Dissolving PLA used as support for ABS prints

Posted by Bertho

|

Dissolving PLA used as support for ABS prints September 10, 2012 04:08AM |

Registered: 12 years ago Posts: 21 |

Success: I tested with an ultrasonic cleaner and laboratory grade Sodium Hydroxide @ 60°C and got a surprise result:

[www.vinland.com]

Bertho

[www.vinland.com]

Bertho

|

Re: Dissolving PLA used as support for ABS prints September 10, 2012 02:54PM |

Registered: 12 years ago Posts: 162 |

Very interesting ! I have a dual extruder project and I want to use it to print soluble support structures. I planed to do the same experiments once my dual extruder is functional.

Does the ultrasonic pulses makes a lot of differences or a heated bath of sodium hydroxide is enough to dissolve the PLA ?

Is the sodium hydroxide has to be laboratory grade ?

Does the ultrasonic pulses makes a lot of differences or a heated bath of sodium hydroxide is enough to dissolve the PLA ?

Is the sodium hydroxide has to be laboratory grade ?

|

Re: Dissolving PLA used as support for ABS prints September 10, 2012 07:12PM |

Registered: 12 years ago Posts: 21 |

|

Re: Dissolving PLA used as support for ABS prints September 11, 2012 02:49PM |

Registered: 13 years ago Posts: 81 |

|

Re: Dissolving PLA used as support for ABS prints September 11, 2012 03:33PM |

Registered: 12 years ago Posts: 21 |

|

Re: Dissolving PLA used as support for ABS prints September 14, 2012 11:50AM |

Registered: 12 years ago Posts: 162 |

|

Re: Dissolving PLA used as support for ABS prints September 14, 2012 12:21PM |

Registered: 12 years ago Posts: 21 |

I initially heated samples in my first set of tests but not for a long time. Afterwards I left the samples in the solution for several weeks but there was not a significant change in appearance. So in summary, it looks like ultrasonic is needed.

Maybe if it was at boiling temperature but that adds significant risks and also possibly warping the desired object from the heat.

Bertho

Maybe if it was at boiling temperature but that adds significant risks and also possibly warping the desired object from the heat.

Bertho

|

Re: Dissolving PLA used as support for ABS prints September 14, 2012 04:47PM |

Registered: 11 years ago Posts: 124 |

Are ultrasonic cleaners that hard to make? these instructions seem easy enough:

[deiwhy.blogspot.ca]

[deiwhy.blogspot.ca]

|

Re: Dissolving PLA used as support for ABS prints September 14, 2012 06:50PM |

Registered: 12 years ago Posts: 21 |

It sounds reasonable but audio power amps are not made to continuously operate at those frequencies and can easily overheat. There is no mentioning of tuning the system so it will be resonant. Many ultrasonic generators required a counter weight mounted to the other side of the transducer to operate efficiently. Plus you must have the unit tied to a PC if you do not design a separate signal generator.

So in summary, more work than it sounds like in the simplified description.

By the way, I have designed several commercial ultrasonic products that were marketed years ago.

So in summary, more work than it sounds like in the simplified description.

By the way, I have designed several commercial ultrasonic products that were marketed years ago.

|

Re: Dissolving PLA used as support for ABS prints September 14, 2012 08:00PM |

Registered: 12 years ago Posts: 162 |

Small ultrasonic cleaners does not have a heater function and the timer is very short. The smallest ultrasonic cleaner with heater function cleaner I found (Velleman VTUSCT5) has a capacity of 2l but the timer's maximum is 30min only. I don't have the space or the usefulness for a bigger one.

It seems the ultrasonic pulses are mandatory, so I think I will need to buy this 2l cleaner and hack it to increase the timer maximum, but it is clearly stated on the manual that this cleaner is not made to run continuously.

It seems the ultrasonic pulses are mandatory, so I think I will need to buy this 2l cleaner and hack it to increase the timer maximum, but it is clearly stated on the manual that this cleaner is not made to run continuously.

|

Re: Dissolving PLA used as support for ABS prints April 14, 2013 03:47PM |

Registered: 12 years ago Posts: 162 |

Eventually, I made an hot plate/stirrer :

The cardboard case is temporary, I will make a wiki about it once finished.

The PLA support is dissolved in 6H30 (heating-up included) with 100g of sodium hydroxide dissolved in 500ml of water at 60°C.

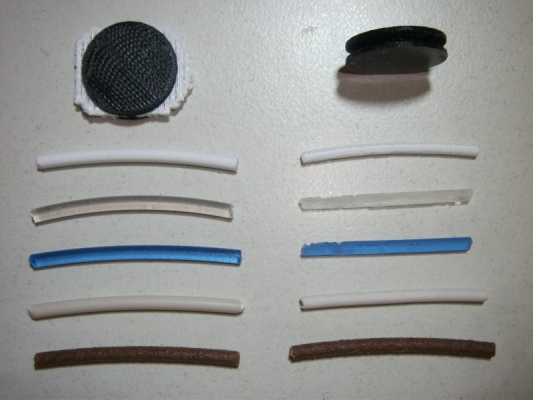

I also put other filament in the bath :

From top to bottom :

-Test part (GRRF white PLA / black ABS)

-GRRF white PLA

-orbi-tech transparent PLA

-GRRF transparent blue PLA

-GRRF soft PLA

-GRRF LAYWOOD

The soft PLA isn't affected so much and LAYWOOD isn't affected at all by the sodium hydroxide, so we can make rubbery or wood-like complex parts using PLA as support

For the next test, I will increase the temperature to 80°C to speed-up the process.

The cardboard case is temporary, I will make a wiki about it once finished.

The PLA support is dissolved in 6H30 (heating-up included) with 100g of sodium hydroxide dissolved in 500ml of water at 60°C.

I also put other filament in the bath :

From top to bottom :

-Test part (GRRF white PLA / black ABS)

-GRRF white PLA

-orbi-tech transparent PLA

-GRRF transparent blue PLA

-GRRF soft PLA

-GRRF LAYWOOD

The soft PLA isn't affected so much and LAYWOOD isn't affected at all by the sodium hydroxide, so we can make rubbery or wood-like complex parts using PLA as support

For the next test, I will increase the temperature to 80°C to speed-up the process.

|

Re: Dissolving PLA used as support for ABS prints April 14, 2013 05:19PM |

Registered: 12 years ago Posts: 21 |

|

Re: Dissolving PLA used as support for ABS prints April 15, 2013 03:38PM |

Registered: 12 years ago Posts: 162 |

|

Re: Dissolving PLA used as support for ABS prints April 20, 2013 08:54PM |

Registered: 11 years ago Posts: 186 |

Sorry, only registered users may post in this forum.