Locally strengthening areas

Posted by Lykle

|

Locally strengthening areas February 23, 2017 02:48AM |

Registered: 8 years ago Posts: 312 |

For me, this is a new idea, but probably not for you guys.

Working on a clamp system for a quick release hot end, I realised that I wanted the area around the clamping bit to be strong and hefty while the rest can be fairly light.

Adding layers to the top and sides is one way, but then that is all over the part, not locally.

So I could make the part in 2 pieces, one piece with light infill and only 3 layers all around and a heavy piece with almost solid infill and 6 layers all around, for instance. Then glue the heavy piece into the light piece and done.

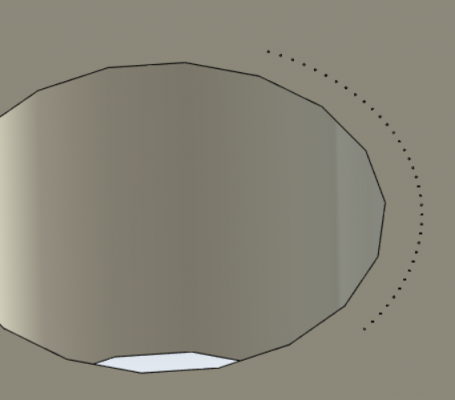

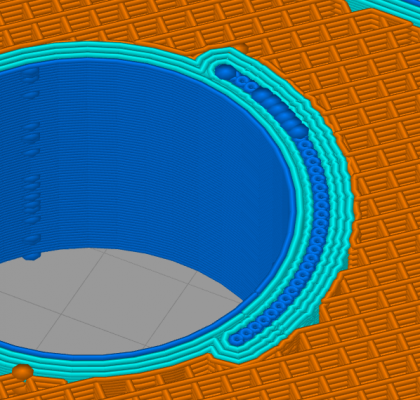

But I realised there is a way to modify the number of side layers around geometry. Add geometry.

Adding a row of micro-holes around a larger hole will make the slicer add layers around the micro holes. Spacing them correctly you get additional layers around the larger hole.

You can even vary the length of the holes so that the extra layers will taper off, the deeper you get. Or place a couple of rows of micro-holes around the larger one. Or place a straight line of micro-holes along a part to create a strong central "spine" inside the piece.

Any other ideas out there to modify and increase strength where needed?

Working on a clamp system for a quick release hot end, I realised that I wanted the area around the clamping bit to be strong and hefty while the rest can be fairly light.

Adding layers to the top and sides is one way, but then that is all over the part, not locally.

So I could make the part in 2 pieces, one piece with light infill and only 3 layers all around and a heavy piece with almost solid infill and 6 layers all around, for instance. Then glue the heavy piece into the light piece and done.

But I realised there is a way to modify the number of side layers around geometry. Add geometry.

Adding a row of micro-holes around a larger hole will make the slicer add layers around the micro holes. Spacing them correctly you get additional layers around the larger hole.

You can even vary the length of the holes so that the extra layers will taper off, the deeper you get. Or place a couple of rows of micro-holes around the larger one. Or place a straight line of micro-holes along a part to create a strong central "spine" inside the piece.

Any other ideas out there to modify and increase strength where needed?

|

Re: Locally strengthening areas February 23, 2017 05:00AM |

Registered: 12 years ago Posts: 1,450 |

Another possibility is to have an area of 100% infill. I think that Slic3r will do this but I have never tried it myself. ref at [slic3r.org]

Mike

Mike

|

Re: Locally strengthening areas February 23, 2017 05:24AM |

Registered: 8 years ago Posts: 3,525 |

I use 100% infill for functional parts which is a great test of extrusion tuning, after layer 5-6 its either printing perfectly or it isn't and it's quite obvious.

It's a bit fiddly in slic3r you load and overlay a modifier which is a second part which can have different settings such as 100% infill.

Ill try the idea with the extra holes though more targeted approach than just turning perimeters up to 5 or 6.

Edited 2 time(s). Last edit at 02/23/2017 05:28AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

It's a bit fiddly in slic3r you load and overlay a modifier which is a second part which can have different settings such as 100% infill.

Ill try the idea with the extra holes though more targeted approach than just turning perimeters up to 5 or 6.

Edited 2 time(s). Last edit at 02/23/2017 05:28AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Locally strengthening areas February 23, 2017 07:19AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Locally strengthening areas February 24, 2017 02:00AM |

Registered: 8 years ago Posts: 312 |

Also, I like the fact that I can do it all in design, not afterwards in a slicer.

But, yes I had forgotten about modifiers in Slic3r. Will look into it a bit more.

If the modifier can be a fully detailed 3d form, then it is a better solution, but not one that will work in S3D.

There is always more ways than one to crack an egg.

Lykle

But, yes I had forgotten about modifiers in Slic3r. Will look into it a bit more.

If the modifier can be a fully detailed 3d form, then it is a better solution, but not one that will work in S3D.

There is always more ways than one to crack an egg.

Lykle

|

Re: Locally strengthening areas February 26, 2017 05:37AM |

Registered: 9 years ago Posts: 1,873 |

I've seen that trick done with very thin slits, but using very small holes seems like a new and very flexible approach to the idea. It would be nice if some of the CAD packages could add features to make it easier to put micro-holes into a model, perhaps along a path with a given spacing.

Slic3rs modifiers are very useful, but I still find it a pain to setup. You end up splitting the design process between the CAD models and the slic3r config, which is messy, and the UI for adjusting the settings in slic3r isn't the greatest. Is there any way to save a complex multi-model plus modifiers configuration in slic3r? The few times I've used it I've ended up recreating the settings from scratch every time, which is lousy for iterative prototyping.

Slic3rs modifiers are very useful, but I still find it a pain to setup. You end up splitting the design process between the CAD models and the slic3r config, which is messy, and the UI for adjusting the settings in slic3r isn't the greatest. Is there any way to save a complex multi-model plus modifiers configuration in slic3r? The few times I've used it I've ended up recreating the settings from scratch every time, which is lousy for iterative prototyping.

|

Re: Locally strengthening areas February 26, 2017 07:08AM |

Registered: 8 years ago Posts: 312 |

|

Re: Locally strengthening areas February 26, 2017 09:52AM |

Registered: 8 years ago Posts: 312 |

Quick test shows a little bar almost doubling in strength.

It went from 21 kg with simple 25% infill to 36 kg with 25% infill and a "spine" of 0.1 mm holes along the center. The holes were spaced 0.5 mm apart.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

It went from 21 kg with simple 25% infill to 36 kg with 25% infill and a "spine" of 0.1 mm holes along the center. The holes were spaced 0.5 mm apart.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

Sorry, only registered users may post in this forum.