Dual headed printer for multimaterial printing

Posted by leadinglights

|

Dual headed printer for multimaterial printing September 24, 2018 07:23PM |

Registered: 12 years ago Posts: 1,450 |

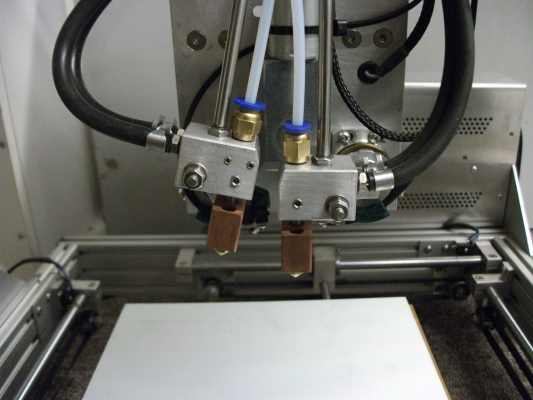

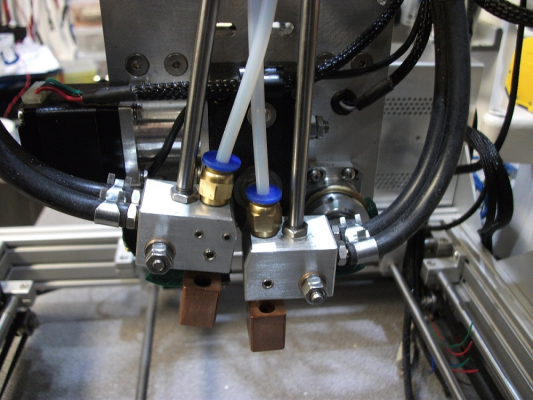

I am working on a promising proof-of-concept model of a a multi-material printer head which may offer some advantages over other types. The main idea is that the complete hotend and nozzle assembly can be rapidly swapped to facilitate the use of two materials in one layer without the unused nozzle dragging across the print or drooling. Additional advantages are that each nozzle can be cleaned as it is being swapped out and the nozzle not in use can be purged of the previous material a new filament selected while the other nozzle is printing. One small extra advantage is that the motion of the nozzle allows it to be used with a "Berd" type air ring for near nozzle cooling.

Photos below show the overall layout of the print head on a 3D printer. There is a short video on YouTube [www.youtube.com]

I have left off the heater elements, and some other bits to reduce clutter and make it a bit plainer how it works.

This is the latest of many attempts to get a multi material printer working but the others had as many as seven printer heads and each was doomed to failure by being too complex even to make - bits of the saga can be seen on [reprap.org] and [reprap.org]

I can't claim that even this multi material printer is without its problems:- my implementation is ferociously complex although I can think of ways to simplify almost every part. For many existing printers this type of head will be far too heavy and the general type is really only suitable only for printers in which the print head is stationary in the X and Y axes.

Problems that I have come up against but not yet resolved are that a geared brushed DC motor and microswitches do not make for a very reproducible positioning because the armature has too much rotating mass - my next job is to design a stepper motor gearbox that can fit into the available space. Software problems had been almost insurmountable in the earlier multi-head (7 and 5 head) designs but are (hopefully) almost trivial here..

Mike

Photos below show the overall layout of the print head on a 3D printer. There is a short video on YouTube [www.youtube.com]

I have left off the heater elements, and some other bits to reduce clutter and make it a bit plainer how it works.

This is the latest of many attempts to get a multi material printer working but the others had as many as seven printer heads and each was doomed to failure by being too complex even to make - bits of the saga can be seen on [reprap.org] and [reprap.org]

I can't claim that even this multi material printer is without its problems:- my implementation is ferociously complex although I can think of ways to simplify almost every part. For many existing printers this type of head will be far too heavy and the general type is really only suitable only for printers in which the print head is stationary in the X and Y axes.

Problems that I have come up against but not yet resolved are that a geared brushed DC motor and microswitches do not make for a very reproducible positioning because the armature has too much rotating mass - my next job is to design a stepper motor gearbox that can fit into the available space. Software problems had been almost insurmountable in the earlier multi-head (7 and 5 head) designs but are (hopefully) almost trivial here..

Mike

|

Re: Dual headed printer for multimaterial printing September 25, 2018 06:57PM |

Registered: 9 years ago Posts: 752 |

That looks really well engineered, leadinglights! It's like ballet dance

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Dual headed printer for multimaterial printing December 19, 2018 11:37AM |

Registered: 12 years ago Posts: 1,450 |

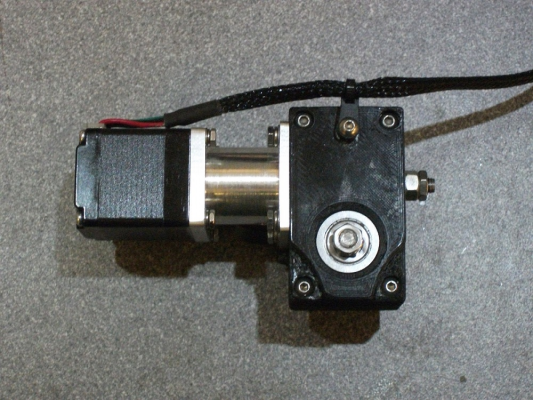

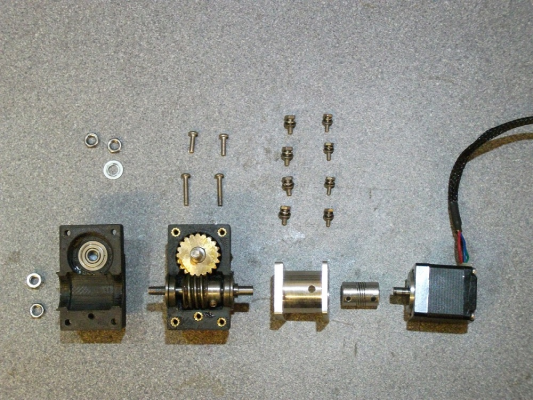

This toggle mechanism on this printer has been proving very unsatisfactory with a repeatibility of about ±100μm so I have had to do some major redesign. I have replaced the DC geared motor with a stepper motor /gearbox that I made to do the job along with a microcontroller to run the stepper accurately between the microswitches. The problem was that the armature of the geared DC motor had too much inertia while the motor itself had only a narrow range of voltages that it would run at. Between these I couldn't find a seek protocol that would give a decent repeatability. I had tested the idea with a much smaller Maxon DC motor/gearbox which showed that 10 microns repeatibility should be achievable but the reality was worse than expected

The very first tests now show that the microswitch will be found within ±1 step (quarter stepping) and this ties up with ±6μm at the nozzle. Pictures below show the gearbox fitted in the frame and the gearbox in an unassembled state. The replaced DC motor can be see in the picture in the first posting.

As this now fits better into the description of a Mechanism than just general I will put further progress reports in that sub-forum.

Mike

The very first tests now show that the microswitch will be found within ±1 step (quarter stepping) and this ties up with ±6μm at the nozzle. Pictures below show the gearbox fitted in the frame and the gearbox in an unassembled state. The replaced DC motor can be see in the picture in the first posting.

As this now fits better into the description of a Mechanism than just general I will put further progress reports in that sub-forum.

Mike

Sorry, only registered users may post in this forum.