Question about linear bushings

Posted by icefire

|

Question about linear bushings February 14, 2016 08:41AM |

Registered: 8 years ago Posts: 168 |

So I've been printing with a self-sourced Mendelmax 2.0-based for a few months (see signature). Currently I am about the change the two threaded rods for the Z axis which got me thinking about the quality of my smooth rod linear bushings. Since I have already taken apart the Z axis now seems a good time to upgrade the linear bushings as well.

The original Mendelmax 2.0 BOM suggests 10mm bronze bearings from SDP. When I couldn't find the exact same brand in Europe I settled for a similar solution from IGUS which actually works fine.

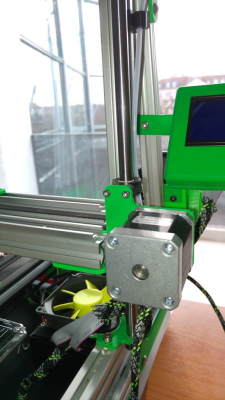

So the mounted igus spherical bearing looks like this:

However, sometimes the whole X carriage jams and doesn't slide down on its own. A probable cause is the uneven load distribution because the X carriage motor is on the one end and there is nothing on the other end. Using a counter weight on the other end of the X carriage helps a lot but I am looking for a more elegant solution.

So I am thinking of using a set of 4 LM10UU linear bearings instead of the original spherical bearings setup. The only thing that troubles me is that there will be no axial adjustment. So what do you think? I wouldn't want the fourth linear bearing to jam because the system is over-defined. On the other hand, I think that a LM10UU will provide much better linear motion.

Any thoughts?

Thank you!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

The original Mendelmax 2.0 BOM suggests 10mm bronze bearings from SDP. When I couldn't find the exact same brand in Europe I settled for a similar solution from IGUS which actually works fine.

So the mounted igus spherical bearing looks like this:

However, sometimes the whole X carriage jams and doesn't slide down on its own. A probable cause is the uneven load distribution because the X carriage motor is on the one end and there is nothing on the other end. Using a counter weight on the other end of the X carriage helps a lot but I am looking for a more elegant solution.

So I am thinking of using a set of 4 LM10UU linear bearings instead of the original spherical bearings setup. The only thing that troubles me is that there will be no axial adjustment. So what do you think? I wouldn't want the fourth linear bearing to jam because the system is over-defined. On the other hand, I think that a LM10UU will provide much better linear motion.

Any thoughts?

Thank you!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Question about linear bushings February 14, 2016 09:12AM |

Registered: 12 years ago Posts: 2,470 |

Ball bearings are (much) less prone to locking than bushings, this should not be an issue for you.

Don't expect the bearings to be better regarding print quality or noise though.

I am a bit surprised that the spherical bearings lock, they shouldn't since locking usually only occurs if you have only fixed bushings or very extreme forces.

Maybe there is another issue but the bushings?

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Don't expect the bearings to be better regarding print quality or noise though.

I am a bit surprised that the spherical bearings lock, they shouldn't since locking usually only occurs if you have only fixed bushings or very extreme forces.

Maybe there is another issue but the bushings?

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Question about linear bushings February 14, 2016 10:11AM |

Registered: 10 years ago Posts: 466 |

I'm not sure I agree with the ball bearings being less prone to locking, maybe high quality ones, but the cheap ones are crap.

By the looks for your design, I would sat the the bushings are too short, allowing your x axis to tilt easily. if you had longer bushing, or a pair on each side, it would be much more stable.

By the looks for your design, I would sat the the bushings are too short, allowing your x axis to tilt easily. if you had longer bushing, or a pair on each side, it would be much more stable.

|

Re: Question about linear bushings February 14, 2016 11:40AM |

Registered: 11 years ago Posts: 5,780 |

I used to use bronze bushings on the X and Y axes of my printer and they chattered and generally misbehaved so I swapped them out for the Thomson ball bushings that were much quieter and smoother, and less prone to jamming. In the Z axis, ball bushings aren't going to make any noise at all. I eventually replaced the X and Y axis round rails and ball bushings with linear guides, something I would have started with had I known they existed when I started building my printer. I am using some industrial linear positioners in the Z axis, with fully supported round rails, so I won't be replacing them any time soon.

The Thomson Super 8 ball bushings (no, not 8mm, 1/2") have races that tilt a little to allow for slightly misaligned guide rails. Thomson's bearing blocks have a screw clamp to adjust "fitment". I used their design as the basis for a 3D printable part that works the same way (https://www.youmagine.com/designs/an-even-better-pillow-block-for-thomson-super-8-ball-bushings). They probably make something like it at 10mm, but unless you find a surplus source, they are going to be expensive. I was buying the 1/2" bushings for $5-10 each via ebay.

I recently bought 3 linear guides that are over 600mm long on ebay, two used, and one unused, for average of $34 each, shipped. I see deals like that on ebay all the time- you just have to pick through the 10 pages or so of "linear guide" search results to find them. You won''t find better bearings, and the rails simplify construction considerably.

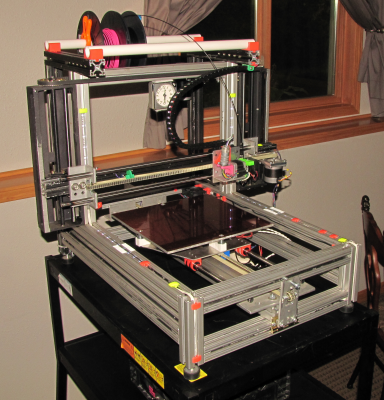

Compare my old X axis here:

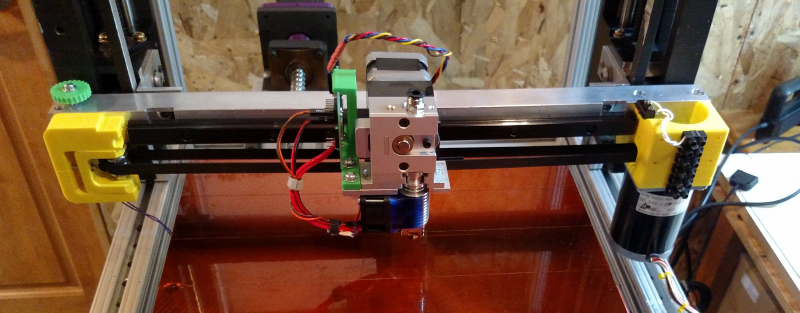

to the newer X axis here:

It's a lot easier, cleaner looking, and much better performing- there's no guide rail flex, and no slop in the bearings. Print quality has gone from very good to extremely good.

I now have linear guides in the X and Y axes. I'm looking at making a coreXY machine that will use linear guides in X, Y, and Z.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The Thomson Super 8 ball bushings (no, not 8mm, 1/2") have races that tilt a little to allow for slightly misaligned guide rails. Thomson's bearing blocks have a screw clamp to adjust "fitment". I used their design as the basis for a 3D printable part that works the same way (https://www.youmagine.com/designs/an-even-better-pillow-block-for-thomson-super-8-ball-bushings). They probably make something like it at 10mm, but unless you find a surplus source, they are going to be expensive. I was buying the 1/2" bushings for $5-10 each via ebay.

I recently bought 3 linear guides that are over 600mm long on ebay, two used, and one unused, for average of $34 each, shipped. I see deals like that on ebay all the time- you just have to pick through the 10 pages or so of "linear guide" search results to find them. You won''t find better bearings, and the rails simplify construction considerably.

Compare my old X axis here:

to the newer X axis here:

It's a lot easier, cleaner looking, and much better performing- there's no guide rail flex, and no slop in the bearings. Print quality has gone from very good to extremely good.

I now have linear guides in the X and Y axes. I'm looking at making a coreXY machine that will use linear guides in X, Y, and Z.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Question about linear bushings February 15, 2016 12:26PM |

Registered: 8 years ago Posts: 168 |

Wow, the_digital_dentist does it right

I am currently looking for a cheaper alternative so probably I'm going to go with LM10UU for now. Seems like a good first step. I have also planned to upgrade the X axis someday - with something similar to your setup. It looks awesome and the precision should become even better.

As far as my Z setup is concerned - I guess the problem is the width of the bushings. There are probably simply too small and they tend to lock. This is why I'd like to try out LM10UU - they are affordable and long enough. I am definitely going to write again once I've installed them.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

I am currently looking for a cheaper alternative so probably I'm going to go with LM10UU for now. Seems like a good first step. I have also planned to upgrade the X axis someday - with something similar to your setup. It looks awesome and the precision should become even better.

As far as my Z setup is concerned - I guess the problem is the width of the bushings. There are probably simply too small and they tend to lock. This is why I'd like to try out LM10UU - they are affordable and long enough. I am definitely going to write again once I've installed them.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Question about linear bushings February 15, 2016 06:47PM |

Registered: 8 years ago Posts: 1,671 |

is it cash or weight that you want to save, go for the 12's and be done with it.

Though my first experience of bushings didnt turn out too good, they are not as smooth as the 12mm bearings, hard to get them moving, they are quite tight, only short and not much wall thickness the not good for clamping, the sort & the long 12's are nice, dont suffer the issues I had with the LM8UU's

Edited 1 time(s). Last edit at 02/15/2016 06:51PM by MechaBits.

Though my first experience of bushings didnt turn out too good, they are not as smooth as the 12mm bearings, hard to get them moving, they are quite tight, only short and not much wall thickness the not good for clamping, the sort & the long 12's are nice, dont suffer the issues I had with the LM8UU's

Edited 1 time(s). Last edit at 02/15/2016 06:51PM by MechaBits.

Sorry, only registered users may post in this forum.