfbite November 29, 2015 01:13PM |

Registered: 9 years ago Posts: 425 |

I gave up on wolfbite a long time ago. I found it unreliable, too adhesive and breaking chunks from glass, even after diluting. I did get some success with it, not all doom and gloom, but at the cost of glass (on top of the cost of the WolfBite). I found the support unhelpful and slow. Latterly there are different WolfBite potions for different materials (ABS PLA). For the cost of a single bottle of wolfbite, i had myself a lifetime surface that worked with all common filament materials, self releasing prints, no material damage, and no potions required.

I also found Sitall very sensitive and not consistent - to the point i tried Wolfbite on the Sital - and yup you guessed right, it took a chunk out of the Sital

Edited 1 time(s). Last edit at 11/29/2015 01:15PM by Mutley3D.

I also found Sitall very sensitive and not consistent - to the point i tried Wolfbite on the Sital - and yup you guessed right, it took a chunk out of the Sital

Edited 1 time(s). Last edit at 11/29/2015 01:15PM by Mutley3D.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite November 29, 2015 01:28PM |

Registered: 10 years ago Posts: 29 |

|

Re: Bed Adhesion Testing - Sitall and Wolfbite December 14, 2015 04:26AM |

Registered: 12 years ago Posts: 1,450 |

Hmm, it seems I spoke too soon. I was printing a batch of small items when I found that they had ripped out chunks of glass as they cooled down. Photo of one of the chips below - 25mm by 8mm

The only difference in this print is that I was running the heated bed at 90o instead of the 110o that I usually use as one of the two parallel circuits on the heated bed had gone open circuit.

Mike

The only difference in this print is that I was running the heated bed at 90o instead of the 110o that I usually use as one of the two parallel circuits on the heated bed had gone open circuit.

Mike

|

Re: Bed Adhesion Testing - Sitall and Wolfbite December 20, 2015 03:29PM |

Registered: 10 years ago Posts: 35 |

I've been using bare sitall glass for abs (heated to 110-120) for the past year and a half - It works flawlessly with a level, clean, heated surface. I've tried all of the other magic potions - some good, some bad, but none stick as well as hot sitall, and no mess to clean up. The only time I clean the glass is when I change rolls or if the machine sits and gathers dust.

I don't use it for any other material - doesn't seem to work for PC, PLA, or nylon... but then again, it works so well with ABS that I don't even use PLA any more.

I don't use it for any other material - doesn't seem to work for PC, PLA, or nylon... but then again, it works so well with ABS that I don't even use PLA any more.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite December 20, 2015 03:32PM |

Registered: 10 years ago Posts: 35 |

Quote

pabloevaristo

I´m pretty sure you are not calibrating your printer in a good way.Quote

moonshine

I got a piece of Sitall galss and all I can tell you is that it's a scam... PLA/ABS sticks better to glass than to this... I finally switched to PET surface on aluminium and it work the best!!!! Waste of money with Sitall....

The bed has to bed setup properly, once you do that sitall glass does its job great. I´ve been using it for the past 6 months and it´s working like a charm.

there is nothing better than sitall glass for printing abs. if you are having trouble, i can assure you that it isn't the glass.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite December 25, 2015 07:37PM |

Registered: 11 years ago Posts: 471 |

Nothing works for everybody.

As a hardcore reductionist I know that sounds weird, but there are so many variables (filament types, slicer settings, air temp and humidity, strength of gravity, cosmic rays) that nothing works for everybody. The closest I have heard to that is PEI, but even that has a few bad reviews.

If something works for almost everyone, but not you, try stuff. But if it keeps not working, it's not black magic, it's just your filament or something.

As a hardcore reductionist I know that sounds weird, but there are so many variables (filament types, slicer settings, air temp and humidity, strength of gravity, cosmic rays) that nothing works for everybody. The closest I have heard to that is PEI, but even that has a few bad reviews.

If something works for almost everyone, but not you, try stuff. But if it keeps not working, it's not black magic, it's just your filament or something.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite December 26, 2015 11:31AM |

Registered: 9 years ago Posts: 425 |

I tested Sitall. It is a particular class of material. Whilst I got it working, over time I found it to be too sensitive. It is also limited in its material compatibility, ie only basic materials ABS PLA Flexibles. This set me on a quest to identify a good "all rounder". This quest lasted over 12 months, with dozens upon dozens of sample materials requested and purchased from various sources. I eventully whittled these down to 3 or 4 surface material candidates, including PEI.

I eventually identified one of these print surface materials (not PEI) as working with the widest range of filament materials including PLA ABS Nylons, Flexibles, PLA blends, ABS Blends, PET filaments, PolyCarb and pretty much everything else I threw at it. Most of these materials self released as the print bed cooled.

The only filament materials that did not show good results with this newly identified print surface were POM (known to be problematic due to its very high shrinkage) and Taulman Tritan (which printed very well on plain glass). The adhesion of ABS to this newly identified surface material was far more consistent, reliable and forgiving than Sitall, whilst having the benefit of working with all the aforementioned filament materials. I called this material PrintBite and there is a thread about it here [forums.reprap.org]

Edited 1 time(s). Last edit at 12/26/2015 11:38AM by Mutley3D.

I eventually identified one of these print surface materials (not PEI) as working with the widest range of filament materials including PLA ABS Nylons, Flexibles, PLA blends, ABS Blends, PET filaments, PolyCarb and pretty much everything else I threw at it. Most of these materials self released as the print bed cooled.

The only filament materials that did not show good results with this newly identified print surface were POM (known to be problematic due to its very high shrinkage) and Taulman Tritan (which printed very well on plain glass). The adhesion of ABS to this newly identified surface material was far more consistent, reliable and forgiving than Sitall, whilst having the benefit of working with all the aforementioned filament materials. I called this material PrintBite and there is a thread about it here [forums.reprap.org]

Edited 1 time(s). Last edit at 12/26/2015 11:38AM by Mutley3D.

|

Re: Bed Adhesion Testing - Sitall and Wolfbite January 29, 2016 07:01AM |

Registered: 10 years ago Posts: 35 |

So I ordered a sheet of Printbite for my Prusa i3, and have been experimenting with it for a couple of weeks. While I never had any issues with Sitall glass and ABS, I do like how much faster the Printbite heats up - glass is not a great heat conductor, so this makes sense. functionally, they are both more than adequate for ABS.

I have not had much luck getting polycarbonate to stick to the printbite though. Mutley - can you tell me how much experimenting you've done with PC before your determination that it works with the Printbite? I am using Gizmodorks PC, 130C bed, a 50-55C heated chamber, and bed levelling. I'm running about 20mm/s and the parts all start to pull away from the bed after about 5-20 layers. Right now I am using Wolfbite to enhance the adhesion which works extremely well, but I'd like to get away from an additional coating - especially a consumable one.

Don

I have not had much luck getting polycarbonate to stick to the printbite though. Mutley - can you tell me how much experimenting you've done with PC before your determination that it works with the Printbite? I am using Gizmodorks PC, 130C bed, a 50-55C heated chamber, and bed levelling. I'm running about 20mm/s and the parts all start to pull away from the bed after about 5-20 layers. Right now I am using Wolfbite to enhance the adhesion which works extremely well, but I'd like to get away from an additional coating - especially a consumable one.

Don

|

Re: Bed Adhesion Testing - Sitall and Wolfbite January 31, 2016 02:20AM |

Registered: 9 years ago Posts: 425 |

Quote

dtwrv6

So I ordered a sheet of Printbite for my Prusa i3, and have been experimenting with it for a couple of weeks. While I never had any issues with Sitall glass and ABS, I do like how much faster the Printbite heats up - glass is not a great heat conductor, so this makes sense. functionally, they are both more than adequate for ABS.

I have not had much luck getting polycarbonate to stick to the printbite though. Mutley - can you tell me how much experimenting you've done with PC before your determination that it works with the Printbite? I am using Gizmodorks PC, 130C bed, a 50-55C heated chamber, and bed levelling. I'm running about 20mm/s and the parts all start to pull away from the bed after about 5-20 layers. Right now I am using Wolfbite to enhance the adhesion which works extremely well, but I'd like to get away from an additional coating - especially a consumable one.

Don

Hi Don,

Ive done a fair bit of Polymaker PC, and i know of someone else that has been running with another brand of PC but dont know which so ill find out and confirm. In the meanwhile, bed @120, nozzle @ 270. OF course these are my own print temp readings so yours may differ slightly, but hot nozzle is important. Also make sure the surface is clean. I run with 40mms bottom layer speed.

HTH

J

Sorry, only registered users may post in this forum.