Launching a new build plate

Posted by andornot

|

Launching a new build plate July 03, 2017 04:39PM |

Registered: 10 years ago Posts: 97 |

I am launching a new build plate and i am looking for beta testers to trial the material. Its a clear thermoplastic the print setup is much the same as Buildtak and Lokbuild but its much more robust and cost effective. Please PM me if you are interested in testing it, its available in 8 inch square and 12 inch square.

Regards

Andrew wade

AndOrNot

|

Re: Launching a new build plate July 03, 2017 05:47PM |

Registered: 11 years ago Posts: 528 |

|

Re: Launching a new build plate July 03, 2017 07:36PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Launching a new build plate July 04, 2017 05:47AM |

Registered: 8 years ago Posts: 3,525 |

I will happily try a sheet, can it be cut?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 04, 2017 02:27PM |

Registered: 10 years ago Posts: 97 |

The material is clear and can be easily cut with a pair of scissors. The main reason in it not coloured like buildtak and lokbuild is the cost it adds to the sheets. Glass and pei is clear like many other bed materials, so why add cost to the end user so the supplier can heavily brand his product. I am offering a very build surface, that is tough and more robust that existing products on the market at a very competitive price.

This a review from one of my testers Kevin Smith:

"The thermoplastic sheet from AndorNot comes in two sizes 8” and 12” square. It comes with 3M self-adhesive backing sheeting.

The Sheet has a smoke matt finish to the surface, so you won’t get a shiny finish to the bottom of you prints, not a real problem for me but be aware of this if this is something you like.

Minor calibration was required after sticking the sheet to my glass bed.

To allow for the sheet, but this was done quickly and with no issues.

In terms of printing, I’m using PLA at the moment and the filament in question works well at 200c, the heater bed was raised slightly from 55 to 60, but to be honest I don’t think it needed it.

First layer went down fine and the following layers also went down clean and even. No issues with lifting of the print from the bed, no unwanted gaps in the print etc. Once the print had finished, I gave It a few seconds to cool down and then used a small spatula to remove the object, it came away with no issues and no breaks. Smaller printed objects can be removed by hand. I have now completed over 12 printed objects of various size / design and not one print has failed."

8KevinSmith.MP4

If you are interested in testing it please PM me with you working printer type, name, address and sheet size either 8" or 12". I am looking for in return a review and possible video's or pictures of the print.

Thanks

Andrew

This a review from one of my testers Kevin Smith:

"The thermoplastic sheet from AndorNot comes in two sizes 8” and 12” square. It comes with 3M self-adhesive backing sheeting.

The Sheet has a smoke matt finish to the surface, so you won’t get a shiny finish to the bottom of you prints, not a real problem for me but be aware of this if this is something you like.

Minor calibration was required after sticking the sheet to my glass bed.

To allow for the sheet, but this was done quickly and with no issues.

In terms of printing, I’m using PLA at the moment and the filament in question works well at 200c, the heater bed was raised slightly from 55 to 60, but to be honest I don’t think it needed it.

First layer went down fine and the following layers also went down clean and even. No issues with lifting of the print from the bed, no unwanted gaps in the print etc. Once the print had finished, I gave It a few seconds to cool down and then used a small spatula to remove the object, it came away with no issues and no breaks. Smaller printed objects can be removed by hand. I have now completed over 12 printed objects of various size / design and not one print has failed."

8KevinSmith.MP4

If you are interested in testing it please PM me with you working printer type, name, address and sheet size either 8" or 12". I am looking for in return a review and possible video's or pictures of the print.

Thanks

Andrew

|

Re: Launching a new build plate July 04, 2017 06:43PM |

Registered: 7 years ago Posts: 62 |

|

Re: Launching a new build plate July 05, 2017 01:50PM |

Registered: 7 years ago Posts: 558 |

|

Re: Launching a new build plate July 05, 2017 01:53PM |

Registered: 10 years ago Posts: 14,672 |

I'd be happy to test a piece with the IR sensor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Launching a new build plate July 05, 2017 04:50PM |

Registered: 10 years ago Posts: 770 |

|

Re: Launching a new build plate July 08, 2017 02:20PM |

Registered: 8 years ago Posts: 3,525 |

Hi got mine today, very first impressions, a thin but fairly stiff polymer sheet with 3M adhesive on the back. Has a slightly sanded, matt surface. Applied a 200x200 piece (can be cut with regular scissors) to a sheet of glass and clipped it on top of my aluminium+printbite surface on my kossel XL.

Works great with the piezo probe, only probing the central 100mm of the bed (as I had to clip it to the edge so its not centralised) but achieving a 0.004 deviation. So its has no issue with nozzle contact sensors, my nozzle was at 130 deg C and no visible marks were left on the surface.

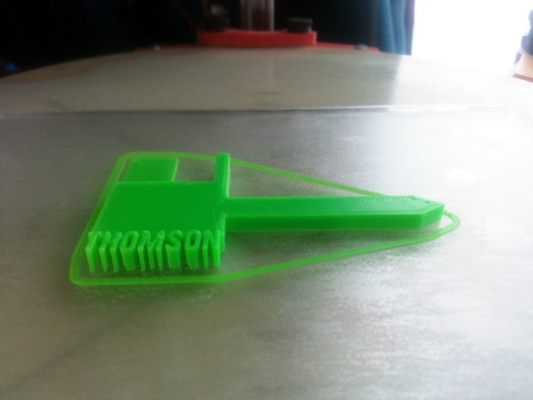

Decided to print this small toy plane, as my son wanted one, and it has a pointy nose which should be a good test of ABS adhesion. Scaled it down 50%.

[www.thingiverse.com]

Since I have no idea what settings to use (quite nice to work from first principles) might as well hit it hard with ABS with no bed heat.

Result the nose of the plane lifted after about 3-4 layers, but the first layer went down really well. Not particularly surprised this is a fairly extreme test.

So I raised the bed temp to 60 deg C. The AndOrNot surface was not quite at 60 when it began to print, but this time the plane stayed attached until completion. At this point it was welded to the surface. But I let it cool to room temp (29 deg C here at the moment) and it still remained well attached, needing a little convincing to pop off the surface which it did, in one piece.

Haven't done any more so far, but if it can hold thin abs at this temperature I suspect it can hold a much tougher part at high bed temps. Still a long way below the 120 deg C I use with printbite which is good, but print bite does self release at 60 degrees or so, which is nice and a time saving feature if printing continuously.

Next for a medium difficulty bed adhesion test, I will try a few different temperatures to see the effect they have.

Then the warpinator 5000....

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Works great with the piezo probe, only probing the central 100mm of the bed (as I had to clip it to the edge so its not centralised) but achieving a 0.004 deviation. So its has no issue with nozzle contact sensors, my nozzle was at 130 deg C and no visible marks were left on the surface.

Decided to print this small toy plane, as my son wanted one, and it has a pointy nose which should be a good test of ABS adhesion. Scaled it down 50%.

[www.thingiverse.com]

Since I have no idea what settings to use (quite nice to work from first principles) might as well hit it hard with ABS with no bed heat.

Result the nose of the plane lifted after about 3-4 layers, but the first layer went down really well. Not particularly surprised this is a fairly extreme test.

So I raised the bed temp to 60 deg C. The AndOrNot surface was not quite at 60 when it began to print, but this time the plane stayed attached until completion. At this point it was welded to the surface. But I let it cool to room temp (29 deg C here at the moment) and it still remained well attached, needing a little convincing to pop off the surface which it did, in one piece.

Haven't done any more so far, but if it can hold thin abs at this temperature I suspect it can hold a much tougher part at high bed temps. Still a long way below the 120 deg C I use with printbite which is good, but print bite does self release at 60 degrees or so, which is nice and a time saving feature if printing continuously.

Next for a medium difficulty bed adhesion test, I will try a few different temperatures to see the effect they have.

Then the warpinator 5000....

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 08, 2017 05:11PM |

Registered: 8 years ago Posts: 3,525 |

Test 2 this object at 75% scale in ABS, with surface at a verified 60 deg C, first layer nozzle temp 245 deg C. Printed without any noticeable lift. Impossible to remove afterwards, at room temp still welded on. Put it in the freezer, then I managed to remove the part with a craft knife and much perseverance. Didn't damage the surface in doing so, so that's a plus. There is a crack in the surface where the ABS has contracted and the adhesion is so good that instead of popping off it's crazed slightly, still perfectly smooth and ready to print again though. Andrew has said to me not to squash the first layer down, so I will try that next. Perhaps with just 60 degrees set on the bed rather than 60 on the surface (which is 75 indicated on the printer with my setup).

The warpinator would be a piece of cake, getting it off afterwards might be tricky.

Edited 3 time(s). Last edit at 07/09/2017 04:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The warpinator would be a piece of cake, getting it off afterwards might be tricky.

Edited 3 time(s). Last edit at 07/09/2017 04:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 09, 2017 04:56AM |

Registered: 8 years ago Posts: 3,525 |

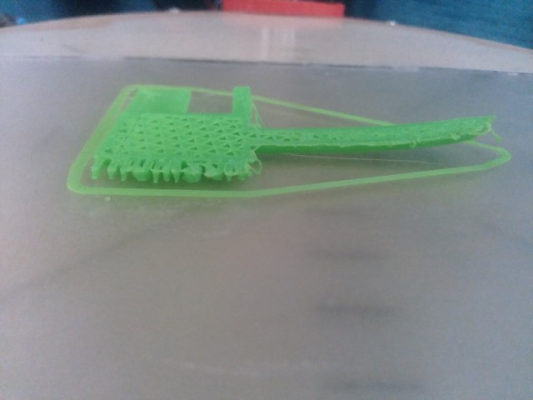

Test 3 this time lower surface temp (around 50 deg C - printer indicated temp 60) and less squash down.

This one failed and the object peeled away at the long pointy bit and the smaller protrusion at the sides. I stopped it.

That being said this is ABS and only at 50 deg C.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This one failed and the object peeled away at the long pointy bit and the smaller protrusion at the sides. I stopped it.

That being said this is ABS and only at 50 deg C.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 09, 2017 05:14AM |

Registered: 8 years ago Posts: 3,525 |

Test 4 ABS 245 Deg C, Bed at 50 deg C with squash down.

So loss of adhesion on the long point and the small protrusion.

But I could remove the part at 40 deg C bed with a bit of persuasion.

So it seems there is a sweet spot with ABS, probably using the 60 deg C surface temp and no squash down.

So that's the next test, whether it can be removed is the question.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So loss of adhesion on the long point and the small protrusion.

But I could remove the part at 40 deg C bed with a bit of persuasion.

So it seems there is a sweet spot with ABS, probably using the 60 deg C surface temp and no squash down.

So that's the next test, whether it can be removed is the question.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 09, 2017 05:46AM |

Registered: 8 years ago Posts: 601 |

Looks interesting. Have you tried it with PLA or other filaments yet? I love Printbite, but its power lies with everything but PLA in my experience. Its possible but requires more tuning in compared to say blue tape or glue. Colorfabb nGen sticks to printbite amazingly well.

Is there a big difference in height tuning in the above examples? Printbite sometimes requires dialing in down to +/- 0.05mm or so if the filament is picky, this is probably the biggest problem for users and is probably why its not in more widespread usage.

Is there a big difference in height tuning in the above examples? Printbite sometimes requires dialing in down to +/- 0.05mm or so if the filament is picky, this is probably the biggest problem for users and is probably why its not in more widespread usage.

|

Re: Launching a new build plate July 09, 2017 07:59AM |

Registered: 8 years ago Posts: 3,525 |

I haven't tried anything else yet, I mainly print abs but once I've got that dialled in, I'll try petg, pla and flex41. First layer height is important but not for outright adhesion more for separating the part after printing. It seems quite tolerant of squash in terms of getting the print to work.

In my experience with printbite (3 machines over 2 years now) it can sometimes give you trouble but once dialled in for any given material it works reliably, pla never seems to cause me any issues. First layer height is critical I agree. What's magic about it is clearly their is a temperature profile for these things and Jason has chosen to formulate it to get adhesion at fairly high temps in order to achieve release at higher temperatures for convenience.

PEI and this new material grip extremely well but release is an issue.

EDIT - I set another bed adhesion object going before work this morning this time, what I think will be the right settings, 60 degrees surface temp (75 indicated) with no first layer squash, the first layer at z=0.34 exactly. No curling as it was finishing up when I left, and it will have had all day to cool to room temperature. If I can get it off the bed then ABS is a winner for me I'd be using half the heat to get twice the adhesion.

Edited 2 time(s). Last edit at 07/10/2017 10:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

In my experience with printbite (3 machines over 2 years now) it can sometimes give you trouble but once dialled in for any given material it works reliably, pla never seems to cause me any issues. First layer height is critical I agree. What's magic about it is clearly their is a temperature profile for these things and Jason has chosen to formulate it to get adhesion at fairly high temps in order to achieve release at higher temperatures for convenience.

PEI and this new material grip extremely well but release is an issue.

EDIT - I set another bed adhesion object going before work this morning this time, what I think will be the right settings, 60 degrees surface temp (75 indicated) with no first layer squash, the first layer at z=0.34 exactly. No curling as it was finishing up when I left, and it will have had all day to cool to room temperature. If I can get it off the bed then ABS is a winner for me I'd be using half the heat to get twice the adhesion.

Edited 2 time(s). Last edit at 07/10/2017 10:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 10, 2017 06:25AM |

Registered: 7 years ago Posts: 62 |

@Origamib

I don't recall ever having problems with getting PLA to stick on Printbite once I bumped the temperature high enough, it did need a much higher temp for all materials I used it with than other bed materials I've tried. if it wasn't for the issues I had with IR sensor based bed levelling, which I think are because I put it on raw Aluminium, I assume painting it black first would likely have resolved resolve it, I'd probably still be using it.

I'm using PEI now, and still keep trying other new materials.

I don't recall ever having problems with getting PLA to stick on Printbite once I bumped the temperature high enough, it did need a much higher temp for all materials I used it with than other bed materials I've tried. if it wasn't for the issues I had with IR sensor based bed levelling, which I think are because I put it on raw Aluminium, I assume painting it black first would likely have resolved resolve it, I'd probably still be using it.

I'm using PEI now, and still keep trying other new materials.

|

Re: Launching a new build plate July 10, 2017 03:37PM |

Registered: 8 years ago Posts: 3,525 |

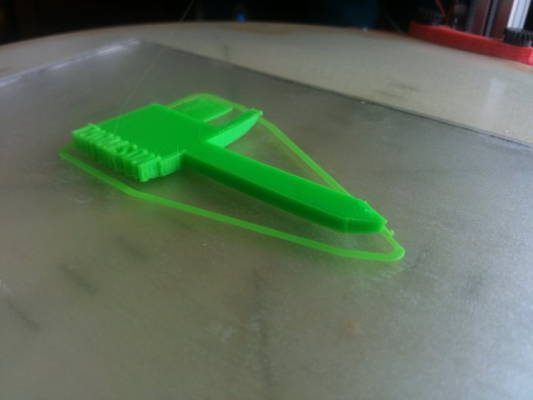

So the ABS sweet spot (I think).

No squash beyond 80% of nozzle width for the first layer and 60 degrees on the surface:

Came off with a sharp knife pushed in under the edge, part undamaged, bed undamaged.

Maybe for ABS it might be worth mounting it to a flexible plate so it can be bent off. If the part had a really big contact area it would be very difficult to remove. Now for some PLA.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

No squash beyond 80% of nozzle width for the first layer and 60 degrees on the surface:

Came off with a sharp knife pushed in under the edge, part undamaged, bed undamaged.

Maybe for ABS it might be worth mounting it to a flexible plate so it can be bent off. If the part had a really big contact area it would be very difficult to remove. Now for some PLA.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 10, 2017 05:04PM |

Registered: 10 years ago Posts: 97 |

|

Re: Launching a new build plate July 10, 2017 05:06PM |

Registered: 10 years ago Posts: 97 |

|

Re: Launching a new build plate July 10, 2017 06:30PM |

Registered: 8 years ago Posts: 3,525 |

Sounds good Andrew keep us posted on that one, and happy to try it when its available.

PLA zero bed heat , 215 deg C first layer nozzle temp, with no squash.

Printed great, one bit curled, the small protrusion, and only the first few layers, but it laid it down slightly kinked, perhaps my first layer was slightly too high, easily fixed. the rest printed just fine.

Pulled it off the surface without any major problems once it was down to room temperature, it was firm but nowhere near as well stuck down as the ABS above.

So as expected PLA is no issue. Next PETG (tomorrow) but that'll work as it's inherently very sticky. I don't have and don't print nylon so I'll leave that up to someone else.

Edited 3 time(s). Last edit at 07/10/2017 06:41PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

PLA zero bed heat , 215 deg C first layer nozzle temp, with no squash.

Printed great, one bit curled, the small protrusion, and only the first few layers, but it laid it down slightly kinked, perhaps my first layer was slightly too high, easily fixed. the rest printed just fine.

Pulled it off the surface without any major problems once it was down to room temperature, it was firm but nowhere near as well stuck down as the ABS above.

So as expected PLA is no issue. Next PETG (tomorrow) but that'll work as it's inherently very sticky. I don't have and don't print nylon so I'll leave that up to someone else.

Edited 3 time(s). Last edit at 07/10/2017 06:41PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 11, 2017 01:11PM |

Registered: 7 years ago Posts: 1 |

|

Re: Launching a new build plate July 11, 2017 04:29PM |

Registered: 8 years ago Posts: 3,525 |

So PETG at 220 deg C nozzle temp (I know this is low but it flows through the hotend really well at this temp - using 3Dprima PETG) with a cold bed is a no go. Doesn't adhere, and with PETG as it adheres to the nozzle so well, I'm limited in first layer heights I can print at, too high and it doesn't lay down, and too low and the nozzle pulls it away.

So I tried 50 deg indicated (40 degrees surface temp) and that was a no go aswell.

At 60 degrees indicated (50 degrees surface) I got some adhesion but it curled in places.

But I could remove it with a bit of effort (no tools used). Had a layer shift as the nozzle hit the area that didn't adhere a few times and lost steps, I find PETG does this more as it sets so hard.

Next one will be 75 degrees (60 surface).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So I tried 50 deg indicated (40 degrees surface temp) and that was a no go aswell.

At 60 degrees indicated (50 degrees surface) I got some adhesion but it curled in places.

But I could remove it with a bit of effort (no tools used). Had a layer shift as the nozzle hit the area that didn't adhere a few times and lost steps, I find PETG does this more as it sets so hard.

Next one will be 75 degrees (60 surface).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 12, 2017 01:48AM |

Registered: 8 years ago Posts: 193 |

|

Re: Launching a new build plate July 12, 2017 01:18PM |

Registered: 8 years ago Posts: 3,525 |

So petg needs the same settings as abs with perhaps 0.05mm more squash but strangely it's easier to remove. Perhaps the surface has more affinity for abs or maybe the higher nozzle temperature used with abs results in greater adhesion.

220 degC nozzle, 60 deg C on surface

So that's me done.

ABS 245 deg, no squash bed at 60.

PETG 220 degrees light squash bed at 60.

PLA 215 degrees light squash bed cold (30 deg C)

These are first layer nozzle temps. I think given how well it grips you could lower bed temps after the first few layers and do what you want with nozzle temps.

Edited 1 time(s). Last edit at 07/12/2017 01:21PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

220 degC nozzle, 60 deg C on surface

So that's me done.

ABS 245 deg, no squash bed at 60.

PETG 220 degrees light squash bed at 60.

PLA 215 degrees light squash bed cold (30 deg C)

These are first layer nozzle temps. I think given how well it grips you could lower bed temps after the first few layers and do what you want with nozzle temps.

Edited 1 time(s). Last edit at 07/12/2017 01:21PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 12, 2017 02:08PM |

Registered: 8 years ago Posts: 312 |

|

Re: Launching a new build plate July 12, 2017 02:18PM |

Registered: 8 years ago Posts: 3,525 |

Thanks, I've got a lot of time for things that can affordably make 3d printing much easier. Bonded to a flexible backing it would be very versatile, as I've used it bonded to glass you just have to keep within the sweet spot to avoid excess adhesion.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 14, 2017 11:30AM |

Registered: 8 years ago Posts: 3,525 |

On thing to add, decided to print some real objects (piezo modules) on this surface, 2 items in black ABS using my settings from above and two peeled away, so slightly more squash and 85 indicated (73 surface) temp and having another go.

EDIT- success!

Edited 1 time(s). Last edit at 07/14/2017 01:15PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

EDIT- success!

Edited 1 time(s). Last edit at 07/14/2017 01:15PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 14, 2017 01:14PM |

Registered: 8 years ago Posts: 193 |

|

Re: Launching a new build plate July 14, 2017 01:55PM |

Registered: 11 years ago Posts: 528 |

|

Re: Launching a new build plate July 14, 2017 02:51PM |

Registered: 10 years ago Posts: 97 |

Sorry, only registered users may post in this forum.