Success with new extruder

Posted by JamesK

|

Success with new extruder February 20, 2016 05:28PM |

Registered: 9 years ago Posts: 1,873 |

I finally got my geared extruder working well with 3mm pla. I set off down the 3mm rabbit hole a few weeks back as a result of filaments.ca having a clearance sale. I started with the flexible filaments TPU and TPE and got those going, but my MK8 style extruder couldn't cope with ABS and really coulldn't cope with with PLA. So I decided to have a go at a simple geared extruder. It probably would have made more sense just to print a Greg/Wade, but that would also have mean't a new carriage as well as a new hot end, so I wanted to try doing my own thing. It's taken a couple of goes - pla is a real pig for heat creep, but I finally got successful prints today

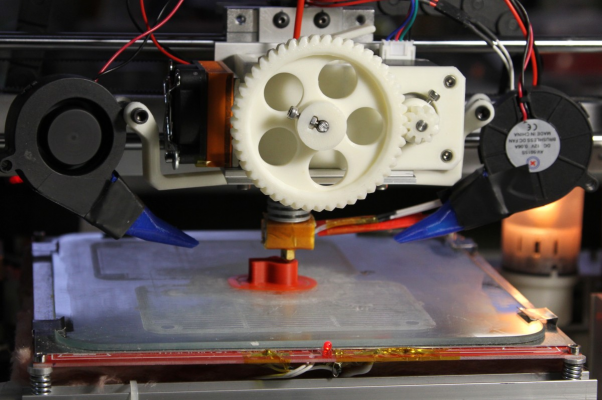

Here's the new extruder doing it's first ABS print

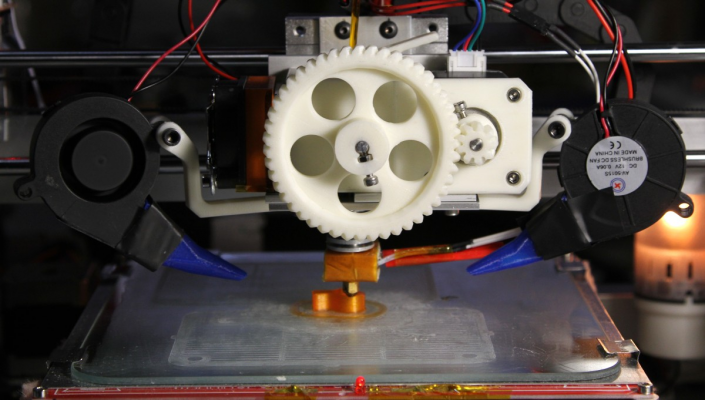

And at last, a PLA print that made it all the way to the end

The gears are supposed to be the other way around on the axles, but the 3mm set screws are on order and there isn't enough clearance to have the normal screws on the other side. Print quality isn't quite there yet, but that's probably because of the temporary shaft between the big and hobbed gears. It's undersized, so the hobbed gear is noticeably off centre. I was intending to wait until the set screws arrive before machining the final drive shaft, but I might get impatient and just make an over long version that I can cut down later.

All good fun!

Edited 1 time(s). Last edit at 02/20/2016 05:40PM by JamesK.

Here's the new extruder doing it's first ABS print

And at last, a PLA print that made it all the way to the end

The gears are supposed to be the other way around on the axles, but the 3mm set screws are on order and there isn't enough clearance to have the normal screws on the other side. Print quality isn't quite there yet, but that's probably because of the temporary shaft between the big and hobbed gears. It's undersized, so the hobbed gear is noticeably off centre. I was intending to wait until the set screws arrive before machining the final drive shaft, but I might get impatient and just make an over long version that I can cut down later.

All good fun!

Edited 1 time(s). Last edit at 02/20/2016 05:40PM by JamesK.

|

Re: Success with new extruder February 20, 2016 10:14PM |

Registered: 8 years ago Posts: 1,671 |

You got me worried now, I've heard the Mk8's are good for nothing, I was hoping to get lucky, I made a little mod to tighten it all up,

and have another hobbed type pulley to add if the stock one doesn't cut it(or slices the filament up)

I don't have as many fans or any that are ducted, and was hoping PLA would be a doddle

without heatbed at first...Halogen heater at the ready just incase.

So did you print the gears or buy them?

and have another hobbed type pulley to add if the stock one doesn't cut it(or slices the filament up)

I don't have as many fans or any that are ducted, and was hoping PLA would be a doddle

without heatbed at first...Halogen heater at the ready just incase.

So did you print the gears or buy them?

|

Re: Success with new extruder February 20, 2016 10:45PM |

Registered: 9 years ago Posts: 1,873 |

I've got two MK8s and they both work great for 1.75mm filament, it's just the 3mm stuff that gets more difficult - in lots of ways! The first time I opened a roll of 3mm pla was a bit of a shock, compared to 1.75mm filaments the 3mm is a real handful to set up. It never seems to go where you want it, and it's always on the verge of throwing loops off the spool. Quite the bundle of fun.

The gears I printed in abs - maybe not the best choice from what I've heard, so I might do another set in nylon. I've also got some short gt2 belts on order so that I can compare the gears with a belt and pulleys version.

The fans are really useful for controlling heat build up, particularly with pla. I'm surprised that they don't come as standard with more kits as pla is the obvious starter filament.

The gears I printed in abs - maybe not the best choice from what I've heard, so I might do another set in nylon. I've also got some short gt2 belts on order so that I can compare the gears with a belt and pulleys version.

The fans are really useful for controlling heat build up, particularly with pla. I'm surprised that they don't come as standard with more kits as pla is the obvious starter filament.

|

Re: Success with new extruder February 20, 2016 11:05PM |

Registered: 8 years ago Posts: 1,671 |

That's good I'm on 1.75 so might get away with it, but will be using it bowden style at first. I have a roll but dont want to open to test just yet, as if it all goes tits up, it might be sat there for a while before next attempt while waiting for other bits to come, and I dont want it taking on moisture, that and the fact I dont want get printer all gunked up just yet. A seasoned pro would have this thing printing in a day, i'll be lucky if I start this month.

|

Re: Success with new extruder February 20, 2016 11:09PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Success with new extruder February 20, 2016 11:51PM |

Registered: 8 years ago Posts: 1,671 |

Yeah almost, I spent at least a year(on & off, but mainly on) designing, and then started buying bits about June last year, almost enough bits left over for second alternate design, and I'm tempted to just build that, but having first one working would be a big help on the second. The crazy thing is I'm already wanting to try an alternate arrangement of the first one, but to tear down what I have, sacrilege, just for a few maybe minor advantages, if I rotate the printer 90 degrees relative to my base frame I get extra support for top of Z axis, and the ability to have a longer bed 400x215 ish, but then more problems to tackle, I really didnt want to be in a continuous tinkering mode, the mechanical side is far more enjoyable at the moment than the next round of rom tweaking & failed prints.

So do you think you want to be on 3mm for a while, or do you have a quick change, to get you back to 1.75 if needed?

or do you have another printer setup?

Edited 2 time(s). Last edit at 02/21/2016 07:35AM by MechaBits.

So do you think you want to be on 3mm for a while, or do you have a quick change, to get you back to 1.75 if needed?

or do you have another printer setup?

Edited 2 time(s). Last edit at 02/21/2016 07:35AM by MechaBits.

|

Re: Success with new extruder February 21, 2016 07:36AM |

Registered: 9 years ago Posts: 1,873 |

Quote

almost enough bits left over for second alternate design, and I'm tempted to just build that, but having first one working would be a big help on the second. The crazy thing is I'm already wanting to try an alternate arrangement of the first one,

You nailed me on both. I have quite a few spares, and ideas for changing the X axis, and lengthening Y. I keep going back and forth between changing the current one or just buying a couple of extra bits to make a second printer. And then it occurred to me that an enclosed delta would be great for high temperature plastics as you can keep all the electronics and motors out of the build volume with very little extra work. So that's a third printer in the back of my mind. Does it never end !??

|

Re: Success with new extruder February 21, 2016 07:56AM |

Registered: 8 years ago Posts: 1,671 |

I'm not sure it does, doesn't matter what they are made out of, they are self replicating...breeding, evolving, hopefully exponentially...

Whovever started the phrase of the machine's taking over, wasn't wrong, and with the delay in receiving parts & spares I'm constantly wondering what do I need next.

Edited 1 time(s). Last edit at 02/21/2016 08:06AM by MechaBits.

Whovever started the phrase of the machine's taking over, wasn't wrong, and with the delay in receiving parts & spares I'm constantly wondering what do I need next.

Edited 1 time(s). Last edit at 02/21/2016 08:06AM by MechaBits.

Sorry, only registered users may post in this forum.