Optimum PolyCarbonate Print settings

Posted by robla85g

|

Optimum PolyCarbonate Print settings March 04, 2016 02:47PM |

Registered: 8 years ago Posts: 3 |

Hello,

I have successfully printed PLA and ABS with very good and clean results on my Ormerod 2 and am now trying to use Polycarbonate. I have the right hot end fitted to cope with the heat (E3D v6 all metal with a thermocouple fitted) and ive got past the setting in the firmware that trips the extruder past 300 degrees so i can print well above this temperature.

There is a 0.25mm nozzle fitted and i measured the diameter of the filament at 1.81mm however the results just arnt coming. I am aware that polycarbonate is a particularly fussy plastic to get right and was hoping some of you may have some recommendations on optimum settings that should be used or some examples of parts that have been printed using this material?

cheers

robla85g

I have successfully printed PLA and ABS with very good and clean results on my Ormerod 2 and am now trying to use Polycarbonate. I have the right hot end fitted to cope with the heat (E3D v6 all metal with a thermocouple fitted) and ive got past the setting in the firmware that trips the extruder past 300 degrees so i can print well above this temperature.

There is a 0.25mm nozzle fitted and i measured the diameter of the filament at 1.81mm however the results just arnt coming. I am aware that polycarbonate is a particularly fussy plastic to get right and was hoping some of you may have some recommendations on optimum settings that should be used or some examples of parts that have been printed using this material?

cheers

robla85g

|

Re: Optimum PolyCarbonate Print settings March 04, 2016 03:32PM |

Registered: 12 years ago Posts: 2,470 |

What type of PC are you printing? I am currently using the new ePC from esun. It prints beautifully @255°C on a 110°C heated aluminum bed prepared with 3dlac. I am using my PEEK/PTFE Merlin hotend with an 0.3mm nozzle.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Optimum PolyCarbonate Print settings March 05, 2016 07:02AM |

Registered: 8 years ago Posts: 3 |

hi thanks for the response, i cant remember exactly where i bought the filament but it could have been from Etsy.

Im currently trying to print onto an aluminium heated bed with kapton tape (standard supplied with the Ormerod 2). Thats interesting you say such a low temperature, ive been trying significantly higher than that so i'll give it a try. do you have any recommendations on how to make it stick to he bed because i find my prints lift off too?

Im currently trying to print onto an aluminium heated bed with kapton tape (standard supplied with the Ormerod 2). Thats interesting you say such a low temperature, ive been trying significantly higher than that so i'll give it a try. do you have any recommendations on how to make it stick to he bed because i find my prints lift off too?

|

Re: Optimum PolyCarbonate Print settings March 05, 2016 10:17AM |

Registered: 12 years ago Posts: 2,470 |

As i said, for me 3Dlac is doing the trick directly on the aluminum plate.

I expect to need a heated enclosure for bigger parts since i notice warping at lengthes of 7+cm.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

I expect to need a heated enclosure for bigger parts since i notice warping at lengthes of 7+cm.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Optimum PolyCarbonate Print settings March 05, 2016 07:41PM |

Registered: 9 years ago Posts: 40 |

Quote

Srek

What type of PC are you printing? I am currently using the new ePC from esun. It prints beautifully @255°C on a 110°C heated aluminum bed prepared with 3dlac. I am using my PEEK/PTFE Merlin hotend with an 0.3mm nozzle.

I'd love to see some photos of your prints.

p.s. I've been contemplating getting some of Polymaker's new PC-Plus polycarbonate. I'm not sure I have a lot of need for it (I've hardly used the PolyMax that I got from their Kickstarter campaign), but I guess I'm a bit of a new filament material junkie.

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 04:35AM |

Registered: 12 years ago Posts: 2,470 |

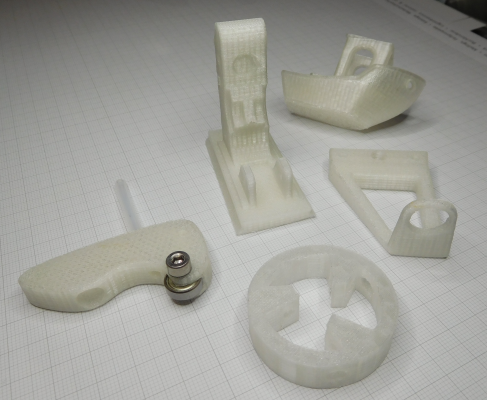

Here are some parts i did

I consider the front most part a failure, but only because i choose perimeter thickness 1 and it wasn't up to the forces i needed. It was still stronger than a correctly printed ABS part

The part on the left is an idler for my slot extruder.

On the right a lens holder and tripod mount for my Thermal Camera.

In the middle an extruder body for my slot extruder (this would have needed a heated chamber to be precise enough, it has a slight warp at the bootom)

In the back a failed benchy.

This is one of the main reasons i tried PC at all, it's a fan duct that is so close to the heating element that i had ABS gone very soft. The PC holds up to the heat.

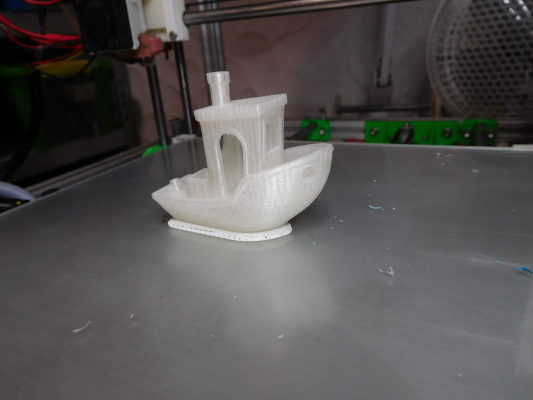

Last not least a complete benchy, stronger than any i printed before.

I don't have any pictures of a small boat i printed in vase mode, it printed as nice as PLA, but for larger parts again a heated chamber seems neccesary.

Over all i found ePC very easy to print, i just wish esun had more than one color on offer

Edited 1 time(s). Last edit at 03/06/2016 04:36AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

I consider the front most part a failure, but only because i choose perimeter thickness 1 and it wasn't up to the forces i needed. It was still stronger than a correctly printed ABS part

The part on the left is an idler for my slot extruder.

On the right a lens holder and tripod mount for my Thermal Camera.

In the middle an extruder body for my slot extruder (this would have needed a heated chamber to be precise enough, it has a slight warp at the bootom)

In the back a failed benchy.

This is one of the main reasons i tried PC at all, it's a fan duct that is so close to the heating element that i had ABS gone very soft. The PC holds up to the heat.

Last not least a complete benchy, stronger than any i printed before.

I don't have any pictures of a small boat i printed in vase mode, it printed as nice as PLA, but for larger parts again a heated chamber seems neccesary.

Over all i found ePC very easy to print, i just wish esun had more than one color on offer

Edited 1 time(s). Last edit at 03/06/2016 04:36AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 08:03AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 09:05AM |

Registered: 12 years ago Posts: 2,470 |

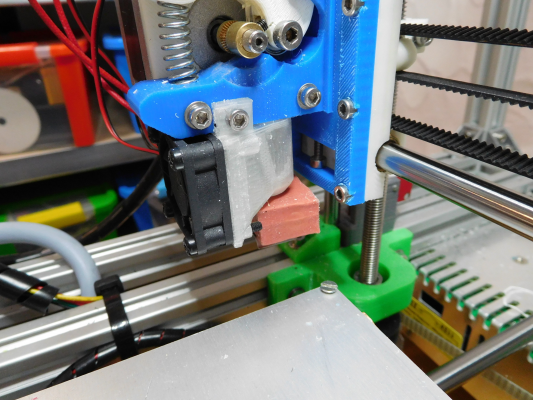

Yes, it's a dovetail with an adjustment screw at the bottom.

I created it for my dual X setup because otherwise the Z adjustment of two independent printheads is a nightmare. It is also working nicely so far for switching printheads.

It only takes seconds to switch between printheads with different nozzle diameters or cooling systems.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

I created it for my dual X setup because otherwise the Z adjustment of two independent printheads is a nightmare. It is also working nicely so far for switching printheads.

It only takes seconds to switch between printheads with different nozzle diameters or cooling systems.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 09:35AM |

Registered: 8 years ago Posts: 3 |

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 10:22AM |

Registered: 12 years ago Posts: 2,470 |

They were all printed with 0.15mm layerheight and a base printing speed of 130mm/s

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 10:41AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Optimum PolyCarbonate Print settings March 06, 2016 10:50AM |

Registered: 12 years ago Posts: 2,470 |

As i said, that is the base print speed. Most of the time the actual printing speed is lower. The outer perimeter for example only prints at 40mm/s.Quote

JamesK

130mm/s?? Wow, that's way faster than I've ever been able to get a decent print at!

I am pretty sure though i can go higer, this was just the speed i started with and since it just worked i haven't tried yet to go faster. I am not obsessed with maximum speed

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Optimum PolyCarbonate Print settings March 07, 2016 12:39AM |

Registered: 9 years ago Posts: 40 |

Sorry, only registered users may post in this forum.